Instruction manual digital dispenser IG-1500D

10

6.2 Manual dispensing

9. Repeat from point 7 (with medium setting on pressure gauge [1]). Connect

the cartridge filled with material with the appropriate adapter to the

compressed air outlet [5]. Cartridge can be used with or without a piston,

depending on the material. Low-viscosity (flowable) materials are suitable

for use without a piston. With the help of a piston, there is an exact switch-

on and switch-off behaviour.

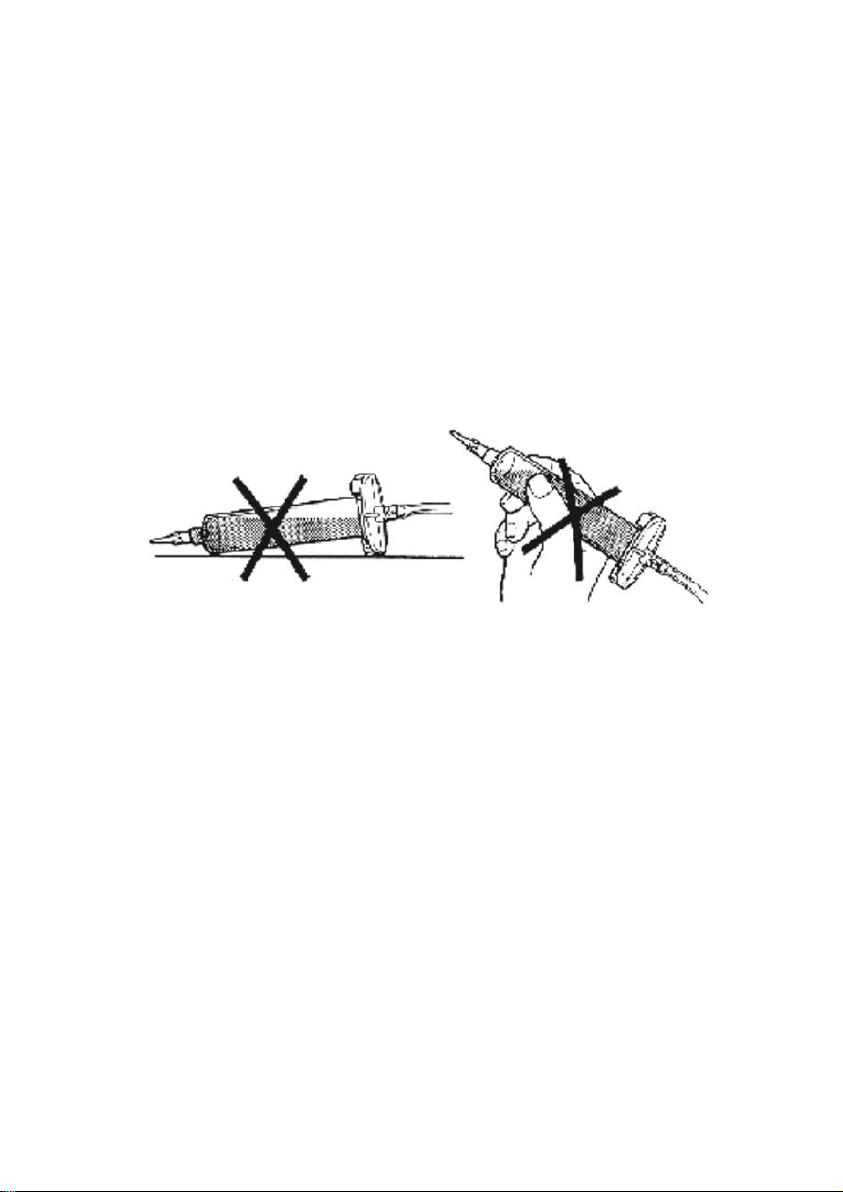

Important: When using the cartridge without a piston, it is best to place the

dispensing device higher above the work place or always hold the cartridge

with the needle tip down, so that the thin material cannot get into the

dispensing device via the adapter hose!

(see illustration)

10. Find a suitable device setting (display time [3], air pressure [1]) with a

suitable dispensing needle on the filled cartridge

11. After dispensing, close the partially filled cartridge with the barrel tip cap

Automatic dispensing with repeating volumes

Maintain the compressed air and display time values found under points 9 to 10.

Manually set the displayed, suitable time on the time setting switch [4]. After

pressing the foot or finger switch, the device automatically switches off the

compressed air on the cartridge after the set time has elapsed.

Time decimal shift on the display by one digit to the right:

After removing the device cover by the mains plug removed, the button on the

control board can be pressed if necessary, to achieve a comma shift or to undo

This does not result in a loss of guarantee if we have been made aware of this

measure written form.