Bores PROTHO User manual

INSTRUCTION MANUAL

Peristaltic Pump for cleansing agents

PROTHO

2

PROTHO Technical Manual Bores Group S.r.l.

(Rev. 01 del 151008)

3

PROTHO Technical Manual Bores Group S.r.l.

Dear Customer, congratulations for having chosen a quality product that will definitely meet your needs. While thanking

you for your choice, we kindly ask you to carefully look at this Instruction manual before using your new peristaltic

metering pump.

INDEX

1 IMPORTANT DIRECTIONS AND RECOMMENDATIONS page 4

2 GENERAL CHARACTERISTICS page 4

2.1 FIELD OF USE page 4

2.2 FUNCTIONING PRINCIPLE page 4

2.3 RATING page 4

3 INSTALLATION page 4

3.1 POSITIONING page 4

3.2 CONNECTING TO THE MAINS SUPPLY page 5

3.3 WATER CONNECTIONS page 5

4 STARTING page 6

4.1 REGULATING THE CAPACITY page 6

5 MAIN CAUSES OF FAILURE TO FUNCTION page 7

6 MAINTENANCE AND CLEANING page 7

6.1 PERIODICAL CHECKS page 7

7 PERIODS OF NON-OPERATION page 7

8 DIRECTIONS FOR THE MAINTENANCE FITTER page 7

9 WARRANTY TERMS page 8

10 TECHNICAL INFORMATION page 9

11 EXPLODED VIEW OF THE METERING PUMP WITHOUT CONTAINER page 10

12 EXPLODED VIEW OF THE METERING PUMP WITH CONTAINER page 11

13 ACCESSORIES AND SPARE PARTS page 12

4

PROTHO Technical Manual Bores Group S.r.l.

1 IMPORTANT DIRECTIONS AND

RECOMMENDATIONS

This instruction manual is an integral part of the

peristaltic metering pump (also more simply

defined in this instruction manual with the terms

pump or device) and must be kept for any future

consultation.

If the device is sold or transferred to another person,

this manual must be handed over to the new user so

that she/he will be informed about its functioning and

the relative directions.

Read the directions contained in this manual

carefully before installing and using the pump.

These directions have been drawn up for safety

during installation, use and maintenance.

Any directions or diagrams that refer to special

models will be supplied enclosed in this manual.

Always remove the plug from the power socket

before proceeding with any maintenance or

cleaning operation.

Any intervention or modification to the electrical

installation that might be necessary, must be carried

out exclusively by skilled and qualified personnel.

This pump is only for the dosage of additives

(detergent or rinse aid) in dishwashing machines.

Any use of the metering pump that is not the

dosage of additives in dishwashing machines is to

be considered improper.

It has been designed to be used by adults, therefore

stop children getting close to it with the intention of

playing.

As well as invalidating all forms of the warranty,

modifying or trying to modify this device is extremely

dangerous.

In order to guarantee the efficiency of the device

and for it to function correctly, you must follow

the Manufacturer’s instructions and have the

maintenance done by professionally qualified

personnel.

Never try to repair it by yourself because as well as

being dangerous, the intervention of people who are

not experts can cause or worsen the damage. If there

is a fault, contact the distributor who sold it to you or

the Manufacturer, who will recommend the nearest

Service Centre. We suggest you always ask for

original spare parts only.

When the pump has to be demolished, we remind you

to make it inoperative removing the power cord (after

having disconnected it from the mains supply, of

course).

We also remind you to:

∗Avoid throwing the components of the metering

pump away into the environment.

∗Arrange for the disposal and the recovery of the

materials in accordance with the relevant national

laws in force.

For this reason we urge you to give maintenance

work and recovery of any replaced components

exclusively to authorised service engineers.

2 GENERAL CHARACTERISTICS

2.1 FIELD OF USE

The peristaltic pumps in the “PROTHO” series are

available in two versions:

-without the container, for use inside dishwashers.

-With the container, for external use.

The functional characteristics of the metering pumps

with the container is, if necessary, completed with

different technical solutions that allow a practical and

effective regulation of the capacity.

2.2 FUNCTIONING PRINCIPLE

Peristaltic pumps are the best that exist in the

metering pumps sector as they do not have valves,

which cause considerable problems.

The functioning principle is based on the elasticity of

the membrane pipe for pumping and on the

alternating sliding compression of the rollers

supported by the central rotor of the device. This

support, driven by a motor reducer, whilst turning,

puts the suction and injection functions into operation

simultaneously.

Suction occurs because of depression, after the

passage of the rollers, thanks to the elasticity of the

pipe, while injection occurs following the sliding

compression of the rollers on the pipe which push the

product towards the outlet.

2.3 RATING

The voltage, frequency and capacity values are

shown on the data plate. Refer to this for all checks

and verifications.

3 INSTALLATION

When delivered the metering pump is protected by a

cardboard packaging (fig. 1).

