BONKOTE PATRIOT User manual

M12

LA type soldering iron controller

Instruction manual

Date prepared: April 2018

The 9th edition

JAPAN BONKOTE CO., LTD.

PATRIOT

Contents page

1Preface············································································································1

2Notes for safety ································································································1

3Auto Tuning before use ·····················································································1

4Notes for installation and use ············································································2

5How to use M12 controller

(A)Contents ·································································································3

(B)Name of the body ·····················································································3

(C)How to assemble ······················································································4

(D)How to use ······························································································5

6Optional function

(A)Alarm function upper limit setting ·····························································7

(B)Alarm function lower limit setting······························································8

(C)Temperature recovery speed setting ···························································8

(D)Upper limit setting of set temperature························································8

(E)Indication of manipulated output value ······················································9

(F)Lock function···························································································9

(G)Anti reset wind up setting··································································· 10

(H)Auto Power Down / Auto Power Off setting ··············································10

(I)PID value manual setting ······································································13

7List of character ····························································································15

8How to maintenance······················································································16

9Standard specification····················································································16

10 Guarantee and After sales service

(A)Trouble shooting ···················································································17

(B)Guarantee····························································································17

(C)After sales service ·················································································17

1

1. Preface

Thank you very much for purchasing M12 CONTROLLER.

Please read this Notes for safety before use, and use this machine properly.

After read this manual, please keep it.

2. Notes for safety

Be sure to read this manual before using this machine.

Never touch the power cord and the soldering iron with dump hands.

Otherwise, you may get hurt due to electric shock and etc. (death at worse)

Never dampen the iron tip with water or other liquid. Otherwise, burst cord

may cause fire, malfunction, electric shock and etc. (death at worse)

Take great care to handle the soldering iron while it is not rested on the

workbench. Otherwise, the heated tip may cause fire or adjacent operations

may get hurt.

Unplug the iron unit and allow sufficient time for it to cool when replacement

or maintenance.

Do not overhaul the machine when the machine has trouble. Otherwise, it may

cause malfunction, electric shock and etc. (death at worse) Contact our

customer service department and follow instructions to make maintenance.

Be sure to use proper replacement parts such as fuse, checking capabilities.

Otherwise, parts with wrong capacities may cause fire, malfunction and tec.

3. Auto Tuning before use

We would recommend Auto Tuning before use, although each parameter is set in

the standard value at the shipment. By doing so, soldering irons will perform with

good effect according to iron tip temperature, shape of iron tip, working

environments and so on.

※This function will be set automatically by keypad. (Please refer to P.7)

!

CAUTION

2

4. Notes for installation and use

This machine is designed with earth specification. Make sure to use an earth

equipped receptacle. If you do not have such receptacle, install an earth

separately.

Use this machine on a neat bench on which a conducive mat is put.

Do not place where the machine would be exposed too much moisture, direct

sunshine, much dust and vibration.

In order to prevent static electricity, we recommend that you use a static

electricity removal device, wrist strap etc.

Odor is generated due to the use of solder and flux. Be sure to ventilate work

places. e.g. Install a ventilation fan etc.

Be sure to pull out the power plug when the machine is not used.

Be sure to grab the power plug instead of the cord, when plugging and

unplugging.

When change power voltage from 100V to 220V for example, make sure to

confirm the specifications of the soldering iron before use.

Please keep flammable objects away from this machine.

Be sure to check the slack of each screw and tighten them securely before use

this machine.

Do not use this machine for purpose other than the original purpose.

3

5. How to use

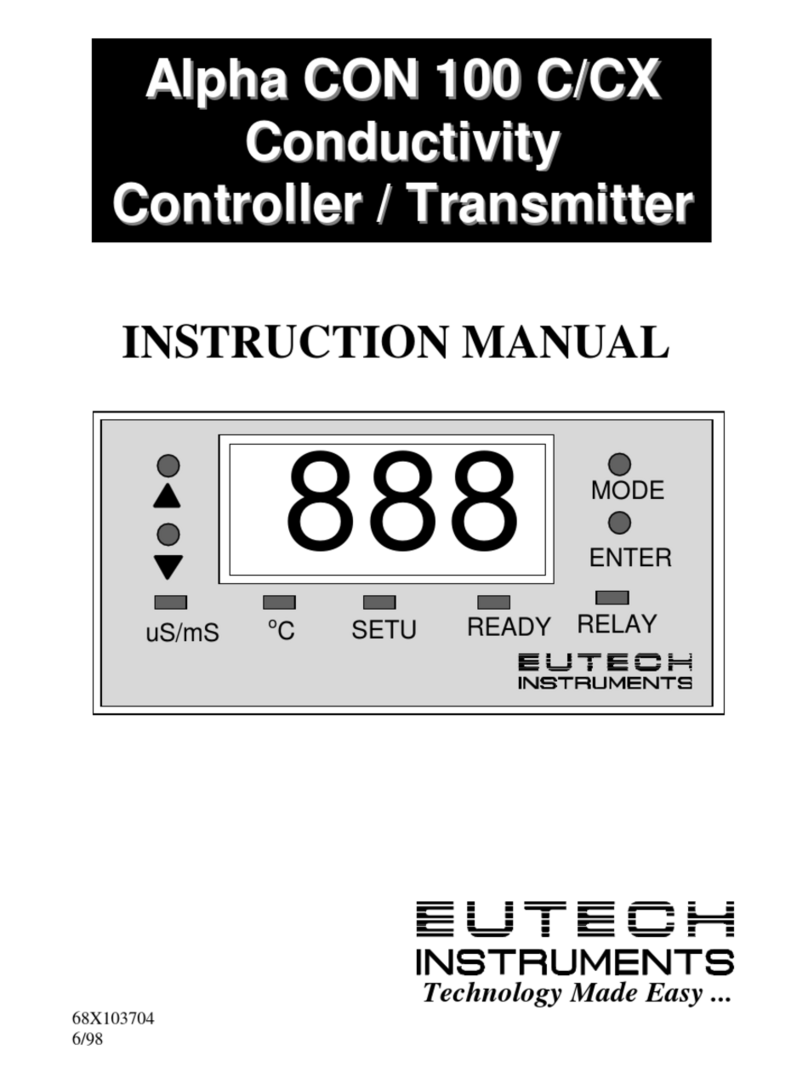

5-A:Contents of soldering station set

①3P Power cord ※

②M12 Controller

③BON-11 Iron stand

④TB-170J Soldering iron

NOTE:

This picture is M12-TB-170J station set.

※3PCHI plug cord for 100V, or 3EPV plug

cord for 220V comes with a controller.

