bono Cannon UNI-MATIC UM 30 Product guide

FLASH COIL STEAM GENERATORS UNI-MATIC

Technical Book Steam Generators UM

2

1. General Information

2. Competitive Advantages

3. Technical Specifications

4. P&ID

5. Dimensions and Connections

6. Generator Layout

7. Installation

8. Maintenance

9. Scope of Supply

10. Appendix 1. Fuel consumption calculation

11. Appendix 2. Thermodynamic characteristics of

saturated steam

FLASH COIL STEAM GENERATORS UNI-MATIC

3

4

Flash coil steam generators of the series UNI-MATIC

(UM) with forced circulation guarantee a steam

production range between 300 and 3000 kg/h; design

pressure is up to 12 bar.

Models of the steam generators series UNI-MATIC:

• UM 30: up to 300 kg/h

• UM 50: up to 500 kg/h

• UM 100: up to 1.000 kg/h

• UM 150: up to 1.500 kg/h

• UM 200: up to 2.000 kg/h

• UM 300: up to 3.000 kg/h

UM-UNIMATIC UM flash coil steam generators’ fields

of application are laundries, texile industry, food &

beverage, rubber, cellulose industry, agrotechnology,

woodworking and others.

UNI-MATIC UM generators are supplied as packaged

units, complete with all necessary equipment and

ready to be connected to site utilities.

As optional, an air preheater can be purchased

additionally to the steam generator.

Preheater enables the boiler to increase efficiency by

2%, therefore reaching 90% at full load.

UM model reaches operating conditions 2-3 minutes

after ignition of the burner.

UNI-MATIC model UM is available both in vertical and

horizontal version - UM compact design is also suitable

for small plants, although always guaranteeing high

quality performances.

UNI-MATIC UM generators are deisgned and produced

according to ISPELS code, PED directive 97/23/CE

Figure 1

Flash Coil Steam Generator UNI-MATIC

UM, vertical version with air pre-heater

1. GENERAL INFORMATION

Figure 2

Flash Coil Steam Generator UNI-MATIC

UM, horizontal version

5

1 Burner 6 Exhaust Gas Outlet

2 Burner Fan 7 Drain

3 UNI-MATIC Inner Coil 8 Steam Outlet Flange

4 Burner Flame 9 Water Inlet Flange

5 Bottom Refractory

Figure 3

Flash coil steam Generator UNI-MATIC UM functional diagram

6

2. COMPETITIVE ADVANTAGES

Figure 4

Safety and control instruments on an horizontal

UNI-MATIC UM steam generator.

Figure 5

Control panel for UNI-MATIC UM steam generator.

•Two versions: vertical and horizontal

•Maximum efficiency and high reliability

•Easy maintenance. The upper cover facili-

tates inspection and cleaning of the combus-

tion chamber and the internal parts of the

steam generator.

•Fast to reach operating conditions. Thanks

to the absence of thermal inertia, UNI-MATIC

UM steam generator is highly efficient in peri-

odic processes. It takes 2÷3 minutes to reach

operating condition after burner ignition.

•High reliable supply of feeding water.

Feeding pump flow sections are made of

Kevlar, a syntetic composite material which

guarantees maximum reliability and efficient

supply of feeding water.

•Easy-to-use and reliable automatic combus-

tion regulation with the following regulating

types:

• “on/off” regulation of gas fuel feeding

to the burner, burner air vent and feeding

water pump. Liquid fuel supply to burner

nozzle is achieved through electromagnetic

opening/closing valve.

• two-stages regulation (1st stage - min.

50%, 2nd stage - 100%), through regulation

of the amount of air and gas in the com-

bustion chamber, regulation of feed wa-

ter supply with two-position valves on the

fuel, air and water lines combined with on/

off regime of water and gas supply. Liquid

fuel supply to burner’s nozzle is achieved

through an opening/closing valve.

modulating regulation of steam produc-

tion with 30-100% range, achieved with an

electronic control of air and fuel supply and

servocontrolled valves. Feeding water sup-

ply is regulated through plunger pump with

frequency transformer. Liquid fuel oil sup-

ply to burner’s nozzle is achieved through

opening/closing electromagnetic valve with

fuel pressure regulation through a bypass

valve.

•Safety. The quantity of water, and thus steam,

is limited, allowing therefore a high level of

safety for personnel if compared to standard

steam boilers types.

