BONKOTE PATRIOT MW50 User manual

MW50

LA type soldering iron controller

Instruction manual(QSS-4000)

Date prepared: March 2019

The 6

th

edition

JAPAN BONKOTE CO., LTD.

PATRIOT

Contents

1 Preface·················································································································· ··1

2 Notesforsafety··········································································································1

3 RecommendationofAuto-tuningbeforeuse····································································1

4 Notesforinstallationanduse····················································································· ··2

5 HowtouseMW50Controller

(A)Contents···············································································································3

(B)Nameofthebody···································································································3

(C)Howtoassemble ·································································································4

(D)Howtouse ···········································································································5

6 Optionalsetting

(A)Alarmfunctionupperlimitsetting ·············································································8

(B)Alarmfunctionlowerlimitsetting···············································································8

(C)Temperaturerecoveryspeedsetting·········································································9

(D)Upperlimitsettingofsettingtemperature···································································9

(E)Monitorindicationofoperationoutputamount·····························································9

(F)Lockfunction······································································································10

(G)Anti-resetwindupsetting·····················································································10

(H)Auto-PowerDown/Auto-PowerOffsetting·······························································11

(I)PIDvaluemanualsetting·······················································································13

(J)DeviceNumbersetting·························································································15

7 CharacterList··········································································································16

8 Howtomaintenance ································································································17

9 Standardspecifications·····························································································17

10 GuaranteeandAfter-sales serviceofMW50

(A)Troubleshootings································································································18

(B)Guarantee ·········································································································18

(C)Aftersalesservice·······························································································18

1

1. Preface

Thank you very much for purchasing [MW50 Controller].

Please read Notes for safety before use, and use this machine properly, keep this

manual after read.

2. Notes for safety

CAUTION!

Be sure to read this manual before using this machine.

・ Never touch the power and 5P core relay cord with dump hands. Otherwise, you may get hurt due to electric

shockandetc.(deathatworse)

・ Never dampen the iron tip with water or other liquid. Otherwise, burst cord may cause fire, malfunction, electric

shockandetc.(deathatworse)

・ Take great care to handle the soldering iron while it is not rested on the workbench. Otherwise the heated tip

maycause fireor adjacentoperatorsmay gethurt.

・ Nevertouch theiron tipwhilecurrentisbeingpassed. Otherwise, youmaygetburnt. If you haveto touch the

tip like replacement of irontipor parts, turn off the power and pull out the power plug from the receptacle, wait for

awhileandcheckifithasalreadycooleddownsufficientlybyusingathermometer oretc.

・ Do not overhaul the machine when the machine has trouble. Otherwise, it may cause malfunction, electric

shock and etc (death at worst). Contact with our customer service department and follow instructions to make

maintenance.

・ Be sure to use proper replacement parts such as fuse, checking capabilities. Otherwise, parts with wrong

capacitiesmaycausefire,malfunctionandetc.

3. Recommendation of Auto-tuning before use

It is recommendable to do Auto-tuning before use, to operate with good effect for each conditions (iron tip

temperature, shape of iron tip, etc.) and each environment, although each parameter is set with the standard

parametervalueattheshipment.

※Auto-tuning withsimplekeyoperation.(How touse,please referP.7)

!

2

4. Notes for installation and use

・ Thismachine isdesignedwithearthspecification. Forsafety, besuretouse anearth-quippedreceptacle.

(Ifyoudonothavesuchreceptacle,installanearthseparately.)

・ Forsurrounding conditions,usethismachineona neat workbench onwhichaconductive matis put.

・ Refrain from place where the machine would be exposed too much moisture, direct sunshine, much dust and

vibration.

・ Inorderto preventstatic electricity, it isrecommended usingastaticelectricityremovaldevice,wriststrapetc.

・ Odoris generatedduetothe useof solder andflux. Besuretoventilate workplaces.

(E.g.fittingofventilatoretc.)

・ Besureto pull outthepowerplug,whenthemachineisnotused.

・ Besureto grab thepowerpluginsteadofcable, wheninserting andpulling outtheplug.

・ If the power voltage is changedfrom 100V to 220V, make sureof confirm the specifications of the soldering iron

unitbefore the change.

・ Ifflammableobjects areplaced nearthismachine, thereisa danger offire. Becareful.

・ Besureto check theslackofeachscrewbeforeuse. Ifthescrewis loosen,tightit.

・ Donotusethismachine for purpose other than theoriginalpurpose.

3

5. How to use MW50 controller

(A) Contents

※100V with 3PCHI-plug cable, 220V with 3EPV-plug cablewill be attached.

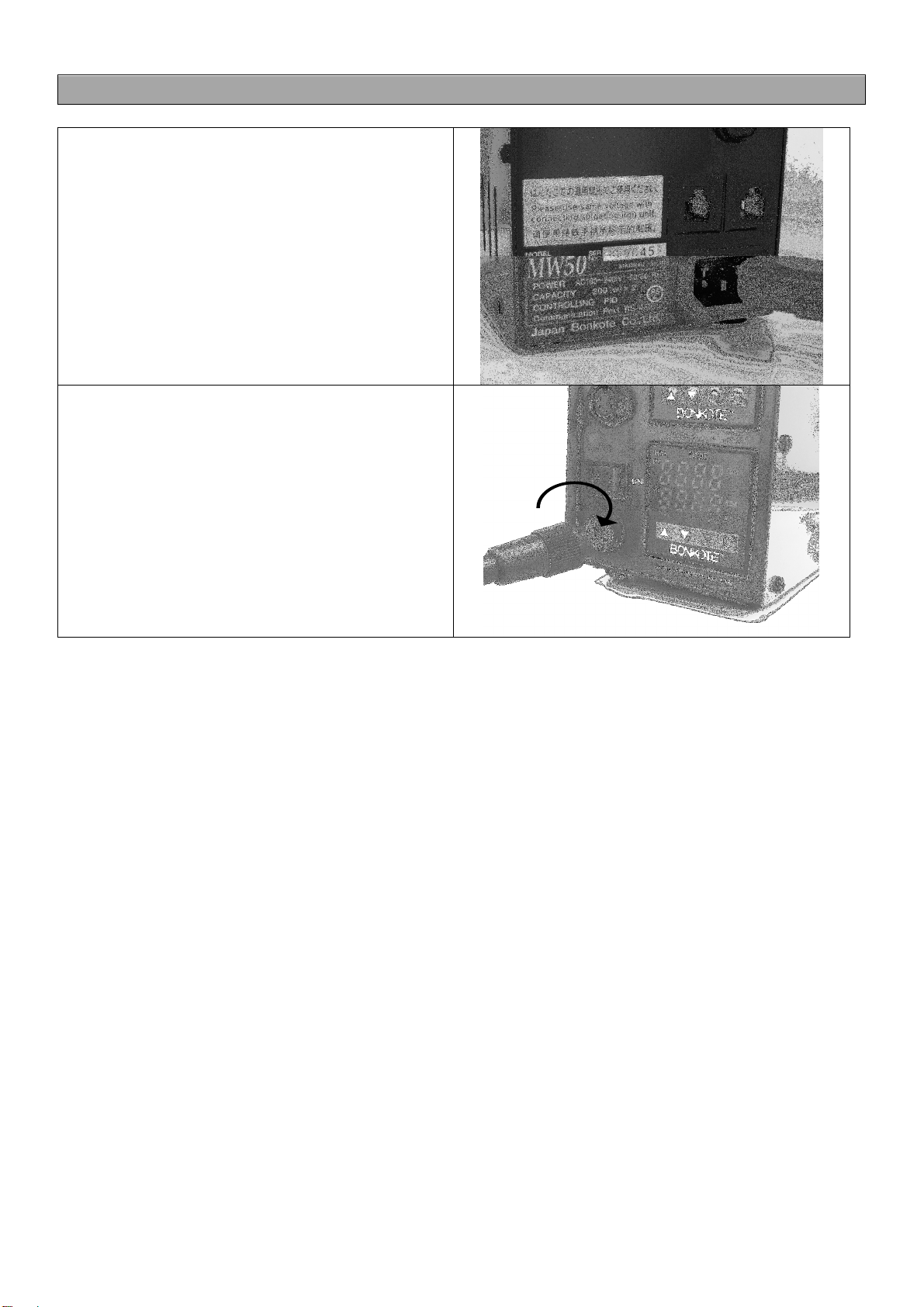

(B) Name of the body

《 Front 》

①

5PConnector

②

Power switch

③

PV display(Working temperature)

