Cryomech PT415 User manual

PT415

Helium Reliquefier

INSTALLATION, OPERATION and

ROUTINE MAINTENANCE MANUAL

The information contained in this document is believed to be accurate and reliable as of

the time of its publication. However, Cryomech, Inc. cannot accept any responsibility

(financial or otherwise) that may result from the use or misuse of the information

contained in this document. Except as expressly contained in this document, there are no

other warranties granted or extended by the manufacturer.

Cryomech, Inc. reserves the right to add, change, modify or delete any or all information

contained herein without prior written notice. Revisions to this document may be issued

at the time such changes and/or deletions occur.

Any duplication of this manual or any of its parts without expressed written permission

from Cryomech, Inc. is expressly prohibited.

Correspondence concerning this document should be forwarded to:

Customer Service Department

Cryomech, Inc.

113 Falso Drive

Syracuse, NY 13211 USA

Telephone (315) 455-2555

FAX: (315) 455-2544

Email: cryoservice@cryomech.com

Website: www.cryomech.com

Contents

Section 1

Overview

Section 2

Warranty

Section 3

Safety

Section 4

Inspection and Unpacking

Section 5

Specifications

Section 6

Installation

Section 7

Operation

Section 8

Routine Maintenance

Appendix A

Appendix B

Spray Lubricant Instructions

1.1

Section 1

Overview

Se

c

1.1

1

c

tion 1

This secti

o

provides

a

used and

e

Helium

R

.1.1 Gen

e

The Cryo

m

helium de

w

establishi

n

helium or

b

A

4 K pul

s

the heliu

m

based on

a

compone

n

heat from

or more

a

refrigeran

t

Flexible s

t

compress

o

The comp

r

pure low-

p

removed

v

series of

o

via the hig

In the col

d

cooling t

o

compress

o

The Puls

e

referred t

o

returning

f

O-ring fitti

with the

C

This red

u

condensi

n

The Liqui

d

bottom o

f

must be

h

Other co

m

monitor, e

relief valv

e

: Over

v

o

n provides

a

a

n overview o

e

xpansion of

R

eliquefi

e

ral descri

p

m

ech Helium

w

ar/cryostats

n

g a closed H

b

e utilized to

s

e tube cryo

r

m

inside the

r

a

closed-loo

p

n

ts: one is th

e

the system;

t

a

dditional ex

p

gas used

i

t

ainless steel

o

r package t

o

r

essor packa

g

p

ressure heli

u

v

ia a heat ex

c

o

il separator

s

h-pressure h

e

d

head, adi

a

o

cryogenic

o

r package vi

e

Tube Cold

o

as the Re-l

i

f

rom the cry

o

ng on the R

e

C

old Head, it

s

u

ces its te

m

n

g chamber;

u

d

helium is

f

f

the conden

s

h

andled wit

h

m

ponents of

l

ectrical feed

t

e

and a vacu

u

v

iew

a

n overview

f this manual

acronyms us

er

p

tion

Re-liquefier i

s

, and then re

t

elium loop. I

t

liquefy heliu

m

r

efrigerator s

r

e-liquefier.

T

p

helium expa

e

compressor

t

he other is t

h

p

ansion cycl

e

i

n the Cryo

m

lines called

o

the cold he

a

g

e works as

f

u

m that is ret

u

c

hanger, and

s

and filters.

T

e

lium flex lin

e

a

batic expan

s

temperature

s

a the low-pr

e

Head is m

o

i

quefier Main

o

stat dewar

e

e

-liquefier M

a

s

heat is ab

s

perature, in

c

u

ntil it contac

t

f

unneled into

s

ing chambe

h

care.

the Helium

t

hrough, silic

o

u

m port.

1-1

discussion o

f

, including th

e

ed in the ma

n

s

designed t

o

t

urn the Liqui

d

t

can be inst

a

m

gas from g

a

upplies the

c

T

he operatio

n

nsion cycle.

A

package, wh

h

e cold head,

e

s to cool it

m

ech cryoge

helium flex l

a

d and carry l

o

f

ollows. An o

i

u

rned from th

the oil from t

h

T

he compres

e

.

s

ion of the

h

s

. The low-

e

ssure helium

o

unted in a

v

Assembly.

T

e

nters into th

e

a

in Assembly

.

s

orbed into t

h

c

reasing its

t

s the 4K con

the Liquid

h

r to the cry

o

Re-liquefier

o

n diode, an

d

f

Cryomech

H

e

organizatio

n

ual.

o

recondense

d

Helium to t

h

a

lled into cry

o

a

s cylinder to

c

ryorefrigerat

i

n

of a cryog

e

A

complete s

y

ich compres

s

which takes

down to cr

y

nic systems

ines carry c

o

o

w-pressure

i

l-lubricated

c

e cold head.

h

e compress

sed helium i

s

h

elium and f

u

-

pressure h

e

flex line.

v

acuum insul

T

he room te

m

e

condensin

g

.