7

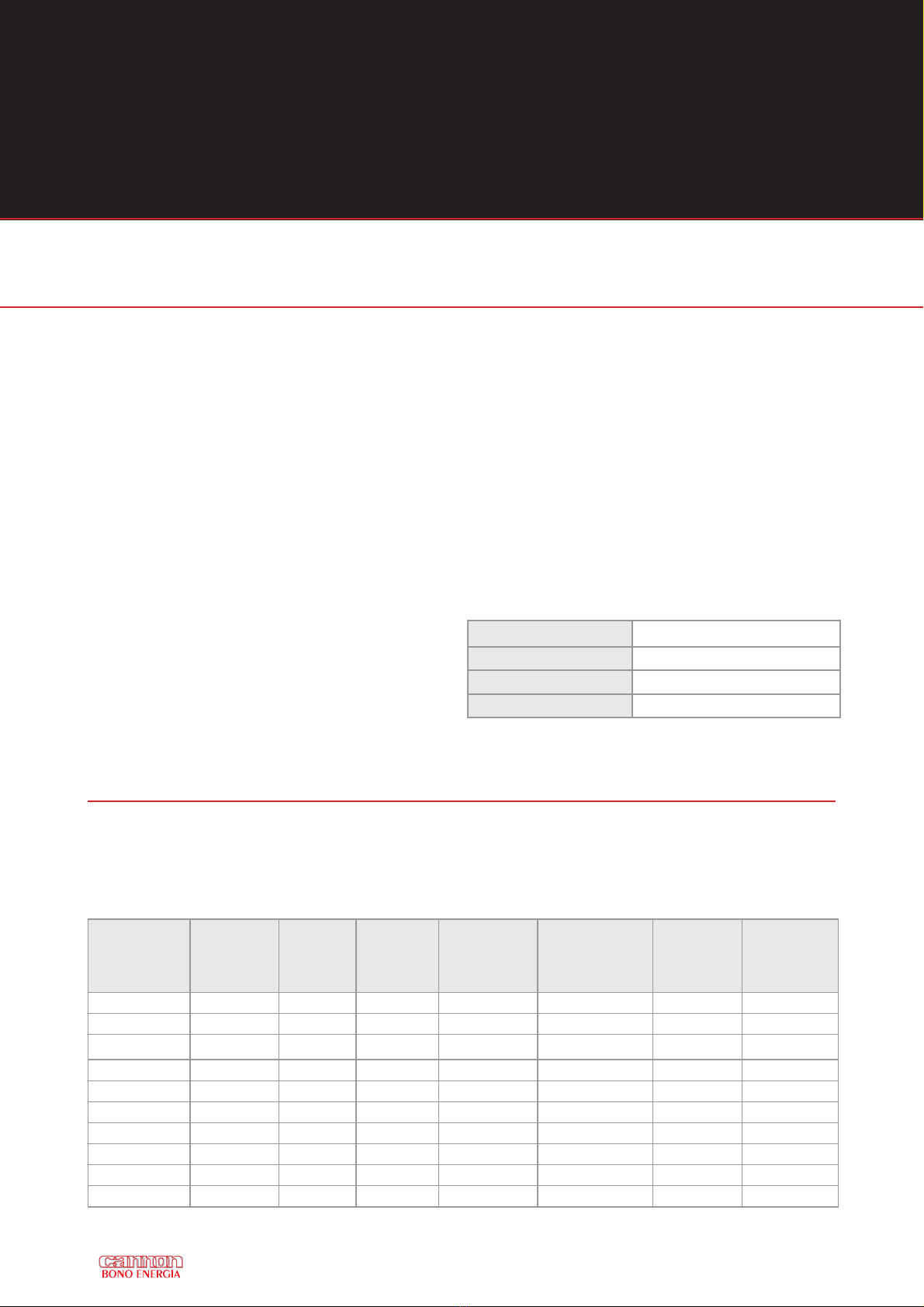

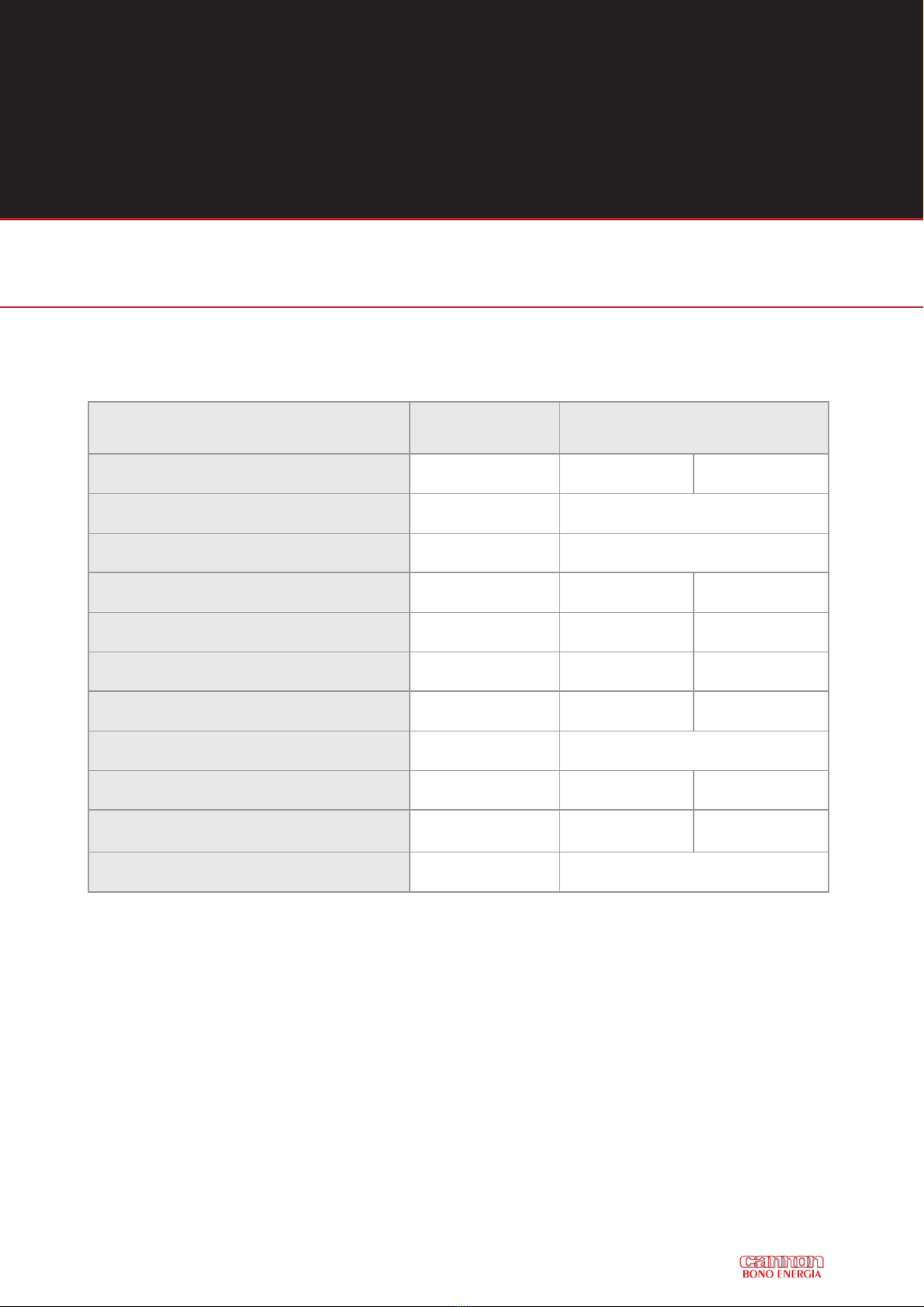

3. TECHNICAL SPECIFICATIONS - CAPACITY AND CONSUMPTION

Table 1

Technical Specifications of steam generator UNI-MATIC UM.*

UNIMATIC – TECHNICAL DATASHEET

Features Unit UM 30 UM 50 UM 100 UM 150 UM 200 UM 300

Steam production Kg/h 300 500 1.000 1.500 2.000 3.000

Design pressure bar 11,7 11,7 11,7 11,7 11,7 11,0

Max working pressure bar 10.0 10.0 10.0 10.0 10.0 9.0

TOTAL ELECTRIC POWER

Heavy fuel oil KW 4,3 5,3 9,6 12,9 16,0 24,0

Natural gas or diesel oil KW 2,3 2,3 4,6 5,9 7,0 12,0

FUEL CONSUMPTION AT 100% OF THE LOAD

Heavy fuel oil Kg/h 21,1 35,1 70,3 105,4 140,6 210,9

Natural gas Nm3/h 24,1 40,1 80,2 120,3 160,4 240,6

Diesel oil kg/h 20,1 33,4 66,8 100,3 133,7 200,5

FUEL CALORIFIC POWER

Heavy fuel oil Kcal/kg 9.700

8.500

10.200

Natural gas Kcal/Nm3

Diesel oil Kcal/kg

Standard electric

power data 380 V / 50 Hz / 3 phases with neutral

Auxiliaries voltage 220 V

Feeding and boiler

water norm EN 12952 – 12:2003 (up to European standard)

* - These are generalized technical information for all UNI-MATIC range model.

Please ask for specific measures indications and eventual available modifications.

8

3. TECHNICAL SPECIFICATIONS - THERMAL EFFICIENCY

Figure 6

The coefficient of performance (COP) of the boiler UNI-MATIC UM crossed with the load, under different

working pressures. Air preheater not included.

9

Figure 7

A plot of the coefficient of performance (COP) of the boiler UNI-MATIC UM with air preheater.

10

The generator must be supplied with water with

hardness less than 0.1° F made up of the condensation

recovery and the make-up water softened by a

purifier (cation resin) or demineralised. The water

supply must always come from the supply tank; a

direct connection to the mains water or to the purifier

is not allowed.

The suction piping must be as straight as possible

and its diameter must be larger than that of the

connection on the pump (see connection diagram).

The supply water must be at a temperature of at least

70° C as lower temperatures cause deterioration in

the generator coils.

If the water temperature is lower than the value

indicated above the supply water must be heated.

The tank capacity must be adequate for the boiler

capacity and normally at least the same as the

consumption of an hour operation at maximum load.

The tank must be fitted with a drainage tube with

cock direct to the sewers for regular drainage and to

empty the tank for cleaning.

Water pump must not suck from the bottom of the

tank but slightly higher to avoid the entry of impurities.

If the oxygen scavenger is required please refer to

the technical specifications of the product in use.

Total hardness Less than 0,05 °F

pH 8.5-10.0

Alkalinity Max 1000 ppm

Silicone (Si O2) Max 100 ppm

Table 2

Water supply specifications. In order to maintain

its best performance the steam generator must

be supplied with water conforming to the below

specifications.