④

SV display(Setting temperature)

⑤ □

key(Speed setting)

⑥

key(Function key)

⑦ ▽

key(Setting value Down key)

⑧ △

key(Setting value Up key)

《 Back 》

⑨3P inlet

⑩Fuse holder (2pcs)

⑪Modular jack (2pcs)

①MW50 Controller

②3P Power Cable

①

②

⑨

⑩

⑪

4

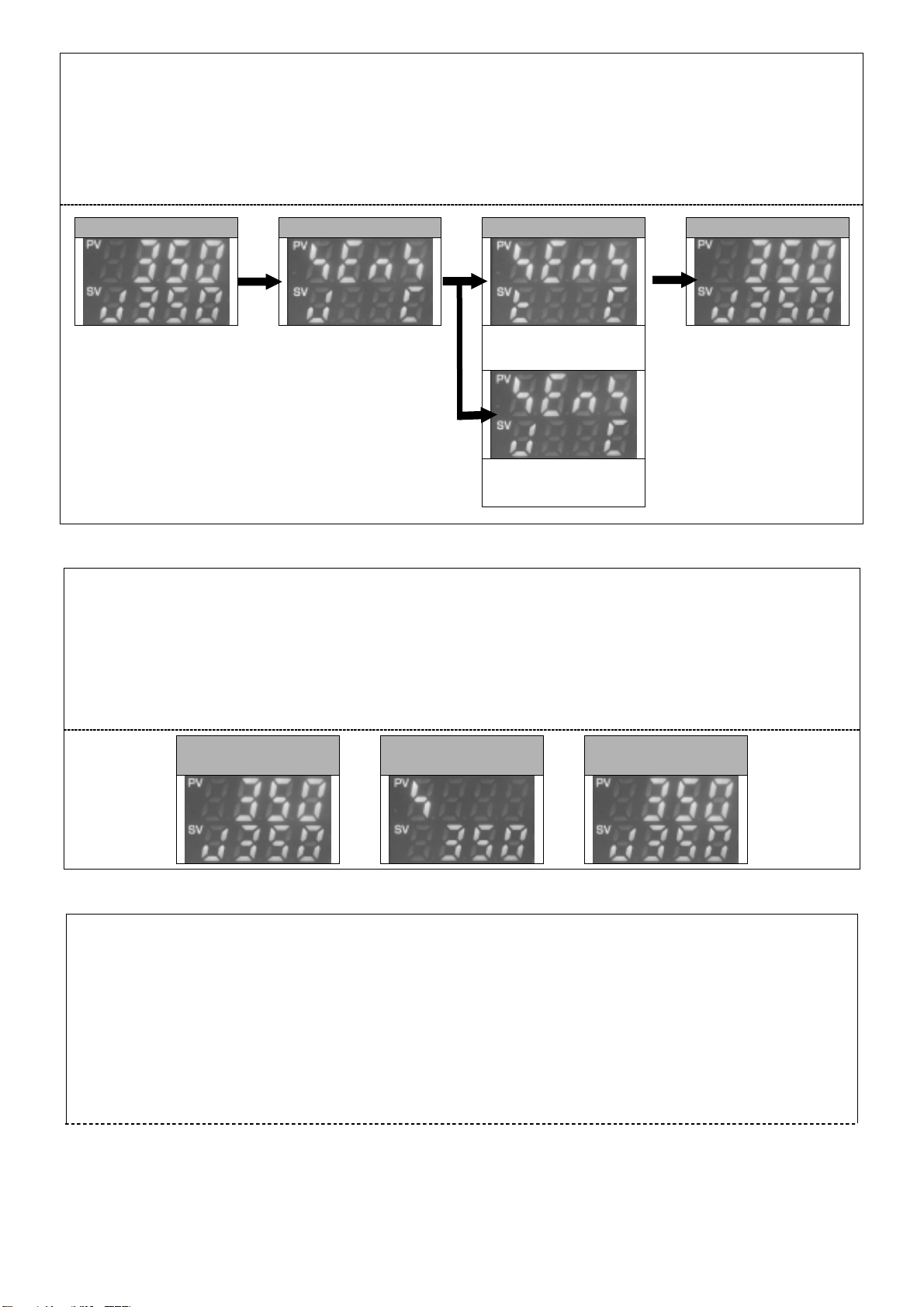

(C) How to assemble

①

Insertthe Power cable into 3Pinlet.

②

Connect the soldering iron to 5P connector

at the front, and lock it with rotating to right.

Please make sure the voltage of the

soldering iron unit is applicable to the

input-voltageof MW50controller.