Open the cardboard packaging, avoiding the use

of unsuitable tools such as knives, penknives,

screwdrivers, etc. and make sure the device is

intact. If you have any doubts about this, DO NOT

USE IT and contact the Distributor or the

Manufacturer who sold it to you.

None of the packaging (bags, cardboard, polystyrene

foam, staples, straps, etc.) must be left in the reach of

children as they are potential sources of danger.

Skilled and qualified personnel must carry out the

installation observing the national laws in force

and following the Manufacturer’s instructions.

Incorrect installation can cause damage to the

environment, animals, people and objects, for which

the Manufacturer cannot be considered responsible.

3.1 POSITIONING

The device has been designed and manufactured to

be installed internally or externally (models with

5

PROTHO Technical Manual Bores Group S.r.l.

container) to a dishwashing machine that controls it

in order to perform the necessary functions.The

device

must be positioned maintaining suitable distances

from the other components of the machine in order to

allow ease of maintenance. This expedient must also

prevent accidental leaks of the product from the

pump, following the breakage of the pumping pipe,

from damaging the surrounding components.

3.2 CONNECTING TO THE MAINS SUPPLY

The electrical safety of this device is only

obtained when it is installed in the dishwashing

machine observing the national safety laws in

force.

The dishwashing machine must be installed by skilled

and qualified personnel.

The Manufacturer cannot be considered

responsible for any damage caused by the

incompetence or carelessness of the installer.

Check that the electrical capacity of the system is

adequate for the maximum power of the metering

pump shown on the data plate.

The installer must also make sure that the cross-

section of the wires in the electrical system is suitable

for the absorbed power of the device.

The peristaltic metering pump for internal fitting

has no switch, therefore the supply voltage

causes the device to start immediately.

The installer must also find the connection points for

the feed to the peristaltic metering pump.

To feed a metering pump for detergent a parallel

connection to the rinsing solenoid or an equivalent

point must be made.

While for a metering pump for rinse aid a connection

to the washing pump of the dishwashing machine or

an equivalent point must be made.

If the detergent metering pump is supplied with

conductimetric regulation, a detergent sensor will

have to be installed and a 12.5 mm Ø hole drilled in

the dishwasher tank, below the water level. (If the

machine that needs the additive is already in service,

remember to empty the washing tank before carrying

out the above operation). After drilling the hole

position the sensor with the gasket for the hole and

tighten the relative nut from the outside of the tank.

Do not overtighten in order not to damage the various

components.

Now connect the wires that come out of the pump

container:

∗one to earth (to the casing of the machine)

∗the other to the fastener on the detergent sensor

previously installed.

We remind you to protect the metering pump feed

wires making sure that they do not get squashed or

damaged in any way.

Read the following directions carefully

Using the metering pump, as with any other electrical

device, entails complying with some fundamental

rules, such as:

∗Do not touch it with damp or wet hands and feet

∗Do not use it when you are bare-footed

∗Do not use extension cables in rooms used as

kitchens, bathrooms or shower rooms

∗Never pull the power cable to disconnect it from

the mains supply

∗Do not let children or mentally incompetent people

use it.

Before carrying out any cleaning or maintenance

operations disconnect the machine that controls

the metering pump from the electrical supply and

remove the plug from the power socket.

If there is a fault on the device or it functions

poorly, turn it off following the procedure

described above and do not carry out any

improvised repairs or direct interventions.

Instead, contact professionally qualified

personnel only and demand the use of only

original spare parts. Failure to comply with what

is written above, besides invalidating all forms of

the warranty, can seriously jeopardise the correct

functioning of the device.

3.3 WATER CONNECTIONS

This peristaltic metering pump is only meant for

the dosage of additives in dishwashing

machines.

Skilled and professionally qualified personnel must

make the water connections following the

Manufacturer’s instructions and using the

components supplied in the kit specifically for

installation.

These connections are divided into two distinct

stages:

1) Suction circuit

2) Injection circuit

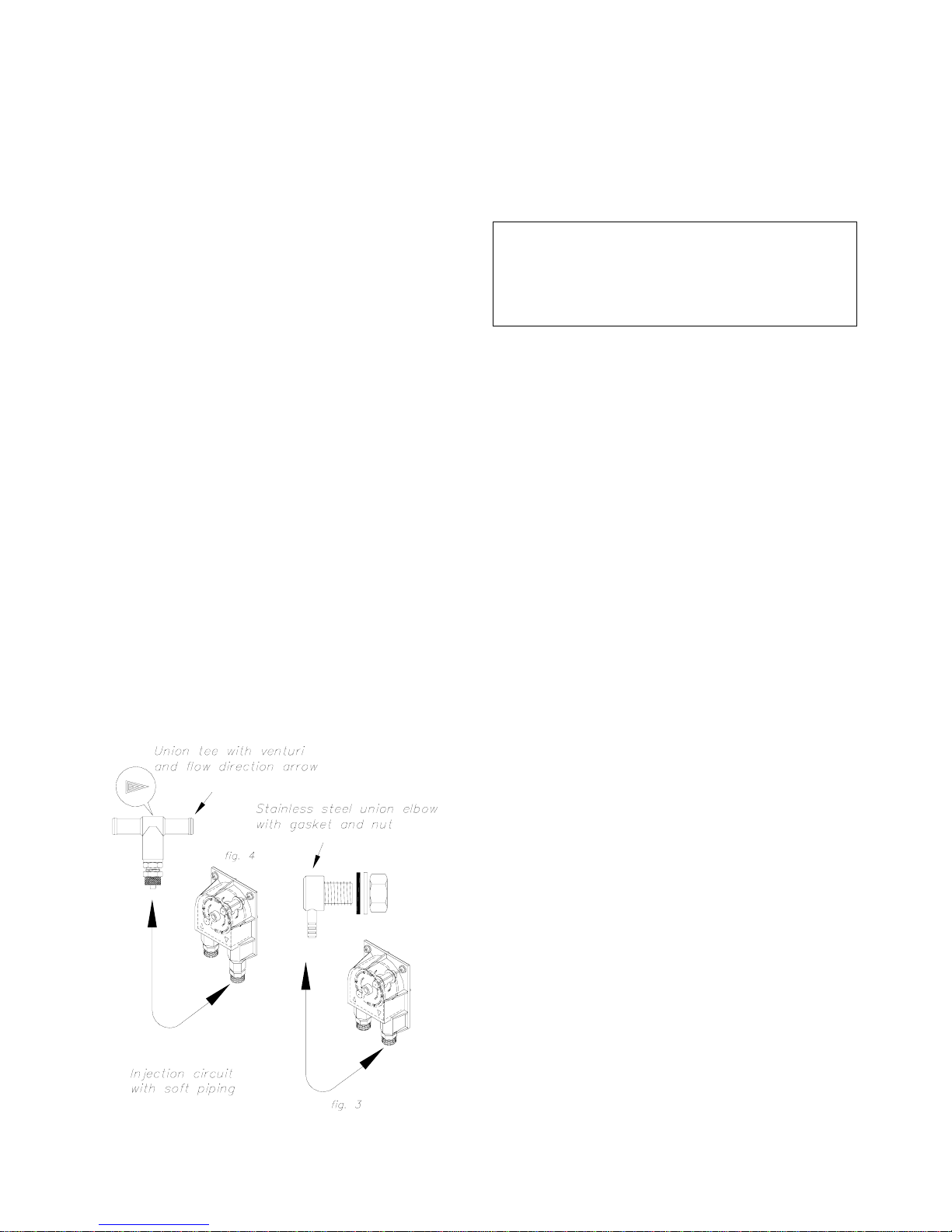

1) Connecting the suction circuit (fig. 2)

- Connect the suction pipe to the pipe fitting (see

indicating arrow) and then reach the tank with

the product that has to be sucked up with the

other end.

- Cut off any excess pipe and install the bottom

filter provided.

- Then put the bottom filter into the tank.

2) Connecting the injection circuit

Depending on the product to be injected, connecting

the injection circuit is divided into:

a) Injecting the detergent

b) Injecting the rinse aid

6

PROTHO Technical Manual Bores Group S.r.l.

a) Connecting the detergent injection

circuit (fig. 3)

- To install the relevant pipe fitting, drill a 12.5 mm

Ø hole in the tank above the water level in a

favourable position.

- Push the threaded part of the union elbow through

the previously drilled hole from the outside of the

tank (if necessary use a file to remove any burrs

that might prevent the gasket from sealing).

- Put the gasket on the thread of the union elbow

from the inside of the tank and then carefully

tighten the relevant bolt. Do not overtighten in

order not to damage the components of the union

elbow.

- Connect the pump’s injection pipe fitting to the

union elbow previously installed in the tank using

the special pipe supplied.

a) Connecting the rinse aid injection circuit

(fig. 4)

When there is this type of installation you have to

identify the ideal point for fitting the components,

considering their dimensions and easy access for

being able to install them readily.

- Remove the rubber pipe into which the product

will be injected.

- Push the end of the previously cut pipe onto the

union tee (T Venturi) making sure that the water

flow follows the direction stamped on the union

tee itself.

- Block the rubber pipes previously fitted onto the

union tee with two metal clamps (not supplied).

If the dishwashing machine is already fitted with a

special injection pipe fitting, a rinse aid injection valve

that allows you to eliminate the operations described

above, is available on request.

- Using the pipe supplied (made of polyethylene)

connect the delivery pipe fitting of the pump to the

injection pipe fitting, with a nonreturn valve,

locking the threaded locking rings carefully.

4 STARTING

Once the electrical and water connections of the

metering pump are complete you can proceed to

starting it. When starting the pump for the first

time, the dishwashing machine has to perform

several washing cycles on empty to allow the

device to fill the pipes in the injection circuit.

This snag can be overcome by manually priming the

pump as follows:

ATTENTION!!

