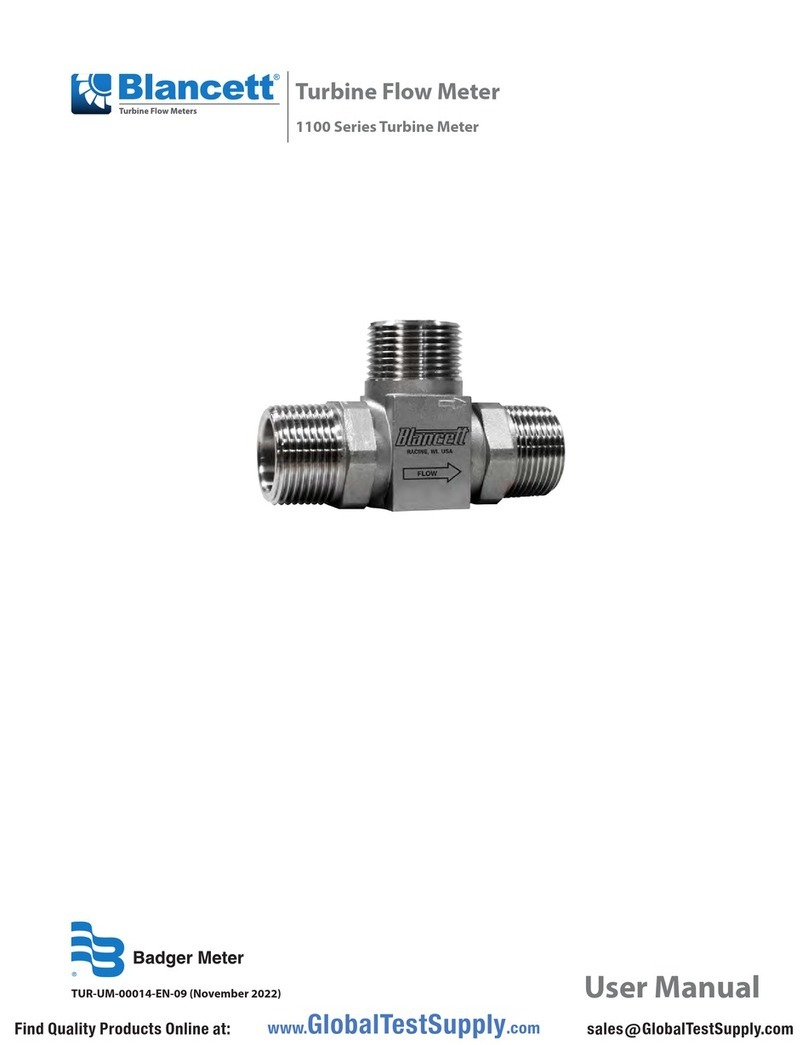

Mounting Location

The Gemini Cone meter should be installed with zero to five pipe diameters of straight run upstream of the meter and zero

to three pipe diameters downstream (see “Straight Pipe Run Requirements” on page8). The meter can be used in pipelines

that are slightly larger than the meter tube; however, if the meter tube is larger than the pipeline, operators should contact

Badger Meter or installation requirements. This is usually determined before supply according to application and the degree

of accuracy and performance required.

Meter Orientation and Transmitter Position

The location of the transmitter with respect to the meter should be based on the properties of the fluid being measured and

the direction of flow through the pipeline. The direction of flow is clearly labeled on the body of every Gemini Cone meter.

The meter must be installed so that the high pressure tap (labeled P1 in Figure 1 on page 6) is always upstream of the low

pressure tap labeled P2.

Vertical installations measuring liquids may introduce a slight hydrostatic head effect, which must be considered when

zeroing a transmitter. With liquid applications, the meter should be installed so flow is moving UP to ensure a full pipe. Use

of a 3-valve manifold for zeroing a transmitter. Before installation of any Gemini Cone meter, inspect the meter for damage,

particularly at the sealing surfaces. Any damage should be reported to Badger Meter as soon as possible. Each flow element

has an arrow indicating the required direction of flow. Failure to properly orient the meter according to the direction of flow

will cause improper results and potentially damage the meter.

For vertical installations, the location of differential pressure taps is unrestricted, as long as the static pressure tap is upstream

of the lower-pressure tap.

WARNING

NEVER EXCEED THE MAXIMUM PRESSURE OR TEMPERATURE RECOMMENDED FOR THE MEASURED PROCESS.

EXCEEDING PROPER PRESSURE OR TEMPERATURE RATINGS CAN LEAD TO PERSONAL INJURY OR EQUIPMENT

DAMAGE. THE PROCESS PIPING FLANGES SHOULD BE IDENTICAL TO THOSE ON THE GEMINI CONE BOTH IN PRESSURE

CLASS AND INSIDE DIAMETER. THE PROCESS TEMPERATURE AND PRESSURE SHOULD NEVER EXCEED THOSE FOR

WHICH THE ELEMENT HAS BEEN DESIGNED.

IF HIGH-TEMPERATURE FLUIDS ARE LIKELY TO BE ENCOUNTERED, MAKE SURE THE CONNECTION FITTINGS VALVES

AND TUBING ARE RATED FOR THE ANTICIPATED TEMPERATURE RANGE.

Pressure Tap Location

Location of the pressure taps will vary with the product flowing through the pipeline (liquid, gas, or steam) and the

orientation of the meter (vertical or horizontal).

For horizontal installations, the following installation guidelines apply:

• For measuring liquid, differential pressure taps should be located in the bottom half of the pipeline, between 4 o’clock and

5 o’clock positions, or between 7 o’clock and 8 o’clock positions.

• For measuring gas, differential pressure taps should be located in the top half of the pipeline. For wet gas, taps should be

located between the 10 o’clock and 2 o’clock positions to allow proper drainage of condensate.

• For steam, differential pressure taps should be located in the side of the pipeline at 3 o’clock or 9 o’clock.

Liquid

120…150° or −120…−150°

Wet Gases

60… −60°

Dry Gases

90… −90°

Steam

90…−90° Only

0° 0° 0° 0°

Figure 3: Typical piping configurations for liquid, gas, and steam

Straight Pipe Run Requirements

Page 10 June 2018DPM-UM-00206-EN-03