bonitron M3539-S600Ax3-1500VDC User manual

4118355

M3539-S600Ax3-1500VDC

1500VDC Crowbar Module

Overvoltage Protector

Customer Reference Manual

Bonitron, Inc.

ii

Bonitron, Inc.

Nashville, TN

An industry leader in providing solutions for AC drives.

ABOUT BONITRON

Bonitron designs and manufactures quality industrial electronics that improve the reliability of

processes and variable frequency drives worldwide. With products in numerous industries, and

an educated and experienced team of engineers, Bonitron has seen thousands of products

engineered since 1962 and welcomes custom applications.

With engineering, production, and testing all in the same facility, Bonitron is able to ensure its

products are of the utmost quality and ready to be applied to your application.

The Bonitron engineering team has the background and expertise necessary to design,

develop, and manufacture the quality industrial electronic systems demanded in today’s market.

A strong academic background supported by continuing education is complemented by many

years of hands-on field experience. A clear advantage Bonitron has over many competitors is

combined on-site engineering labs and manufacturing facilities, which allows the engineering

team to have immediate access to testing and manufacturing. This not only saves time during

prototype development, but also is essential to providing only the highest quality products.

The sales and marketing teams work closely with engineering to provide up-to-date information

and provide remarkable customer support to make sure you receive the best solution for your

application. Thanks to this combination of quality products and superior customer support,

Bonitron has products installed in critical applications worldwide.

Bonitron, Inc.

iii

AC DRIVE OPTIONS

In 1975, Bonitron began working with AC inverter drive specialists at synthetic fiber plants to

develop speed control systems that could be interfaced with their plant process computers.

Ever since, Bonitron has developed AC drive options that solve application issues associated

with modern AC variable frequency drives and aid in reducing drive faults. Below is a sampling

of Bonitron’s current product offering.

WORLD CLASS PRODUCTS

Undervoltage Solutions

Power Quality Solutions

Uninterruptible Power for Drives

(DC Bus Ride-Thru)

Voltage Regulators

Chargers and Dischargers

Energy Storage

12 and 18 Pulse Kits

Filtering

Noise and Transient Suppression

Power Factor Correction

Overvoltage Solutions

Common Bus Solutions

Braking Transistors

Braking Resistors

Transistor/Resistor Combo

Line Regeneration

Dynamic Braking for Servo Drives

Single Phase Power Supplies

3-Phase Power Supplies

Common Bus Sharing Diodes

Isolation Diodes

Bus Filter Capacitance

Green/Sustainable Solutions

Portable Maintenance Solutions

Voltage Boosters

(for Solar and Wind Applications)

Line Regeneration

Power Factor Correction

Capacitor Formers

Battery Testers

Capacitor Testers

Capacitor Dischargers

M3539-S600Ax3-1500VDC

iv

This page intentionally left blank

Table of Contents

v

1. INTRODUCTION..........................................................................................................................1

1.1. Who Should Use...........................................................................................................................1

1.2. Purpose and Scope........................................................................................................................1

1.3. Manual Version and Change Record............................................................................................1

Figure 1-1: M3539-S600Ax3-1500VDC .................................................................................................1

1.4. Symbol Conventions Used in this Manual and on Equipment.....................................................2

2. PRODUCT DESCRIPTION............................................................................................................3

2.1. Part Number Breakdown ..............................................................................................................3

Figure 2-1: Example of Part Number Breakdown....................................................................................3

2-1: Current Rating per SCR....................................................................................................................3

2.2. General Specifications..................................................................................................................4

Table 2-2: General Specifications Table..................................................................................................4

2.3. General Precautions and Safety Warnings ...................................................................................5

3. INSTALLATION INSTRUCTIONS..................................................................................................7

3.1. Environment .................................................................................................................................7

3.2. Unpacking..................................................................................................................................... 7

3.3. Mounting ......................................................................................................................................7

Table 3-1: Chassis and Mounting Dimensions for the M3539 Module ...................................................7

3.4. Wiring and Customer Connections...............................................................................................8

3.4.1. Power Wiring....................................................................................................................................8

Table 3-2: Power Connection Specifications ...........................................................................................8

3.4.2. I/O Wiring.........................................................................................................................................8

Table 3-3: I/O Wiring Specifications.......................................................................................................8

