9

Engine oil alarm

The engine oil alarm is designed to funcon when the engine oil in the

crankcase is insucient. Lack of engine oil may damage the engine. Once

oil level in the crankcase is too low, the engine oil alarm will stall the engine

automacally to make it free of damage while the engine switch is sll at

"ON".

CAUTION:

If cannot restart the engine, check the engine oil level rst before go to

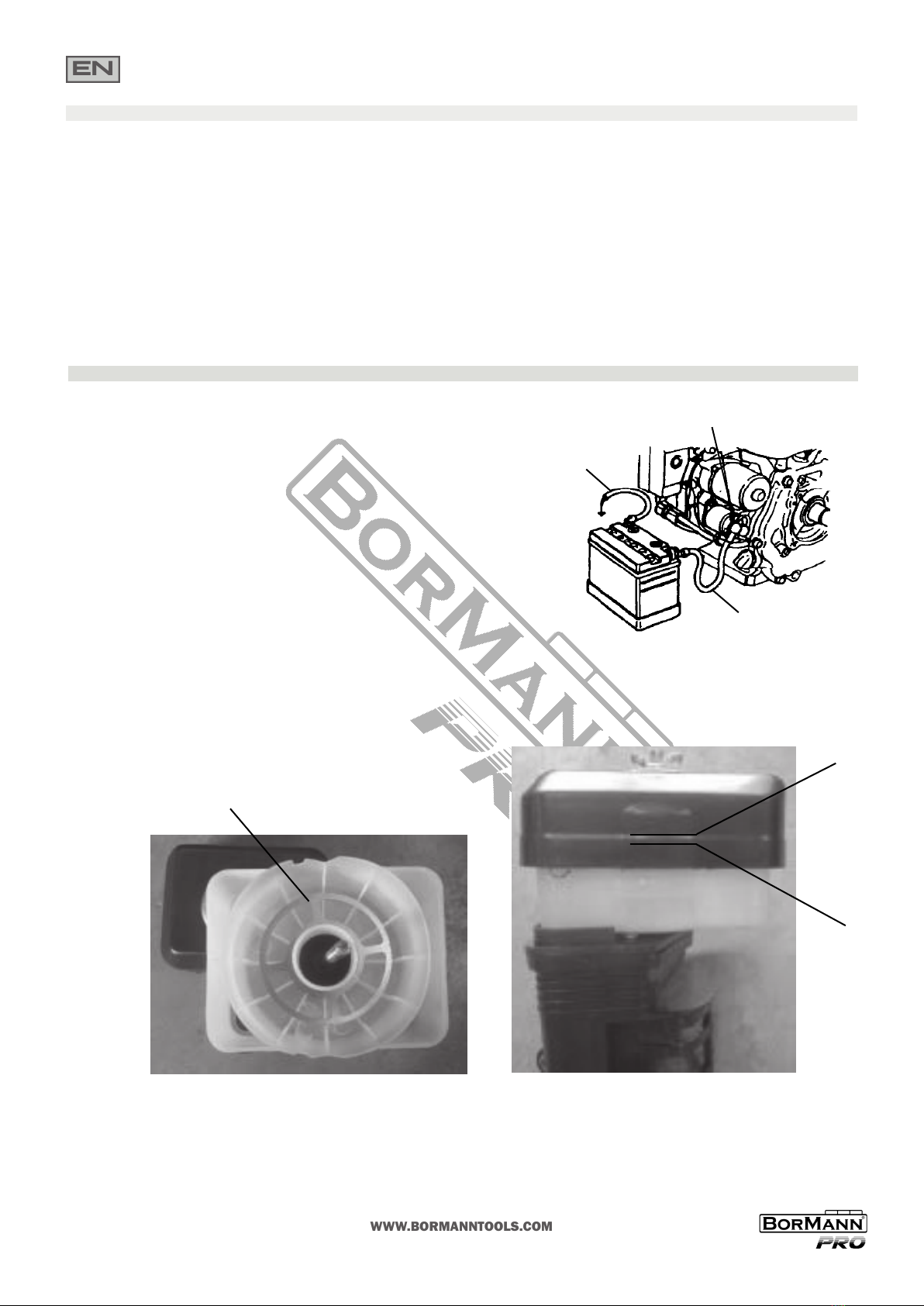

other check items. BREAKER (Electric-start type).

The breaker will cut o automacally to protect the charging circuit of the

baery in the case that short circuit or incorrect connecon of the baery

poles occurs. The green indicator in the breaker will jump out with the

circuit cung o. Aer nding troubles and troubleshoong, depress the

breaker buon to tun the breaker on.

Operang on mountainous areas

On mountainous areas, the standard mixture rao is relavely too big so the engine performance may be impaired while the fuel consumpon may increase,

besides, too big mixture rao will pollute the spark plug to result in starng the engine dicultly. This' problern can be solved by amending the carburetor

technological status. If always using on highlands with a height above sea level of 1800 meters, ask your dealer for doing the job. However, the engine power

will decrease by about 3.5% with every 305 meters up in height.

CAUTION : Amended engine applicable to highlands may be damaged seriously in area below altude of 1800 meters for overheang, because its mixture

rao is too small tor operaon in low altude area. In the case, ask your dealer to recover the engine to its normal technical status.