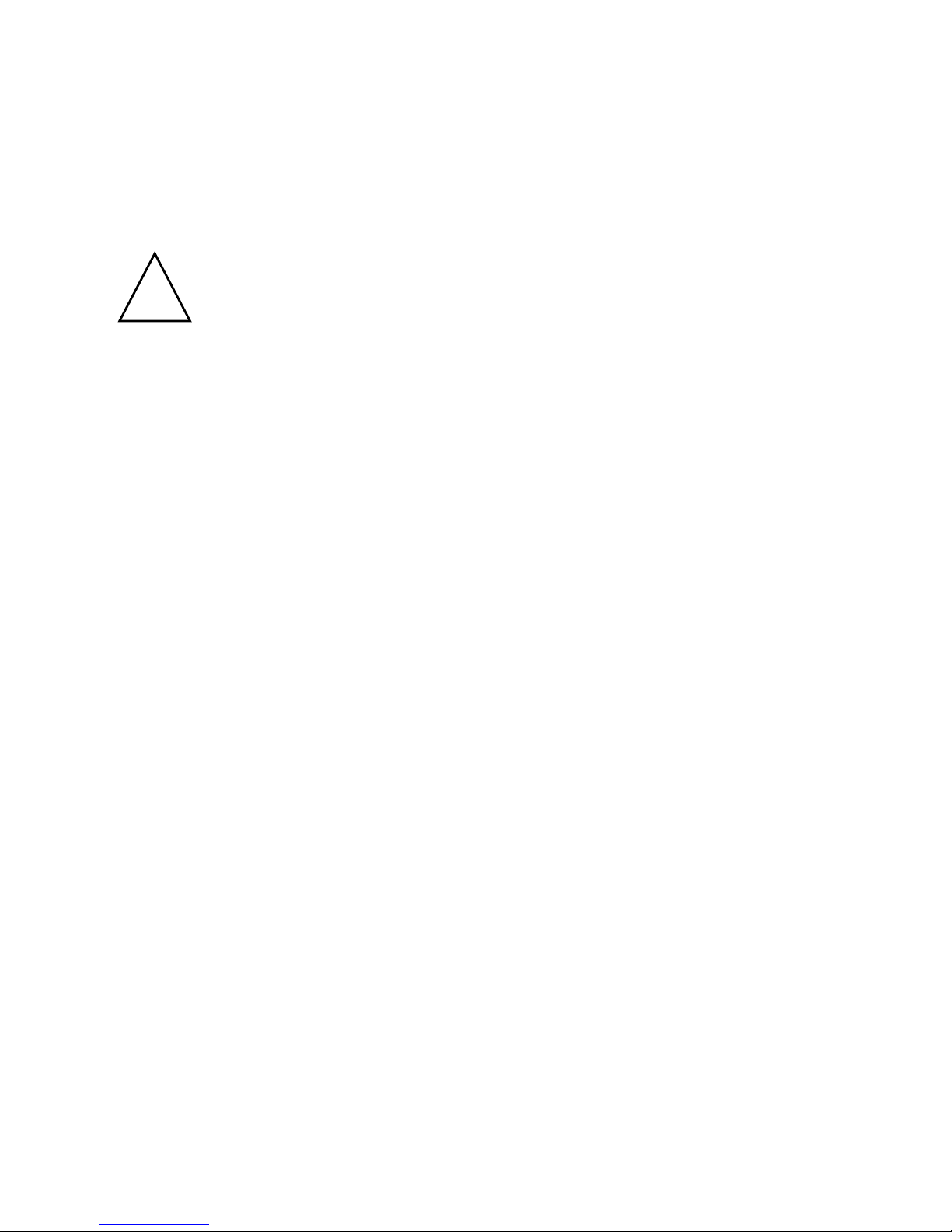

5-B:Name of the body

《FRONT 》《BACK 》

①Power switch ⑨Fuse holder

②5 pin connector ⑩3 pin inlet

③PV display (working temperature)

④SV display (setting temperature)

⑤△key (value up)

⑥▽key (value down)

⑦

⑧□key (speed setting)

②

③

④

①

⑤

⑥

⑧

⑦

⑨

⑩

①

②

③

④

4

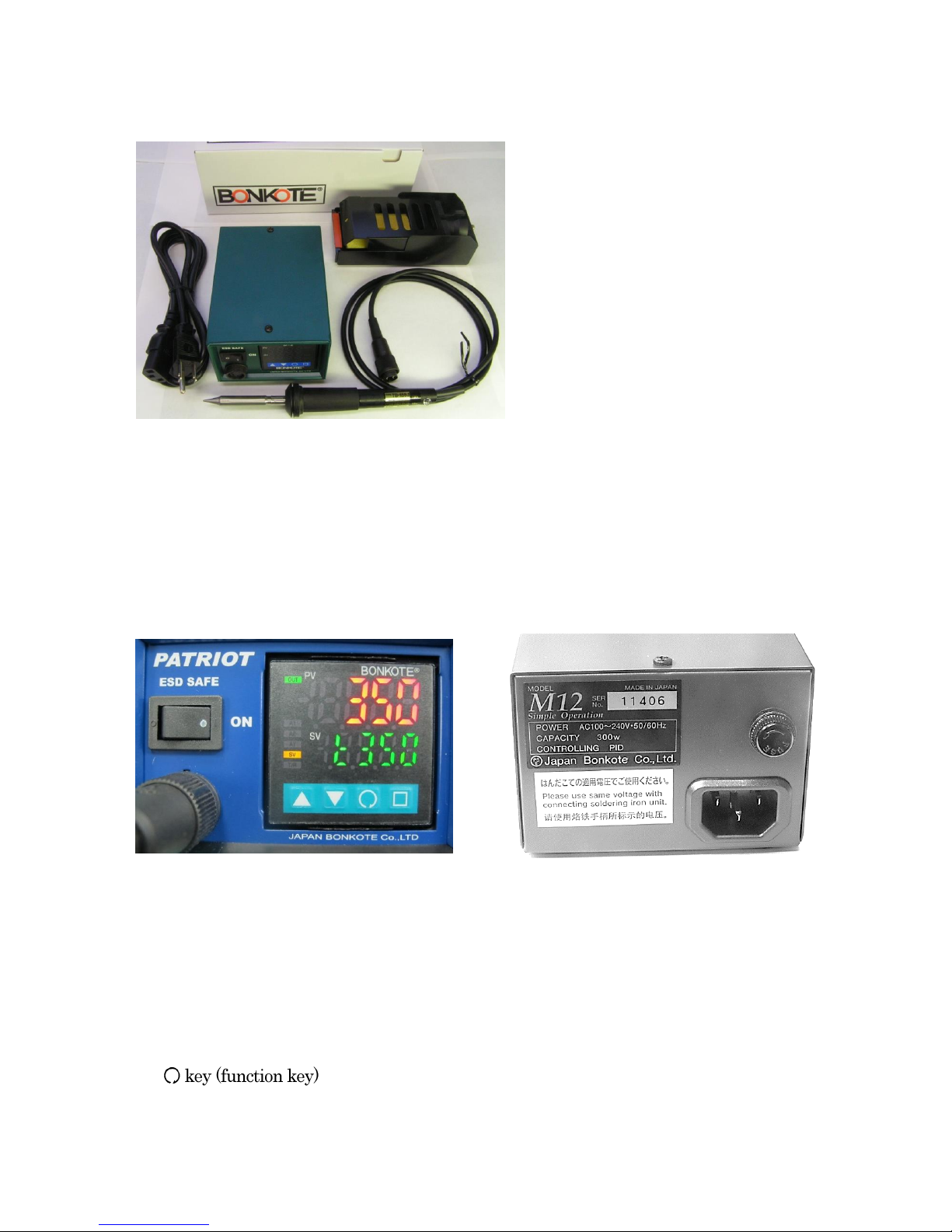

5-C:How to assemble

①Insert the power cord into the 3 pin inlet at the back face.