This operation is valid only for models with

asynchronous motors (motors without brushes).

On the other hand in the other models, with motor in

continuous cycle (with brushes), it is NOT POSSIBLE

to make this operation.

- Take the utmost care to check the direction of

rotation of the pump, since an incorrect manoeuvre

could irreparably damage the motor reducer of the

device.

- Turn the rollers support rotor in the direction of

rotation of the pump (see arrow) using a 6 mm

setscrew (Allen) wrench in the hexagonal hole on

the device until the circuit is completely full (fig. 5).

This operation must be carried out by skilled and

qualified personnel only when the pump is

started for the first time and after each time the

pumping pipe is replaced.

- Check that there are no leaks from the water

connections.

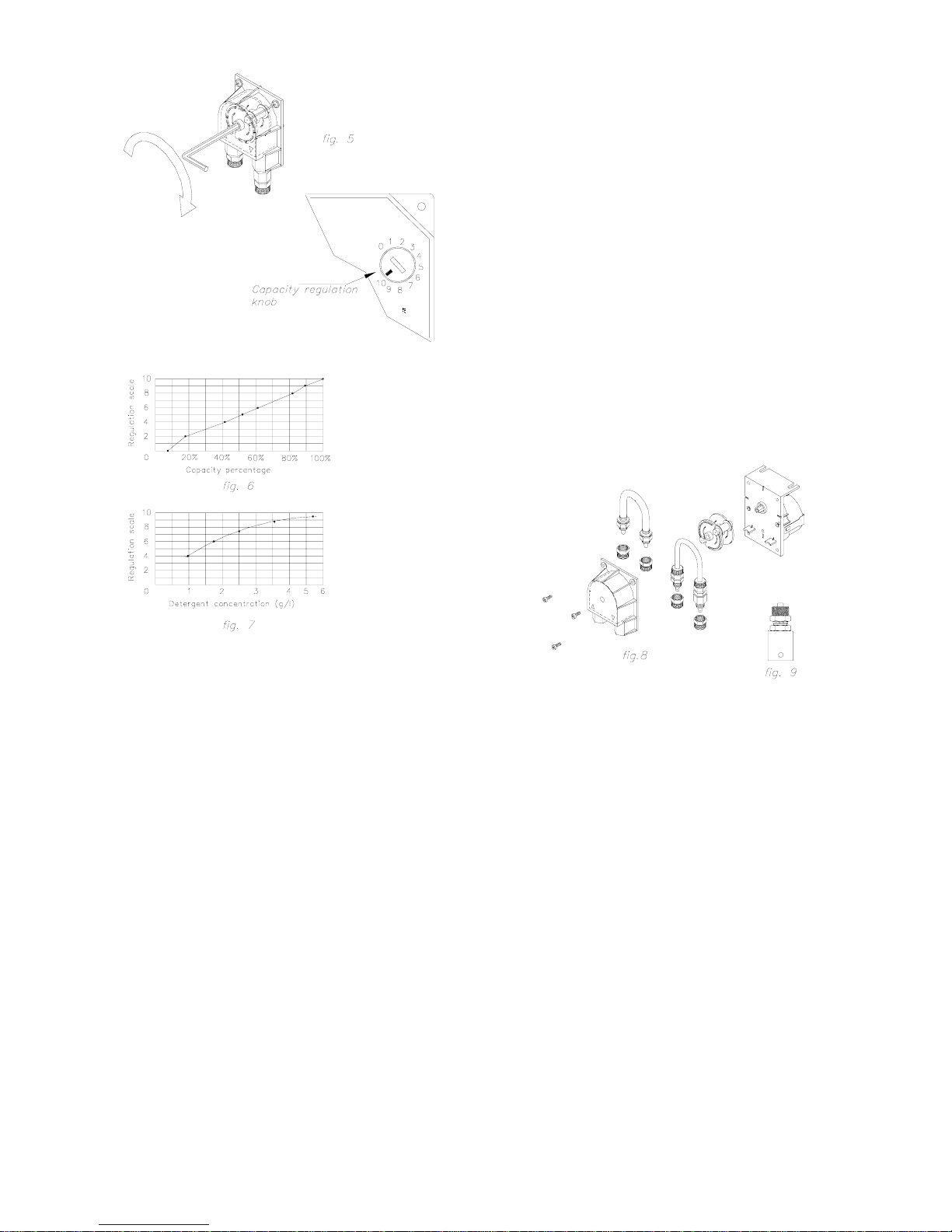

4.1 REGULATING THE CAPACITY

The functional characteristics of the metering pump

are completed with some technical solutions:

- intermittent electronic regulation (fig. 6)

this regulation allows you to vary the capacity of the

pump quickly and rapidly by turning a special knob

on the front of the container of the device.

- conductimetric electronic regulation (fig. 7)

this regulation, on the other hand, allows you to keep

the concentration of the detergent in the water of the

dishwasher’s washing tank constant. To increase or

decrease the dosage, turn the knob on the front of

the container of the metering pump manually.

