bonitron M3452ON User manual

Model M3452ON

Active Braking Indicator

Customer Reference Manual

Bonitron, Inc.

2

Bonitron, Inc.

Nashville, TN

An industry leader in providing solutions for AC drives.

ABOUT BONITRON

Bonitron designs and manufactures quality industrial electronics that improve the reliability of

processes and variable frequency drives worldwide. With products in numerous industries, and

an educated and experienced team of engineers, Bonitron has seen thousands of products

engineered since 1962 and welcomes custom applications.

With engineering, production, and testing all in the same facility, Bonitron is able to ensure its

products are of the utmost quality and ready to be applied to your application.

The Bonitron engineering team has the background and expertise necessary to design, develop,

and manufacture the quality industrial electronic systems demanded in today’s market. A strong

academic background supported by continuing education is complemented by many years of

hands-on field experience. A clear advantage Bonitron has over many competitors is combined

on-site engineering labs and manufacturing facilities, which allows the engineering team to have

immediate access to testing and manufacturing. This not only saves time during prototype

development, but also is essential to providing only the highest quality products.

The sales and marketing teams work closely with engineering to provide up-to-date information

and provide remarkable customer support to make sure you receive the best solution for your

application. Thanks to this combination of quality products and superior customer support,

Bonitron has products installed in critical applications worldwide.

Bonitron, Inc.

3

AC DRIVE OPTIONS

In 1975, Bonitron began working with AC inverter drive specialists at synthetic fiber plants to

develop speed control systems that could be interfaced with their plant process computers. Ever

since, Bonitron has developed AC drive options that solve application issues associated with

modern AC variable frequency drives and aid in reducing drive faults. Below is a sampling of

Bonitron’s current product offering.

WORLD CLASS PRODUCTS

Undervoltage Solutions

Overvoltage Solutions

Uninterruptible Power for Drives

(DC Bus Ride-Thru)

Voltage Regulators

Chargers and Dischargers

Energy Storage

Braking Transistors

Braking Resistors

Transistor/Resistor Combo

Line Regeneration

Dynamic Braking for Servo Drives

Common Bus Solutions

Portable Maintenance Solutions

Single Phase Power Supplies

3-Phase Power Supplies

Common Bus Diodes

Capacitor Formers

Capacitor Testers

Power Quality Solutions

Green Solutions

12 and 18 Pulse Kits

Line Regeneration

M3452ON

4

This page intentionally left blank

Table of Contents

5

1. INTRODUCTION..........................................................................................................................7

1.1. Who Should Use...........................................................................................................................7

1.2. Purpose and Scope........................................................................................................................7

1.3. Manual Version and Change Record............................................................................................7

Figure 1-1: Model M3452ON......................................................................................................................7

2. PRODUCT DESCRIPTION............................................................................................................9

2.1. Related Products...........................................................................................................................9

2.2. Part Number Breakdown ..............................................................................................................9

2.3. General Specifications..................................................................................................................9

Table 2-1: General Specifications Chart......................................................................................................9

2.4. General Precautions and Safety Warnings .................................................................................10

3. INSTALLATION INSTRUCTIONS................................................................................................11

3.1. Environment ...............................................................................................................................11

3.2. Unpacking................................................................................................................................... 11

3.3. Mounting ....................................................................................................................................11

3.4. Wiring and Customer Connections............................................................................................. 11

Figure 3-1: Typical Interconnection Diagram ...........................................................................................12

3.4.1. Power Wiring..................................................................................................................................12

3.4.2. I/O Wiring.......................................................................................................................................12

Table 3-1: Wiring Specifications...............................................................................................................13

4. OPERATION..............................................................................................................................15

4.1. Functional Description ...............................................................................................................15

4.2. Features....................................................................................................................................... 15

4.2.1. Connectors ......................................................................................................................................15

4.2.2. Output Selection Switch..................................................................................................................15

Table 4-1: Output Switch selections..........................................................................................................15