5

(D) How to use

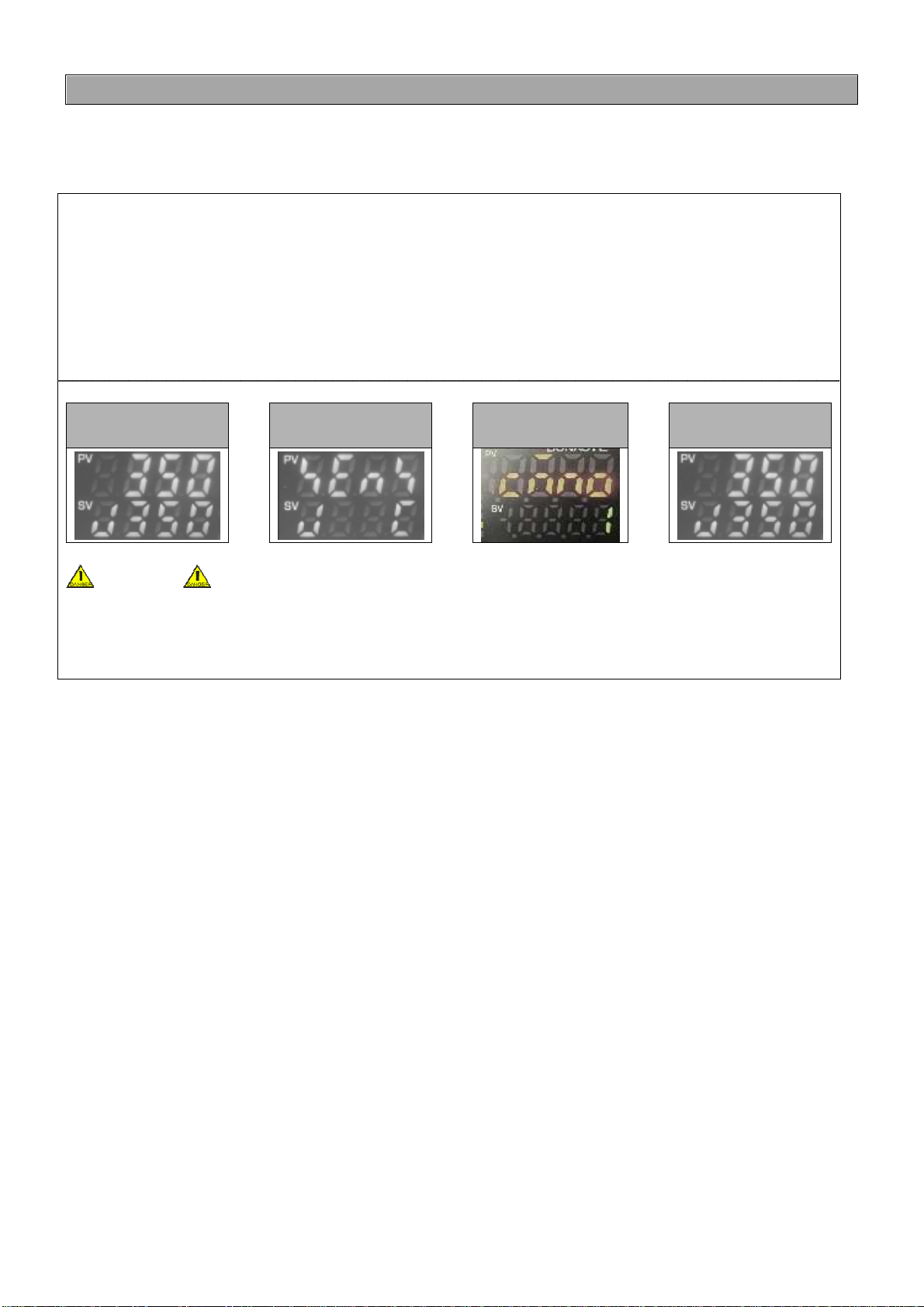

① Turn on Power

Insert the power plug intothe receptacle and confirm the input voltage of soldering iron and theone of

this controller are same, then set the power switch to ON.

※Ifuse100Vtypeof soldering ironwith220input voltageinoversea, itmakes heaterdamaged.

②Setting and confirmation of the sensor input type

MW50 controller is workable for 2 different kinds of soldering iron units, one is J-sensor type and other

K-sensor type. Please make sure that the each sensor-type of soldering iron unit and the one of

controller should bethesame. Otherwise, temperature control isunabletowork.

※The sensor type is set at the shipment.

~How to confirm the sensor type~

A: Controller

Atthe operation mode,

or

is indicated at left side of SV screen.

ControllingwithJ typeindicates

. ControllingwithKtype indicates

.

Pleasecheck thesensortypeofthecontrollerissamewith theoneof connecting solderingiron unit.

《Jtype》 《Ktype》

B: Soldering iron unit

LAsoldering ironunithas 2differentkinds of sensortype,J type andK type

Please checkthelabel ofthesolderingironunit.

Letter J printed after the model number is J type, no letter printed after the model number is

Ktype.

Ktypesoldering ironunit

Jtypesoldering ironunit

あ

6

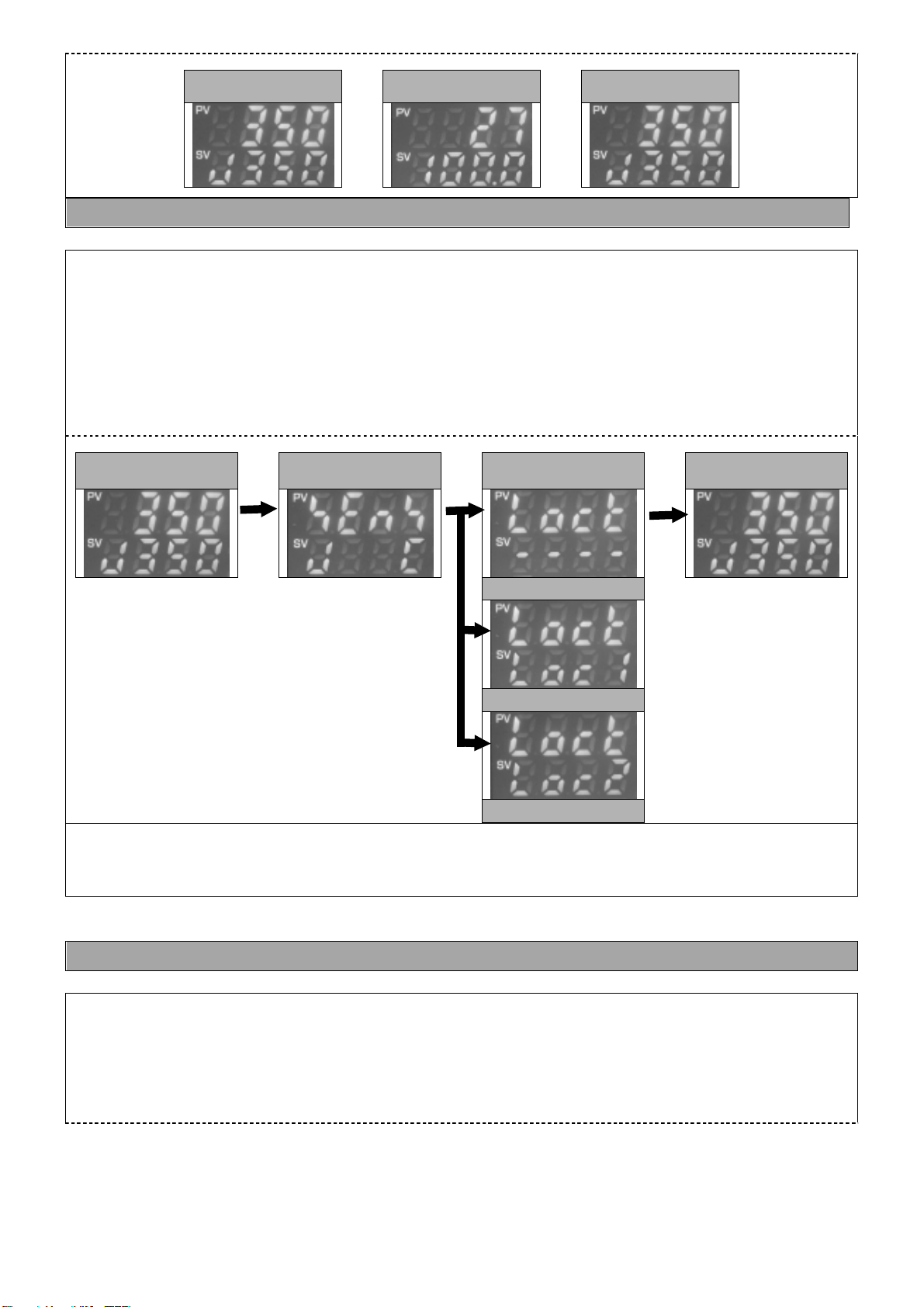

~How to set the sensor type and temperature indication~

Ⅰ:Attheoperationmode,press

key approx. 3 seconds with pressing ▽key.

is indicated at PVscreen.

Ⅱ:Inputsuitable sensortypeby △or ▽key, and push

key8 timestoreturnto operationmode.

Operation mode

⇒

Sensortypeinputscreen

⇒

Selectsensortype

⇒

Operation mode

・Control with K type

・Indication in (℃)

・Control with J type

・Indication in (℃)

③ Set the temperature

Initial setting : 350℃ Setting range : 0~500℃

Ⅰ:Attheoperationmode,press

keyonceand

is indicated at PV screen.

Ⅱ:Setthetemperatureby △or ▽ key.

Ⅲ:Press

keyonceto return tooperation mode.

Operation mode

⇒

Settingtemperature

settingscreen

⇒

Operation mode

④ Compensation of temperature differences

Initial setting: 0℃ Setting range:-100.0℃ ~ 100.0℃

Ⅰ:Attheoperationmode,press

key approx. 3 seconds with pressing ▽key.

isindicatedatPVscreen.

Ⅱ:Push

key3 times and

is indicatedatPV screen.

Ⅲ:Inputthecompensate value by △or ▽key at SVscreen.

Ⅳ:Afterinput thevalue,push

key5 timestoreturntooperationmode.