Specialised personnel must do these regulations

as several checks must be done on site, such as:

the type of detergent used and any hardness in

the water, etc.

7

PROTHO Technical Manual Bores Group S.r.l.

5 MAIN CAUSES OF FAILURE TO

FUNCTION

If the additive is not injected the User must verify and

check:

- whether there is any of the product to be

consumed in the storage tank

- whether the filter is blocked

- whether the electric current is on

If faults occur or are found that are different to the

above, such as:

- difficulty in sucking up the product to be

injected

- rapid and continuing emptying of the suction

pipe after each functioning

- breakage of the pumping pipe

- breakage of the motor reducer

- breakage of the electronic card

It is a good idea to contact a Service Centre as

maintenance is necessary.

For a rapid and efficient intervention it is important

when calling to indicate precisely the model of the

pump, which can be seen on the data plate.

6 MAINTENANCE AND CLEANING

Before carrying out any type of maintenance

work on the device you must turn off the power

and remove the plug from its socket.

The component that needs maintenance is:

- the pumping pipe (fig. 8)

the efficiency of the pump is linked to this

component so it must be periodically replaced, at

least every 3 months, in order to guarantee a

constant capacity to the device itself. This also

prevents the pipe from breaking through wear.

Maintenance on this component must be carried out

by competent and professionally qualified personnel

from a Service Centre and demanding the use of

original spare parts.

The component that needs cleaning is:

- the suction filter (fig. 9)

The filter will have to be periodically washed in case

the additives used contain sediments that prevent

the product being sucked up to the pump itself.

The state of the filter must be checked each time

the pump is refilled with the product. When cleaning

the filter protect your hands with rubber gloves.

6.1 PERIODICAL CHECKS

The device must be periodically checked and if

necessary refilled with the consumed product. Also

verify that there are no leaks in the water circuit.

7 PERIODS OF NON-OPERATION

If a long period of non-operation is expected,

when the pump is going to be used again an extra

repair must be carried out, replacing the pumping

pipe (fig. 8)

This operation is necessary because the product that

has remained in the pipe tends to solidify removing

the natural elasticity of the pumping pipe.

Skilled and qualified personnel must carry out this

maintenance.

8 DIRECTIONS FOR THE

MAINTENANCE FITTER

All the operations that entail working on circuits

or internal parts, for the performance of which

electrical protection devices have to be removed,

must be carried out with the device stopped and

only after having turned off the voltage.

8

PROTHO Technical Manual Bores Group S.r.l.

The device can only be energised for starting once

the operations are concluded and once you have

moved away from the device

. 9 WARRANTY TERMS

•This peristaltic metering pump (defined in the

following points more simply as pump or

device) is guaranteed for a period of one year

from the date of purchase which is proved by a

document valid for fiscal purposes issued by

the Retailer or the Manufacturer, which shows

the date in which the purchase was made.

•The fiscal document that proves the date of

purchase, issued by the Retailer or the

Manufacturer, must be kept together with this

instruction manual; both must be exhibited to the

technical personnel in the case of work done in the

warranty period.

•Warranty is understood to be the free replacement

or repair of the parts that prove to be defective in

origin or because of manufacturing flaws.

•The user is obliged to pay the “fixed call-out fee”

should she/he require the work to be done at

her/his own home.

•All the parts that prove to be defective due to the

carelessness of negligence in use (failure to comply

with the instructions for the operation of the device),

or incorrect installation and maintenance carried out

by personnel that are not professionally qualified,

transport damages, that is due to circumstances

that in any case cannot be traced back to

manufacturing defects in the device are not covered

by the warranty.

•Work inherent to the installation and the connection

of supply systems as well as the maintenance

mentioned in this instruction manual are also

excluded from the warranty services.

•The warranty is also excluded in all cases of

improper use of the pump.

•The Manufacturer declines all responsibility for

any damages that might, directly or indirectly,

be caused to people, objects and animals as a

result of the failure to comply with the

directions indicated in this instruction manual

and especially those which concern the

directions about the installation, use and

maintenance of the device.

•If the device is repaired at an Authorised Service

Centre or by the Manufacturer, the transport risks

are at the expense of the User.

In any case, the transport costs are understood to

be at the expense of the User.

•In any circumstance the extension of the warranty

in the event that a fault should occur is excluded.

9

PROTHO Technical Manual Bores Group S.r.l.