4.2.3. Test Mode (Position 9)....................................................................................................................16

Figure 4-1: Front View..............................................................................................................................17

5. MAINTENANCE AND TROUBLESHOOTING...............................................................................19

5.1. Troubleshooting..........................................................................................................................19

6. ENGINEERING DATA................................................................................................................21

6.1. Dimensions and Mechanical Drawings ......................................................................................21

Figure 6-1: M3452ON Chassis Dimensional Outline Drawing.................................................................21

M3452ON

6

This page intentionally left blank

User’s Manual

7

1. INTRODUCTION

1.1. WHO SHOULD USE

This manual is intendedfor use by anyone who is responsiblefor integrating, installing,

maintaining, troubleshooting, or using this equipment with any DC energy storage

system.

Please keep this manual for future reference.

1.2. PURPOSE AND SCOPE

This manual is a user’s guide for the Model M3452ON Active Braking Indicator. It will

provide the user with the necessary information to successfully install, integrate, and

use the M3452ON.

In the event of any conflict between this document and any publication and/or

documentation related to the system, the latter shall have precedence.

1.3. MANUAL VERSION AND CHANGE RECORD

Rev 00 is the original release of the M3452ON manual.

Updates to About Bonitron were made in Rev 00a.

The manual template was updated in Rev 00b.

Figure 1-1: Model M3452ON

M3452ON

8

This page intentionally left blank

User’s Manual

9

2. PRODUCT DESCRIPTION

The M3452ON Active Braking Indicator has been designed for use with the M3452 high

current braking chopper series. It is intended to provide a contact that may be used to

indicate braking activity. The M3452ON module is intendedto connect to the Master/Slave

control signal of the standard braking modules and provide a Form C MOSFET output

isolated from the input. The Form C output may follow the input signal directly or provide

a signal with a selectable minimum pulse width.

2.1. RELATED PRODUCTS

This product is designed for use with any M3452 braking chopper with Master/Slave

control signal connections. Contact your distributor for more information.

2.2. PART NUMBER BREAKDOWN

BASE MODEL NUMBER

The Base Model Number, M3452, indicates that the unit is related to braking modules.

‘ON’ specifies a buffer board and ‘M1’ specifies the version.

There are no special options at this time.

2.3. GENERAL SPECIFICATIONS

Table 2-1: General Specifications Chart

PARAMETER

SPECIFICATION

Power

24VDC ± 10%, 100 mA

Input Signal

Control Signal from M3452 Braking Chopper

Outputs

Active braking

Form C Solid State Relay,

250V, 100mA, 35 Ω

Operation Temperature

0ºC to +40ºC

Storage Temperature

-20ºC to +65ºC

Humidity

Below 90% non-condensing

Atmosphere

Free of corrosive gas and dust

M3452ON

10

2.4. GENERAL PRECAUTIONS AND SAFETY WARNINGS

DANGER!

HIGH VOLTAGES M AY BE PRES ENT!

FAILURE TO HEED THESE WARNINGS MAY

RESULT IN SERIOUS BODILY INJURY OR DEATH!

CAUTION!

NO USER-SERVICEABLE PARTS ARE CONTAINED WITHIN

THIS PRODUCT.

INOPERABLE UNITS SHOU LD BE REPLACED OR RETURNED

FOR EVALUATION AND /OR REPAIR BY QUALIFIED

TECHNICIANS

BEFORE ATTEMPTING INS TALLATION OR REM OVAL OF

THIS PRODUCT,BE SURE TO REVIEW DOCUMENTATION OF

ALL CONNECTED DEVISE S FOR PERTINENT SAFETY

PRECAUTIONS.

INSTALLATION AND/OR REMOVAL OF THIS PRODUCT

SHOULD ONLY BE ACCOM PLISHED BY A QU ALIFI ED

ELECTRICIAN IN ACCOR DANCE WITH NATIONAL

ELECTRICAL CODE OR EQUIVALENT REGULATIONS.