7

Operation mode

⇒

Sensortypeinput

screen

⇒

Temperature

compensation

screen

⇒

Operation mode

How to calculate the compensation value by Standard measurement instrument

Example:

Temperatureinstruments indicates: 350℃ Controller indicates: 355℃

Setthecompensation valueas -5

Thecompensation value=Standard measurement instrument indication-Controller indication

⇒350-355=-5

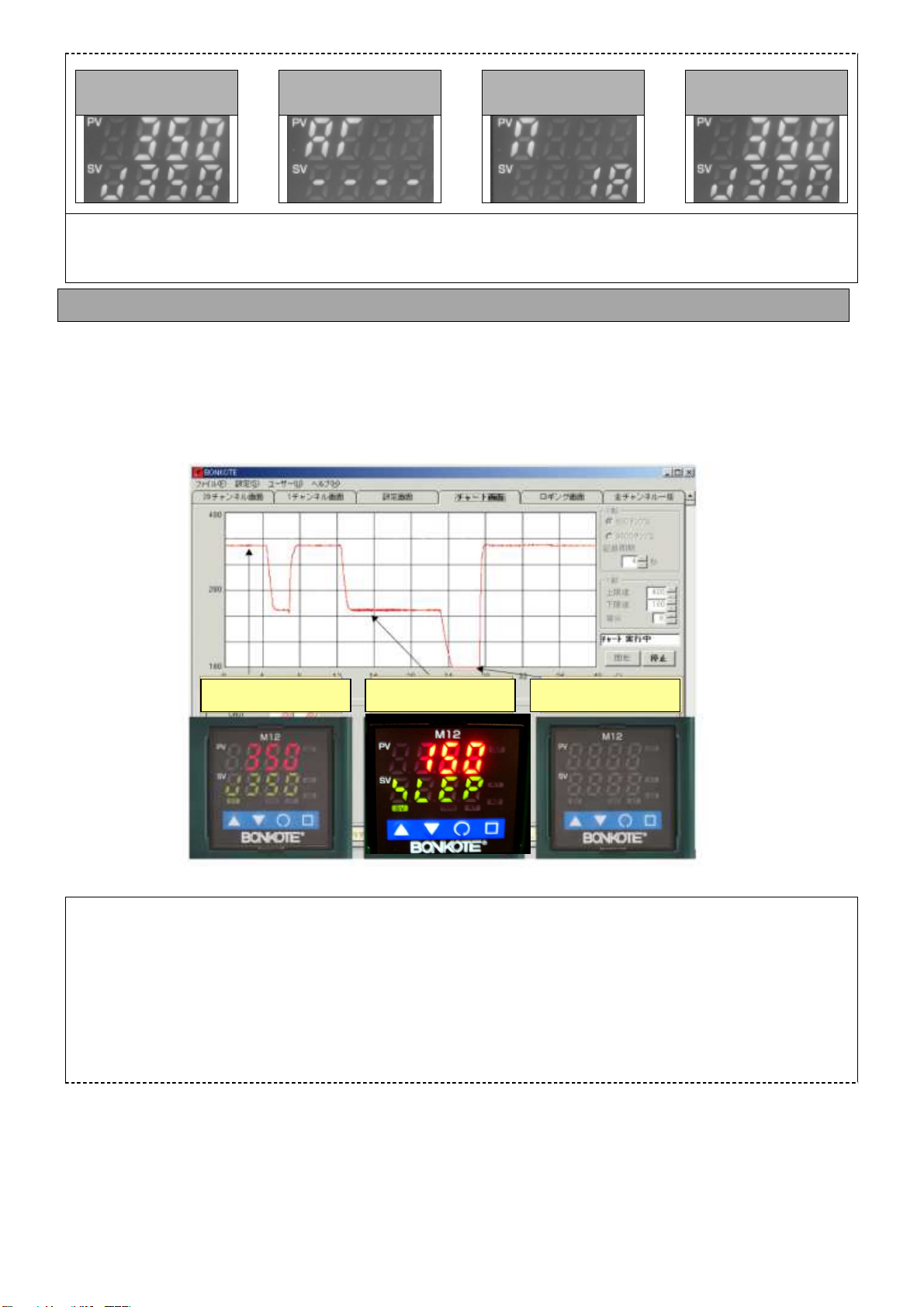

⑤ StartAuto-tuning after reach to setting temperature

Ⅰ:Attheoperationmode,push

keywithpressing △key,

is indicatedat PV screen.

Ⅱ:Push △key oncein order toindicate

atSVscreenaswell.

Ⅲ:Push

keyto startAuto-tuning. (ATblinkingstarts at rightbottom ofthescreen)

Auto-tuningis doneabout 2minuites(ATstopsat right bottomofthe)

Operation mode

⇒

ATsetting screen

⇒

ATsetting screen

⇒

Operation mode

あ

Auto-tuning: Itautomatically calculate suitable PIDvaluewhichcontrolsoldering iron.

Please make sure to do Auto-tuning otherwise, soldering iron may not perform with enough effect.

Attention

PleasemakesuretodoAuto-tuning after reach to setting temperature.

Please do not touch the soldering iron during Auto-tuning (during AT is blinking at right bottom of

the screen). PID value is automatically calculated by fluctuating

temperature (about 2minutes).

Touching the soldering iron during the fluctuation in temperature, it cause incorrect PID value

calculation and soldering iron may not perform with enough effect.

Auto-tuningis done when the blinkingstops.

Above ④、⑤ areunnecessarytodoeverytime. Pleasedoitwhenchangeirontipand changesettingtemperature.

※At shipment,Auto-tuning is not done yet. Please make sure to doAuto-tuning before use.

8

6. Optional setting

MW50 has various functions. Please use the function with your convenience.

(A)Alarm function Upper limit setting

① Set the upper limit alarm of soldering temperature

Initial setting: 50℃

Ⅰ:Attheoperationmode,press

keywithpressing △ key.

is indicatedatPV screen.

Ⅱ:Push

key5 times,

isindicated at PV screen.

Ⅲ:Input thevalueby △or ▽keyatSVscreen. Push

key2timestoreturnto operationmode.

Operation mode

⇒

AT setting screen

⇒

Upper limit alarm function

⇒

Operation mode

あ

Upper limit alarm: It alarms when the temperature exceed the range ○○℃ of settingtemperature.

Example:

Theupperlimitissetas50. setting temperature is 350℃.

Italarmswhen temperature becomeover 400℃.

Set 0 whenalarmfunction is unnecessary.

(B)Alarm function Lower limit setting

① Set the lower limit alarm of soldering temperature

Initial setting:-50℃

Ⅰ:Attheoperationmode,press

keywithpressing △ key.

is indicatedatPV screen.

Ⅱ:Push

key6 times,

isindicated at PV screen.

Ⅲ:Inputthevalueby △▽ keyat SVscreen. Push

keyonceto returntooperationmode.

Operation mode

⇒

AT Setting Screen

⇒

lower limit alarm function

⇒

Operation mode

あ

Lower limit alarm: It alarms when the temperature exceed the range ○○℃ of settingtemperature.

Example:

Thelowerlimitis setas -50. settingtemperature is 350℃.

Italarmswhen temperature becomeunder 300℃.

Set 0 whenalarmfunction is unnecessary.