②Connect the soldering iron to 5 pin connector at the front, and turn the connector housing

clockwise to lock it in place.

③Assemble the iron stand and store the soldering iron in its holder ①.

1

2

3

5

6

4

No.

Name

Model No.

1

Holder

B-11

2

Cover

-

3

Screw with spring-

washer

M4 x 6

4

Cleaner case

K-5

5

Cleaner base

-

6

Cleaning sponge

S-6

Assemble order

Ⅰ:Remove the screw ③from the cleaner base ⑤.

Ⅱ:Align a screw hole of the holder ①and the cleaner base ⑤, then tighten the screw.

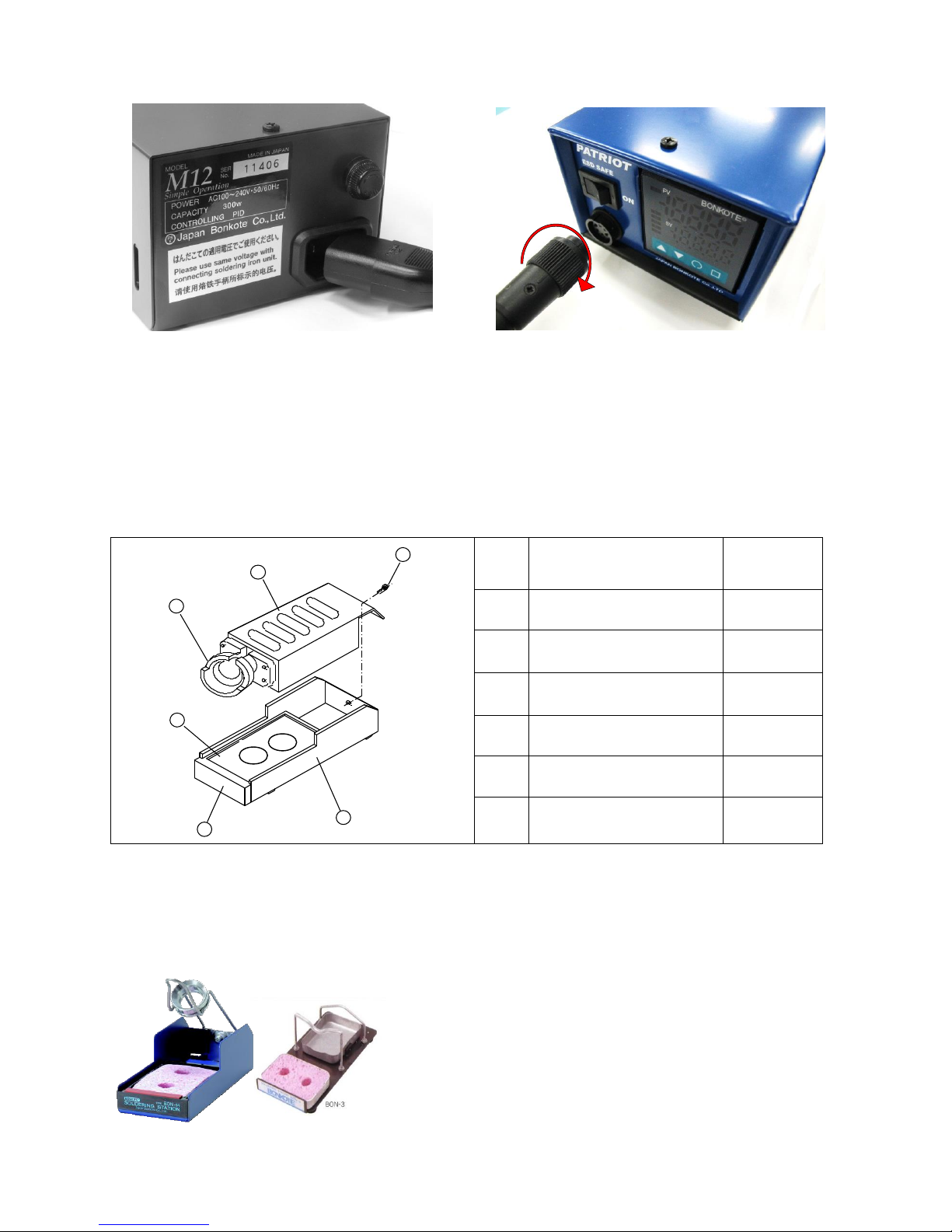

Iron stand BON-14 is for TB-1175 iron,

BON-3 is for TB-1100.

①

②

BON-14 BON-3

5

5-D:How to use

①Turn on power

Insert the power plug into the receptacle. Confirm each input voltage of the soldering iron and

the controller is the same, then turn on the power.

※Do not use a 100V soldering iron with 220V power source. Failure to do so may damage the

heater.