Table 3

Minimum pressure / suction head for water. The tank must be raised up and have sufficient head for correct

pump operation and to avoid phenomena of cavitation due to insufficient supply

Temperature

°C

Had Height

mH2O

Pressure

bar

Pressure

MPa

Temperature

°C

Liquid Column

Height

mH2O

Pressure

bar

Pressure

MPa

0 0.00 0.00 0.00 50 1.25 0.12 0.012

5 0.00 0.00 0.00 55 1.75 0.17 0.017

10 0.00 0.00 0.00 60 2.00 0.20 0.02

15 0.20 0.02 0.002 65 2.50 0.25 0.025

20 0.20 0.02 0.002 70 3.00 0.29 0.029

25 0.25 0.02 0.002 75 4.00 0.39 0.039

30 0.50 0.05 0.005 80 5.00 0.49 0.049

35 0.80 0.08 0.008 85 6.00 0.59 0.059

40 0.90 0.09 0.009 90 7.00 0.69 0.069

45 1.00 0.10 0.01 95 9.00 0.88 0.088

3. TECHNICAL SPECIFICATIONS - WATER SUPPLY REQUIREMENTS

11

Table 4

Feedwater Quality Requirements for best UNI-MATIC UM operation and preservation

(a) with copper alloys in the system the pH value shall be maintained in the range be from 8.7 to 9.2

(b) with softened water pH value >7.0 - see the manual of the boiler

(c) If the operating pressure is <1 bar, the max total acceptable hardness should be 0.05 mmol / l

(d) Instead of observing this value at intermitted operation or operation without deareator if forming agents and/or excess

of oxygen scavenger shall be used.

(e) Organic substances are generally a mixture of several different compounds. The composition of such mixtures and

behaviour of their individual components under the conditions of boiler operation are difficul to predict.

Organic substances may be decomposed to form carbonic acid or other acidic decomposition products which increase the

acid conductivity and cause corrosion or deposits. They also may lead to foaming and/or priming which shall be kept as

low as possible.

PARAMETERS UNIT FEED WATER PROPERTIES

ACCORDING TO EN 12953

OPERATING PRESSURE (X) bar (= 0,1 MPa) 0,5 < X< 20 X > 20

APPEARANCE / Clean, free from suspended solids

DIRECT CONDUCTIVITY AT 25°C μS/cm Not specified

pH VALUE AT 25 °C (a) / >9,2 (b) >9,2 (b)

TOTAL HARDNESS (Ca + Mg) mmol/l <0,01 (c) <0,01

IRON (Fe) CONCENTRATION mg/l <0,3 <0,1

COPPER (Cu) CONCENTRATION mg/l <0,05 <0,03

SILICA (SiO2) CONCENTRATION mg/l Not specified

OXYGEN (O2) CONCENTRATION mg/l <0,05 (d) <0,02

OIL/GREASE CONCENTRATION

(see EN 12953-6) mg/l <1 <1

ORGANIC SUBSTANCES CONCENTRATION / See footnote (e)