As the wa

r

h

e heat exch

density, dr

o

densing surf

a

h

elium Retur

n

o

stat. The r

e

are a press

u

d

heater ass

e

H

elium Reliq

n, basic defi

n

the boil off fr

o

h

e dewar/cry

o

o

stats alread

y

fill a dewar.

i

on necessa

r

e

nic refriger

a

y

stem consis

s

es refrigera

n

the refrigera

y

ogenic tem

p

is 99.999%

o

mpressed h

e

helium back.

c

ompressor c

o

The heat of

c

ion process i

s

s

then fed to

u

rther heat

r

e

lium then

r

ated conden

m

perature he

l

g

chamber th

r

m helium co

m

angers on t

h

o

pping it lo

w

a

ce, where it

n Line whic

h

e

turn line i

s

u

re controlle

e

mbly as well

Overvie

w

uefiers. It al

s

n

itions of ter

m

o

m liquid

o

stat

y

full of liquid

r

y to conden

s

a

tion system

ts of two maj

o

n

t and remov

e

nt through o

n

p

eratures. T

h

%

pure heliu

m

e

lium from t

h

o

mpresses t

h

c

ompression

s

removed in

the cold he

a

r

emoval allo

w

r

eturns to t

h

sing chamb

e

lium gas/vap

o

rough the 1/

4

m

es in conta

h

e Pulse Tub

e

w

er inside t

h

condenses.

h

connects t

h

s

delicate a

n

r, temperatu

r

as a pressu

r

w

s

o

m

s

s

e

is

o

r

e

s

n

e

h

e

m

.

h

e

h

e

is

a

a

d

w

s

h

e

e

r,

o

r

4

"

ct

e

.

h

e

h

e

n

d

r

e

r

e

1

1.1.

3

1.2

1

.1.2 Feat

u

The Cryo

m

provide y

e

Primary f

e

Easy i

Cryo

m

Fully

a

Primary

b

Requi

r

Very l

o

High r

e

Long

m

Redu

c

Lower

3

Feature

s

Primary f

e

Primary f

e

The CPA

2

Controller

Fault

s

A

uto

m

Remo

t

Touch

Remo

t

Phas

e

Serial

Cryome

c

This man

u

review thi

s

.2.1 Org

a

The main

in order t

o

maintena

n

needed fo

r

u

res and

b

m

ech Pulse

T

e

ars of troubl

e

e

atures

nstallation

m

ech Pulse T

u

a

utomatic pre

s

b

enefits

r

es only elec

t

o

w vibration

e

liability

m

ean time b

e

c

ed magnetic

costs of ope

r

s

and ben

e

e

atures

e

atures

2

800 and CP

A

(PLC) with t

h

s

ensing

m

atic error &

d

t

e operation

Screen inter

f

t

e indication

o

e

error sensin

g

& Ethernet c

o

c

h Heliu

m

u

al covers th

e

s

manual car

e

nization o

f

body of the

m

o

install and

n

ce. It is divi

r

clarification.

enefits of

T

ube Cold He

e

free service

.

u

be technolo

g

s

sure control

t

rical power a

e

tween maint

e

fluctuation fr

o

r

ation and m

a

e

fits of the

A

1000 Serie

s

h

e following f

e

d

ata logging

f

ace

o

f faults

g

o

mmunicatio

n

m

Reliqu

e

e

complete

C

e

fully before

b

f

the man

u

m

anual provi

d

operate the

ded into 8

s

Additional in

1-2

the Cryo

m

ad has been

.

g

y

led operation

nd cooling w

a

e

nance

o

m rare eart

h

a

intenance

Cryomec

h

s

Compresso

r

e

atures:

n

e

fier Ma

n

C

ryomech He

b

eginning the

u

al

d

es a detaile

d

Cryomech

C

s

ections. Illu

s

formation wil

m

ech Puls

e

carefully de

s

a

ter

h

materials

h

Compre

s

r

Packages i

n

n

ual

lium Relique

f

installation

p

d

discussion

C

ryorefrigera

s

trations acc

o

l be in the ap

e

Tube Col

d

s

igned and

m

s

sor

n

clude Progr

a

f

ier. It is imp

o

p

rocess.

of everythin

g

tor and to p

ompany the

pendix.

