elco ELKM43 User manual

ELKM43

CONTROLLER AND

MINI-PROGRAMMER

Quick guide

ELKM43-GB-06-05-B

EL.CO. S.r.l.

Via Lago di Molveno, 20 - 36015 Schio (VI)

ITALY

Tel.: +39 0445 661722 - Fax: +39 0445 661792

www.elco-italy.com

e-mail: [email protected]

PREFACE

m This manual contains the information necessary for

the product to be installed correctly and also in-

structions for its maintenance and use; we therefore

recommend that the utmost attention is paid to the

following instructions and to save it.

This document is the exclusive property of EL.CO. S.r.l.

which forbids any reproduction and divulgation, even

partially, of the document, unless expressly authori-

zed. EL.CO. S.r.l. reserves the right to make any formal

or functional changes at any moment and without

notice.

EL.CO. S.r.l. and its legal representatives do not assume

any responsibility for any damage to people, things or

animals deriving from violation, wrong or improper

use or in any case not in compliance with the instru-

ment features.

m Whenever a failure or a malfunction of the control

device may cause dangerous situations for persons,

thing or animals, please remember that the plant

has to be equipped with additional safety devices.

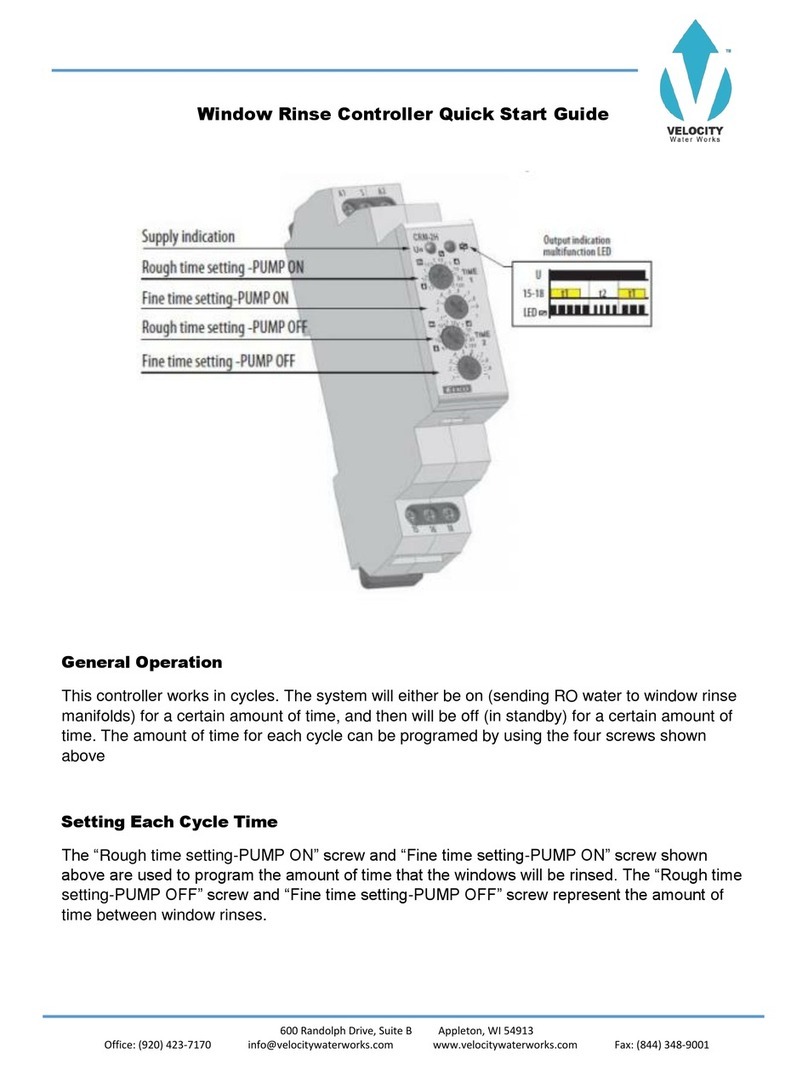

1. DIMENSIONS AND CUTOUT mm)

Controller with non removable terminals

48

48

4811 14

Panel cut-out

65 mm min.

45

+0.6

mm

45

+0.6

mm

65 mm min.

Mounting requirements

This instrument is intended for permanent installa-

tion, for indoor use only, in an electrical panel which

encloses the rear housing, exposed terminals and

wiring on the back. Select a mounting location having

the following characteristics:

1. It should be easily accessible;

2. There is minimum vibrations and no impact;

3. There are no corrosive gases;

4. There are no water or other uids (i.e. condensation);

5. The ambient temperature is in accordance with the

operative temperature (0... 50°C);

6. The relative humidity is in accordance with the

instrument specications (20... 85%);

The instrument can be mounted on panel with a

maximum thickness of 15 mm.

When the maximum front protection (IP65) is desired,

the optional gasket must be mounted.