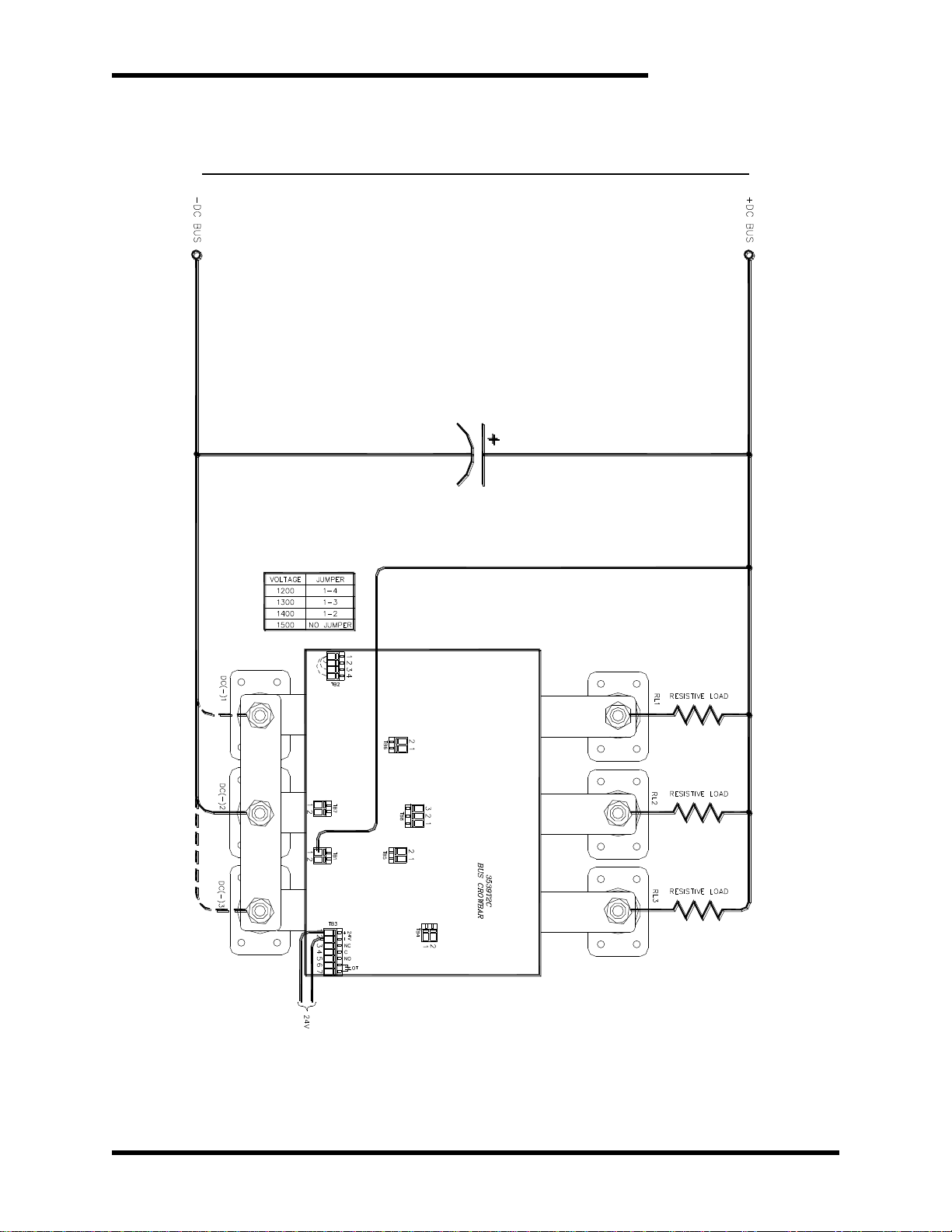

3.5. Typical Configuration...................................................................................................................9

Figure 3-1: A006593-01 Overvoltage Protector Field Wiring Diagram ..................................................9

4. OPERATION..............................................................................................................................11

4.1. Functional Description ...............................................................................................................11

4.1.1. Jumper Selection.............................................................................................................................11

4.1.2. I/O Inputs and Outputs....................................................................................................................11

4.1.3. Internal Power Indicator..................................................................................................................12

4.2. Operation....................................................................................................................................13

Figure 4-1: Firing Response...................................................................................................................13

