Bornack LH200 User manual

Translation of the original instructions

EN

Directive 2006/42/EC on machinery

LH200

|

LH200

Load holder

INTENDED USE

The load holder LH may only be used

to manually lift, position or lower loads

from or to a higher or lower level. A suit-

able rope clamp can be used to facilitate

a better grip on the rope.

The load holder must be securely

attached to an adequately strong

anchor point. A hoist can be integrated

to move heavier loads.

Maximum useful load depending on the

ratio:

• : without a hoist kg

• : hoist kg

• : hoist kg

• : hoist kg

• : hoist kg

Minimum weight of the load: depending

on the ratio, see diagrams from page

Application temperature: - °C to

+°C

All other uses are deemed improper. The

company BORNACK will not be liable for

any ensuing damages. The user bears

the sole risk.

FUNCTION

Loads can be positioned in a controlled

manner with the LH. If the user lets

go of the pull rope, the auto-stop func-

tion blocks and prevents the load from

falling.

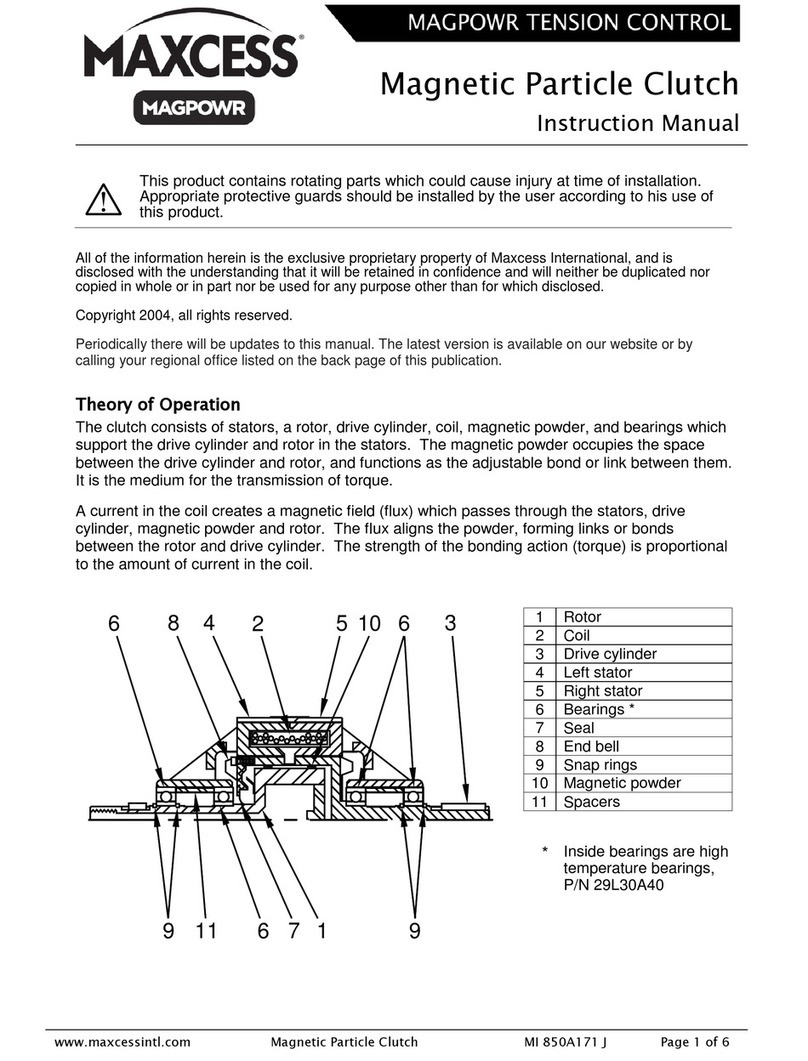

BRIEF DESCRIPTION

Subject to technical changes

EN

EQUIPMENT

• Load holder basic unit made of metal

and plastic.

• BORNACK kernmantle rope GEOSTATIC

mm or mm made of polyamide

with

- connector acc. to EN made of

aluminium or steel and

- sewn rope end connections with

thimbles

• DRYPACK

ACCESSORIES

• Accessories for mm kernmantle

rope:

- Rope clamp right

- Rope clamp left

- Pulleys for a ratio of : or :

- connectors acc. to EN

• Accessories for mm kernmantle

rope:

- Pulleys for a ratio of : or :

- connectors acc. to EN

• Collapsible bucket

USE

• Lifting, lowering and positioning of

loads

CAUTION: RISK TO LIFE!