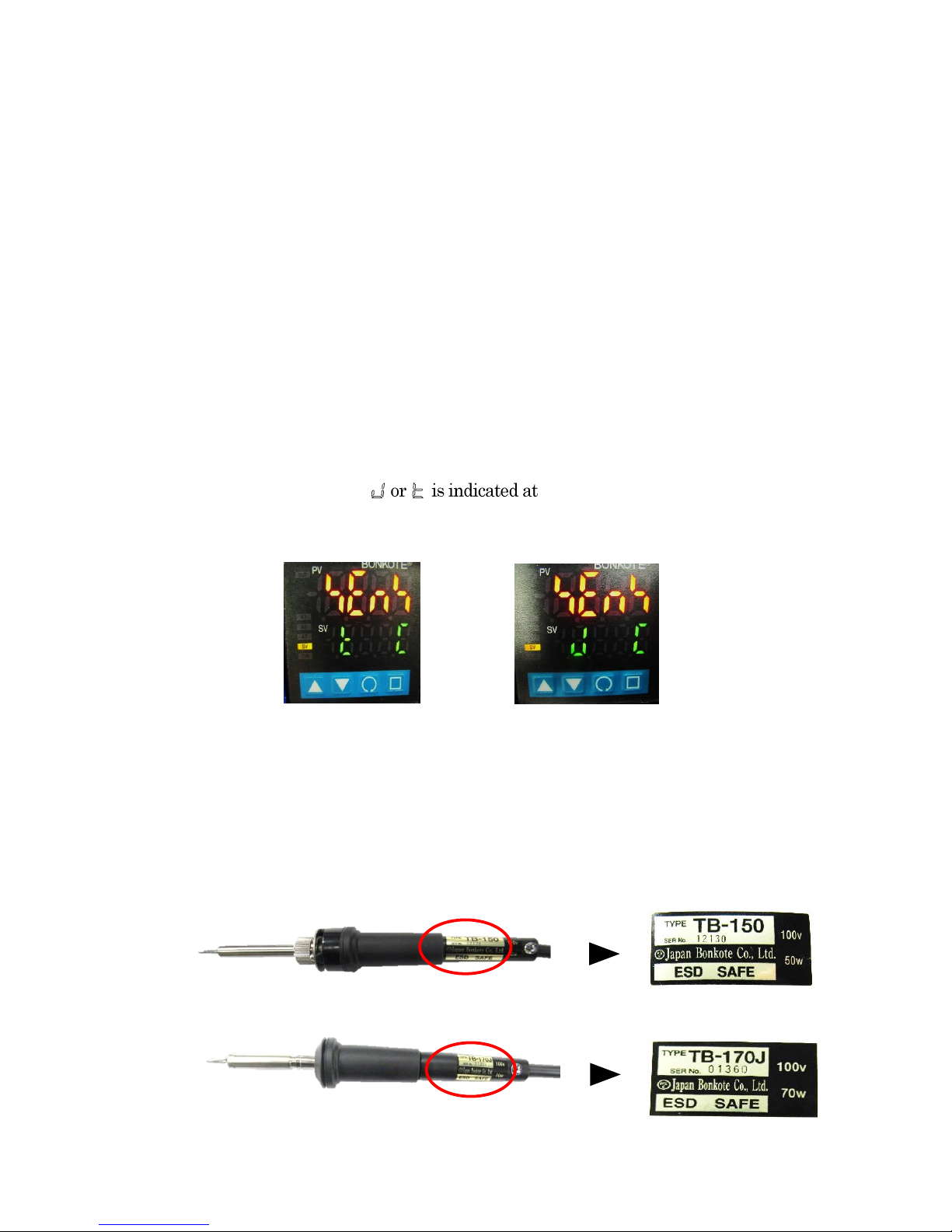

②Setting and confirmation of the sensor type

M12 Controller is workable for 2 different kinds of soldering iron, one is type J sensor and the

other type K sensor. Please make sure that the each sensor type of the soldering iron and that of

the controller should be the same. Otherwise temperature control is unable to work.

※The sensor type of controller and soldering iron is adjusted the same at the shipment.

The sensor type of controller itself is type K at the shipment.

②-1 How to confirm the sensor type.

Controller part

At the operation mode, SV display as show below.

Check the sensor type of the controller whether it is the same as that of a connected

soldering iron.

《Type K 》《Type J 》

Soldering iron

There are 2 different kinds of sensor type, which are type J and type K.

Please check the label of the soldering iron.

Type J soldering iron has a capital letter “J” as below.

TYPE K soldering iron

TYPE J soldering iron

6

②-2 How to set the sensor type

Ⅰ:At the operation mode, press key approx. 3 seconds while pressing ▽key.

is indicated at PV display.

Ⅱ:Enter suitable sensor type by △key or ▽key, then push

mode.

Operation modee

⇒

Input screen

⇒

Select sensor type

Operation modee

⇒

TYPE K

( ℃)

⇒

TYPE J

( ℃)

③Set the set temperature

Default:350℃Setting range:0 ~500℃

Default:200℃※when「BNJT7」type iron tip equipped.

Ⅰ:At the operation mode, press key once, and is indicated at PV display.

Ⅱ:Enter the desired temperature by △key or ▽key.

Ⅲ:Press key once to return to the operation mode.

Operation modee

⇒

Setting temp.

⇒

Operation mode

④Temperature compensation

Default:0℃Setting range:-100.0℃~100.0℃

Ⅰ:At the operation mode, press seconds while pressing ▽key.

is indicated at PV display.

Ⅱ:Press key 3 times, and is indicated at PV display.

Ⅲ:Enter the desired value by △key or ▽key at SV display.

Ⅳ:After entering the value, push key 4 times to return to the operation mode.

Operation mode

Input screen

Compensation screen

Operation mode

⇒

⇒

⇒

How to calculate the compensation value with a standard thermometer.

e.g.:Thermometer value:「350℃」Controller value:「355℃」Compensation value is「-5」

Compensation value =Thermometer value -Controller value ⇒「350」-「355」=「-5」

7

⑤Start Auto Tuning

after reach to the set temperature

Ⅰ:At the operation mode, press for 3 seconds while pressing △key, and

is indicated at PV display.

Ⅱ:Push △key once, and is indicated at SV display, too.

Ⅲ:Push key to startAuto Tuning. (“AT” lamp starts blinking. )

Auto Tuning function completes in about 2 minutes. (“AT” lamp stops blinking.)

Auto Tuning function automatically calculates the suitable PID value which controls soldering irons.

Make sure to implement Auto Tuning function to make soldering irons perform with enough effect.

ATTNTION

After reach to the set temperature

, please implement Auto Tuning function.

Do not touch the soldering iron in operation.

The fluctuation in temperature of soldering iron automatically calculates PID value. Thus, touching

the soldering iron in operation causes incorrect PID value calculation and the soldering iron may not

perform with enough effect. Auto Tuning completes when “AT” lamp stops blinking.

Above ④and ⑤are unnecessary to do every time. Do it when iron tips or set temperature are

changed.

※At shipment, Auto Tuning function has NOT done yet. Make sure to do it at the first time to use.

6. Optional functions

M12 controller has various functions. Please use them with your convenience.