12

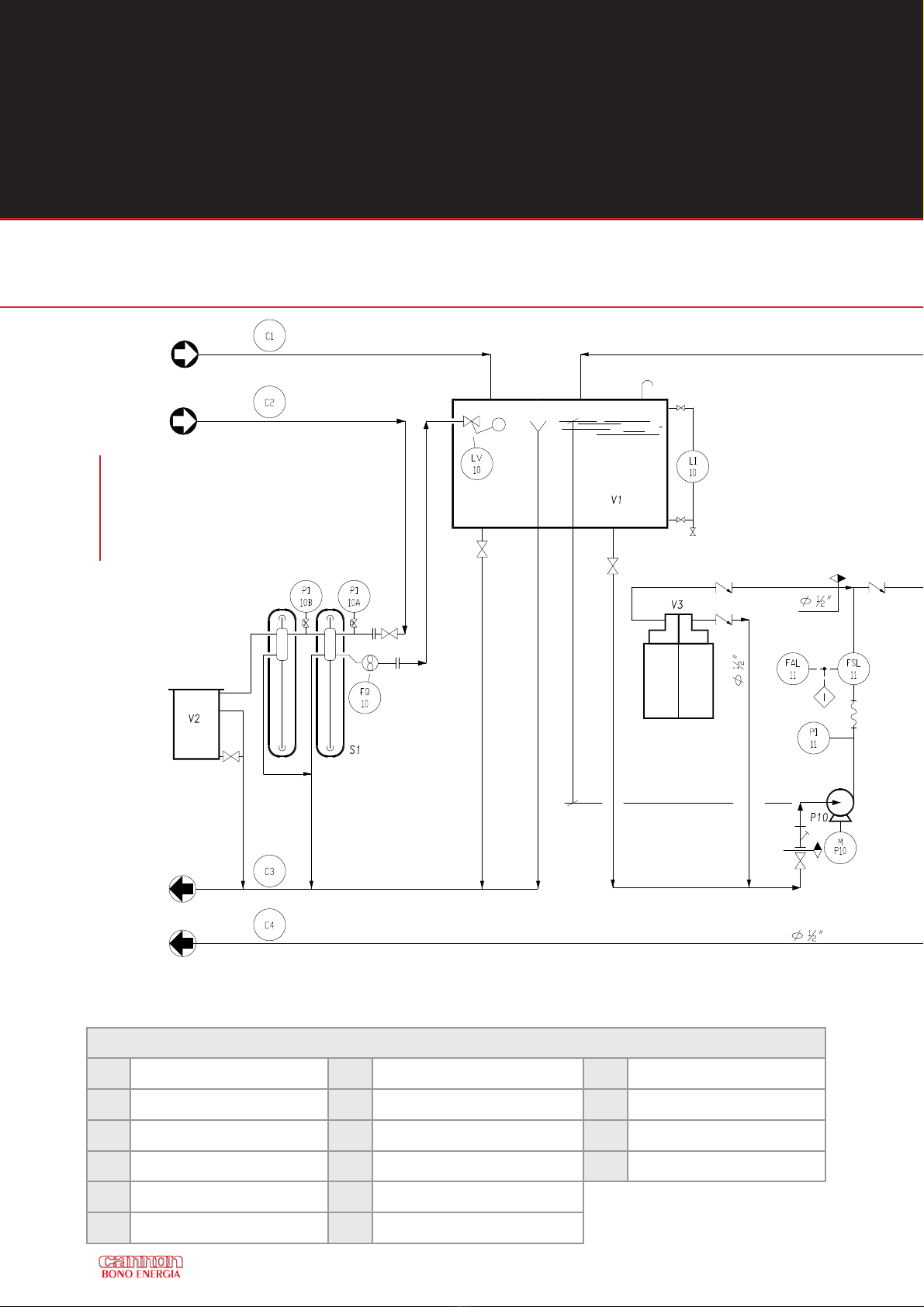

4. P&ID

UM – P&ID Elements Description

B1 Steam Generator UM S1 Water Softener C3 Drain to Sewer Pipe

L1 Chimney V1 Feed Water / Condensate Tank C4 Drain to Hot Pit Pipe

QE Electrical Cabinet V2 Brine Tank C5 Steam to User Pipe

D1 Instrument Header V3 Chemical Dosing Station F1 Feed Fuel Pipe

D2 Steam Separator C1 Condensate Return Pipe

P10 Feed Water Pump C2 Feed Water Pipe

Figure 8

The data processing schemes are

standardized to the entire UNI-

MATIC range; further measurements

and modifications are available on-

demand.

13

UM – P&ID Ancillaries Symbols Meaning

LV Level Valve MMotor TI Temperature Indicator

LI Level Indicator PAH Pressure Alarm High TAH Temperature Alarm High

PI Pressure Indicator PAHH Pressure Alarm High Above PAH TAHH Temperature Alarm High Above TAH

FQ Flow Indicator Totaliser PSH Pressure Switch High TSH Temperature Switch High

FAL Flow Alarm Low PSHH Pressure Switch High Above PSH TSHH Temperature Switch High Above TSH