ANY QUESTIONS AS TO APPLICATION, INSTALLATION OR SERVICE

SAFETY SHOULD BE DIRECTED TO THE EQUIPMENT SUPPLIER.

User’s Manual

11

3. INSTALLATION INSTRUCTIONS

WARNING!

Installation and/or removal of this product should only be performed by a

qualified electrician in accordance with National Electrical Code or local

codes and regulations.

Proper installation of the Model M3452ON Active Braking Indicator is described below.

Please direct all installation and start up inquiries regarding this product to your supplier

or system integrator.

3.1. ENVIRONMENT

The installation site should be dry and clean without extreme temperatures.

3.2. UNPACKING

Upon receipt of this product, please verify that the product received matches the

product that was ordered and that there is no obvious physical damage to the unit. If

the wrong product was received or the product is damaged in any way, please contact

the supplier from which the product was purchased.

3.3. MOUNTING

The unit is mounted with a standard DIN rail clip attached to the back of the enclosure.

Refer to Figure 6-1 to determine the correct mounting dimensions for your unit.

3.4. WIRING AND CUSTOMER CONNECTIONS

This section provides information about the field connection of the M3452ON Active

Braking Indicator.

Be sure to review all system documentation as well as the power wiring information in

Section 3.4.1 before proceeding.

For the maximum wire size accepted by the individual field connection terminals, refer

to Table 3-1. Wire types and sizes should be chosen in accordance with national and

local electrical codes to meet the voltage and current levels present for your

application.