6-A:Alarm function Upper limit setting

Set the upper limit of operation temperature range

Default:0℃

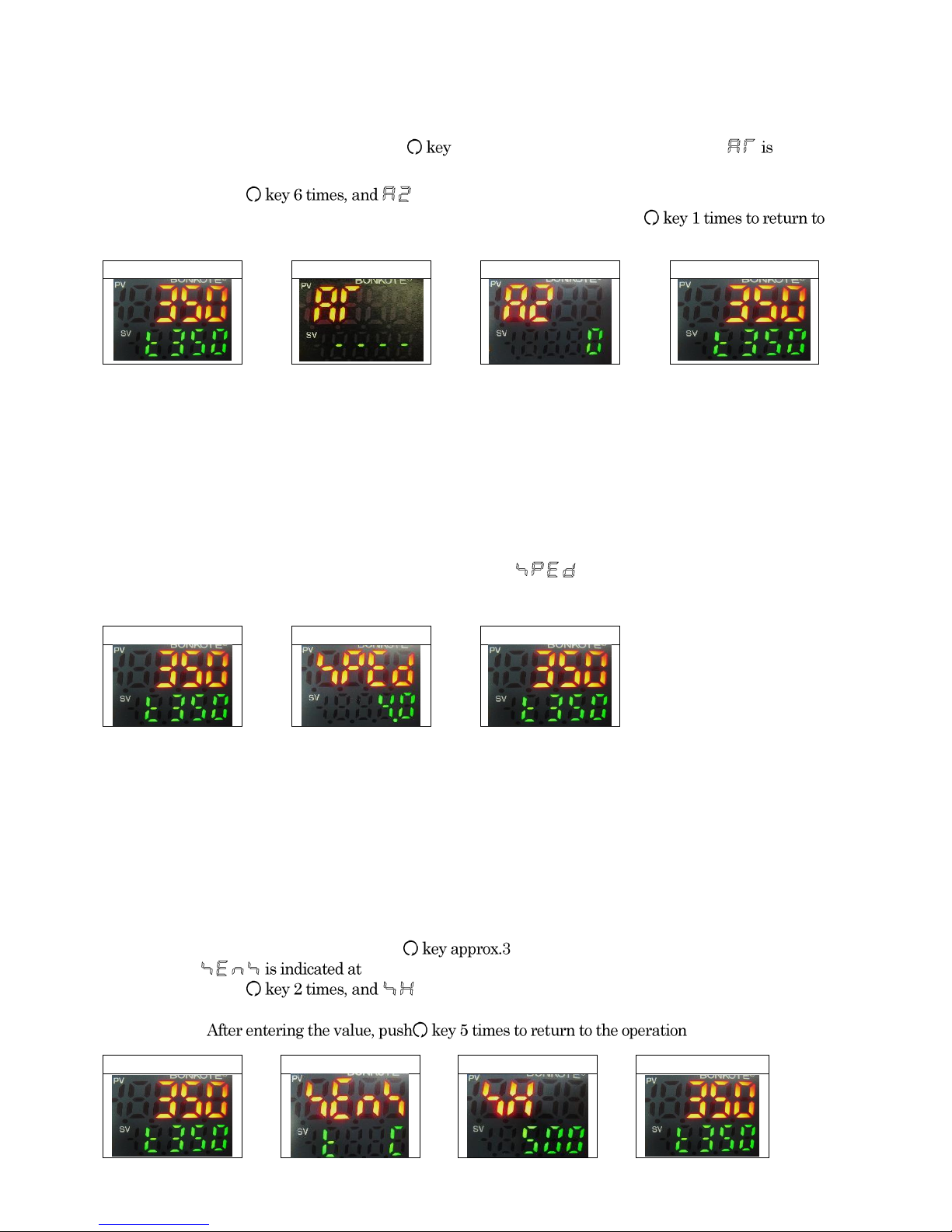

Ⅰ:At the operation mode, press for 3 seconds while pressing △key, and is indicated

at PV display.

Ⅱ:Push key 5 times, and is indicated at PV display.

Ⅲ:Enter the desired value by △or ▽key at SV display. Push key 2 times to return to the

operation mode.

This function can alarm when the operation temperature exceeds the upper limit you set up.

e.g. Controller set temperature: 「350℃」and Upper limit temperature: 「100℃」

When the operating temperature exceeds 「450℃」at above condition, it will work.

Operation modee

⇒

Auto Tuning

⇒

AT setting screen

⇒

Operation modee

Operation mode

⇒

Auto Tuning

⇒

Upper limit alarm

⇒

Operation mode

8

6-B:Alarm function Lower limit setting

Set the lower limit of operation temperature range

Default:0℃

Ⅰ:At the operation mode, press for 3 seconds while pressing △key, and

indicated at PV display.

Ⅱ:Push is indicated at PV display.

Ⅲ:Enter the desired value by △or ▽key at SV display, then push

the operation mode.

This function can alarm when the operation temperature exceeds the lower limit you set up.

e.g. Controller set temperature: 「350℃」and Upper limit temperature: 「-100℃」

When the operating temperature exceeds 「-250℃」at above condition, it will work.

6-C:Temperature Recovery speed

Adjust the recovery speed to the set temperature.

Default:4.0Setting range:1.0~10.0

Ⅰ:At the operation mode, press □key once, and is indicated at PV display.

Ⅱ:Enter the desired value by △or ▽key at SV display.

Ⅲ:After entering the value, push □key once to return to the operation mode.

Set value: 1.0 Recovery speed is fast, but overshooting becomes large.

Set value: 10.0 Recovery speed is slow, but overshooting becomes small.

6-D:Upper limit of set temperature

Set the upper limit of set temperature

Default:500℃Setting range:0 ~500℃

Ⅰ:At the operation mode, press seconds while pressing ▽key, and

PV display.

Ⅱ:Push is indicated at PV display.

Ⅲ:Enter the desired value by △key or ▽key at SV display.

Ⅳ:mode.

Operation mode

⇒

Auto Tuning

⇒

Lower limit alarm

⇒

Operation mode

Operation mode

⇒

Recovery speed

⇒

Operation mode

Operation mode

⇒

Input screen

⇒

Upper limit temp.

⇒

Operation mode

9

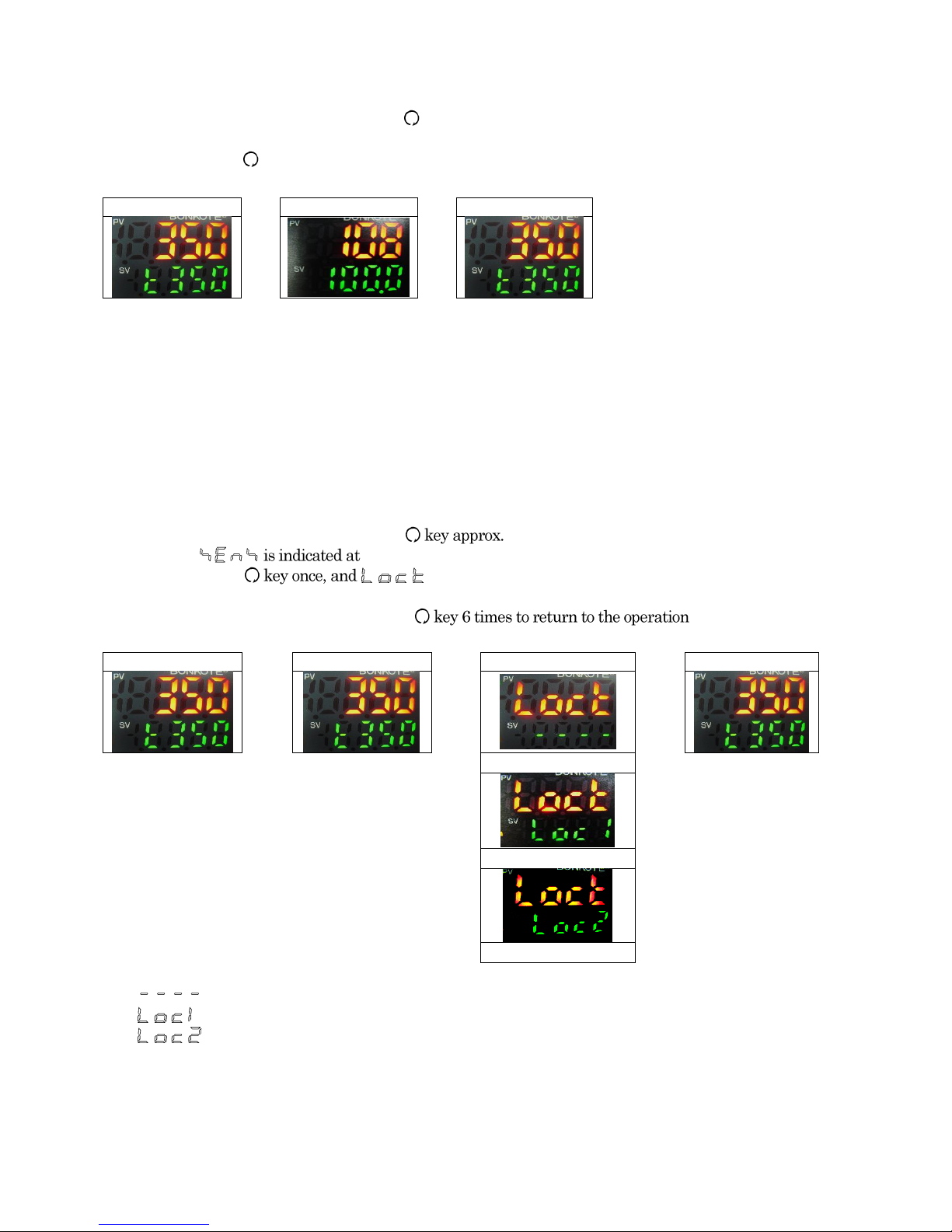

6-E:Manipulated output value

Monitoring the output amount of heater

Ⅰ:At the operation mode, press key about 3 seconds , and operation output amount

(0~100%) is indicated at SV display.