5. MAINTENANCE AND TROUBLESHOOTING...............................................................................15

5.1. Periodic Testing..........................................................................................................................15

5.2. Maintenance Items......................................................................................................................15

5.3. Troubleshooting..........................................................................................................................15

5.3.1. Signal indicator is not on ................................................................................................................15

5.3.2. Overtemperature .............................................................................................................................15

5.4. Technical Help –Before you call...............................................................................................15

6. ENGINEERING DATA................................................................................................................17

6.1. Ratings Charts.............................................................................................................................17

Table 6-1: Ratings Chart ........................................................................................................................17

6.2. Losses.........................................................................................................................................17

Table 6-2: Watt and Energy Losses .......................................................................................................17

6.1. Dimensions and Outlines............................................................................................................17

Figure 6-1: Chassis and Mounting Dimensional Outline .......................................................................17

7. APPLICATION NOTES...............................................................................................................19

M3539-S600Ax3-1500VDC

vi

This page intentionally left blank

User’s Manual

1

1. INTRODUCTION

1.1. WHO SHOULD USE

This manual is intended for use by anyone who is responsible for integrating,

installing, maintaining, troubleshooting, or using this equipment.

Please keep this manual for future reference.

1.2. PURPOSE AND SCOPE

This manual is a user’s guide for the Model M3539-S600Ax3-1500VDC Overvoltage

Protector. It will provide you with the necessary information to successfully install

and use this module in your application.

In the event of any conflict between this document and any publication and/or

documentation related to the application, the latter shall have precedence.

1.3. MANUAL VERSION AND CHANGE RECORD

Rev 01a adds the option jumpers TB7 for response time, remote firing option on

TB8, and a full form C contact on connector U3.

The Wiring Diagram was updated in Rev 01b.

The part number changed in Rev 01c.