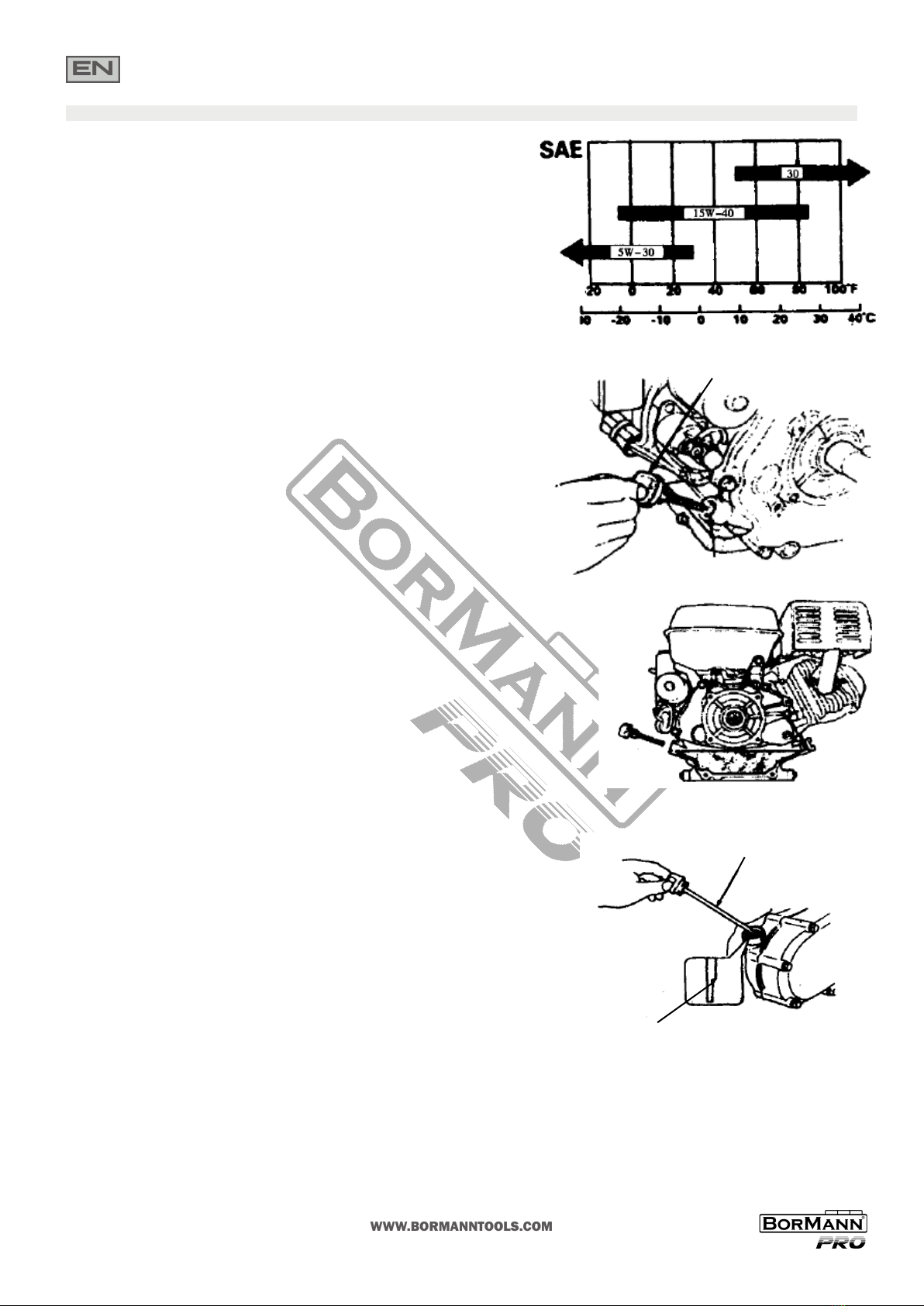

STOP

In emergency, push the engine switch to "OFF" to stall the engine; to stop it in normal, do

as follows:

1. Push right the throle lever to the boom.

2. Push the engine switch to "OFF".

3. Set the fuel cock to "OFF".

CAUTION: Sudden stopping at high speed under heavy load is forbidden, otherwise damage will result.

Exhaust control system

With the engine running, carbon monoxibe, oxide of nitrogen and hydrocarbon will produce, and in certain condions, oxide of nitrogen and hydrocarbon will

react chemically each other to make smoke while carbon monoxide is toxic, so exhaust control of them is very important. The company decreases the exhaust

emissions by introducing poor-fuel carburetors and other devices into the engine to solve the problem. To keep the exhaust of your engine with in the standard

exhaust emission, pay aenon to the following :

1. Maintenance

maintain the engine periodically in accordance with the maintenance schedule in the manual. The aintenance schedule is made out on the base of normal use

in normal condions, if using under heavy load, dusty or wet circumstances or in high temperature, service of -the engine should be done more oen.

2. Replacement of Parts

We recommend that you should choose such parts which are manufactured by the company or equivalent to these in quality as replacement ones. Replacement

without so high quality as the original ay the exhaust conbrol systan in eecveness.

3.Modifying

Modifying the exhaust control system may make actual exhaust emissions exceeding statutory limit values. Illegal modicaons as such:

a) Dismantle or modify any part of air intake or exhaust system.

b) Modify or take o speed - adjusng connecon device or speed adjustment device to result in the engine's running beyond the set parameters.

Exhaust control system

Fuel cock

OFF

Engine switch Throle valve

lever

Low speed

Throle lever

Dipsck

Upper level mark