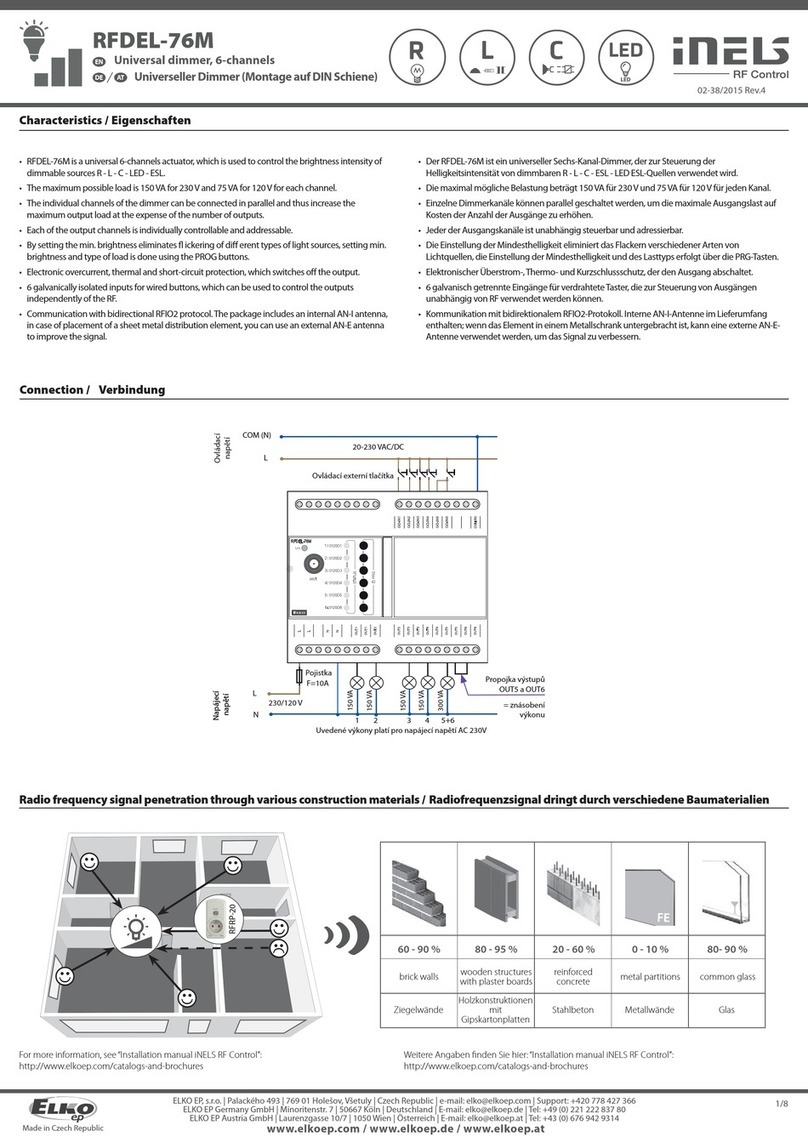

2. ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

RS485

Thermo-

couple

DI1

OP3

OP2

OP1

OP4

(note)

DI2 (note)

Analogue input

mV, V mA

12 VDC

(note)

PV

4... 20 mA

3 wire transmitter

12 VDC

(note)

PV

Pt100Pt1000/NTC/PTC

4... 20 mA

2 wire transmitter

Neutral

Line

Power

supply

Terminals

Pin: q1.4 mm max. (0.055 in.)

Stropped wire: L: 5.5 mm (0.21 in.)

L

Note: Terminal 4 can be programmed as:

- Digital Input (DI2) connecting a free of voltage

contact between terminals 4 and 16;

- 0... 12 V SSR Drive Output (OP4) connecting the load

between terminals 4 and 16;

- 12 Vdc (20 mA) transmitter power supply connect-

ing the 2 wire transmitter between terminals 4

and 1; for 3 wire transmitter connect terminal

4 to transmitter power supply input and termi-

nal 1 and 2 to transmitter signal output.

Power supply voltage: 100... 240 Vac/20... 30 Vdc/

18... 28 Vac/24... 240Vac/dc;

Out1 relay: 4 (4) A/250 VAC, SPST;

Out2, 3 relay: 2 (1) A/250 VAC, SPST NA (*);

Out1, 2, 3 SSR:

10 VDC/15 mA;

Linear Out1: 0/4... 20 mA, 0/2... 10 V;

Out4 SSR: 12 VDC/20 mA.

*For

ELKM43 servodrive models both Out2 and Out3

are to be selected as “M” in Conguration code;

Out2: open, Out3: close.

General notes about wiring

1. Safety regulations require a line switch marked as

instrument disconnecting device. This switch must

be easily reachable by the operator;

2. Do not run input wires together with power cables;

3. External components (like zener barriers, etc.) con-

nected between sensor and input terminals may cause

errors in measurement due to excessive and/or not

balanced line resistance or possible leakage currents;

4. When a shielded cable is used, it should be con-

nected at one point only;

5. Pay attention to the line resistance, a high line

resistance may cause measurement errors.

6. To avoid electrical shocks, connect power line at last;

7. Before connecting the instrument to the power

line, make sure that line voltage is equal to the

voltage shown on the identication label;

8. The power supply input is NOT fuse protected.

Please, provide an external fuse T type 1A, 250 V.

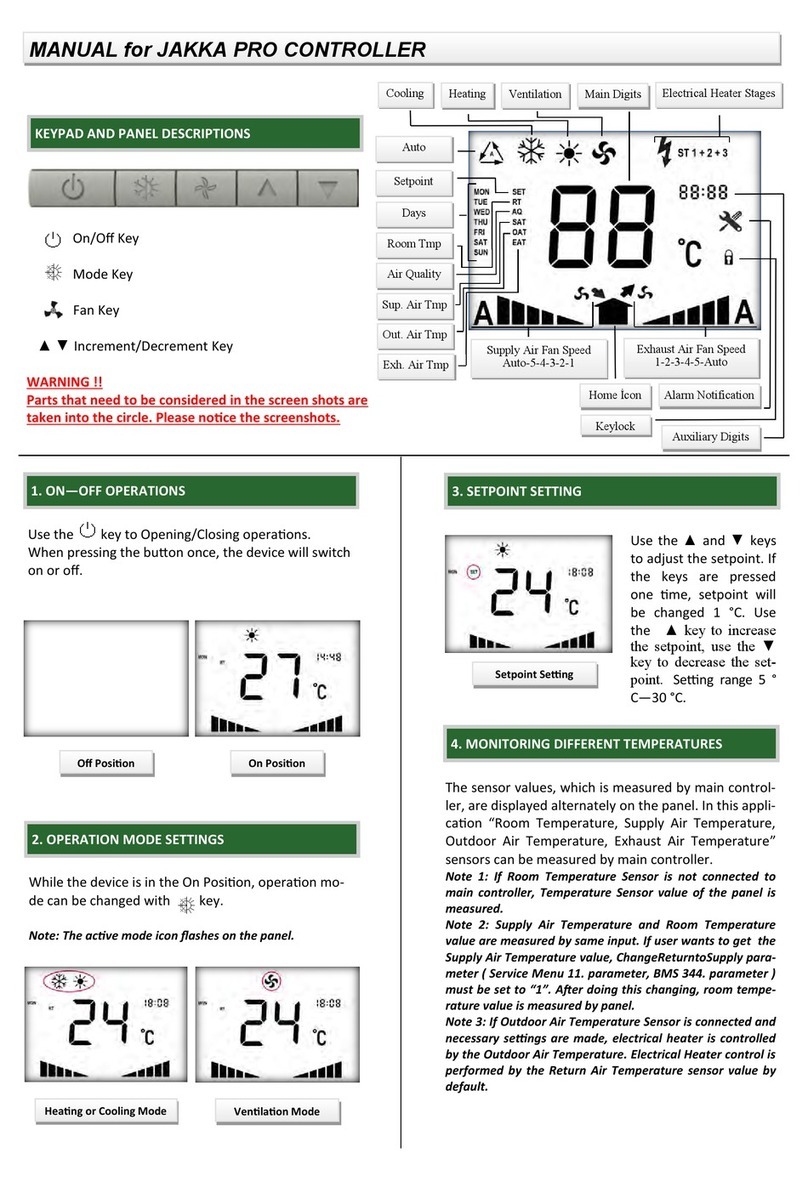

3. CONFIGURATION PROCEDURES

Setting the parameters

Press the ke

y

for 3 seconds

Access to

parameters

Insert

password

(default: 30)

PV

AT

PV

AT

PV

AT

Key Editing Mode

Conrm and go to Next parameter

Increasethedisplayedvalueorselectthenextelement

Decreasethedisplayedvalueorselectthepreviouselement

ExitfromOperatorcommands/Parametersetting/Configuration

How to exit the“Conguration mode”

To exit from the Conguration mode,

press the key for 3 seconds.