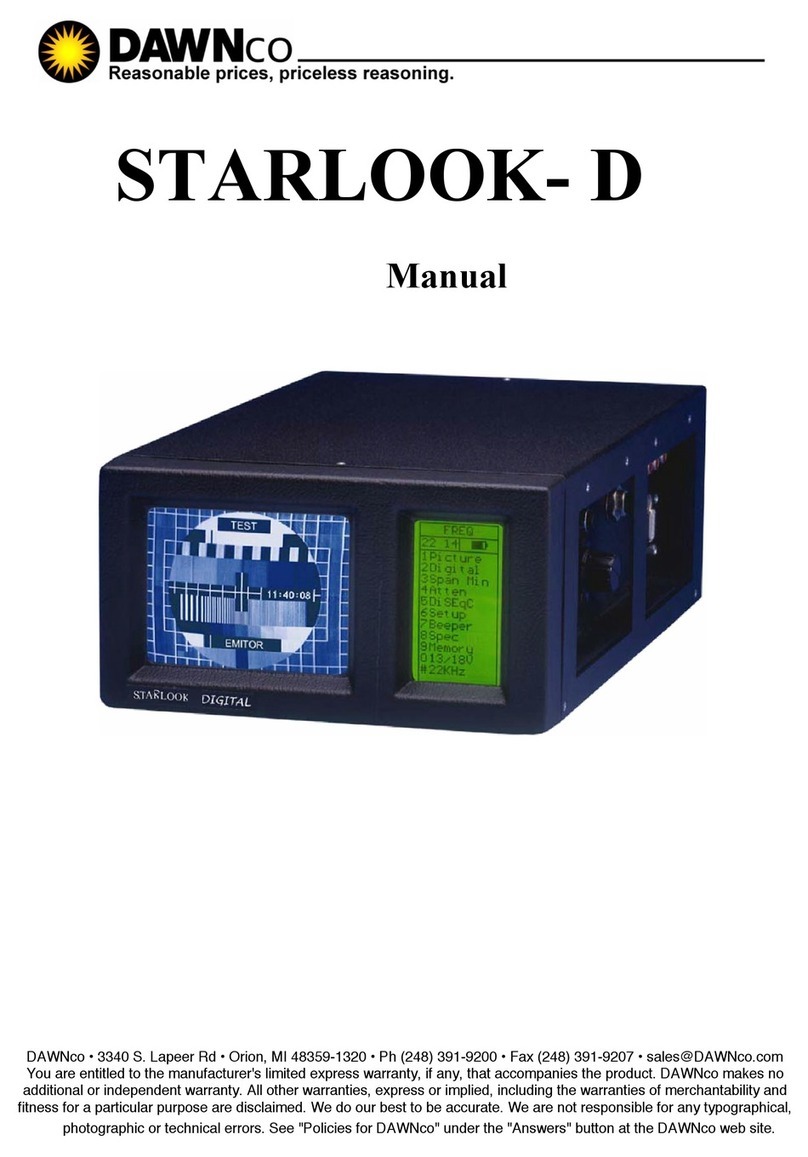

Figure 1-1: M3539-S600Ax3-1500VDC

M3539-S600Ax3-1500VDC

2

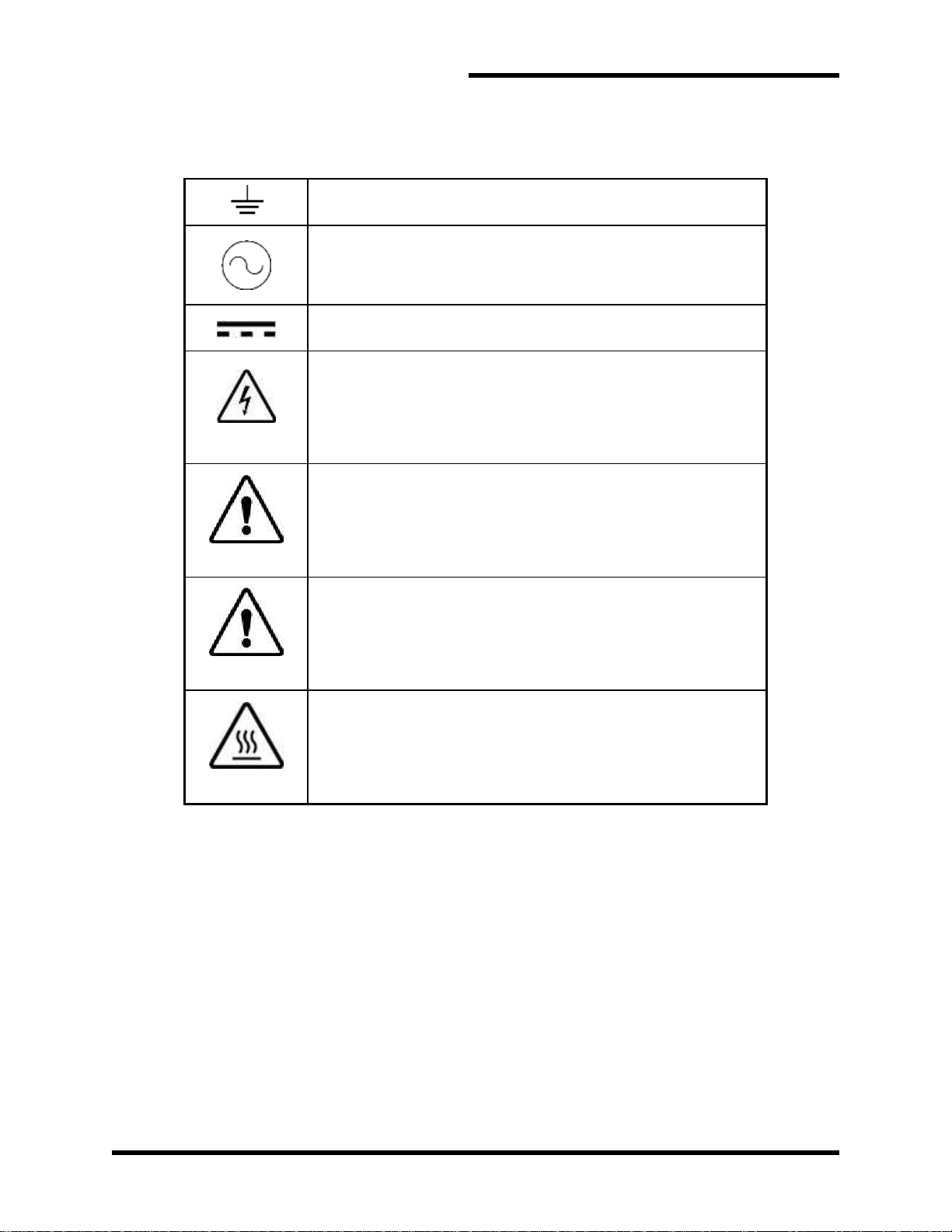

1.4. SYMBOL CONVENTIONS USED IN THIS MANUAL AND ON

EQUIPMENT

Earth Ground or Protective Earth

AC Voltage

DC Voltage

DANGER!