It is not allowed to use the LH to

secure persons!

CONTENTS

Brief description

Product presentation

Possible misuses

Information before use

LH in use

Safety regulations

Other

EC Declaration of conformity

Test card

BRIEF DESCRIPTION

|

DRYPACK

Connector acc.

to EN

Pull rope

Strap for attaching

the hoist

Carrying handle

Basic unit with

identification

Thimble with

identification

Connector acc. to

EN, permanently

attached to the

basic unit

Supporting

rope

LH200

Pin

Cover over the

mechanical

part

Lock

washer

EN

Rope clamp

Simple pulley

for mm rope

Simple pulley

for mm

rope

Connector

acc. to EN

Double pulley

for mm rope

Double

pulley for

mm rope

Connection

opening

ACCESSORIES

Clamping

cam

Load hook

Connection

opening

Load hook

|

• Overloading can cause the LH to

fail and the transported load to fall!

Therefore, observe the minimum

useful weight of the LH.

• If the minimum weight is undercut,

this will restrict the lowering and posi-

tioning function. Therefore, observe

the minimum weight of the load.

• It is not allowed to use the LH to

secure persons.

• Incorrectly attached loads may fall and

endanger the operator. Therefore, use

suitable connectors to attach the load

to the support rope or the pulleys.

• Positioning the anchor point outside

the designated location can cause the

load to swing, and therefore endanger

the operator and other persons in the

vicinity. Therefore, always attach the

anchor point directly above the desig-

nated place.

• When selecting the anchor point,

ensure that it can bear a load of at

least kg.

• Icy or heavily soiled ropes can hinder

the blocking mechanism and cause

the load to fall. Therefore, look after

and clean the ropes; if necessary.

• When using the LH, there is a risk

of tripping on the unwound pull rope.

• Using this device without gloves can

lead to injuries of the hands. Therefore,

wear safety gloves when using this

device.

• Long, loose hair can become caught in

the moving part of the load holder.

Therefore, wear appropriate hair

protection and a helmet, or attach the

load securing device out of reach.

• The transported load can fall, if unsuit-

able lanyards are used (rope diameter,

rope expansion etc.). Only use original

ropes from BORNACK. Wear a safety

helmet.

• Rule out the risk of a fall load caused

by slack rope.

• Do not stand under suspended loads.

Operators must wear a safety helmet

and safety shoes.

• When working close to live parts,

select a suitable anchor point outside

the electrical hazard zone for the load

holder.

• The rope may jump out of the pulley, if

the pulley is not mounted or secured

correctly.

• When using pulleys, both plates of the

pulley always need to be secured by a

connector acc. to EN .

• When using double pulleys, the rope

needs to be inserted through both

rollers of the double pulley.

• A rope clamp must be used when

using the mm kernmantle rope.

• In case of strong winds, conduct a

hazard assessment to check whether it

can be used outdoors.

POSSIBLE MISUSES

EN

• The load may only be hooked into the

support rope or the pulleys to which

the support rope is connected.

• The lock function of the LH cannot

be guaranteed, if it is used over edges.

Therefore do not use the LH over

edges. When using the LH, ensure

that the support rope has not been

retracted too far because this may

cause the system to block and the load

can no longer be lowered.

• Any misuses not listed here can be

identified reliably by means of a sepa-

rate risk analysis by the user, and

appropriate safety measures can be

taken.

POSSIBLE MISUSES

|

Always check every time be-

fore use!

• The LH may no longer be used if

even very minor faults are discovered

when inspected.

• Faulty LHs may only be tested or

repaired by BORNACK or in a workshop

authorised in writing by BORNACK.

• Regular inspections are essential

because the safety of the user depends

on the eciency and durability of the

machine.

• The user must have completely read

and understood the instructions

before use.

VISUAL INSPECTION

• Check that the LH, in particular

rope, rope end connections, connector

and possible rolls of rope) is complete

and in a flawless condition.

• LH without mechanical or chem-

ical damage.

• No corrosion of metal parts.

• All rivets and screw connections are

complete and tightened.

• The last inspection by an expert was

carried out within the past months.