Code conguration procedure

For ELKM43 version (without timer and programmer) a

simplied code conguration method is available. Only

essential functions can be set up with code congura-

tion procedure. See the “Engineering User Manual” for

more details.

4. LIST OF THE PARAMETERS pAss: 30

]inP Group - Main and auxiliary input configuration

no. Par. Description Dec. Values Default Notes

SEnS

Model C

J TC J (-50... +1000°C/-58... +1832°F);

crAL TC K (-50... +1370°C/-58... +2498°F);

S TC S (-50... 1760°C/-58... +3200°F);

r TC R (-50... +1760°C/-58... +3200);

t TC T (-70... +400°C/-94... +752°F);

Ir.J Exergen IRS J(-46... +785°C/-50... +1445°F);

Ir.cA Exergen IRS K(-46... +785°C/-50... +1445°F);

Pt1 RTD Pt 100(-200... +850°C/-328... +1562°F);

Pt10 RTD Pt 1000(-200... +850°C/-328... +1562°F);

0.60 0... 60 mV linear;

12.60 12... 60 mV linear;

0.20 0... 20 mA linear;

4.20 4... 20 mA linear;

0.5 0... 5 V linear;

1.5 1... 5 V linear;

0.10 0... 10 V linear;

2.10 2... 10 V linear. J

Model E

J TC J (-50... +1000°C/-58... +1832°F);

crAL TC K (-50... +1370°C/-58... +2498°F);

S TC S (-50... 1760°C/-58... +3200°F);

r TC R (-50... +1760°C/-58... +3200);

t TC T (-70... +400°C/-94... +752°F);

Ir.J Exergen IRS J(-46... +785°C/-50... +1445°F);

Ir.cA Exergen IRS K(-46... +785°C/-50... +1445°F);

Ptc PTC KTY81-121(-55... +150°C/-67... +302°F);

ntc NTC 103-AT2 (-50... +110°C/-58... +230°F);

0.60 0... 60 mV linear;

12.60 12... 60 mV linear;

0.20 0... 20 mA linear;

4.20 4... 20 mA linear;

0.5 0... 5 V linear;

1.5 1... 5 V linear;

0.10 0... 10 V linear;

2.10 2... 10 V linear.

2 dp Decimal Point Position (linear inputs) 00... 3 0

DecimalPointPosition(non linearinputs) 0/1

3 SSC Initial scale read-out for linear inputs dp -1999... 9999 0

4 FSc Full Scale Readout for linear inputs dp -1999... 9999 1000

5 unit Engineer unit °C/°F °C

6Fil Digital lter on the measured value 1 0 (= OFF)... 20.0 s 1.0

7 inE Sensorerrorusedtoenablethesafetyoutput

value

or Over range;

ur Under range;

our Over and under range.

our

8 oPE Safety output value (% of the output) -100... 100 0

9 IO4.F I/O 4 function

on Output used as PWS for TX;

out4 Output 4 (digital output 4);

dG2c Digital input 2 driven by contact;

dG2U Digital input 2 driven by voltage.

out4

9 IO4.F I/O 4 function

on Output used as PWS for TX;

out4 Output 4 (digital output 4);

dG2c Digital input 2 driven by contact;

dG2U Digital input 2 driven by voltage.

out4

10 diF1 Digital Input 1 function

oFF Not used;

1 Alarm reset;

2 Alarm acknowledge (ACK);

3 Hold of the measured value;

4 Stand by mode;

5 Manual mode;

6 HEAt with SP1 and CooL with SP2;

7 Timer RUN/Hold/Reset;

8 Timer Run;

9 Timer Reset;

10 Timer Run/Hold;

11 Timer Run/Reset;

12 Timer Run/Reset with lock;

13 Program Start;

14 Program Reset;

15 Program Hold;

16 Program Run/Hold;

17 Program Run/Reset;

18 Sequential SP selection;

19 SP1 - SP2 selection;

20 SP1... SP4 binary selection;

21 Digital inputs in parallel to / keys.

oFF

12 di.A Digitalinputaction(DI2onlyifcongured)

0 DI1directaction,DI2(ifcongured)directaction;

1 DI1inverseaction,DI2(ifcongured)directaction;

2 DI1directaction,DI2(ifcongured)inverseaction;

3

DI1

inverse action

, DI2 (

if congured

)

inverse

action

.

0

]Out group - Output parameters

no. Par. Description Dec. Values Default Notes

13 o1t Output 1 type (when Out 1 is a linear

output)

0-20 0... 20 mA;

4-20 4... 20 mA;

0-10 0... 10 V;

2-10 2... 10 V.

0-20

14 o1F

Out 1 function (when Out 1 is a linear

output) 0

NonE Output not used;

H.rEG Heating output;

c.rEG Cooling output;

r.inP Measure retransmission;

r.Err Error (SP - PV) retransmission;

r.SP Set point retransmission;

r.SEr Serial value retransmission.

H.reG

Out 1 function (when Out1 is a digital

output) 0

NonE Output not used;

H.rEG Heating output;

c.rEG Cooling output;

AL Alarm output;

t.out Timer output;

t.HoF Timer out -OFF in hold;

P.End Program end indicator;

P.HLd Program hold indicator;

P.uit Program wait indicator;

P.run Program run indicator;

P.Et1 Program Event 1;

P.Et2 Program Event 2;

or.bo Out of range or burn out indicator;

P.FAL Power failure indicator;

bo.PF

Outofrange/burnout/Powerfailureindicator;

St.bY Stand by status indicator;

diF.1 Theoutputrepeatsthedigitalinput1status;

diF.2 Theoutputrepeatsthedigitalinput2status;

on Out 1 always ON;

riSP Inspection request.

15 Ao1L Initialscalefortheanalogretransmission dP -1999 ... Ao1H -1999

16 Ao1H Full scale for the analog retransmission dP Ao1L ... 9999 9999

17 o1AL Alarms linked up with the out 1 0

0... 63:

+1 Alarm 1;

+2 Alarm 2;

+4 Alarm 3;

+8 Loop break alarm;

+16 Sensor Break;

+32 Overload on output 4.