Electrical Hazard - Identifies a statement that indicates a shock

or electrocution hazard that must be avoided.

DANGER!

DANGER: Identifies information about practices or

circumstances that can lead to personal injury or death,

property damage, or economic loss.

CAUTION!

CAUTION: Identifies information about practices or

circumstances that can lead to property damage, or economic

loss. Attentions help you identify a potential hazard, avoid a

hazard, and recognize the consequences.

CAUTION!

Heat or burn hazard - Identifies a statement regarding heat

production or a burn hazard that should be avoided.

User’s Manual

3

2. PRODUCT DESCRIPTION

DC bus can experience dangerously high voltages. The M3539-S600Ax3-1500VDC

Overvoltage Protector (4118355) is designed to save all devices connected to the DC

bus by firing three SCRs when the voltage reaches a predetermined point, thus shunting

the potentially damaging energy.

2.1. PART NUMBER BREAKDOWN

Figure 2-1: Example of Part Number Breakdown

BASE MODEL NUMBER

The Base Model Number for all Overvoltage Protectors is M3539.

PROTECTION TYPE

One letter represents the selected Protection Type.

S –Uni-directional protection

D –Bi-directional protection

CURRENT RATING

Current Rating is indicated by a 3 digit number.

2-1: Current Rating per SCR

RATING CODE

CURRENT

300

300A

600

600A

NUMBER OF SCRS

Enter an “x” followed by the number of SCRs requested. Single SCR units have no

“x”.

VOLTAGE RATING

A 4-digit code represents the voltage trip point.

M3539

VDC

Ax

S

Ax

600

1500

3

BASE MODEL

PROTECTION TYPE

CURRENT RATING

NUMBER OF SCRS

VOLTAGE RATING

M3539-S600Ax3-1500VDC

4

2.2. GENERAL SPECIFICATIONS

Table 2-2: General Specifications Table

PARAMETER

SPECIFICATION

Input Voltage

24 VDC

System load bank

3x 2.7 ohm, Wye connected

System Voltage

900VDC Nominal

Peak Current

1800ADC

Trip Point

Jumper adjustable, 1200V, 1300V, 1400V, 1500V

Discharge Time

6 seconds

10 minute off time

Reaction Time

100 µS

Operating Temp

-40C to +70C

Discharge Waveform

Exponential

Cooling

Convection, no forced air

Storage Temp

-40C to +70 C

Operating Temperature Range:

-40C to +70 C

Humidity

95% non-condensing

Altitude

10,000 ft

Control I/O

Input: 24VDC, 120mA max

Outputs: 125VAC, 120mA,

Over-temp

Crowbar Fired Signal

Indicators

Power

User’s Manual

5

2.3. GENERAL PRECAUTIONS AND SAFETY WARNINGS

DANGER!

HIGH VOLTAGES MAY BE PRESENT!

NEVER ATTEMPT TO OPERATE OR SERVICE THIS EQUIPMENT

WITH ACCESS DOORS OR COVERS OPENED!

FAILURE TO HEED THESE WARNINGS MAY RESULT IN

SERIOUS BODILY INJURY OR DEATH!

CAUTION!

HIGH TEMPERATURES MAY BE GENERATED BY THIS

EQUIPMENT DURING NORMAL OPERATION!

THIS EQUIPMENT SHOULD BE INSTALLED ON A NON-

FLAMMABLE SURFACE IN A WELL VENTILATED AREA WITH A

MINIMUM OF 2INCHES OF CLEARANCE ALL AROUND.

LETHAL VOLTAGES CAN EXIST IN UNIT AFTER POWER HAS

BEEN REMOVED.ALLOW 5MINUTES FOR CAPACITOR BANKS

TO DISCHARGE,AND INSURE THERE IS LESS THAN 40VDC

ON THE DC BUS BEFORE ATTEMPTING SERVICE.