10 TECHNICAL INFORMATION

Some models in our range of products

Capacity Product

Model cc/” l/h

Tube

diameter Pressur

bar Detergent Rinseaid

PD1.5 0.41 1.5 6.4x1.6 0.1 *

PD2.0 0.56 2.0 6.4x1.6 0.1 *

PD3.3 0.92 3.3 6.4x1.6 0.1 *

PB0.4 0.11 0.4 3.2x6.4 3 *

PD3.3E 0.92 3.3 6.4x1.6 0.1 *

PD3.3ER 0.92 3.3 6.4x1.6 0.1 *

PB1.0E 0.28 1.0 3.2x6.4 3 *

PB1.0ET 0.28 1.0 3.2x6.4 3

PDF2.0 0.56 2.0 6.4x1.6 0.1 *

PBF0.4 0.11 0.4 3.2x6.4 3 *

PDE3.3 0.92 3.3 6.4x1.6 0.1 *

PDE4.0 1.12 4.0 6.4x1.6 0.1

PDER3.3 0.92 3.3 6.4x1.6 0.1 *

PBE1.0 0.28 1.0 3.2x6.4 3 *

PDE8.0 2.24 8.0 6.4x1.6 0.1 *

PDE8.024 2.24 8.0 6.4x1.6 0.1 *

PDER8.024 2.24 8.0 6.4x1.6 0.1 *

PBE2.0 0.56 2.0 3.2x6.4 3 *

PBE2.024 0.56 2.0 3.2x6.4 3 *

PDS4.0 1.12 4.0 6.4x1.6 0.1 *

PDS8.0 2.24 8.0 6.4x1.6 0.1 *

PDS8.024 2.24 8.0 6.4x1.6 0.1 *

PDBE3/1 0.84 - 0.28 3 – 1 6.4x1.6

3.2x6.4 0.1 – 3 * *

PDBER3/1 0.84 - 0.28 3 – 1 6.4x1.6

3.2x6.4 0.1 – 3 * *

PDSBE8/2 2.24 - 0.56 8 – 2 6.4x1.6

3.2x6.4 0.1 – 3 * *

PDBER8/224 2.24 - 0.56 8 – 2 6.4x1.6

3.2x6.4 0.1 – 3 * *

PDSBE8/224 2.24 0.56 8 – 2 6.4x1.6

3.2x6.4 0.1 – 3 * *

Available with voltages of 220 and 24 V ac – 50/60 Hz

10

PROTHO Technical Manual Bores Group S.r.l.