• The pins on the roller of the LH are

in a flawless condition, are tight and

complete in number.

FUNCTION TEST

• Moving components of the basic unit

runs smoothly.

• The snapper function of the connec-

tor(s) run smoothly. The snapper closes

and locks automatically.

• Arresting function responds to jerking

on the support rope and blocks the

rope.

• The device unlocks again when the

pull rope is pulled.

INFORMATION BEFORE USE

EN

PREPARATION

Before using the LH, calculate how

long the rope needs to be to reach the

required lifting height. The required rope

length is calculated as follows:

Rope length

= Lifting height + (ratio x lifting height)

In case of ratios of : (LH without a

hoist) e.g. at least m + ( x m) =

m rope is required for a lifting height

of m.

In case of ratios of : (LH with a :

hoist) e.g. at least m + ( x m) =

m rope is required for a lifting height

of m.

ATTENTION:

If possible, select an anchor point that is

directly above the load. The anchor point

must be able to bear at least kg.

CAUTION: RISK TO LIFE!

Select a work position for the operator

that ensures a clear line of vision to both

the load holder and the load. It is prohib-

ited to stand under suspended loads!

LH200 IN USE

Höhe = H

Übersetzung 1:1

Seillänge = 2 x H

Höhe = H

Übersetzung 2:1

Seillänge = 3 x H

Ratio 1:1

Rope length = 2 x H

Height = H

Ratio 2:1

Rope length = 3 x H

Height = H

|

LH200 IN USE

ATTENTION:

Select an anchor point that allows the

load holder to be used without it being

in the fall space of the load holder and

load!

A Attach the load holder basic unit

directly to the anchor point using the

connector acc. to EN . If necessary,

create an anchor point on a strong

building element using appropriate

anchor equipment (e.g. STEP sling).

B Lower the end of the load rope with a

connector acc. to EN or the pulley

with a connector down to the load

and attach.

AB

EN

APPLICATION OPTIONS

The LH is designed for a manual

tensile force of up to kg. As the load is

pulled with the LH manually using

physical force/body weight, the load

may not be too heavy. Otherwise, the

load cannot be lifted or lowered in a

controlled manner. Attach a hoist for

heavier loads (see page ).

C One/two rope clamp(s) (ascender

right/left) can be used for a better grip

on the mm rope and to facilitate use

of the LH. To do this, open the

clamping cam and insert the rope.

Observe the User Manual of the

rope clamp.

ATTENTION:

Wear safety gloves when using the

LH.

ATTENTION:

The rope must be free of knots and

kinks.

LH200 IN USE

C

|

LH200 IN USE

Lifting

D Pull the pull rope until the load is lifted

from the surface. Lift the load to the

required parking position.

Positioning

E Pull the load to the required position.

The auto-stop function of the LH

is activated by slowly releasing the

pull rope. The load can be parked in

this way.

Lowering

F The auto-stop function of the LH

is unlocked by pulling the pull rope.

The load can now be lowered in a

controlled manner. The lowering

process is blocked by the auto-stop

function, if the lowering speed is too

high.

1

2

F

E

D

EN

LH200 IN USE

ATTACHMENT OF THE HOIST

Observe the User Manual of the

pulleys.

ATTENTION:

To integrate the hoist, only the pulleys

sold as accessories for the LH may

be used.

ATTENTION:

The plates of the connection opening

must surround the rope and be secured

with a connector.

G To hook in the pulley, unscrew the

plates of the connection opening and

insert the rope. The rope must lie on

the roller on the connection opening

side. When inserting the rope, secure

the connection opening of the pulley

with a connector.

H When using double pulleys, ensure

that the ropes run parallel to one

another between the pulleys, and do

not cross.

H

G

G

|

LH200 IN USE

I A ratio of : is achieved as follows:

- . Place the support rope into the

lower pulley.

- . Attach the support rope with the

connector on the strap of the LH

to mount the hoist.

J A ratio of : is achieved as follows:

- . Place the support rope into the

lower pulley.

- . Place the support rope into the

upper pulley.

- . Attach the support rope with the

connector to the load hook of the

lower pulley.

1

2

3

J

1

2

I

EN

K A ratio of : is achieved as follows:

- . Place the support rope into the left

roller of the lower double pulley.

- nd Place the support rope into the

upper pulley.