Overvie

w

d

Head

m

anufactured

t

a

mmable Log

o

rtant that y

o

g

you will ne

e

erform routi

n

discussion

a

w

t

o

ic

o

u

e

d

n

e

a

s

1.3

1

Numbere

d

for seque

n

not import

a

The man

u

Cryomech

should ta

k

warranty

b

Sections

4

Cryomech

maintena

n

where ob

s

Sectio

Sectio

Sectio

Sectio

Sectio

Sectio

Sectio

Sectio

A

ppe

n

Glossar

y

.3.1 Defi

n

The terms

is made

b

(compres

s

The terms

that are al

s

Aeroquip

The term

that conn

e

and heliu

m

Category I

Category I

connectio

n

Closed Lo

o

This refer

s

through a

helium.

d

lists labeled

n

tial actions t

a

nt are bullet

e

u

al contains

e

Cryorefiger

a

k

e and also

b

y doing som

e

4

through 8

p

Cryorefrige

n

ce. Each s

a

s

erving the c

a

n 1: Overvie

w

n 2: Warrant

y

n 3: Safety

n 4: Inspecti

o

n 5: Specific

a

n 6: Installati

o

n 7: Operati

o

n 8: Routine

n

dix: Addition

a

y

n

itions

defined bel

o

b

etween the

s

or) module.

are in alph

a

s

o defined in

Couplings:

"Aeroquip

c

e

ct compone

n

m

flex lines to

I Installation:

I refers to th

e

n

to the equi

p

o

p System:

s

to a cryoge

closed loop.

with 1), 2),

e

h

at must be

e

d, using soli

e

ssential info

a

tor. Section

s

explain the

e

thing that w

o

p

rovide comp

l

rator, from

a

fety precauti

a

ution or war

n

w

(including

d

y

o

n and unpa

c

a

tions

o

n

o

n

maintenance

a

l informatio

n

o

w are used

w

(cryorefrige

r

a

betical order

this section.

c

ouplings" is

n

ts e.g. that

c

the cold hea

d

e

potential fo

r

p

ment. See I

E

nic system t

h

The advant

a

1-3

e

tc and letter

e

p

erformed in

d or hollow b

rmation for t

h

s

2 and 3 cl

e

ways in w

h

o

uld damage

l

ete step-by-

s

inspection

o

on is also s

n

ing is import

a

efinitions an

d

c

king

n

w

ith precisio

n

r

ator) syste

m

, and italiciz

e

used generi

c

c

onnect heli

u

d

.

r

transient ov

e

E

C 664, Sub-

c

h

at has no h

e

a

ge of such

a

e

d lists label

e

the order lis

t

b

ullets.

he safe and

e

arly lay out

h

ich you mi

g

the system.

s

tep instructi

o

o

f the pack

i

hown in the

s

a

nt.

d

acronyms)

n

in the man

u

m

, the (com

p

e

d terms wit

h

c

ally to desc

u

m flex lines

t

e

r-voltage co

c

lause 5.6 fo

r

e

lium loss b

e

a

system is t

h

e

d with a., b.

t

ed. Lists for

effective op

e

all safety p

r

g

ht inadverte

o

ns on the h

a

i

ng crate t

h

s

e sections

i

u

al. For exa

m

p

ressor) pac

k

h

in the definit

ribe the self-

t

o the compr

e

nditions in th

e

r

further detai

e

cause the h

e

h

at there is

n

Overvie

w

, etc. are us

e

which order

e

ration of yo

u

r

ecautions y

o

ntly void yo

u

a

ndling of yo

u

h

rough routi

n

i

n every pla

c

m

ple, distincti

o

k

age, and t

h

ions are ter

m

-

sealing fittin

g

e

ssor packa

g

e

mains pow

e

ls.

e

lium is cycl

e

n

o need to a

d

w

e

d

is

u

r

o

u

u

r

u

r

n

e

c

e

o

n

h

e

m

s

g

s

g

e

e

r

e

d

d

d

Cold Hea

d

The cold

temperatu

r

the PT se

r

Cold Hea

d

The heat

e

transferrin

g

Cold Hea

d

The cold

h

that attac

h

electrical

p

Compress

Located i

n

commerci

a

pressure.

Compress

The comp

cool and

p

compress

e

high-pres

s

Cryogenic

Temperat

u

Cryorefrig

e

A

cryorefr

i

expansion

(expansio

n

Gifford-M

c

A Gifford-

M

the heliu

m

Helium Fl

e

The heliu

m

the compr

e

Nitrogen

F

Nitrogen f

l

only apply

Pollution

D

Pollution

d

affect the

e

Pulse Tub

e

A

pulse t

u

helium usi

d

:

head is a

n

r

es. In the A

L

r

ies systems

t

d

Heat Excha

n

e

xchanger(s

)

g

heat to the

d

Motor Cord

h

ead motor c

h

to the cold

h

p

ower from th

or Module:

n

side the co

m

a

l compress

o

or Package:

ressor packa

p

urify helium

e

s the low-p

r

s

ure helium t

o

Temperatur

e

u

res lower th

a

e

rator (Cryoc

o

i

gerator is a

cycle. It con

n

device).