9

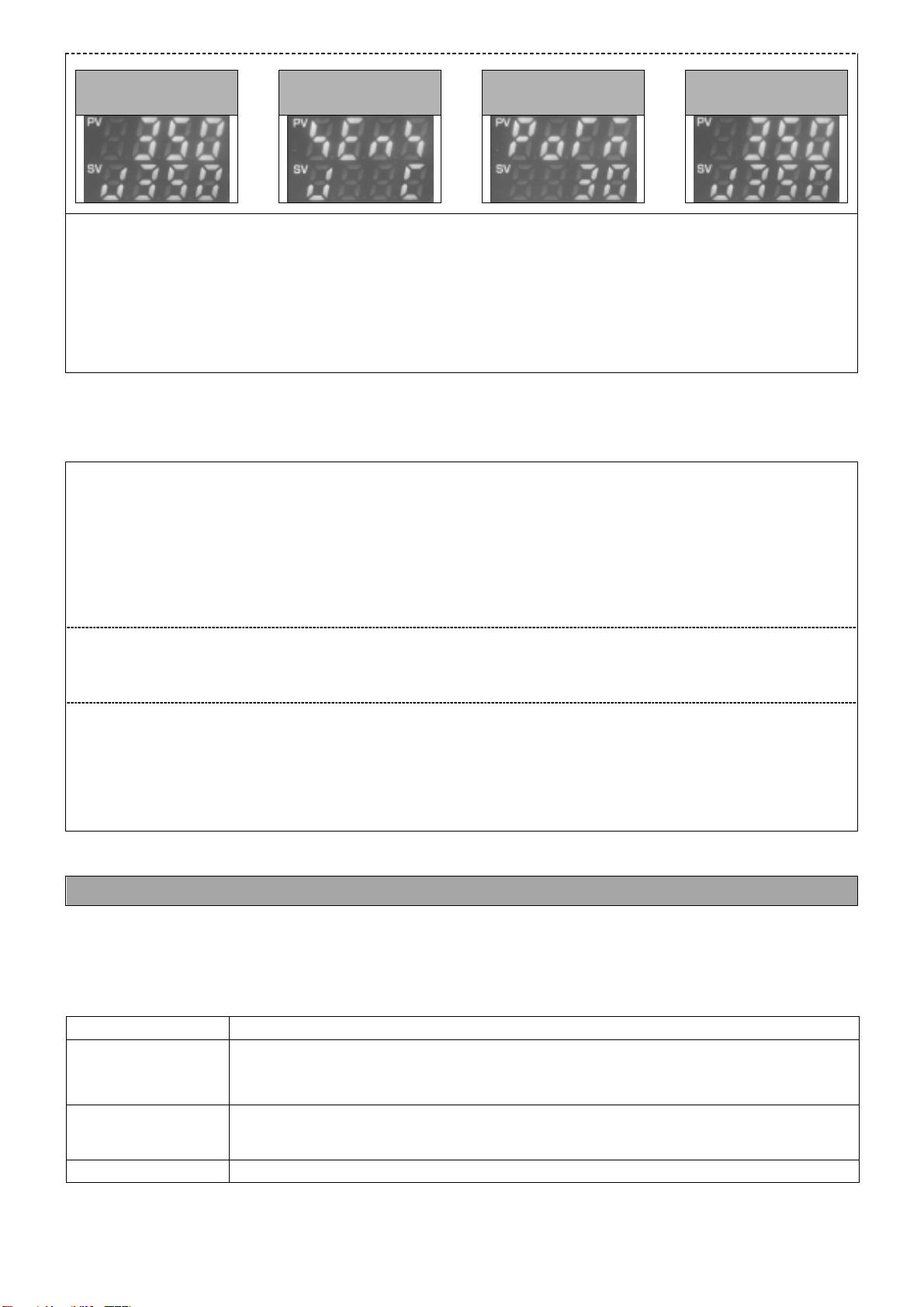

(C) Speed Setting

① Control the recovery speed to setting temperature

Initial setting:4.0 Setting range:1.0 ~ 10.0

Ⅰ:Attheoperationmode,push □keyonce.

isindicated atPVscreen.

Ⅱ:Inputsuitable value by △or ▽keyat SV screen.

Ⅲ:Afterinput thevalue,push □key onceto returntooperationmode.

Operation mode

⇒

Speedsettingscreen

⇒

Operation mode

Set 1.0: Recovery speed isfast, and overshooting becomelarge.

Set10.0: Recoveryspeedisslowly, and overshooting become less.

(D) Upper limit of setting temperature

① Set the upper limit of setting temperature

Initial setting:500℃ Setting range:0 ~500℃

Ⅰ:Attheoperationmode,press

keywithpressing ▽key about3 seconds.

isindicatedatSVscreen.

Ⅱ:Push

keytwice.

isindicatedat SV screen.

Ⅲ:Inputthevalueby △or ▽key at SVscreen,push

key6 timestoreturntooperationmode.

Operation mode

⇒

Inputtypesettingscreen

⇒

Upper limit setting

temperature setting screen

⇒

Operation mode

(E) Monitor indication of operation output amount

① Monitoring operation output amount of heater

Ⅰ:Attheoperationmode,press

keyabout3 seconds.

Operation output amount(0~100%) is indicated atSV screen.

Ⅱ:Push

keyto returntooperationmode.

10

Operation mode

⇒

operationoutputamount

screen

⇒

Operation mode

① Lock setting value prevention from error setting

Initial setting:Non-lock

Ⅰ At the operation mode, press

keywithpressing ▽ key about3 seconds.

isindicatedatPVscreen.

Ⅱ Push

keyonce,

is indicated at PVscreen.

Ⅲ Select thetypeof lock by △or ▽key, push

key7 timestoreturn tooperationmode.

Operation mode

⇒

Inputtypesetting

screen

⇒

Lock selection screen

⇒

Operation mode

Non-lock

Lock1

Lock2

: Non lock

: Lockup all function-setting exceptlockfunction.

: Lockup all function-setting exceptlockand temperature function.

(G)Anti-reset wind-up setting

① Control Overshooting

Initial setting:18% Setting range:0 ~ 100%

Ⅰ:Attheoperationmode,push

keywithpressing △key.

is indicated at PV screen.

Ⅱ:Push

key4 times,

is indicated at PV screen.

Ⅲ:Afterinput thevalueby △▽ keyat SV screen, push

key3 timestoreturnto operationmode.

(F) Lock function

11

Operation mode

⇒

AT Setting screen

⇒

Anti-reset wind-up

setting screen

⇒

Operation mode

It is recommendable NOT to change the initial setting value. Setting lower value could restrain from

overshooting, however,there ispossibility unableto recovertothesetting temperature.

(1)Setting of parameter value

Prevent from Deterioration and Oxidization of the iron tip, the soldering iron tip temperature is lowered

(Power Down) and supplying electric power to the heater is stopped (Power Off) automatically when

theirontip temperatureis no changed during the specified time(available tosetthe time).

Thisfunctionis alsoeffectivefor savingenergy andsafety.

① Setting ofAuto-Power Down time

Initial setting :30 minutes Setting range:0 ~ 120 minutes

Ⅰ At the operation mode, press

keywithpressing ▽key about3 seconds toindicate

on PV screen.

Ⅱ Push

key5 timestoindicate

on PVscreen.

Ⅲ Set thevalue by △or ▽key, push

key3 timestoreturntooperationmode.

(H)Auto-Power Down/Auto-Power Off setting

Power Down

Power Off

Operation mode

12

Operation mode

⇒

Input type setting

screen

⇒

Auto-Power down time

setting screen

⇒

Operation mode

AboutAuto-Power Down time:

e.g.:setvalue30minutes

No fluctuation in the temperature of iron tip during stand-by mode for more than 30 minutes, the

decline intemperaturewill startautomatically.

Duringtheprocess“

”andthesetting value ofAuto-Power Downwillbeindicated alternately.

Set the value “0” if you want to cancel this mode.

② Setting ofAuto-Power Down temperature

Initial setting:150℃ Setting range:0~ Setting temperature-1℃

Ⅰ At the operation mode, press

keywithpressing ▽key about3seconds.

isindicatedatPVscreen.

Ⅱ Push

key6 timestoindicate

is indicated at PV screen.

Ⅲ Input thevalueby △or ▽key, push

key3 timesto return tooperationmode.

Operation mode

⇒

Input type setting

screen

⇒

Auto-Power down

temperature setting

screen

⇒

Operation mode

Auto-PowerDown temperature isthe temperatureduringAuto-Power Down procedure.

Example:

WhensetAuto-Power Downtemperatureto「150℃」,controller willstandby with「150℃」.

Settingtemperature inoperation is350℃Itonlycan setto lowerthan349℃.