ALWAYS ALLOW TIME FOR THE UNIT TO COOL BEFORE

ATTEMPTING SERVICE ON THIS PRODUCT!

INSTALLATION AND/OR REMOVAL OF THIS PRODUCT SHOULD

ONLY BE ACCOMPLISHED BY A QUALIFIED ELECTRICIAN IN

ACCORDANCE WITH NATIONAL ELECTRICAL CODE OR

EQUIVALENT REGULATIONS.

ANY QUESTIONS AS TO APPLICATION, INSTALLATION, OR SERVICE

SAFETY SHOULD BE DIRECTED TO THE EQUIPMENT SUPPLIER.

M3539-S600Ax3-1500VDC

6

This page intentionally left blank

User’s Manual

7

3. INSTALLATION INSTRUCTIONS

WARNING!

Installation and/or removal of this product should only be performed by a

qualified electrician in accordance with National Electrical Code or local

codes and regulations.

Proper installation of the Power Supply Modules should be accomplished following the

steps outlined below. Be sure to refer to the AC Drive instruction manual as these steps

are performed. Please direct all installation inquiries that may arise during the

installation and start up of this product to the equipment supplier or system integrator.

3.1. ENVIRONMENT

The module should be installed in an area protected from moisture and falling debris.

Buildup of dust or debris may cause poor performance and possibly a failure.

Operating in a wet environment can pose a shock hazard. The recommended

temperature range for operating or storing this module is -40C to +70C.

3.2. UNPACKING

Upon receipt of this product, please verify that the product received matches the

product that was ordered and that there is no obvious physical damage to the unit. If

the wrong product was received or the product is damaged in any way, please

contact the supplier from which the product was purchased.

3.3. MOUNTING

The installation site for the module should be chosen with several considerations in

mind:

The unit requires a minimum clearance of two (2) inches in all directions around it

when mounted near a non-heat source.

Unit should not be exposed to falling debris or condensation.

See Figure 6-1 for the Chassis and Mounting Dimensional Outline.

Table 3-1: Chassis and Mounting Dimensions for the M3539 Module

MODEL NUMBER

OVERALL

(IN INCHES)

MOUNTING

(IN INCHES)

WEIGHT

(LBS.)

HEIGHT

WIDTH

DEPTH

HEIGHT

WIDTH

M3539-S 600Ax3-1500VDC

13

12.3

7.6

10

11.57

30

M3539-S600Ax3-1500VDC

8

3.4. WIRING AND CUSTOMER CONNECTIONS

3.4.1. POWER WIRING

DANGER!

This unit contains substantial capacitance and can

maintain lethal voltages for a long time after power is

removed! Insure that the DC bus level has dropped below

40VDC before attempting to work on or with this unit!

WARNING!

Only qualified electricians should perform and maintain the

interconnection wiring of this product. All wiring should be

done in accordance with local codes.