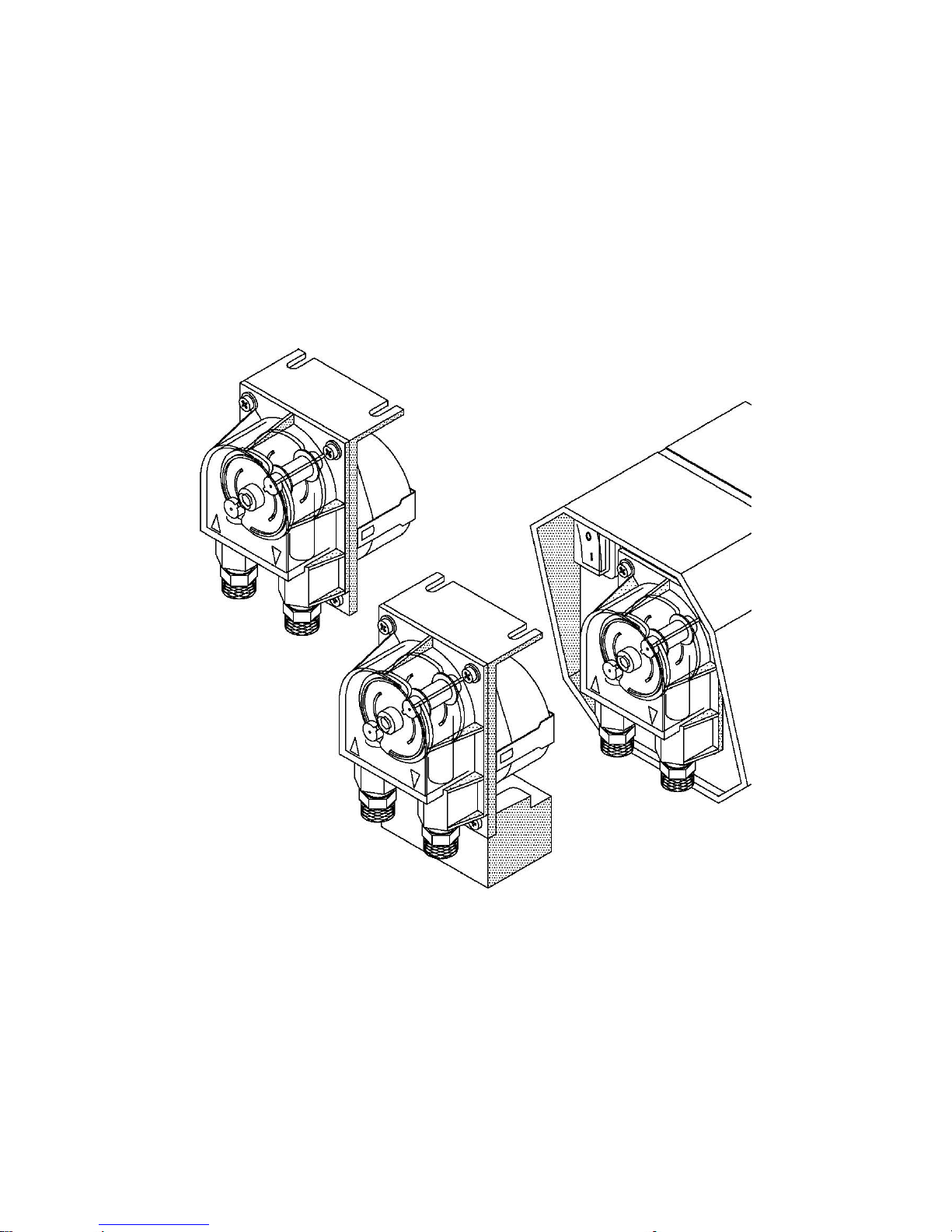

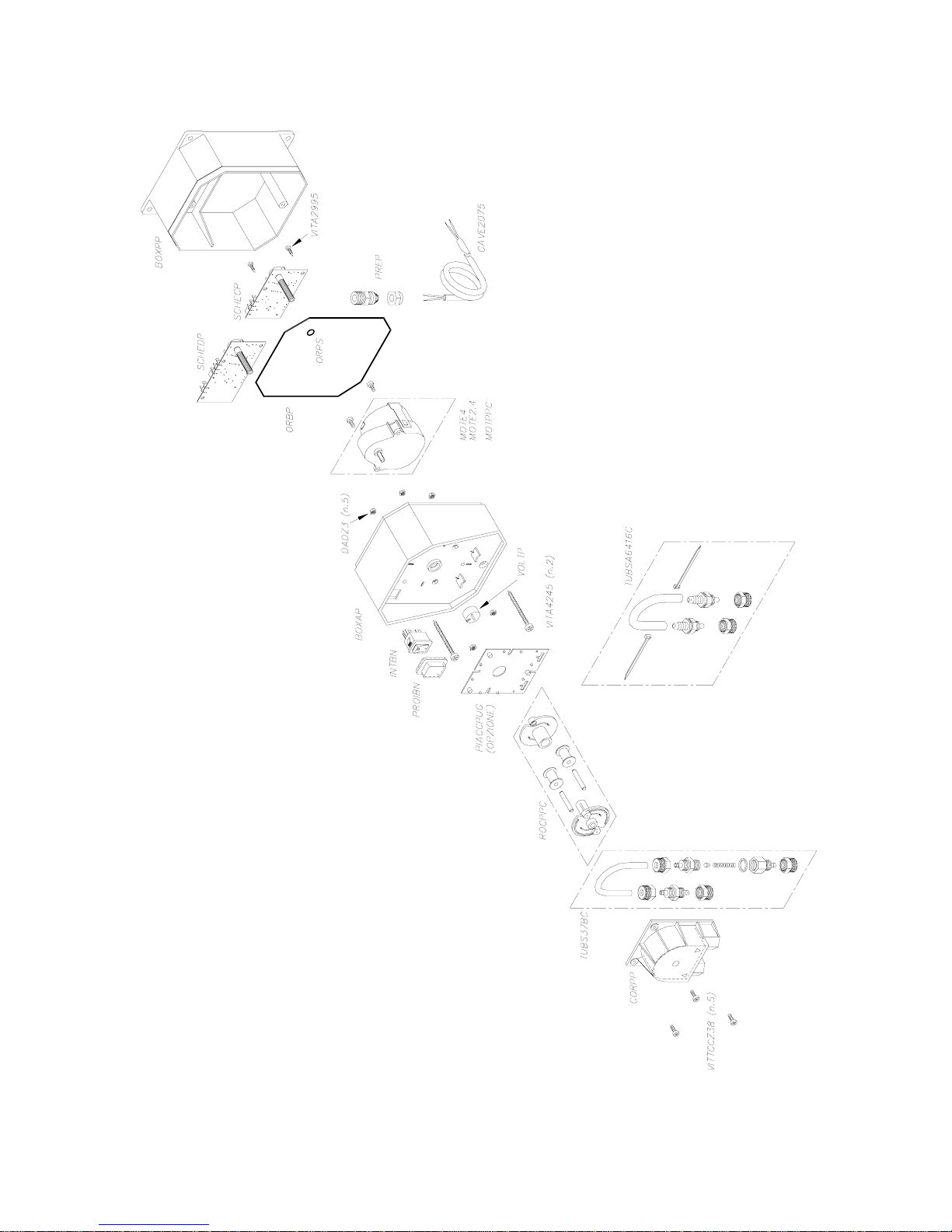

11 EXPLODED VIEW OF THE METERING PUMP WITHOUT CONTAINER

11

PROTHO Technical Manual Bores Group S.r.l.

12 EXPLODED VIEW OF THE METERING PUMP WITH CONTAINER

12

PROTHO Technical Manual Bores Group S.r.l.