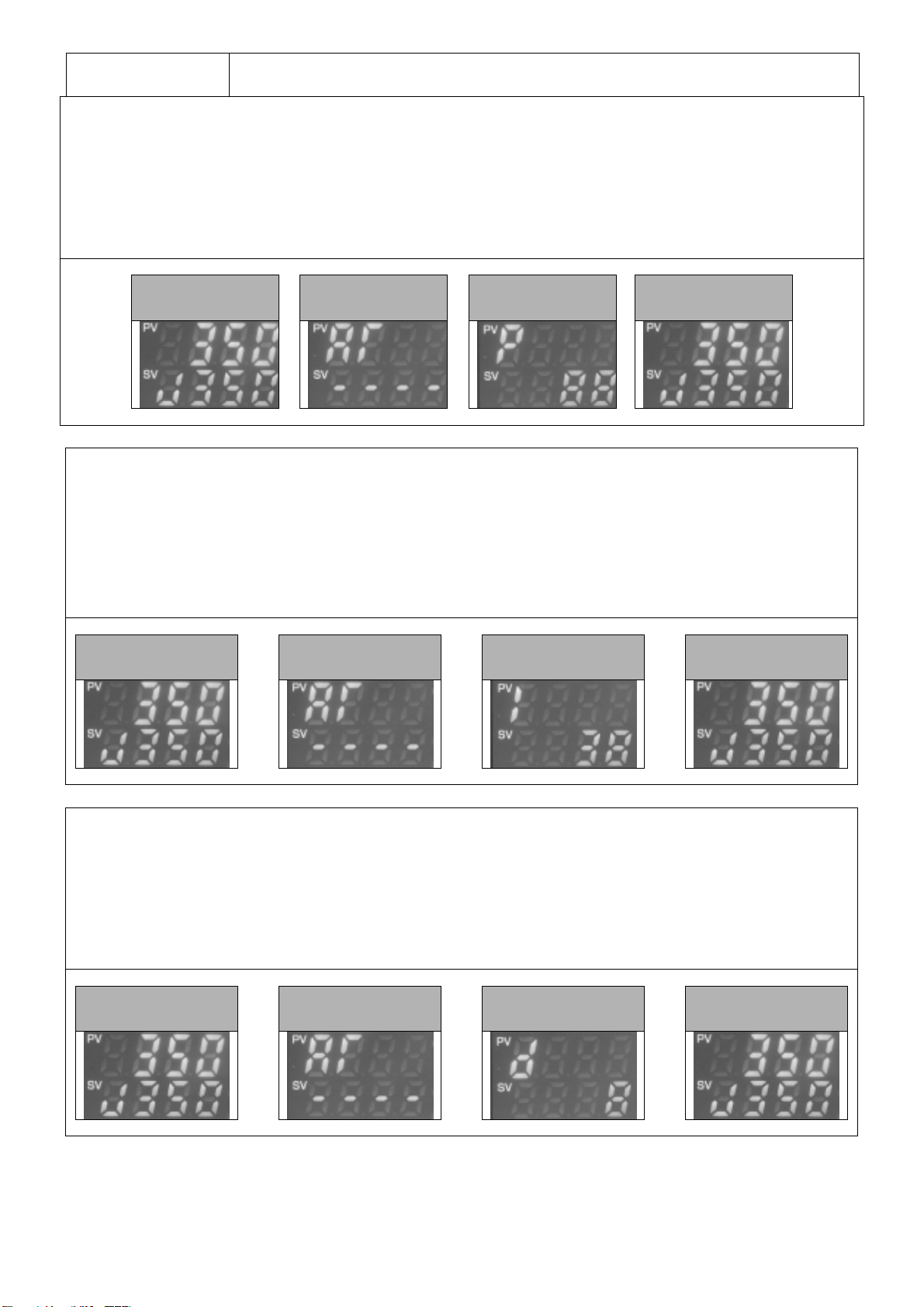

③ Setting ofAuto-Power Off time

Initial setting:30 minutes Setting range:0 ~ 120 minutes

Ⅰ At the operation mode, press

keywithpressing ▽key about3secondstoindicate

on PV screen.

Ⅱ Push

key7 timestoindicate

on PVscreen.

Ⅲ Set thevalue by △or ▽key, push

keyonce toreturn tooperationmode.

13

Operation mode

⇒

Input type setting

screen

⇒

Auto-Power down time

range setting screen

⇒

Operation mode

AboutAuto-Power Off time:

e.g.:Settingvalue 「30 minutes」

During Auto-Power Down operation (

is blinking at SV value), no fluctuation within the

temperature range while「30 minutes」, the controller recognizes that soldering iron is not using, and

automaticallyturn offthe power.

OnceAuto-Power Off operation starts,it becomes same condition with Power off.

Set the value “0” if you want to cancel this mode.

(2) Other operation method

① Return to operation mode fromAuto-Power Down mode

Ⅰ:When the temperature move outfrom the Auto-Power Down temperature range(initial value: 5℃),

Auto-Power Down function is released, and return to operation mode. For example clean iron tip

bymoisturizedspongeis easytoreturn.

When Auto-Power Down function is not released, press △or ▽key more than 3seconds to

release.

Ⅱ:AtAuto-PowerDownmode,press △ or ▽keymorethan3secondstoreturntooperationmode.

② Return to operation mode fromAuto-Power Off mode

Ⅰ:Turn onthe power again.

③ Manual operation

Ⅰ:At the operation mode, after reach to setting temperature, press △ or ▽key more than 3

secondstomovetoAuto-Power Downmode.

Ⅱ:AtAuto-PowerDownmode,press △ or ▽keymorethan3secondstoreturntooperationmode.

(I) PID value manual setting

Thismachine is basicallyunnecessarytodo PIDsettingdue toloadingAuto-tuningfunction. It isable to

domanualsettingifovershootingwhichsolderingirontiptemperaturebecome highoccurredwithspecial

work. Please use PIDmanual setting withyourconvenience.

Major effect

P

Proportional

band

Overshoot become less with bigger value however, temperature recovery time

become longerandtemperature drops during soldering maybelarger.

I

integration time

Overshoot become less with bigger value however, temperature recovery time

become longerandtemperature drops during soldering maybelarger.

D Overshoot become less with smaller value however, temperature recovery time

14

derivative time

becomelonger. Thisvaluewillbeset or adjustedafter PvalueandIvalue isset.

① Setting of Proportional band

Initial setting:88℃ Setting range:0 ~ 1000℃

Ⅰ:Attheoperationmode,push

keywithpressing △key.

isindicatedat PVscreen.

Ⅱ:Push

keyonce,

isindicatedatPV screen.

Ⅲ:Inputthevalueby △or ▽key,push

key6 timesto return tooperationmode.

Operation mode

⇒

AT setting screen

⇒

Proportional band

setting screen

⇒

Operation mode

あ

② Setting of Integration time

Initial setting:38seconds Setting range:0 ~ 1000℃

Ⅰ:Attheoperationmode,push

keywithpressing △key.

isindicatedat PVscreen.

Ⅱ:Push

key2 times,

is indicated at PV screen.

Ⅲ:Inputthevalueby △▽ key, push

key5 timestoreturntooperationmode.

Operation mode

⇒

AT setting screen

⇒

Integration time

setting screen

⇒

Operation mode

あ

③ Setting of Derivative time

Initial setting: 8 seconds Setting range: 0 ~ 300℃

Ⅰ:Attheoperationmode,push

keywithpressing △key.

isindicatedat PVscreen.

Ⅱ:Push

key3 times,

is indicated at PV screen.

Ⅲ:Inputthevalueby △▽ key, push

key4 timestoreturntooperationmode.