Table 3-2: Power Connection Specifications

UNIT

TERMINAL

CONNECTION

TORQUE

M3539-S600Ax3 1500VDC

RL1, RL2, RL3,

DC1-, DC2-, DC3-

½” stud

300 in-lbs

3.4.2. I/O WIRING

Table 3-3: I/O Wiring Specifications

TERMINAL

FUNCTION

ELECTRICAL

SPECIFICATIONS

MIN WIRE

AWG

MAX WIRE

AWG

DESCRIPTION

SECTION

TB1-1

TB1-2

DC+ Sense Line

1500V, 1mA

28

12

4.1.2.1

TB2

Voltage Trip

Point Selection

Jumper

300V, 1mA

28

12

4.1.1.1

TB3-1

SCR Fire Signal

24V, 100mA

28

12

4.1.2.2

TB3-2

SCR Fire Signal

24V, 100mA

28

12

4.1.2.2

TB3-3

TB3-4

TB3-5

SCR Fired

Signal

300VAC, 120mA max

28

12

4.1.2.3

TB3-6

TB3-7

Normally closed

Over temp

125VAC, 15 Amps

28

12

4.1.2.4

TB7-1

TB7-2

Response Time

Selection

Jumper

300V, 1mA

28

12

4.1.1.2

TB8-1

TB8-2

TB8-3

Crowbar Fire

Signal Operation

Jumper

300V, 1mA

28

12

4.1.1.3

User’s Manual

9

3.5. TYPICAL CONFIGURATION

Figure 3-1: A006593-01 Overvoltage Protector Field Wiring Diagram

Dwg #: 100287 Rev: 20120717

M3539-S600Ax3-1500VDC

10

This page intentionally left blank

User’s Manual

11

4. OPERATION

4.1. FUNCTIONAL DESCRIPTION

The M3539-S600Ax3-1500VDC Overvoltage Protector (4118355) is

connected to the DC bus. When the voltage goes above a certain

threshold, the SCRs will fire, limiting the voltage from going higher. The

energy is dissipated through the field resistance. This is designed with

heatsinks to handle time constants up to 12 seconds without fan or

other air circulation. Once the current drops below the SCR latching

threshold, the circuit turns off resets for another high voltage spike.

Unit has three parallel SCRs, each capable of carrying 600A peak. This

will allow for parallel load resistor connections.

WARNING!

Each connection must have a separate resistor element! If the

resistor connections are all connected at the crowbar module, the

SCRs will not share current, and may misfire!

This can cause overheating and catastrophic failure!

4.1.1. JUMPER SELECTION

4.1.1.1. TB2-OVERVOLTAGE SETPOINT SELECTION JUMPERS

A jumper is used to determine the overvoltage setpoint. This is the

point at which the SCRs will fire regardless of other conditions. The

voltage is sensed between TB1 and the DC- power connection.

Jumper adjustment:

For 1200V: connect TB2-1 to TB2-4

For 1300V: connect TB2-1 to TB2-3

For 1400V: connect TB2-1 to TB2-2

For 1500V: no jumper

4.1.1.2. TB7 -RESPONSE TIME SELECTION JUMPER

This jumper determines the response time of the circuit. If the jumper is

installed, the unit will fire when the voltage sensed on TB1 is above the

setpoint within 2ms.

If the jumper is not installed, the unit will fire within 20ms.

4.1.1.3. TB8 -CROWBAR FIRE SIGNAL OPERATION JUMPER

This jumper determines the firing operation of the external override

signal. See Section 4.1.2.2 for details on the settings.

4.1.2. I/O INPUTS AND OUTPUTS

4.1.2.1. TB1-1&2 HIGH VOLTAGE SIGNAL +

The unit will sense the DC BUS positive voltage from TB1-1 or TB1-2.

The differential voltage between this terminal and the DC- terminals will

determine when the SCR crowbar fires.

These terminals are an electrical node, and are connected on the

board. Do not hook the DC- reference to these terminals as it will be a

direct short.

M3539-S600Ax3-1500VDC

12

The voltage attached to this terminal is referenced to the DC1-, DC2-,

and DC3- main power terminals.

4.1.2.2. TB3-1&2 CROWBAR FIRE SIGNAL

This signal can be used to remotely fire the SCRs with a 24VDC signal.

Terminal 1 is the +24V signal, terminal 2 is the 24V- or common signal.

The firing operation will be determined by the jumper on TB8.

If the jumper on TB8 is installed in terminals 2 and 3, the unit will fire

when there is a 24VDC falling edge on TB3-1&2.

If the jumper is on TB8 terminals 1 and 2, the SCR fire signal has no

effect.

In either case, the unit will fire when the High Voltage sensing voltage

between TB1 and DC- reaches the level set by the jumpers on TB2.

4.1.2.3. TB3-3&4&5 SCR FIRED SIGNAL

The SCR Fired signal will change when the SCRs are triggered. These

outputs are isolated so they may be interfaced with PLC or external

switch.

Terminal 3 is a normally closed signal.

Terminal 4 is common to both signals.

Terminal 5 is a normally open signal.

4.1.2.4. TB3-6&7 OVER TEMPERATURE SIGNAL

The over temperature contact opens when the heatsink temperature

reaches 220±5°F and closes when it reaches 190±10°F.

4.1.3. INTERNAL POWER INDICATOR

The unit has an indicator in the control board that will be illuminated when

external 24V is applied.

User’s Manual

13

4.2. OPERATION

The crowbar is designed to allow for remote firing and indication. The DC bus is

monitored constantly, and the SCRs will fire under the following conditions:

1. If it goes above the overvoltage setpoint, the SCRs will fire regardless of the

state of the 24V input supply.