FSL Minimum Flow Switch PSV Pressure Safety Valve

SUPPLY LIMIT

CANNON BONO CUSTOMER

14

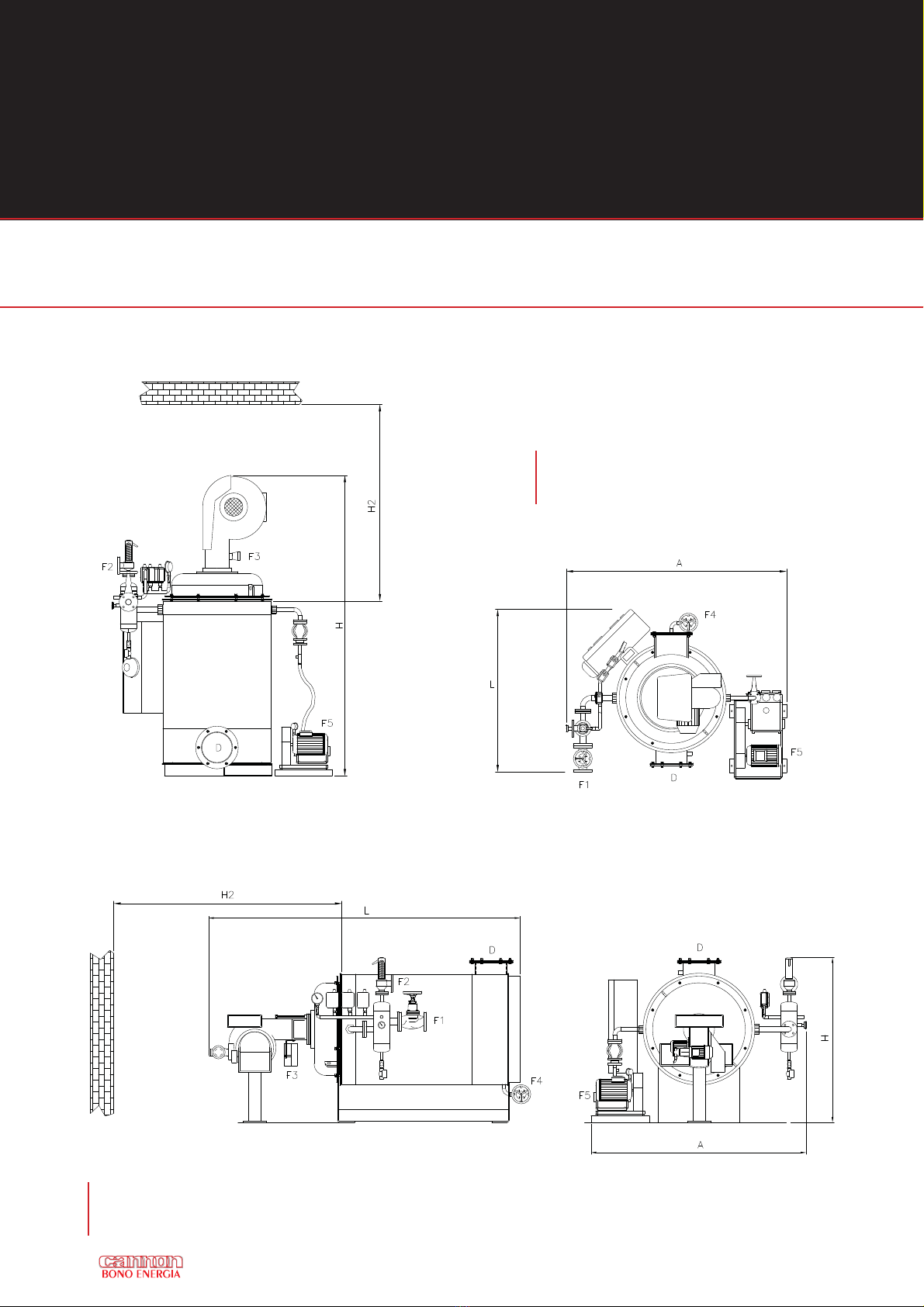

5. DIMENSIONS AND CONNECTIONS

Figure 10

Steam generator UNI-MATIC UM Horizontal

version steam generator overall dimensions

Figure 9

Steam generator UNI-MATIC UM vertical

steam generator overall dimensions

15

Table 5

Dimensions of flash coil steam generators UNI-MATIC UM. These dimensions are generalized to the entire

range of models UNI-MATIC. Measurement and modification are available on-demand.

OVERALL DIMENSIONS AND CONNECTIONS OF STEAM GENERATORS UNI-MATIC UM

MODEL UM 30 UM 50 UM 100 UM 150 UM 200 UM 300

VERTICAL VERSION DIMENSIONS

L Length mm 1450 1550 1800 1900 2100 2700

A Width mm 1350 1350 1700 1700 1800 2000

H Height mm 2100 2100 2660 2750 3400 3750

HORIZONTAL VERSION DIMENSIONS

L Length mm 2100 2100 2660 2750 3400 3750

A Width mm 1350 1350 1700 1700 1800 2415

H Height mm 1450 1550 1800 1900 2100 2385

GENERAL TECHNICAL DATA

D Stack connection mm 125 162 263 314 346 400

F1 Steam outlet DN 32 32 50 50 65 80

PN 16 16 16 16 16 16

F2 Safety valve DN 20/40 20/40 20/40 25/40 25/40 32/50

PN 25/16 25/16 25/16 25/16 25/16 25/16

F3 Natural gas connection 1”G 1 ½”G 2”G 2”G 2”G 2 ½”G

F4 Coil drain outlet ½”G ½”G ½”G ½”G ½”G ½”G

F5 Feed water inlet 1 ¼”G 1 ¼”G 1 ¼”G 1 ½”G 1 ½”G 2”G

H2 Coil extraction distance mm 1100 1300 1750 1950 2000 2700

Total volume l 33 49 79 110 240 271

Pipes diameter mm 33.7 33.7 33.7 33.7/38 33.7/51 38/51

Heating surface m26 8.8 14 18 32 34

Water capacity l/h 345 575 1150 1750 2300 3300

Standard feeding

water temperature °C 70÷95*

Empty weight t 1.2 1.2 1.5 2.0 2.8 3.1

* - In case of feed water temperature above 70 °C, please contact Bono Energia technical specialists for pump flow

section configuration

16

6. GENERATOR LAYOUT

Figure 11

Typical layout of steam gen-

erator UNI-MATIC UM on a

portable device; the trailer is

equipped with a UNI-MATIC

UM, two feed water pumps, a

feed water/condensate return

tank, a booster pump to create

a head for the hot waters de-

riving from condensation and

a chimney.

The trailer hook is orientable.