1

18 o1Ac Out 1 action 0

dir Direct action;

rEU Reverse action;

dir.r Direct with reversed LED;

ReU.r Reverse with reversed LED.

dir

19 o2F Out 2 function 0 See O1F - Out 1 function (digital output) AL

20 o2AL Alarms linked up with the out 2 0 See O1AL - Alarms linked up with the out 1 1

21 o2Ac Out 2 action 0 See O1Ac - Out 1 action dir

22 o3F Out 3 function 0 See O1F - Out 1 function (digital output) AL

23 o3AL Alarms linked up with the out 3 0 See O1AL - Alarms linked up with the out 1 2

no. Par. Description Dec. Values Default Notes

24 o3Ac Out 3 action 0 See O1Ac - Out 1 action dir

25 o4F Out 4 function 0 See O1F - Out 1 function (digital output) AL

26 o4AL Alarms linked up with the out 4 0 See O1AL - Alarms linked up with the out 1 AL1+AL2

27 o4Ac Out 4 action 0 See O1Ac - Out 1 action dir

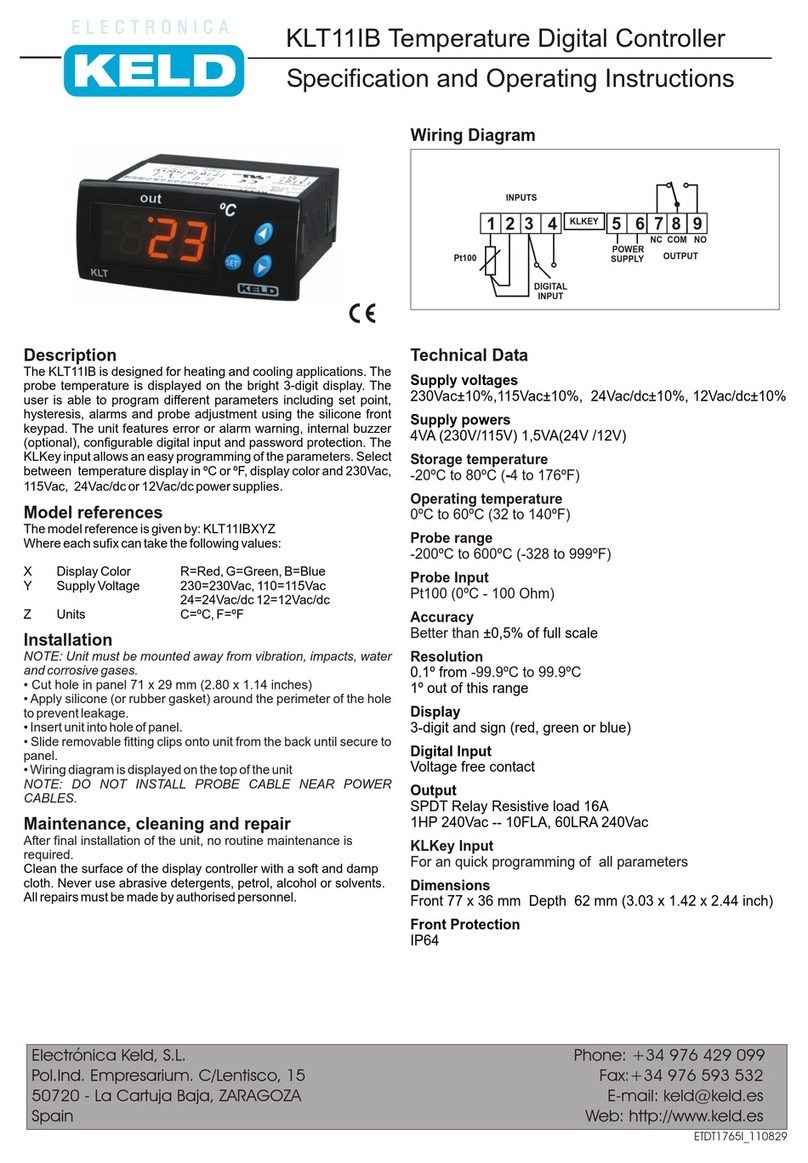

Alarm types

ON

ONON

ONON

ONON

ONON

ON

ON ON

ONON

ON ONON

PV

PV

PV

Time

PV

External

band

alarm

Internal

band

alarm

Time

Relative band alarm

Deviation

low

alarm

Deviation

High

alarm

Deviation alarm

Absolute band alarm

External

alarm

Iternal

alarm

Time

ON

PV Alarm not active at power ON

Time

Absolute alarm

Absolute

high

alarm

Absolute

low

alarm

Time

PV

Time

Relative alarm not active at set point change

Ab1 = +1

Ab1 = +0

ON

ON

PV Latched alarm

Time

Alarm Reset Alarm Reset

Ab1 = +2

Ab1 = +0

Ab1 = +8

Ab1 = +0

Alarm ACK Alarm ACK

PWR ON

ONON

ON

PV Acknowledgeable alarm

Time

Ab1 = +4

Ab1 = +0 ON ONON

ONON

Sp2

Sp1

ALX

ALX

]AL1 Group - Alarm 1 parameters

no. Par. Description Dec. Values Default Notes

28 AL1t Alarm 1 type 0

nonE Alarm not used;

LoAb Absolute low alarm;

HiAb Absolute high alarm;

LHAo Windowsalarminalarmoutsidethewindows;

LHAI Windowsalarminalarminsidethewindows;

SE.br Sensor Break;

LodE Deviation low alarm (relative);

HidE Deviation high alarm (relative);

LHdo Relativebandalarminalarmoutoftheband;

LHdi Relativebandalarminalarminsidetheband.

HiAb

29 Ab1 Alarm 1 function 0

0... 15:

+1 Not active at power up;

+2 Latched alarm (manual reset);

+4 Acknowledgeable alarm;

+8

Relative alarm not active at set point change.

0

30 AL1L

ForHigh/lowalarm,AL1thresholdlowlimit;

Forbandalarm,AL1lowalarmthreshold dp From -1999 to AL1H (E.U.) -1999

31 AL1H

ForHigh/lowalarm,AL1thresholdhighlimit;

Forbandalarm,AL1highalarmthreshold dp From AL1L to 9999 (E.U.) 9999

32 AL1 AL1 threshold dp From AL1L to AL1H (E.U.) 0

33 HAL1 AL1 hysteresis dp 1... 9999 (E.U.) 1

34 AL1d AL1 delay 0 From 0 (oFF) to 9999 (s) oFF

35 AL1o Alarm1enablingduringStand-bymode

and out of range conditions 0

0

Alarm1disabledduringStandbyandoutofrange;

1 Alarm 1 enabled in stand by mode;

2 Alarm 1 enabled in out of range condition;

3 Alarm 1 enabled in stand by and overrange.

0

]AL2 Group - Alarm 2 parameters

no. Par. Description Dec. Values Default Notes

36 AL2t Alarm 2 type 0 See AL1t Loab

37 Ab2 Alarm 2 function 0 See Ab1 0

38 AL2L

ForHigh/lowalarm,AL2thresholdlowlimit;