Operation mode

⇒

AT setting screen

⇒

Derivative time setting

screen

⇒

Operation mode

あ

15

(J) Device Number Setting

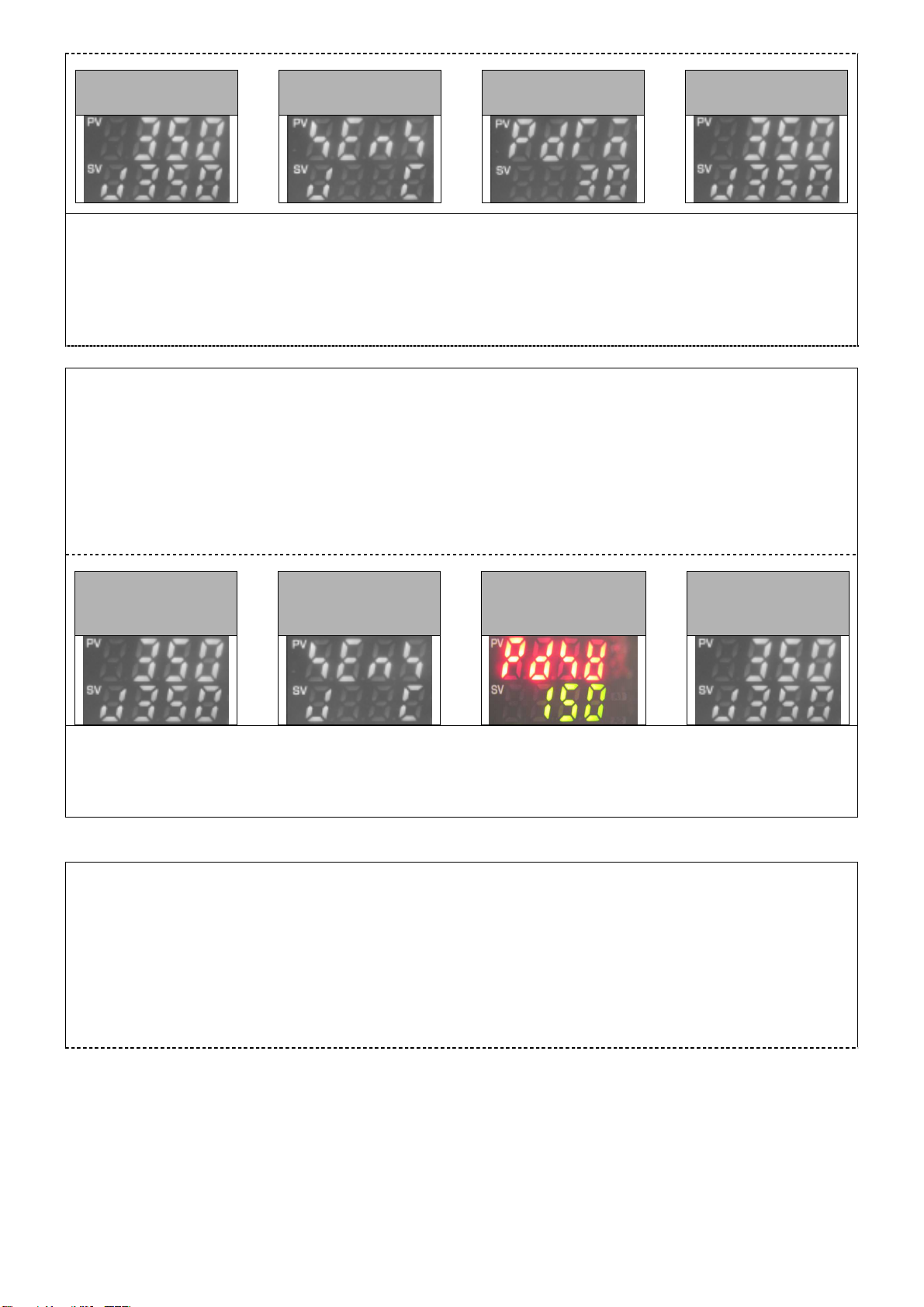

(1) Device Number Setting is required under the condition of QSS-4000 Concentrated temperature

management System forsoldering iron.

①Setting of Device Number

Initial Setting: 1 Setting Range: 1 ~ 95

: At the operation mode, push

△

key with pressing key in 3 seconds, is indicated at

PVscreen

:Pushkey 4 times, isindicatedatPVscreen.

: Input Device Number by △▽ keyon the SV screen, thenpushkey 6times toreturn to

operationmode.

Operation mode

⇒

Input type setting

screen

⇒

Device No. setting

screen

⇒

Operation mode

Attention

Thenumbering muststartwith“1”

e.g. The firstconnectedM50’sdevice number mustbe“

1

” ,and 2nd one is“2”andcontinued

16

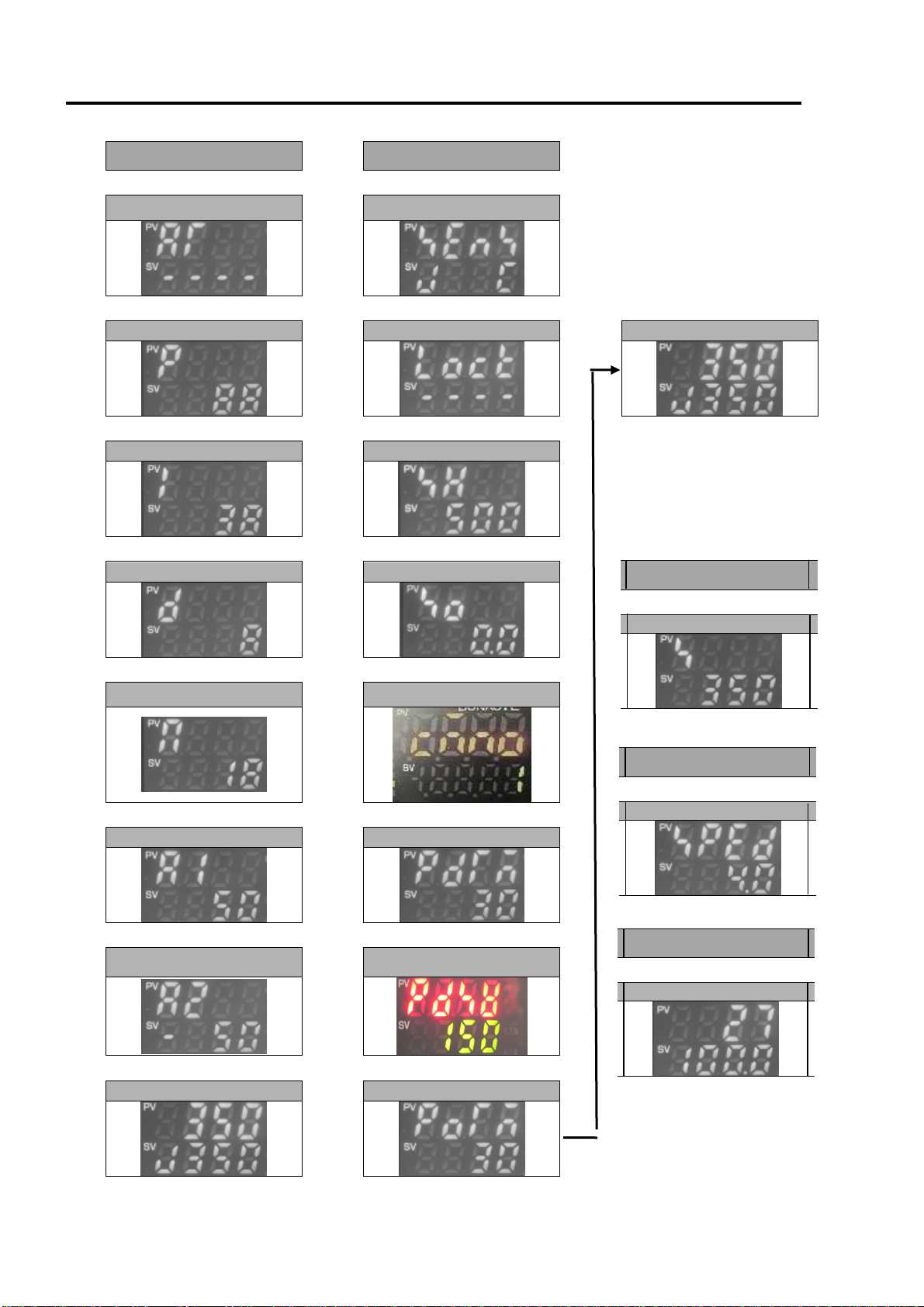

7.Character list

Allcharactersetting of M50 listed.