2. If the DC bus is at a level below the overvoltage trip point, a negative edge, or

removal of power from the 24V input will cause the SCRs to fire. This may be

useful to drain the bus for maintenance after the main input power supply has

been removed or disabled. This function can be disabled by removing the

jumpers from TB8-2&3

Please see the timing chart below for a graphical representation of the firing

responses.

Figure 4-1: Firing Response

DC Bus

SCR Fire

Signal

(input)

SCR

Fired

Signal

(output)

Time

0 Volts

Normal

Trip Point

~200 Volts

M3539-S600Ax3-1500VDC

14

This page intentionally left blank

Table of contents

Other bonitron Power Distribution Unit manuals

Popular Power Distribution Unit manuals by other brands

Ediseja 21

Ediseja 21 LSU 110/32 user manual

Eaton

Eaton FlexPDU user manual

ITT

ITT POWERLOCK BOX Translation of the original operating instructions

Belkin

Belkin PureAV PF30 user manual

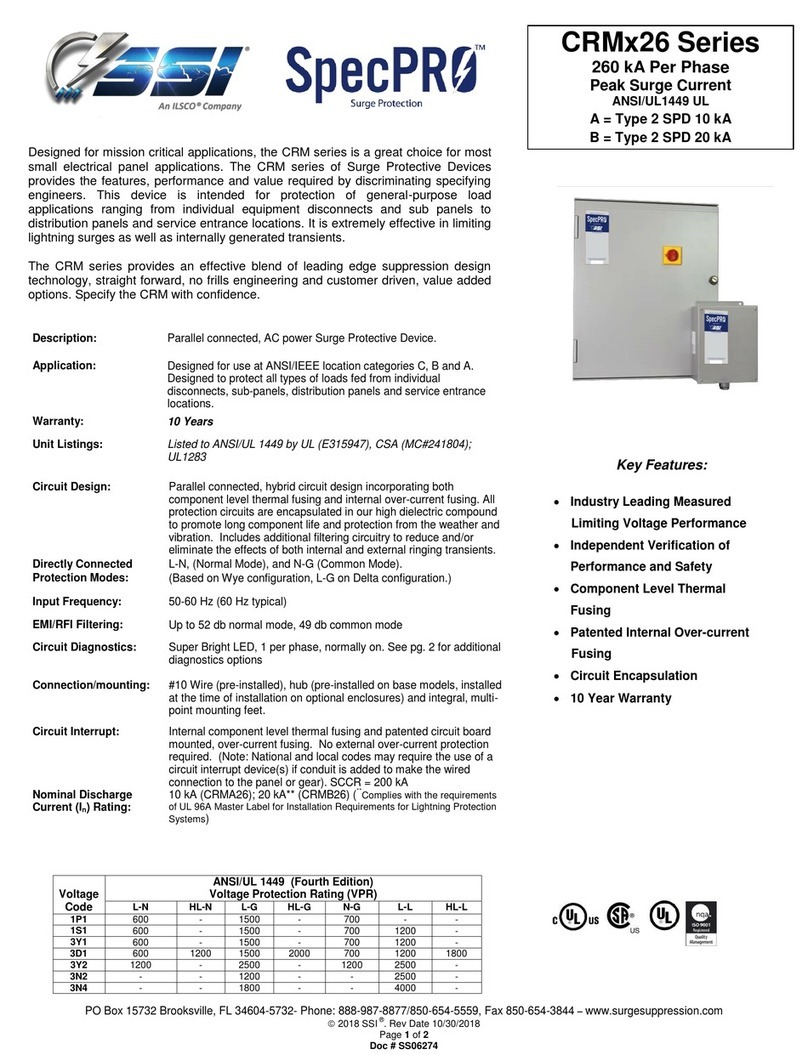

Ilsco

Ilsco SpecPRO CRM 26 Series quick start guide

Scame electrical solutions

Scame electrical solutions ADVANCE-GRP Series Installation, use and maintenance

Dawnco

Dawnco STARLOOK- D manual

Siemens

Siemens XJ-L Busway System Storage, Installation and Maintenance Instructions

CyberPower

CyberPower 649532893522 Specification sheet

S&C

S&C VacuFuse Installation and operation

Middle Atlantic Products

Middle Atlantic Products RackLink RLNK-915R quick start guide

nVent Hoffman

nVent Hoffman DPC user manual