Forbandalarm,AL2lowalarmthreshold dp See AL1L -1999

39 AL2H

ForHigh/lowalarm,AL2thresholdhighlimit;

Forbandalarm,AL2highalarmthreshold dp See AL1H 9999

40 AL2 AL2 threshold dp See AL1 0

41 HAL2 AL2 hysteresis dp See HAL1 1

42 AL2d AL2 delay 0 See AL1d oFF

43 AL2o Alarm2enablingduringStand-bymode

and out of range conditions 0 See AL1o 0

]AL3 Group - Alarm 3 parameters

no. Par. Description Dec. Values Default Notes

44 AL3t Alarm 3 type 0 See AL1t nonE

45 Ab3 Alarm 3 function 0 See Ab1 0

46 AL3L

ForHigh/lowalarm,AL3thresholdlowlimit;

Forbandalarm,AL3lowalarmthreshold dp See AL1L -1999

47 AL3H

ForHigh/lowalarm,AL3thresholdhighlimit;

Forbandalarm,AL3highalarmthreshold dp See AL1H 9999

48 AL3 AL3 threshold dp See AL1 0

49 HAL3 AL3 hysteresis dp See HAL1 1

50 AL3d AL3 delay 0 See AL1d oFF

51 AL3o Alarm3enablingduringStand-bymode

and out of range conditions 0 See AL1o 0

]LBA Group - Loop break alarm

no. Par. Description Dec. Values Default Notes

52 LbAt LBA time 0 From 0 (oFF) to 9999 (s) oFF

53 LbSt

DeltameasureusedbyLBAduringSoftstart

dP From 0 (oFF) to 9999 (E.U.) 10

54 LbAS Delta measure used by LBA dP 1...9999 (E.U.) 20

no. Par. Description Dec. Values Default Notes

55 LbcA Condition for LBA enabling 0

uP Active when Pout = 100%;

dn Active when Pout = -100%;

both Active in both cases.

both

]rEG Group - Control parameters

no. Par. Description Dec. Values Default Notes

56 cont Control type 0

Pid PID (heat and/or);

On.FA ON/OFF asymmetric hysteresis;

On.FS ON/OFF symmetric hysteresis;

nr Heat/CoolON/OFFcontrolwithneutralzone;

3Pt Servomotor control.

Pid

57 Auto Autotuning selection 0

-4Oscillatingauto-tunewithauto-restartatpowerON

and after all point change;

-3Oscillating auto-tune with manual start;

-2

Oscillatingtunewithauto-startatrstpowerONonly;

-1

Oscillatingauto-tunewithauto-restartatallpowerON;

0 Not used;

1

Fast auto tuning with auto-restart at all power ON;

2

Fastauto-tunewithauto-starttherstpowerONonly;

3 FAST auto-tune with manual start;

4 FASTauto-tunewithautomaticrestartatpowerON

and after a set point change;

5 Smart-tune with auto-restart at all power ON;

6 Smart-tunewithauto-startatrstpowerONonly;

7 Smart-tune with manual start;

8 Smart-tunewithauto-restartatpowerONandafter

a set point change.

7

58 Aut.r Manual start of the Autotuning 0 oFF Not active;

on Active. oFF

59 SELF Self tuning enabling 0 no Theinstrumentdoesnotperformtheself-tuning;

YES The instrument performs the self-tuning. no

60 HSEt Hysteresis of the ON/OFF control dP 0... 9999 (E.U.) 1

61 cPdt Time for compressor protection 0 From 0 (oFF) to 9999 (s) oFF

62 Pb Proportional band dP 1... 9999 (E.U.) 50

63 ti Integral time 0 From 0 (oFF) to 9999 (s) 200

64 td Derivative time 0 From 0 (oFF) to 9999 (s) 50

65 Fuoc Fuzzy overshoot control 2 0.00... 2.00 0.50

66 tcH Heating output cycle time 1 0.1... 130.0 (s) 20.0

67 rcG Powerratiobetweenheatingandcool-

ing action 2 0.01... 99.99 1.00

68 tcc Cooling output cycle time 1 0.1... 130.0 (s) 20.0

69 rS Manual reset (Integral pre-load) 1 -100.0... +100.0 (%) 0.0

70 Str.t Servomotor stroke time 0 5...1000 seconds 60

71 db.S Servomotor dead band 0 0...100% 50

72 od Delay at power up 2 From 0.00 (oFF) to 99.59 (hh.mm) oFF

73 St.P Maximumpoweroutputusedduring

soft start 0 -100... 100 (%) 0

74 SSt Soft start time 2

0.00 (oFF);

0.01... 7.59 (hh.mm);

inF (always ON).

oFF

75 SS.tH Threshold for soft start disabling dP -1999... +9999 (E.U.) 9999

]SP Group - Set point parameters

no. Par. Description Dec. Values Default Notes

76 nSP Number of used set points 0 1... 4 1

77 SPLL Minimum set point value dP From -1999 to SPHL -1999

78 SPHL Maximum set point value dP From SPLL to 9999 9999

79 SP Set point 1 dP From SPLL to SPLH 0

80 SP 2 Set point 2 dP From SPLL to SPLH 0

81 SP 3 Set point 3 dP From SPLL to SPLH 0

82 SP 4 Set point 4 dP From SPLL to SPLH 0

83 A.SP Selection of the active set point 0 From 1 (SP 1) to nSP 1

84 SP.rt Remote set point type 0

RSP Thevalue comingfrom seriallink is usedas

remote set point;

trin Thevaluewillbeaddedtothelocalsetpoint

selectedby A.SPand thesum becomesthe

operative set point;

PErc The value will be scaled on the input range

and this value will be used as remote SP.

trin

85 SPLr Local/remote set point selection 0 Loc Local;

rEn Remote. Loc

86 SP.u RateofriseforPOSITIVEsetpointchange

(ramp UP) 2 0.01... 99.99 (inF) engineering units per minute inF

87 SP.d Rate of rise for NEGATIVE set point

change (ramp DOWN) 2 0.01... 99.99 (inF) engineering units per minute inF

]TIN Group - Timer function parameter

no. Par. Description Dec. Values Default Notes

88 tr.F Independent timer function 0

NonE Timer not used;

i.d.A Delayed start timer;

i.uP.d Delayed start at power up;

i.d.d Feed-through timer;

i.P.L

Asymmetrical oscillator with start OFF

;

i.L.P Asymmetrical oscillator with start ON.

nonE

89 tr.u Timer unit 0

hh.nn Hours and minutes;

nn.SS Minutes and seconds;

SSS.d Second and tenth of seconds.