Ⅱ:Push key to return to the operation mode.

6-F:Lock function

Lock the set values to prevent error setting Default:-

Ⅰ:At the operation mode, press 3 seconds while pressing ▽key.

PV display.

Ⅱ:Push is indicated at PV display.

Ⅲ:Enter the desired function by △key or ▽key at SV display.

Ⅳ:After entering the value, push mode.

:LOCK-NON

:Only LOCK FUNCTION is available

:LOCK FUNCTION and Changing set temperature are available

Operation mode

⇒

Output amount

⇒

Operation mode

Operation mode

1⇒

Input screen

る

⇒

⇒

⇒

Lock select screen

⇒

Operation mode

LOCK - NON

LOCK - 1

LOCK - 2

10

6-G:Anti reset wind up setting

Control the overshooting

Default:18% Setting range:0 ~100%

Ⅰ:At the operation modee, press for 3 seconds while pressing △key. is

indicated at PV display.

Ⅱ:Push 4 times , and is indicated at PV display.

Ⅲ:Enter the desired value by △key or ▽key at SV display.

Ⅳ:3 times to return to the operation mode.

We recommend that you should keep the default. The lower value than the default can restrain

overshooting, but there might be possible not to recover to the set temperature.

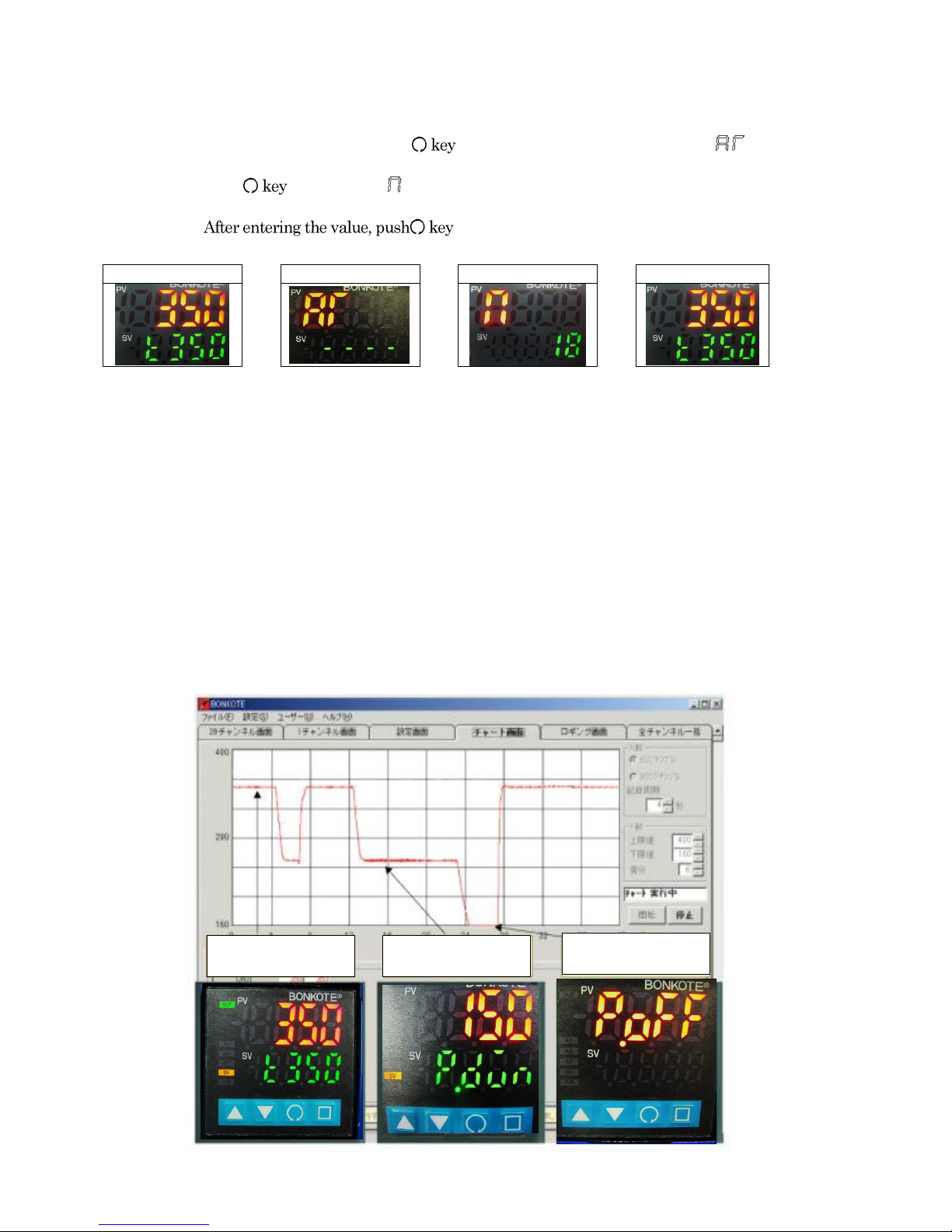

6-H:Auto Power Down / Auto Power Off

In order to prevent soldering iron tips from Deterioration and Oxidization, the tip

temperature is lowered ( Power Down), and the supplying electric power to the heater is

stopped (Power Off) automatically when the tiptemperature does not change for a certain

period of time (User- settable). This function is not only effective for saving energy, but

also for safety.