- rd Place the support rope into the

right roller of the lower double pulley.

- th Attach the support rope with the

connector to the load hook of the

upper pulley.

LH200 IN USE

1

2

K

3

4

K

|

L A ratio of : is achieved as follows:

- . Place the support rope into the left

roller of the lower double pulley.

- . Place the support rope into the left

roller of the upper double pulley.

- . Place the support rope into the

right roller of the lower double pulley.

- . Place the support rope into the

right roller of the upper double pulley.

- . Attach the support rope with the

connector to the load hook of the

lower pulley.

COMBINATION

When combining this product with

other parts, there is a risk of mutual

impairment with respect to the function

and safety. Compatibility must be

assessed in a risk analysis. Only combine

with components that bear a CE symbol.

If you have any questions about compat-

ibility or you require help with the risk

analyses, feel free to contact BORNACK.

LH200 IN USE

1

3

2

L

4

5

L

EN

LH200 IN USE

MINIMUM WEIGHT

Depending on the ratio and work height,

the load requires a minimum weight to

guarantee the function of the LH.

To be able to lower the load when

operated from below, the load must,

e.g., have a minimum weight of approx.

kg, at a ratio of : and a lift height of

m.

0

5

10

15

20

25

30

35

010 20 30 40 50 60 70 80 90 100

Mindestlast (kg)

Arbeitshöhe (m)

Übersetzung 1:1

Ratio 1:1

Work height (m)

Minimum load (kg)

|

LH200 IN USE

0

5

10

15

20

25

30

35

010 20 30 40 50 60 70 80 90 100

Mindestlast (kg)

Arbeitshöhe (m)

Übersetzung 3:1

0

5

10

15

20

25

30

35

010 20 30 40 50 60 70 80 90 100

Mindestlast (kg)

Arbeitshöhe (m)

Übersetzung 2:1

Ratio 2:1

Work height (m)

Minimum load (kg)

Ratio 3:1

Work height (m)

Minimum load (kg)

EN

LH200 IN USE

0

5

10

15

20

25

30

35

010 20 30 40 50 60 70 80 90 100

Mindestlast (kg)

Arbeitshöhe (m)

Übersetzung 4:1

0

5

10

15

20

25

30

35

010 20 30 40 50 60 70 80 90 100

Mindestlast (kg)

Arbeitshöhe (m)

Übersetzung 5:1

Ratio 4:1

Work height (m)

Minimum load (kg)

Ratio 5:1

Work height (m)

Minimum load (kg)

|

SAFETY REGULATIONS

There is a risk to life if these safety

instructions are not observed!

• The LH may no longer be used

even in the case of very minor faults.

• Damaged, fall-stressed or dubious

equipment must be immediately with-

drawn and not used. Inspections may

only be carried out by BORNACK or an

expert briefed by BORNACK about the

inspection, including the corre-

sponding certificate. This must be

documented in the test card.

• Independent modifications or repairs

are not allowed.

• The LH may only be used by

trained sta that are familiar with the

material. They must be proficient in

handling the device and must have

been briefed about the possible risks

associated with its use.

• If it is no longer possible to position

the load in a controlled manner, the

device needs to be serviced by the

manufacturer.

• When operating the LH in areas

where there is a risk of falls, the oper-

ator must wear fall protection equip-

ment.

• Health impairments can jeopardise

the safety of the user when working at

heights or depths.

• Protect equipment during storing, use

and transportation against the eects

of heat (e.g. welding flames or sparks,

burning cigarettes) and chemicals (e.g.

acids, alkalis, oils) and mechanical

impact (e.g. sharp edges).

• The local safety guidelines (e.g. in

Germany, the DGUV Regulations

- and - issued by the

professional associations) and the

accident prevention guidelines for the

specific industry (UVV) must be

observed.

Table of contents

Popular Industrial Equipment manuals by other brands

Cascade Sciences

Cascade Sciences MAXTRAP 50 Supplemental Installation & Operation Manual

Danfoss

Danfoss VLT AQUA Drive D-Frame operating instructions

Deekax

Deekax DIVK-C121 DEMA Installation and user manual

FrontLine

FrontLine 10SS-NA Operation manual

Maxcess

Maxcess MAGPOWR C1 instruction manual

Eaton

Eaton easyE4 series Instruction leaflet