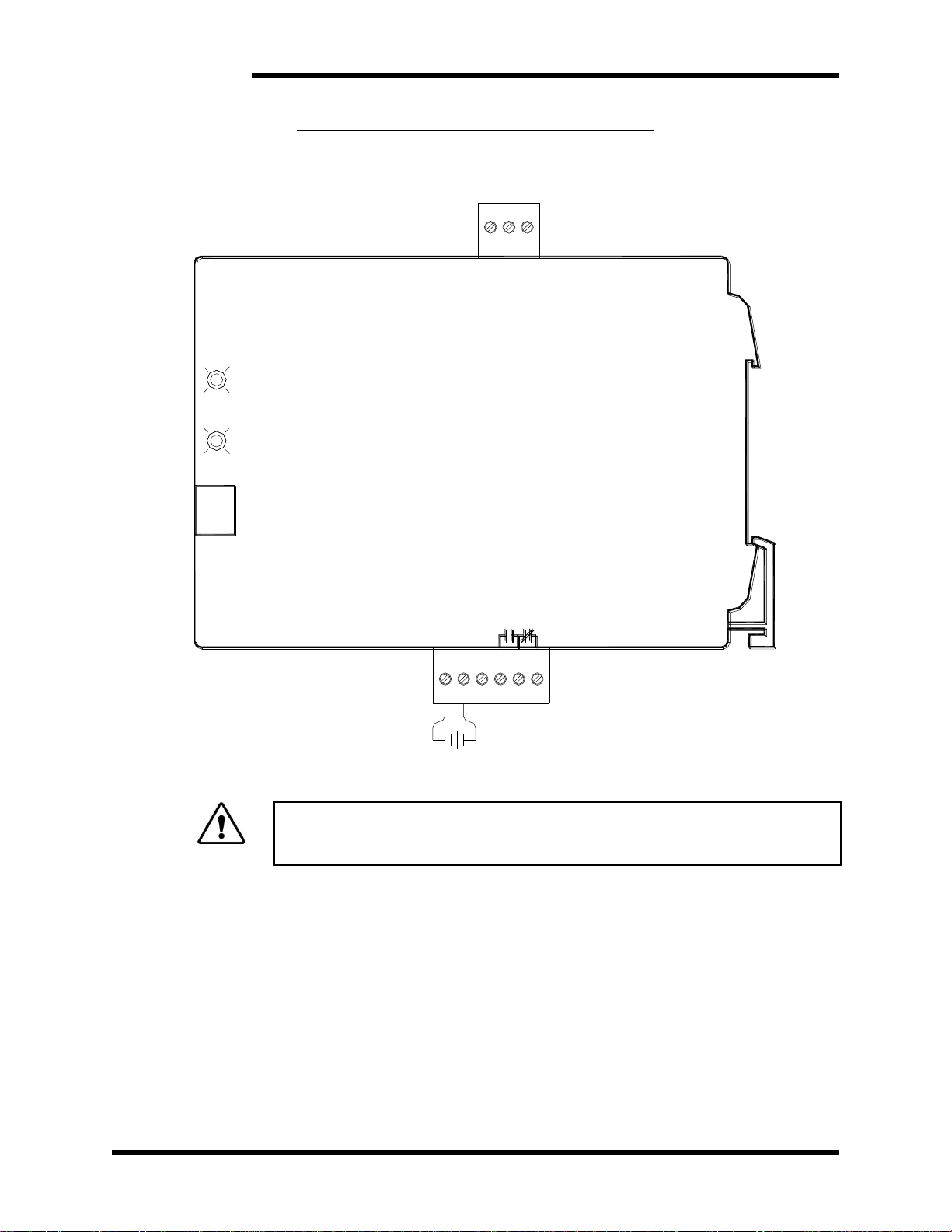

Figure 3-1 shows a typical interconnection of the M3452ON with a typical braking

chopper and I/O signals.

M3452ON

12

Figure 3-1: Typical Interconnection Diagram

ACTIVE BRAKING INDICATOR

M3452ON-M1

FROM M3452 BRAKING UNIT

MASTER / SLAVE SIGNAL

NO C NC

6

CONTACTS

ACTIVE

+

OUTPUT

SELECT

WIDTH

PULSE

POWER LED

5

4

3

21

TB2

POWER

24Vdc

+ -

ACTIVE LED

SIGNAL

- +

INPUT

23

1

TB1

WARNING!

Only qualified electricians should perform and maintain the interconnection

wiring of this product. All wiring should be done in accordance with

National Electrical Code or equivalent regulations.

3.4.1. POWER WIRING

This unit requires an external 24Vdc power supply . The system must be

supplied with at least 100 mA at 24VDC +/- 10% to guarantee correct

operation.

3.4.2. I/O WIRING

The Input Signal connector should only be connected to the Master/Slave

control signal of a M3452 Braking Transistor. The Output Contacts ratings

are listed in the table below.

Dwg: 100044 Rev: 20100323

User’s Manual

13

Table 3-1: Wiring Specifications

TERMINAL

FUNCTION

ELECTRICAL

SPECIFICATIONS

MIN

WIRE

AWG

MAX

WIRE

AWG

TORQUE

TB1-1

Signal Input +

0-30VDC to TB1-3

28

16

.22-.25 Nm

TB1-2

No Connection

TB1-3

Signal Input -

Common to TB1-1

28

16

.22-.25 Nm

TB2-1

Power Input +

+24VDC to TB2-2

28

16

.22-.25 Nm

TB2-2

Power Input -

24VDC common to TB2-1

28

16

.22-.25 Nm

TB2-3

No Connection

TB2-4

NO Output Contact

250V AC/DC 120mA Max

28

16

.22-.25 Nm

TB2-5

Contact Common

250V AC/DC 120mA Max

28

16

.22-.25 Nm

TB2-6

NC Output Contact

250V AC/DC 120mA Max

28

16

.22-.25 Nm

M3452ON

14

This page intentionally left blank

User’s Manual

15

4. OPERATION

4.1. FUNCTIONAL DESCRIPTION

The M3452ON Module monitors the signal from the standard M3452 Braking

Transistor module and provides isolated output contacts that follow the input. The

output pulse width may be adjusted for longer on-state periods for use by other

devices. The module uses a 10 position switch to select the output pulse width.