Operation mode

⇒

Auto Tuning

⇒

Anti reset wind up

⇒

Operation mode

Operation mode

Power Down

Power Off

11

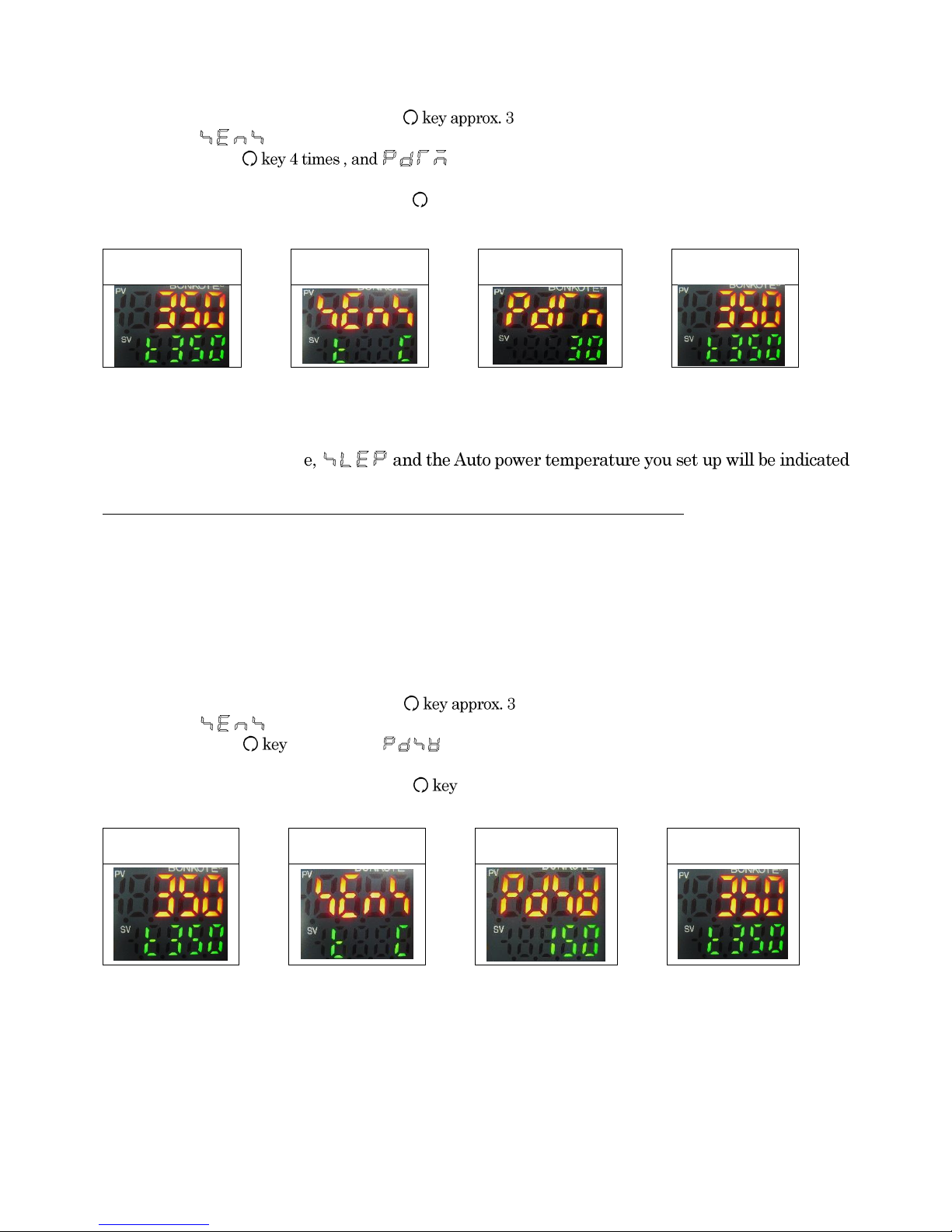

①Auto Power Down time

Default:30 minutes Setting range:0 ~120 minutes

Ⅰ:At the operation mode, press seconds while pressing ▽key.

is indicated at PV display.

Ⅱ:Push is indicated at PV display.

Ⅲ:Enter the desired value by △key or ▽key at SV display.

Ⅳ:After entering the value, push key 3 times to return to the operation mode.

This function lowers the tip temperature automatically when the temperature is no change for more

than a certain period of time you set up, since the controller recognizes that the soldering iron is

inactivity. During this mod

alternately.

If unnecessary, set the value “0” (zero), and this function becomes ineffective.

②Auto Power Down temperature

Default:150℃Setting range:0 ~(set temp.) -1℃

Ⅰ:At the operation mode, press seconds while pressing ▽key.

is indicated at PV display.

Ⅱ:Push 5 times , and is indicated at PV display.

Ⅲ:Enter the desired value by △key or ▽key at SV display.

Ⅳ:After entering the value, push 2 times to return to the operation modee.

The tip temperature falls down and stands by at the specific temperature you set up.

e.g. If you set up 「150℃」, the temperature drops and stands by around 「150℃」when not in

use. In case the operation temperature is 「350℃」, Auto PowerDown temperature can be set under

349℃only.

Operation mode

⇒

Input screen

⇒

Auto power down

time setting screen

⇒

Operation mode

Operation mode

⇒

Input screen

⇒

Auto power down

temp. setting screen

⇒

Operation mode

12

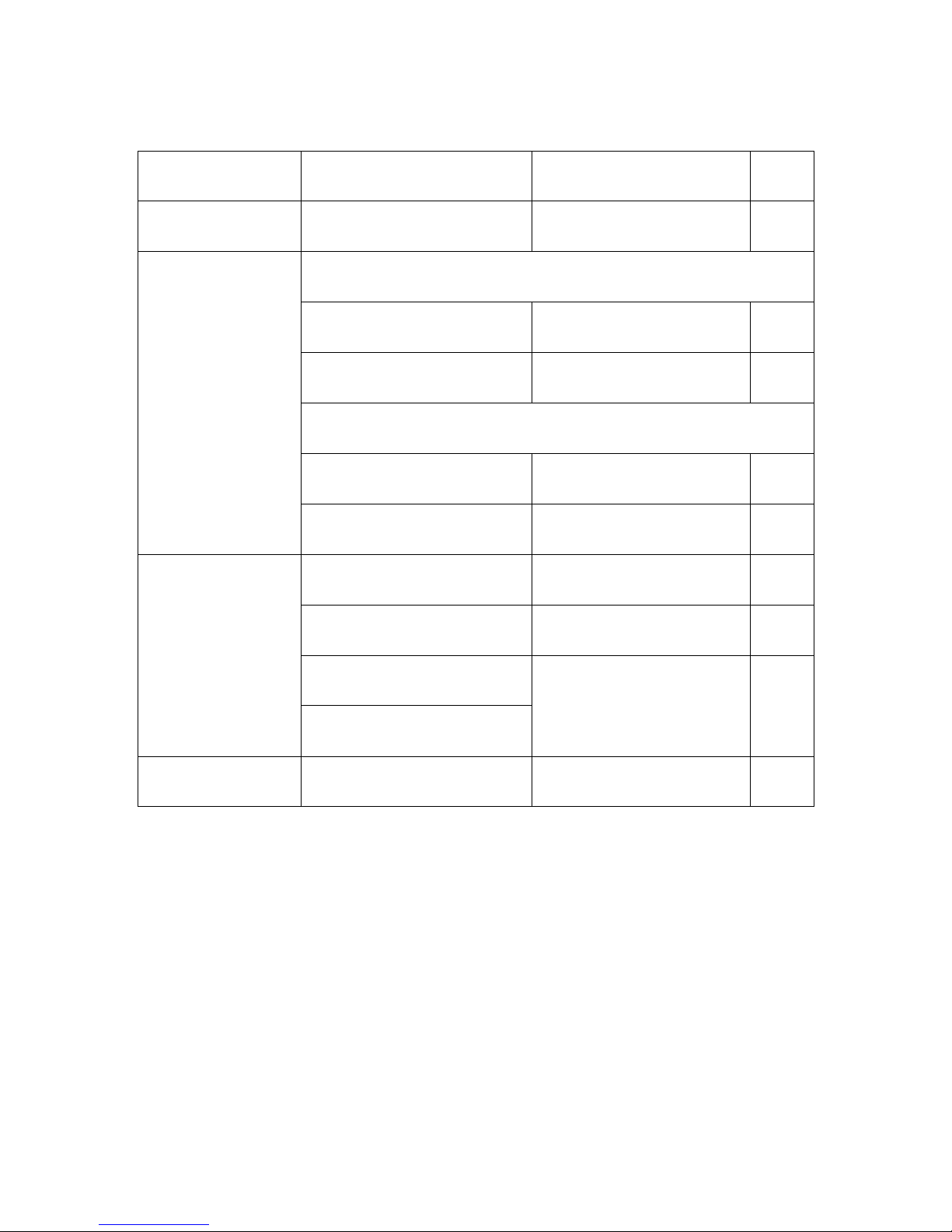

③Auto Power Off time

Default:30 minutes Setting range:0~120 minutes

Ⅰ:At the operation mode, press seconds while pressing ▽key.

is indicated at PV display.