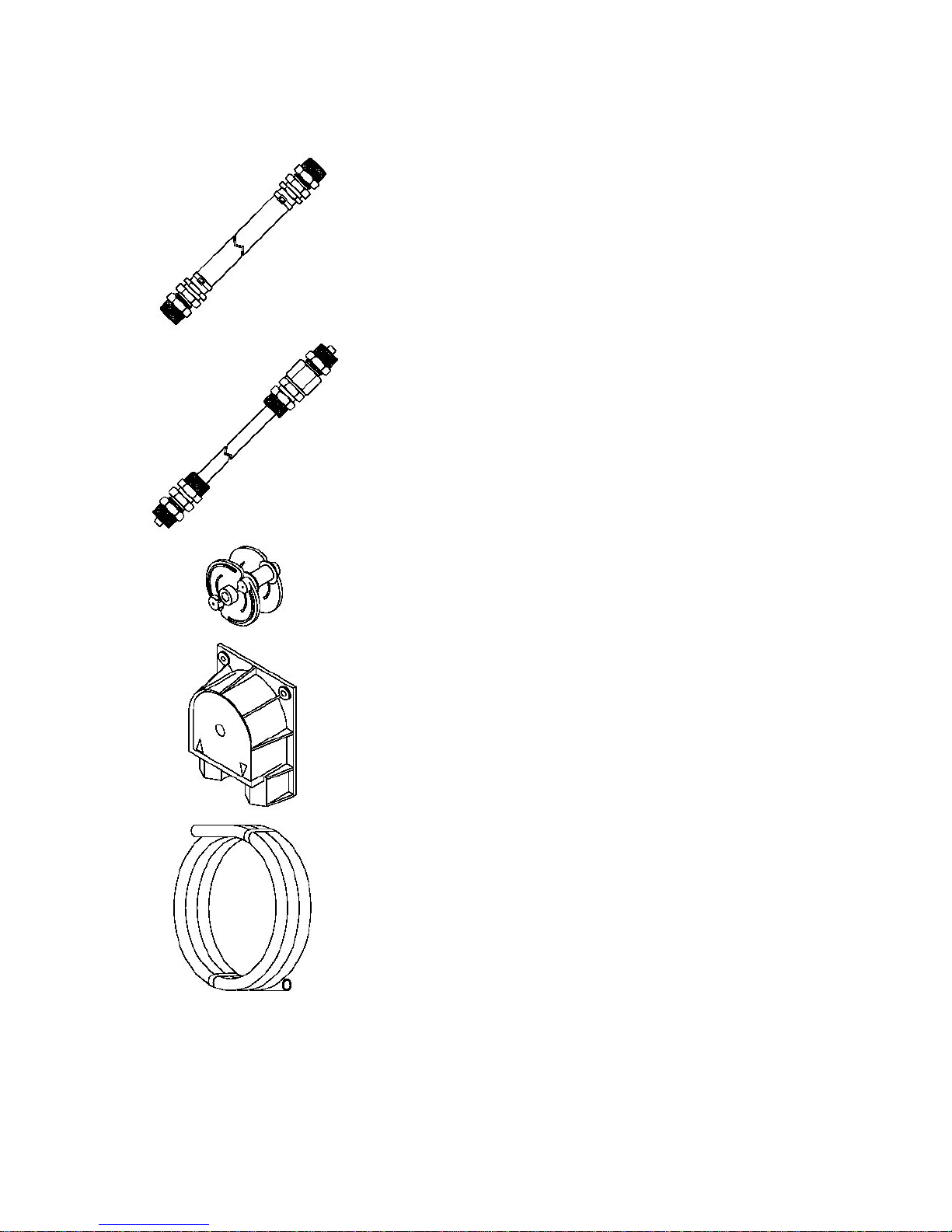

13 ACCESSORIES AND SPARE PARTS

ILLUSTRATION OF THE

COMPONENT CODE DESCRIPTION

GOMDIC Stainless steel union elbow for

detergent injection, complete

SENSC Sensor for detergent

conductimetric control card

FILFIC

VALFC

- Stainless steel bottom filter,

complete

- Stainless steel bottomfilter with

non-return valve, complete

FILTR Bottom filter with rigid pipe

VALBD Non-returne valve for rinse aid

injection

TW T Venturi with non-return valve for

rinse and injection

13

PROTHO Technical Manual Bores Group S.r.l.

ILLUSTRATION OF THE

COMPONENT CODE DESCRIPTION

TUBSA6416DRC Santoprene pipe for detergent

complete with pipe fitting

TUBS3264ABC Silicone pipe for rinse aid

complete with pipe fittine with

non-returne valve

ROCPPC

ROCPPBC

- Support with Protho rollers, for

detergent, complete

- Support with Protho rollers, for

rinseaid, complete

CORPPA Protho pump body

TUBC46

TUBP46

- 3 m. Cristal PVC pipe for

detergent

- 3 m. polyethylene pipe for

rinseaid

Table of contents