nn.SS

90 tr.t1 Time 1 2 When tr.u < 20: 0.01... 99.59 1.00

1 When tr.u = 200: 0.1... 995.9

91 tr.t2 Time 2 2 When tr.u < 2: From 00.00 (oFF) to 99.59 (inF) 1.00

1 When tr.u = 2: From 000.0 (oFF) to 995.9 (inF)

92 tr.St Timer status 0

rES Timer reset;

run Timer run;

HoLd Timer hold.

rES

i.d.a Delayed ON at Start command

i.up.d Delayed ON at Power ON

i.d.d At Start command

i.p.l Asymmetrical oscillator with start in OFF

i.L.p Asymmetrical oscillator with start in ON

Start

OUT ON

off

Tr.t1 Tr.t2

off

OUT

PWR ON

ON

off

Tr.t1 Tr.t2

off

Start

OUT

Reset

ON

Tr.t1

off

Start

OUT

Reset

ONoff

Tr.t2

ONoff

Tr.t1Tr.t1

Tr.t2

ON

off

Tr.t1

Tr.t2

Start

OUT

Reset

ON off

Tr.t2

off

Tr.t1Tr.t1

Tr.t2

off

Tr.t1

Tr.t2

ON ON

PWR ON

PWR ON

Timer Types (selected by tr.f) (option)

]PRG Group - Programmer function parameters

Time

SPx

Status

Temperature

OFF

Pr.e= SPAt

Pr.S1

P

r.S4

P

r.S2

P

r.S3

Prog.

END

prg.1

prt.1

prg.3

prt.3

prg.4

prt.4

prg.2

prt.2

Program RUN

Start

Program Step

no. Par. Description Dec. Values Default Notes

93 Pr.F Program action at power up 0

nonE Programmer not used;

S.uP.d

Start at power up with a first step in stand-by

;

S.uP.S Start at power up;

u.diG

Start at Run command detection only

;

u.dG.d

StartatRuncommandwithafirststepinstand-by.

nonE

94 Pr.u Time unit of the soaks 2 hh.nn Hours and minutes;

nn.SS Minutes and seconds. hh.nn

95 Pr.E Instrumentbehaviourattheendof

the program execution 0

cnt Continue;

SPat Go to the set point selected by SPat;

St.by Go to stand-by mode.

SPat

96 Pr.Et Timeoftheendprogramindication 2 From 0.00 (oFF) to 99.59 (inF) minutes and seconds oFF

97 Pr.S1 Set point of the rst soak dP From SPLL to SPHL 0

98 Pr.G1 Gradient of the rst ramp 1 0.1...999.9EngineeringUnit/minute(inF=Steptransfer) inF

99 Pr.t1 Time of the 1st soak 2 0.00... 99.59 (time unit of the soaks) 0.10

100 Pr.b1 Wait band of the 1st soak dP 0 (oFF)/1... 9999 (E.U.) oFF

101 Pr.E1 Events of the 1st group 2 00.00... 11.11 (0= Event OFF; 1= Event ON) 00.00

102 Pr.S2 Set point of the 2nd soak dP OFF or from SPLL to SPHL 0

103 Pr.G2 Gradient of the 2nd ramp 1 0.1...999.9EngineeringUnit/minute(inF=Steptransfer) inF

104 Pr.t2 Time of the 2nd soak 2 0.00... 99.59 (time unit of the soaks) 0.10

105 Pr.b2 Wait band of the 2nd soak dP 0 (oFF)/1... 9999 (E.U.) oFF

106 Pr.E2 Events of the 2nd group 2 00.00... 11.11 (0= Event OFF; 1= Event ON) 00.00

107 Pr.S3 Set point of the 3rd soak dP OFF or from SPLL to SPHL 0

108 Pr.G3 Gradient of the 3rd ramp 1 0.1...999.9EngineeringUnit/minute(inF=Steptransfer) inF

109 Pr.t3 Time of the 3rd soak 2 0.00... 99.59 (time unit of the soaks) 0.10

110 Pr.b3 Wait band of the 3rd soak dP 0 (oFF)/1... 9999 (E.U.) oFF

111 Pr.E3 Events of the 3rd group 0 00.00... 11.11 (0= Event OFF; 1= Event ON) 00.00

112 Pr.S4 Set point of the 4th soak dP OFF or from SPLL to SPHL 0

113 Pr.G4 Gradient of the 4th ramp 1 0.1...999.9EngineeringUnit/minute(inF=Steptransfer) inF

114 Pr.t4 Time of the 4th soak 2 0.00... 99.59 (time unit of the soaks) 0.10

115 Pr.b4 Wait band of the 4th soak dP 0 (oFF)/1... 9999 (E.U.) oFF

116 Pr.E4 Events of the 4th group 0 00.00... 11.11 (0= Event OFF; 1= Event ON) 00.00

117 Pr.St Program status 0

rES Program reset;

run Program start;

HoLd Program hold.

rES

]PAn Group - Operator HMI

no. Par. Description Dec. Values Default Notes

118 PAS2 Level 2 password

(limited access level) 0oFF (Level 2 not protected by password);

1... 200. 20

119 PAS3 Level 3 password

(completeconguration) 0 3... 200 30

120 PAS4 Level 4 password

(CODEcongurationlevel) 0 201... 400 300

121 uSrb button function

during RUN TIME

nonE No function;

tunE Auto-tune/self-tuneenabling.Asinglepress(longerthan1

second) starts the auto-tune;

oPLo

Manual mode. The first pressure puts the instrument in

manualmode(oPLo)whileasecondoneputstheinstrument

in Auto mode;

AAc Alarm acknowledge;

ASi Alarm reset;

chSP Sequential set point selection;

St.by

Standbymode.Thefirstpressputstheinstrumentinstandby

modewhileasecondoneputstheinstrumentinAutomode;

Str.t Timer run/hold/reset;

P.run Program run;

P.rES Program reset;

P.r.H.r Program run/hold/reset.

tunE

no. Par. Description Dec. Values Default Notes

122 diSP Display management

nonE Standard display;

Pou Power output;

SPF Final set point;

Spo Operative set point;

AL1 Alarm 1 threshold;

AL2 Alarm 2 threshold;

AL3 Alarm 3 threshold;

Pr.tu -

Duringasoak,theinstrumentshowsthesoakelapsedtime;

-

Duringarampthedisplayshowstheoperativesetpoint

.

Atprogramend,theinstrumentalternatelydisplays

P.End and the measured value;

- Whennoprogramisrunning,theinstrumentshowsthe

standard display;

Pr.td - Duringasoak,theinstrumentshowsthesoakremai-

ning time (count down);

-

Duringarampthedisplayshowstheoperativesetpoint.