4.2. FEATURES

4.2.1. CONNECTORS

4.2.1.1. TB1 –1&3(INPUT SIGNAL)

The input signal connector accepts the control signal from an M3452

braking transistor. This signal is a 24Vpk pulse which may vary from a

200µS to 10mS. The signal from the M3452 unit may be common to the

Negative DC Bus and wire should be rated for 600V. The input signal is

optically isolated from all other connections on the M3452ON.

4.2.1.2. TB2 –1&2 (POWER)

The power input accepts 24VDC to supply power to the voltage monitor

board.

4.2.1.3. TB2–4, 5, &6 (FORM COUTPUT CONTACT)

The output contact is composedof a Form C optomosrelay. The optomos

relay is much faster than a mechanical relay allowing lower input to output

delays. This relay will accept AC and DC voltages up to 250V and a

current of 120mA. For loads requiring more current, buffer relays may be

needed.

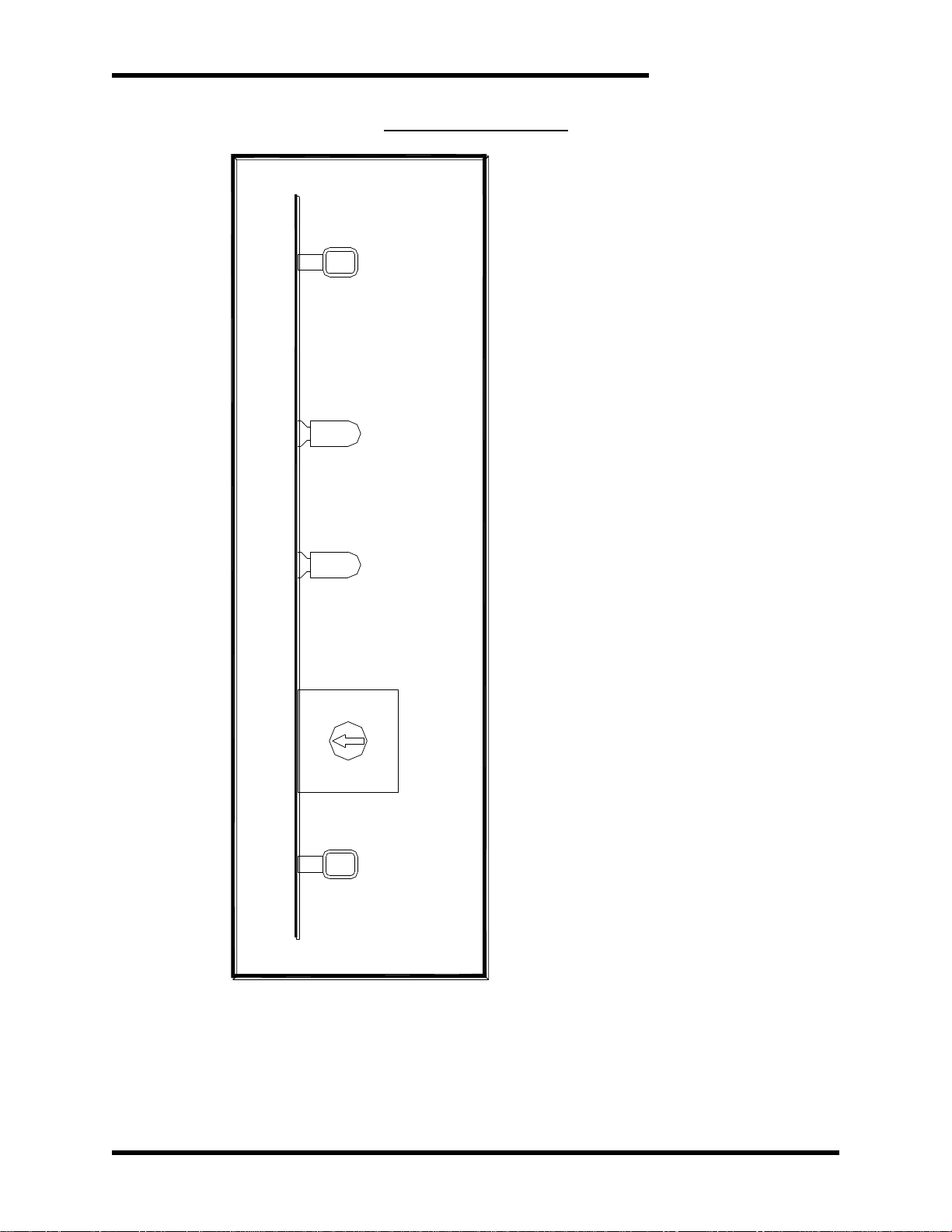

4.2.2. OUTPUT SELECTION SWITCH

4.2.2.1. RANGE (POSITION 0TO 8)

The Output Selection Switch allows the user to choose the output pulse

time when an input signal is received. The output contact times may be

found in the following table.

Table 4-1: Output Switch selections

SELECTION

OUTPUT

0

= INPUT

1

= INPUT + 100mS

2

= INPUT + 200mS

3

= INPUT + 300mS

4

= INPUT + 400mS

5

= INPUT + 500mS

6

= INPUT + 1 Sec

7

= INPUT + 2 Sec

8

= INPUT + 5 Sec

9

TEST MODE 1 Sec Off/On

M3452ON

16

4.2.3. TEST MODE (POSITION 9)

Test mode is used to insure the wiring for the output of the module is correct.

In test mode, the output will cycle on and off at 1 second intervals regardless

of the input.

To enter test mode:

1. Remove 24V power from the module.

2. Select Position “9” on the output selection switch.

3. Apply 24V power from the module.

4. Output will cycle.

5. When finished testing, select a different switch position and cycle power.

Note: Unit will stay in test mode until power is cycled.

User’s Manual

17

Figure 4-1: Front View

COMMON Test Point

SIGNAL Test Point

SELECTION

POWER LED

ACTIVE SIGNAL LED

9

6