△key +

key ▽key +

key

↓

↓

Auto-tuning

Inputtype setting

↓

↓

Proportionalbandsetting

Lockfunction selection

Operation mode

↓

↓

↓

Integration timesetting

Uppertemperaturesetting

↓

↓

Derivative timesetting

Compensatetemperature

↓

↓

Anti-reset wind-upsetting

Devise number setting

↓

↓

Upperlimitalarmsetting

Auto-PowerDowntimesetting

↓

↓

Lowerlimitalarmsetting

Auto-Power Downtemperature

setting

↓

↓

Operation mode

Auto-Power Off time setting

□key

↓

Settingtemperaturechange

Key press

↓

Operationamountoutput

key

↓

Settingtemperaturechange

17

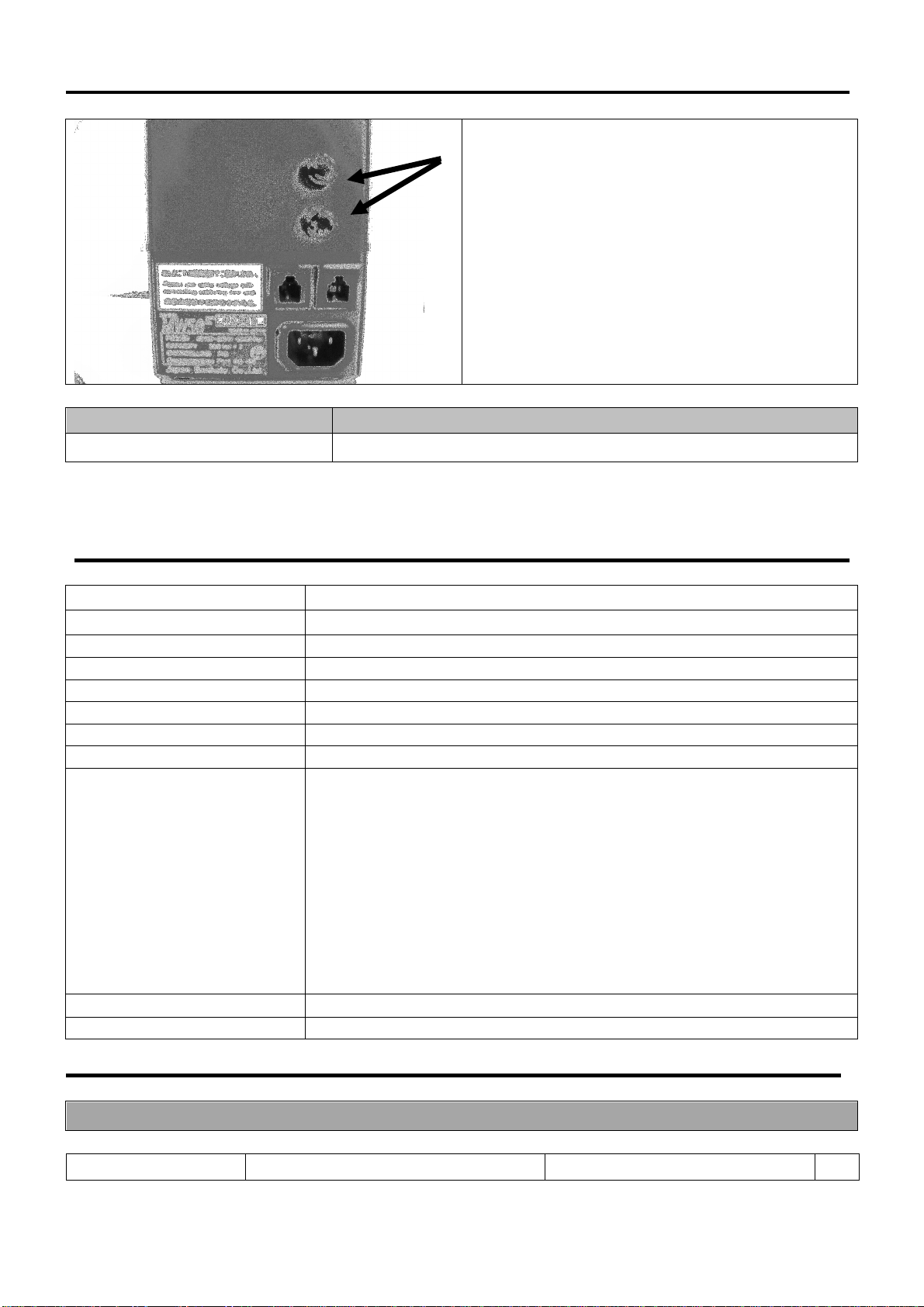

8. How to maintenance

①Loosen the fuse holder and remove it

.

Check the fuse if need change, and

replace to a new fuse.

Model No. Specification

Fuse 3A Glass fuse 250V 3A(φ5.2×20mm)

9. Standard specification

Inputvoltage AC100~240V

Temperaturerange 0~500℃(At shipment)

Powercode 100V:3PCHI 220V:3EPV

Dimension 97(W)×73(H)×130(D)mm

Weight Lessthan750kg

Fuse 3A

Temperaturecontrolmethod PIDcontrol(Auto-tuningsetting)

Temperatureindication PV:LED(red), SV:LED(green)

Errorindication

“ ̄ ̄ ̄ ̄” Over scale :Temperature exceed upper limitation of

indicatable temperature

※Error of sensor

(indication)

“____” Under scale :Temperature exceed lower limitation of

indicatable temperature

※Oppositepoleof sensor

(indication)

Material(case) Steel

Power consumption Less than 10VA(Controller only)

(A) Trouble shooting

Condition Cause Measures Pag

10. Guarantee and After sales service of MW50

18

e

Soldering iron does not

heat. 1. Unableto power on

①The power cable/switch are set

correctly? Check the power cable and the

switch 4

②Isthefuseblown? Replacetoa new fuse 17

2. Soldering iron is not heated although

poweron

①Is the soldering iron and the controller

completelyconnected? Check theconnecting

②Is the soldering iron tip sensor

completely connected to the soldering

iron?

Check how to replace soldering iron

tip

③Istheheaterelementconsumed? Check theconduction and replace to

newheater element

Temperatureunstable ①IsAuto-tuning done? Set upAuto-tuningfunction 7

②Temperature does not reach to setting

temperature SetupAnti-reset windfunction 10

③Over-shooting islarge

Keyoperation isunable

①Isthelockfunctioneffective? CheckthesettingofLockfunction 10

(B) Guarantee

Our products are shipped after sever factory tests and inspections. However, if you find

malfunctions or defects due to problems in workmanship or transportation, please contact your

dealersorus. Theguaranteeperiod of yourproducts is inoneyearafteryourpurchase,except

for replacement parts

.

(C)After sales service

Whenyouthink the product doesnot operateproperly, read thismanual againtocheck.

Ifstilltroubles are notsolved, pleasecontactwithyourdealeror us.

JAPAN BONKOTE CO., LTD.

600-14Kasahara,Mito,Ibaraki 310-0852 JAPAN

TEL: +81 29-241-2725

FAX:+8129-241-2726

http://bonkote.co.jp

E-mail :info@bonkote.co.jp

Table of contents

Other BONKOTE Controllers manuals