Atprogramend,theinstrumentalternatelydisplays

P.End and the measured value;

- Whennoprogramisrunning,theinstrumentshowsthe

standard display;

P.t.tu When the programmer is running, the display shows

thetotalelapsedtime. Atprogramend,theinstrument

alternately displays P.End and the measured value;

P.t.td

Whentheprogrammerisrunning,thedisplayshowsthetotal

remainingtime(countdown).Atprogramend,theinstru-

mentalternatelydisplaysP.End andthemeasuredvalue;

ti.uP Whenthetimerisrunning,thedisplayshowsthetimer

countingup. Atcount end,the instrumentalternately

displays t.End and the measured value;

ti.du Whenthetimerisrunning,thedisplayshowsthetimer

countingdown.Atcountend,theinstrumentalternately

displays t.End and the measured value;

PErc

Percentofthepoweroutputusedduringsoftstart(whenthe

softstarttimeisequaltoinfinite,thelimitisalwaysactive

anditcanalsobeusedwhenON/OFFcontrolisselected);

PoS Valve position (servomotor control).

0

123 di.cL Display colour

0

The display colour shows the actual deviation (PV - SP);

1 Display red (fix);

2 Display green (fix);

3 Display orange (fix).

0

124 AdE Deviationfordisplaycolour

management 1... 999 (E.U.) 5

125 di.St Display Timeout 2oFF (display always ON);

0.1... 99.59 (mm.ss). oFF

126 Ld Filter on the displayed

value 1oFF (filter disabled);

From 0.0 (oFF) to 20.0 (E.U.). oFF

128 dSPu Instrumentstatusatpower

ON

AS.Pr

Starts in the same way it was prior to the power down;

Auto Starts in Auto mode;

oP.0 Starts in manual mode with power output = 0;

St.bY Starts in stand-by mode.

AS.Pr

129 oPr.E Operativemodesenabling

ALL All modes will be selectable by the next parameter;

Au.oP Autoandmanual(oPLo)modeonlywillbeselectableby

the next parameter;

Au.Sb AutoandStand-bymodesonlywillbeselectablebythenext

parameter

ALL

130 oPEr Operativemodeselection

If oPr.E = ALL: - Auto = Auto mode;

- oPLo = Manual mode;

- St.bY = Stand by mode;

If oPr.E = Au.oP:

- Auto = Auto mode;

- oPLo = Manual mode;

If oPr.E = Au.Sb: - Auto = Auto mode;

- St.bY = Stand by mode.

Auto

]Ser Group - Serial link parameter

no. Par. Description Dec. Values Default Notes

131 Add Instrument address oFF;

1... 254. 1

132 bAud baud rate

1200 1200 baud;

2400 2400 baud;

9600 9600 baud;

19.2 19200 baud;

38.4 38400 baud.

9600

133 trSP Selection of the value to be

retransmitted (Master)

nonE Retransmissionnotused(theinstrumentisaslave);

rSP TheinstrumentbecomesaMasterandretransmitsthe

operative set point;

PErc

TheinstrumentbecomeaMasteranditretransmitsthe

power output.

nonE

]COn Group - Consumption parameters

no. Par. Description Dec. Values Default Notes

134 Co.tY Count type

oFF Not used;

1 Instantaneous power (kW);

2 Power consumption (kW/h);

3 Energyusedduringprogramexecution.Thismeasurestarts

fromzerowhenaprogramrunsendstopsattheendofthe

program. A new program execution will reset the value;

4 Totalworkeddays:numberofhourstheinstrumentisturned

ON divided by 24;

5

Totalworkedhours:numberofhoursthattheinstrumentis

turned ON;

6

Totalworkeddayswiththreshold:numberofhourstheinstru-

mentisturnedONdividedby24,thecontrollerisforcedinstand-

bywhenCo.tyvaluereachesthethresholdsetin[137]h.Job;

7 Totalworkedhourswiththreshold:numberofhoursthatthe

instrumentisturnedON,thecontrollerisforcedinstand-by

whenCo.tyvaluereachesthethresholdsetin[137]h.Job;

8 Totalizerofcontrolrelayworkeddays:numberofhoursthe

control relay has been in ON condition, divided by 24;

9 Totalizerofcontrolrelayworkedhours:numberofhoursthe

control relay has been in ON condition;

10 Totalizerofcontrolrelayworkeddayswiththreshold:number

ofhoursthecontrolrelayhasbeeninONconditiondivided

by24,thecontrollerisforcedinstand-bywhenCo.tyvalue

reaches the threshold set in [137] h.Job;

11 Totalizer of control relay worked hours with threshold:

numberofhoursthecontrolrelayhasbeeninONcondition,

thecontrollerisforcedinstand-bywhenCo.tyvaluereaches

the threshold set in [137] h.Job.

oFF

135 UoLt NominalVoltageoftheload 1... 9999 (V) 230

136 cur Nominalcurrentoftheload 1... 999 (A) 10

137 h.Job Threshold of the working

period

oFF Threshold not used;

0... 9999 days (when [134] cotY = 4);

0... 9999 hours (when [134] cotY = 5).

0

138 t.Job Workedtime(notresettable) 0... 9999 days

]CAL Group - User calibration group

no. Par. Description Dec. Values Default Notes

139 AL.P Adjust Low Point From -1999 to (AH.P - 10) in engineering units 0

140 AL.o Adjust Low Oset -300... +300 (E.U.) 0

141 AH.P Adjust High Point From (AL.P + 10) to 9999 engineering units 9999

142 AH.o Adjust High Oset -300... +300 0

Note: To access all the instrument features, please see the“Complete conguration procedure”in the “Engineering User

Manual”.

Complete Conguration and Parameter setting can be easily uploaded from the controller and downloaded to

other controllers using the: Conguration Key ELCO: KEY A-01.

Factory reset - Default parameters loading procedure

Sometime, e.g. when you re-congure an instrument previously used for other works or from other people or

when you have made too many errors during conguration and you decided to re-congure the instrument, it

is possible to restore the factory conguration.

This action allows to put the instrument in a dened condition (the same it was at the rst power ON).

The default data are those typical values loaded in the instrument prior to ship it from factory.

To load the factory default parameter set, proceed as follows:

1. Press the button for more than 5 seconds. The upper display will show PASS while the lower display

shows 0;

2. Using and buttons set the value -481;

3. Push button;

4. The instrument will turn OFF all LEDs for a few seconds, then the upper display will show dFLt (default) and

then all LEDs are turned ON for 2 seconds. At this point the instrument restarts as for a new power ON.

The procedure is complete.

5. OPERATIVE MODES

Keyboard function when the instrument is in Auto mode

Key Operator Mode

Access to:

- Operator Commands (Timer, Setpoint selection ...)

- Parameters

- Conguration

Access to

Operator additional information (Output value, running time ...)

Accesso to Set Point

Start programmed function with usrb parameter (Autotune, Auto/Man, Timer ...)