1 Steam Generator UM 6 Booster Pump

2 Burner 7 Feed Water Pump

3 Steam Generator Chimney 8 Trailer

4 Feed Water/Condensate Tank 9 Trailer Hook

5 Tank Level Indicator

17

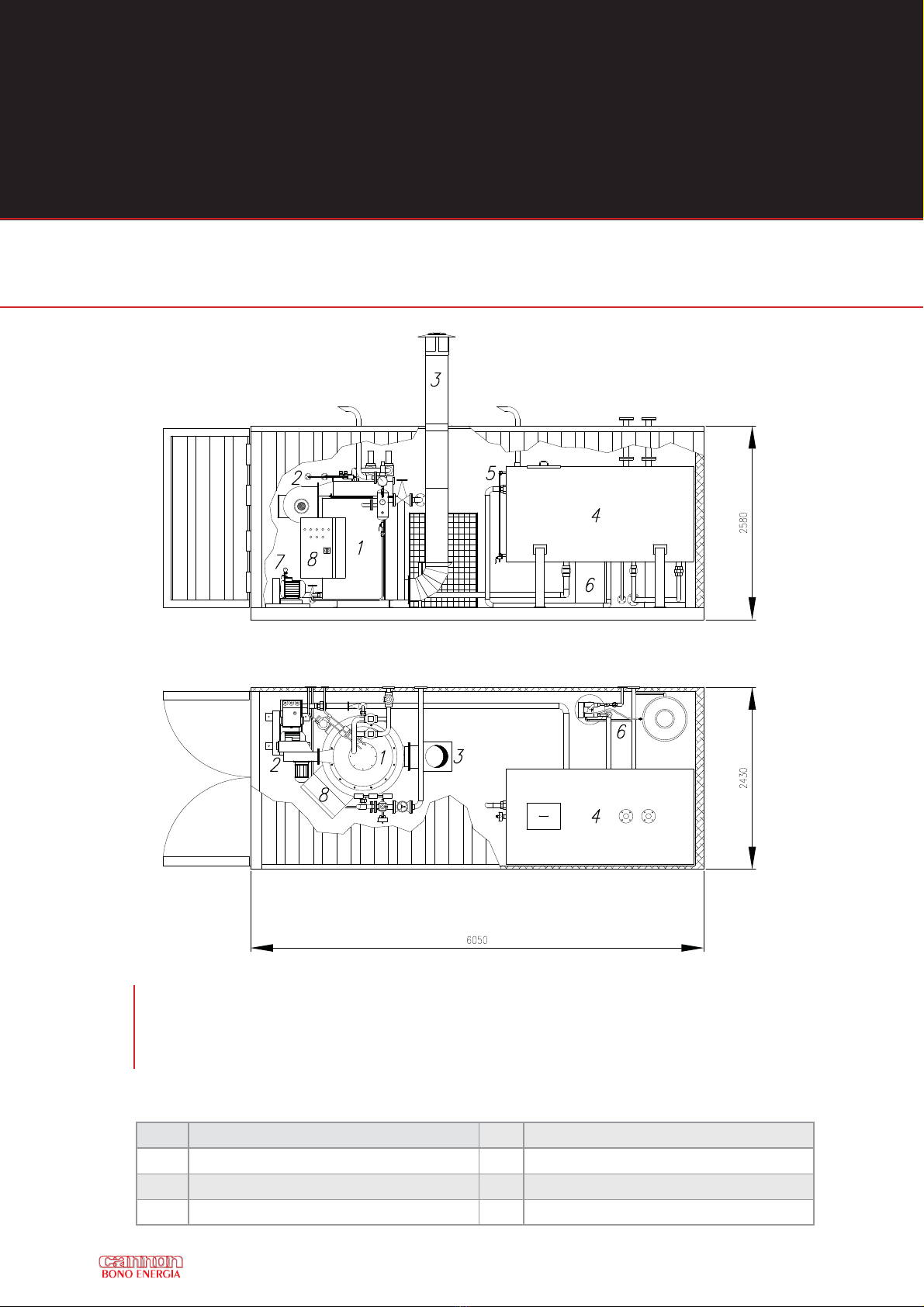

Figure 12

Layout of a UNI-MATIC UM in a container; the container is

equipped with a UM steam generator, an electrical cabinet

mounted on the container’s wall, one feed water pump, a feed

water/condensate return tank, a chimney and a water softening

system.

1 Steam Generator UM 5 Tank Level Indicator

2 Burner 6 Water Softening System

3 Steam Generator Chimney 7 Feed Water Pump

4 Feed Water/Condensate Tank 8 Electrical Cabinet

18

Figure 13

Layout of a steam generator UNI-MATIC UM in a container; the

container is equipped with a UM, an electrical cabinet mounted

on the generator, one feed water pump, a feed water/condensate

return tank, a chimney and a water softening system.