Ⅱ:Push is indicated at PV display.

Ⅲ:Enter the desired value by △key or ▽key at SV display.

Ⅳ:After entering the value, push mode.

During Auto Power Down mode, SV display, this function turn off the power

of controller automatically when the tip temperature is no change for more than a certain period of

time you set up, since the controller recognizes that the soldering iron is inactivity.

If unnecessary, set the value “0” (zero), and this function becomes ineffective.

④Exiting Auto Power Down mode

Press △key or ▽key more than 3 seconds to return to the operation mode.

Temperature deviation by more than 5℃can release Auto power down mode.

e.g. Touch the iron tip with a moisturized sponge.

⑤Exiting Auto Power Off mode

Turn on the power again.

⑥Manual operation

After the tip temperature has reached to the set temperature, at the operation mode, press

△key or ▽key approx. 3 seconds to enter the power down mode.

At the power down mode, press △key or ▽key approx. 3 seconds to release the mode and

return to the operation mode.

Operation mode

⇒

Input screen

⇒

Auto Power Down

time setting screen

⇒

Operation mode

13

6-I:PID value manual setting

M12 controller is basically unnecessary PID setting becauseit comes standard withAuto Tuning function.

In case of Overshoot or special soldering work, you can set PID value by manual.

Please use PID manual setting with your convenience.

①Proportional band

Default:88℃Setting range:0 ~1570℃(type J:0~1200℃)

Higher set value can reduce overshoot, however, it makes temperature recovery time longer

and temperature reduction during soldering work larger.

Ⅰ:At the Operation mode, press for 3 seconds while pressing △key. is

indicated at PV display.

Ⅱ:Push key once, and is indicated at PV display.

Ⅲ:Enter the desired value by △key or ▽key at SV display, then push key 6 times to

return to the operation mode.

②Integration time

Default:38 seconds Setting range:0 ~3600 seconds

Higher set value can reduce overshoot, however, it makes temperature recovery time longer

and temperature reduction during soldering work larger.

Ⅰ:At the Operation mode, press for 3 seconds while pressing △key.

indicated at PV display.

Ⅱ:Push key 2 times, and is indicated at PV display.

Ⅲ:Enter the desired value by △key or ▽key at SV display, then push

return to the operation mode.

Operation mode

⇒

Auto Tuning

⇒

Proportional band

⇒

Operation mode

Operation mode

⇒

Auto Tuning

⇒

Integration time

⇒

Operation mode

14

③Derivative time

Default:8 seconds Setting range:0 ~1800 seconds

Lower set value can reduce overshoot, however, it makes temperature recovery time longer.

This value is supposed to be set or adjusted after value “P” and “I” are almost fixed.

Ⅰ:At the Operation mode, press for 3 seconds while pressing △key.

indicated at PV display.

Ⅱ:Push

Ⅲ:Enter the desired value by △key or ▽key at SV display, then push

return to the operation mode.

Operation modee

⇒

Auto Tuning

⇒

Derivative time

⇒

Operation mode

15

7. Character List

△key +key

▽key +key

key

↓

↓

↓

Auto Tuning

Input screen

Setting temperature

↓

↓

Proportional band

Lock function

□key

↓

↓

↓

Integration time

Upper limit temp.

Recovery speed

↓

↓

Derivative time

Compensation screen

key long press

↓

↓

↓

Anti reset wind up

Auto Power Down time

Operation amount output

↓

↓

Upper limit alarm

Auto Power Down temp.

↓

↓

Lower limit alarm

Auto Power Off time

↓

↓

Operation mode

Operation mode

16

8. How to maintenance

How to replace a fuse

Loosen a fuse holder and remove it.

Check the fuse if it needs to be

replaced to a new one.

Model No.

Specification

Fuse 3A

Glass fuse 250Ⅴ3A(φ5.2×20mm)

9. Standard specification

Input voltage

100VAC ~240VAC

Temperature range

0~500℃

Power cord

100VAC:3pin 3PCHI plug cord

220VAC: 3pin 3EPV plug cord

Dimension

97(W)×130(D)×73(H)mm

Weight

≦750 g

Fuse

3A

Temperature control

method

PID control ( Auto Tuning )

Temperature

indication

PV display:LED(RED)SV display:LED(GREEN)

Error indication

“ ̄ ̄ ̄ ̄” Over scale :Temperature exceed the upper

limit of temperature range.

※Error of sensors

“____” Under scale :Temperature exceed the lower

limit of temperature range.

※Reversed polarity of sensors

Material ( case )

Steel

Power consumption

≦10VA ( controller only )

17

10. Guarantee and after sales service

10-A:Trouble shooting

Symptom

Probable cause

Measures

page

“----”is blinking at

PV display

Tip sensor is disconnected or comes off

the iron unit.

Replace iron tips

Soldering iron does not

heat

※No power to controller

Power cord is NOT connected with the

receptacle.

Power switch is NOT ON.

Check the power cord or power switch

again.

P4

Blown fuse

Replace the fuse.

P15

※Power is ON

Soldering iron and controller is NOT

connected properly.

Check the connection again.

P4

The heater element is consumed.

Replace the heater.

Unstable temperature

Sensor type of controller and soldering

iron are NOT matched.

Match the sensor type of controller

and soldering iron.

P5

Auto Tuning function is NOT

implemented.

Implement Auto Tuning function.

P7

Temperature does NOT reach the set

temperature.

Adjust the value of recovery speed.

Implement Anti reset wind up

function.

P8

P10

Overshooting is large.

Key operation is unable

Lock functions are ON.

Check the lock functions.

P9

10-B:Guarantee

Our products are shipped after sever factory tests and inspections.

However, if you find malfunctions or defects due to problems in workmanship or transportation,

please contact your dealers or us.

The guarantee period of your products is in one year after your purchase, except for

replacement parts.

10-C:After sales service

When you think your system does not operate properly, read this manual again to check.

If still troubles are not solved, please contact your dealers or us.

®

JAPAN BONKOTE CO., LTD.

600-14 Kasahara, Mito, Ibaraki, 310-0852 JAPAN

TEL : +81-29-241-2725

FAX : +81-29-241-2726

http://bonkote.co.jp

Email: info@bonkote.co.jp

This manual suits for next models

1

Table of contents

Other BONKOTE Controllers manuals

Popular Controllers manuals by other brands

Siemens

Siemens SIRIUS S2 owner's manual

Digital Loggers

Digital Loggers Ethernet Power Controller II user guide

Parker

Parker ACR Series Programmer's guide

Interactive Technologies

Interactive Technologies SceneStation 3 user manual

sauter

sauter NRT405F901 manual

Swann

Swann Smith's TCAS T1 Installation and user guide