Operator Commands

run

tr.st

248.0

sp

Confirm/Next

Confirm/Next

Confirm/Next

Confirm/Next

Operator Command

Increase

Decrease

run : Start

hold : Hold

res : Reset

Active

Set Point

selection

1

a.sp

If more than

1 Set Point

active

(nsp > 1)

Confirm/Next

1

st

SP

value

change

If timer

activated

( tr.F )

250

AL1

If AL1 is active

Back to the

first parameter

To return to the Normal Mode, press the key for 3 seconds or wait for the 10s timeout

run : Start

hold : Hold

res : Reset

run

pr.st

Confirm/Next

If program

activated

( pr.F )

sp4

nsp > 1

nsp > 2

nsp > 3

340.0

225.0

sp3

120.0

sp2

Additional information

t45.2

248.0

h854

248.0

C045

248.0

Additional Information

Output Value %

(e.g. heating = 35%,

cooling = 45%)

Program

Segment

If active

To return to the Normal Mode, press the key for 3 seconds or wait for the 10s timeout

H035

248.0

s1.00

248.0

r1.00

248.0

d854

248.0

U854

248.0

Heating

Cooling

Worked time

(days)

Worked time

(hours)

Power (kW)

or

Energy (Wh)

Program/Timer

remaining time

P04.8

248.0

Soak

Ramp

Timer

Program

Set Point Change

Press the key (3 s) or wait

for the 10s time out to

store the new Set Point

and return to Normal Mode

Increase value

Decrease value

Operative

Set Point

Changed

operative

Set Point

248.0

sp

250.0

sp

Set Point Change

Running the Tuning functions

Press the key

for 3 s

Auto-tune

started

Auto-tune

in progress

tunE

248.0

248.0

248.0.

Note:

The key could be assigned by the user to other functions using the Usrb parameter

setting

Dot flashes while the Smart TUNE is in progres

s

Smart TUNE

is a fast and fully automatic procedure that can be

started in any condition, regardless the deviation

from SP. The controller selects automatically the

best tune methodand computes the optimum

PID parameters.

Smart TUNE Start

6. ERROR MESSAGES

Out of range signals

The instrument points out, on the upper display, the OVER-RANGE and UNDER-RANGE conditions using the fol-

lowing indications:

Over-range Under-range

The sensor break will be signalled as an out of range:

Note: When an over-range or an under-range is detected, the alarms operate as in presence of the maximum

or the minimum measurable value respectively

.

To check the out of span Error condition, proceed as follows:

1. Check the input signal source and the connecting line.

2. Make sure that the input signal is in accordance with the instrument conguration.

Otherwise, modify the input conguration (see section 4).

3. If no error is detected, send the instrument to your supplier to be checked.

List of possible errors

ErAT Fast Auto-tune cannot start. The measure value is too close to the set point.

Push the button in order to delete the error message.

ouLd Overload on output 4. The message shows that a short circuit is present on Out 4 when it is used as ou-

tput or transmitter power supply. When the short circuit disappears the output restarts to operate.

NoAt Auto-tune not nished within 12 hours.

ErEP Possible problem in the instrument memory. The message should automatically disappear, if the error

persists, send the instrument to your supplier.

RonE Possible problem of the rmware memory. If this error is detected, send the instrument to your supplier.

Errt Possible problem of the calibration memory. If this error is detected, send the instrument to your supplier.

7. GENERAL NOTES

Proper use

Every possible use not described in this manual must be consider as a improper use.

This instrument is in compliance with EN 61010-1“Safety requirements for electrical equipment for measure-

ment, control and laboratory use”; for this reason it could not be used as a safety equipment.

Whenever a failure or a malfunction of the control device may cause dangerous situations for persons, thing

or animals, please remember that the plant has to be equipped with additional safety devices.

EL.CO. S.r.l. and its legal representatives do not assume any responsibility for any damage to people, things

or animals deriving from violation, wrong or improper use or in any case not in compliance with the instru-

ment’s features.

Declaration of conformity and Manual retrieval

ELKM43 is a panel mounting, Class II instrument. It has been designed with compliance to the European Direc-

tives.

All information about the controller use can be found in the Engineering User Manual available on the down-

load area of our website www.elco-italy.com .

The Declaration of Conformity is available for free on request by our web-ticketing support service on our

website.

Maintenance

This instrument does not requires periodical recalibration and it have no consumable parts so that no particular

maintenance is required.

Sometimes it is advisable to clean the instrument.

1. SWITCH THE EQUIPMENT OFF (power supply, relay output, etc.).

2. Using a vacuum cleaner or a compressed air jet (max. 3 kg/cm

2

) remove all deposits of dust and dirt which may

be present on the case and on the internal circuits being careful not to damage the electronic components.

3. To clean external plastic or rubber parts use only a cloth moistened with:

Ethyl Alcohol (pure or denatured) [C2H5OH] or

Isopropyl Alcohol (pure or denatured) [(CH3)2CHOH] or

Water (H2O).

4. Make sure that there are no loose terminals.

5. Before turning ON the instrument make sure it is perfectly dry.

6. Apply the power supply to the instrument.

Disposal

The appliance (or the product) must be disposed of separately in

compliance with the local standards in force on waste disposal.

Warranty

This product is under warranty against manufacturing defects or faulty materials that are found within 12

months from delivery date. The warranty is limited to repairs or to the replacement of the instrument.

The tampering of the instrument or an improper use of the product will bring about the immediate withdrawal

of the warranty eects.

In the event of a faulty instrument, either within the period of warranty, or further to its expiry, please contact

our our support team through the web-ticketing service on our website.

The return policy will be communicated once the request will be accepted and is also available on the “Sales

Condition”.

8. ORDER CODE

Model

ELKM43 = Controller

ELKM43T = Controller + timer

ELKM43P = Controller + timer + programmer

Power supply

240 = 100... 240 VAC

EV = 24…240 VAC-VDC

Analogue input + Digital input DI1 (standard)

C= J, K, R, S, T, PT100, PT 1000 (2 fili), mA, mV, V

E= J, K, R, S, T, NTC, PTC, mA, mV, V

Output 1

A= 0/4...20 mA, 0/2...10V

R= Relais SPST 4A (resistive load)

S= VDC forSSR

Output 3

-= Not available

3R = Relais SPST 2 A (resistive load)

3S = VDC forSSR

3M= Relè SPST 2 A (servomotor drive)

Serial communications

- = TTL Modbus

S= RS485 Modbus + TTL Modbus

Output 2

-= Not available

2R = Relais SPST 2 A (resistive load)

2S = VDC for SSR

2M= Relais SPST 2 A (servomotor drive)

Note: Add“W” after the product name for white coloured display led’s

Note: For servomotor drive, both Output 2 and Output 3 codes must be selected as“M”

Other elco Controllers manuals