1 Steam Generator UM 5 Tank Level Indicator

2 Burner 6 Water Softening System

3 Steam Generator Chimney 7 Feed Water Pump

4 Feed Water/Condensate Tank 8 Electrical Cabinet

6. GENERATOR LAYOUT

19

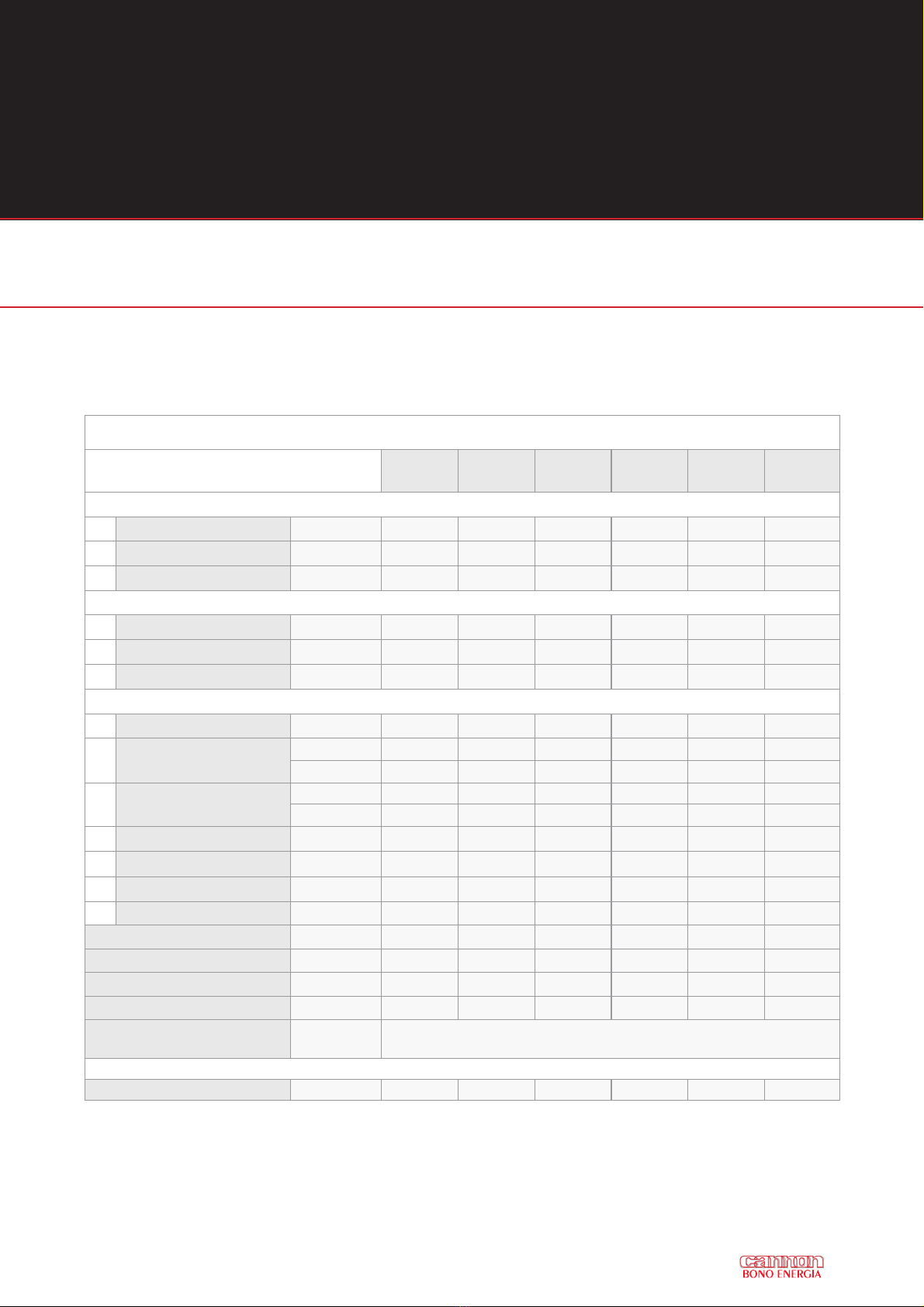

Table 6

UNI-MATIC range model matching with Riello burners for the three main fuels on the market, for further de-

tails and other fuels available please ask.

Steam generator UNI-MATIC models

UM 30 UM 50 UM 100 UM 150 UM 200 UM 300

Steam capacity (kg/h) 300 500 1000 1500 2000 3000

Riello burners - natural gas or LPG - 1 or 2 stages regulation

Riello type RS 34/1 tc RS 44/1 MZ

tc RS 100 tc RS 130 tc RS 190 tc GAS 9/2 tc

Regulation type 1 stage 1 stage 2 stages 2 stages 2 stages 2 stages

Riello burners natural gas or LPG modulating regulation

Riello type - - RS 100/M tc RS 130/M tc RS 190/M tc GAS 9 P/M tc

Minimum gas pressure

at train (mbar) 50 50 50 50 60 100

Riello burners – diesel oil – 1 or 2 stages regulation

Riello type RL 34/1 tc RS 38 tc RL 100 tc RL 130 tc RL 190 tc PRESS 300

P/G tc

Regulation type 1 stage 1 stage 2 stages 2 stages 2 stages 2 stages

Riello burners – diesel oil – modulating regulation

Riello type - - RL 100/M tc RL 130/M tc RL 190/M tc PRESS 300

P/G tc

Riello burners – heavy fuel oil *– 1 or 2 stages regulation

Riello type P45/N ECO P60/N ECO P100/N ECO P140 T/N

ECO

P200 T/N

ECO

P300 T/N

ECO

Regulation type 1 stage 1 stage 2 stages 2 stages 2 stages 2 stages

Riello burners – heavy fuel oil *– modulating regulation

Riello type - - P140 P/N P140 P/N P200 P/N P300 P/N

* = heavy fuel oil max viscosity considered is 7°E at 50°C, please ask for higher viscosities.

20

GENERAL COMMENTS

The Generator must be installed on a rigid, levelled base, preferably on a concrete slab, in a room which

ensures adequate access to all the equipment and for the personnel.

The boiler room must comply with the prevention standards in force and must be dry, clean and well ven-

tilated.

Good ventilation is essential to supply enough air for combustion and a temperature which is suitable for

the regular operation of the electrical equipment, in any case not higher than 35-40°C.

The boiler room must have at least two constantly open air inlets, one of which as close to the fan as pos-

sible.

The boiler room must be high enough for the coil to be taken out.

Connections to be made

Make the following connections to start the generator:

• Chimney pipe to drain the fumes from the boiler outlet to the outside.

• Steam piping at the distribution system.

• Water piping at the water/condensation collection tank.

• Humidity separator (if fitted) drainage piping.

• Safety valve drainage piping.

• Boiler drainage piping.

• Fuel piping to the burner.

• Electricity to the panel.

!INSTALLATION OUTSIDE IS ABSOLUTELY FORBIDDEN, EVEN UNDER A ROOF

UNLESS THE GENERATOR HAS BEEN SPECIALLY MADE FOR THIS PURPOSE

!DURING INSTALLATION ALWAYS MAKE THE HYDRAULIC CONNECTIONS FIRST

AND THEN THE ELECTRICAL CONNECTIONS.

7. INSTALLATION

This manual suits for next models

5