8

7

2

1

0

3

5

4

PULSE

OUTPUT

Dwg: 100045 Rev: 20100323

M3452ON

18

This page intentionally left blank

User’s Manual

19

5. MAINTENANCE AND TROUBLESHOOTING

5.1. TROUBLESHOOTING

If a problem occurs on start-up or during normal operation, refer to the problems

described below. If a problem persists after following the steps below, contact the

product supplier or your system integrator for assistance.

Repairs or modifications to this equipment are to be performed by Bonitron approved

personnel only. Any repair or modification to this equipment by personnel not

approved by Bonitron will void any warranty remaining on this unit.

OUTPUT CONTACTS DO NOT CHANGE

Remove power and set selection switch to position “9”. Apply power and the Power

LED should be on as well as Signal LED pulsing in 1 second intervals. The output

contacts should be following the Signal LED. The Output contacts should read

approximately 30 ohms when closed. If the module functioned properly during the

preceding step you may set the selection switch back to the desired mode. Verify the

connection including polarity on the Input Signal and check for proper operation again.

If the module does not operate correctly during this step, contact Bonitron.

M3452ON

20

This page intentionally left blank

Table of contents

Popular Measuring Instrument manuals by other brands

Fluke

Fluke SMFT-1000 Calibration manual

Greenlee

Greenlee 93-172 instruction manual

Brooks

Brooks 1250-55 Series Installation and operation manual

Thermo Scientific

Thermo Scientific Orion Star A216 reference guide

Reed Instruments

Reed Instruments R3530 instruction manual

VOLTCRAFT

VOLTCRAFT PA-10 operating instructions

Titan

Titan Metraflow 240-020 instruction manual

AQUASCAN INTERNATIONAL

AQUASCAN INTERNATIONAL DX-300 operating instructions

PCB Piezotronics

PCB Piezotronics 353B77 Installation and operating manual

Spirent

Spirent NOMAD UX Operation guide

SAEHAN

SAEHAN DHD-3 user manual

Badger Meter

Badger Meter Preso Gemini Cone user manual