c

Mahon (GM)

M

cMahon cr

y

using a disp

e

x Lines:

m

flex lines a

r

e

ssor packa

g

F

lexible Lines

l

ex lines are

to Liquid Nit

r

D

egree 2:

d

egree 2 refe

e

lectrical saf

e

e

Cryorefrige

u

be cryorefri

g

ng a pulse tu

n

expansion

L

or GB syst

e

t

he cold hea

d

n

ger:

)

on the cold

helium withi

n

ord is pre-wi

r

h

ead and co

m

e compress

o

m

pressor p

a

o

r that com

p

ge houses t

h

and that pro

v

r

essure heliu

o

the cold he

a

e

s:

a

n 120K or -1

o

oler):

cryogenic re

f

sists of a co

m

Cryorefriger

a

y

orefrigerator

lacer or pisto

r

e corrugate

d

g

eand the co

l

or Flex Line

s

corrugated

s

r

ogen Plant

m

rs to the ext

e

e

ty of the sys

t

rator:

g

erator is a

c

be instead of

1-4

device, wh

i

e

ms the cold

d

is a Pulse T

u

head provid

n

the system.

r

ed and fitte

d

m

pressor pac

k

o

r package to

ckage, the

c

p

resses low-

p

h

e compress

o

v

ide system

s

m returning

f

a

d.

53°C.

f

rigeration s

y

m

pressor pa

c

a

tor

is a cryorefr

i

n.

d

stainless st

e

l

d head.

s

:

s

tainless stee

m

odels.

e

nt to which

t

t

em. See EN

c

ryorefrigerat

o

a displacer

o

i

ch is capa

b

head is a Gi

f

Tu

be style uni

t

e cooling at

d

with electri

c

k

a

g

e. The col

the cold hea

d

c

ompressor

m

p

ressure heli

o

r module an

d

s

afety contro

l

f

rom the col

d

y

stem based

c

kage, heliu

m

i

gerator in w

h

e

el hoses th

a

e

l hoses that

t

he local env

i

61010 or UL

o

rin which

t

o

r piston.

b

le of reac

h

f

ford-McMah

o

t

.

cryogenic te

c

al connector

d head moto

r

d

motor.

m

odule is a

n

um to the n

d

all other c

o

l

. The compr

e

d

head and

p

upon a clos

e

m

flex lines a

n

h

ich the cold

a

t transport h

carry nitrog

e

ironmental c

o

61010A for f

u

t

he cold hea

d

Overvie

w

h

ing cryoge

n

o

nstyle unit.

mperatures

b

s on each e

n

r

cord provid

e

n

oil-lubricat

e

ecessary hi

g

o

mponents th

a

e

ssor packa

g

p

rovides cle

a

e

d loop heliu

n

d a cold he

a

head expan

d

elium betwe

e

e

n. These lin

e

o

nditions cou

u

rther details

d

expands t

h

w

n

ic

In

b

y

n

d

e

s

e

d

g

h

a

t

g

e

a

n

m

a

d

d

s

e

n

e

s

ld

.

h

e

1

1.4

System:

The term

"

package,

h

.3.2 Acro

The follo

w

FPT F

e

GPM G

a

LPM Li

t

MPT M

a

OFHC O

x

PSIG P

o

Cryome

c

Cryomech

113 Falso

Syracuse,

Phone: +1

Fax: +1 (3

Email: su

p

Website:

w

"

system" is u

s

h

elium flex li

n

nyms

ing acronym

s

e

male Pipe T

h

a

llons per Mi

n

t

ers per Minu

t

a

le Pipe Thr

e

x

ygen-Free

H

o

unds per Sq

u

c

h Cont

a

, Inc.

Drive

NY 13211

(315) 455-2

5

15) 455-254

4

p

port@cryom

e

w

ww.cryome

c

s

ed as a syn

o

n

es and cold

h

s

are used in

h

read

n

ute

t

e

e

ad

H

igh Conducti

u

are Inch Ga

a

ct Infor

m

5

55

4

e

ch.com

c

h.com

1-5

o

nym for cry

o

h

ead.

the text and

p

v

ity (describ

e

uge

m

ation

o

refrigerator.

p

rovided her

e

e

s a form of

C

It consists o

f

e

for conveni

e

C

opper)

Overvie

w

f

a compress

o

e

nt lookup.

w

o

r

2.1

Section 2

Warranty

Se

c

2.1

2.2

c

tion 2

Statem

e

Provided

according

extends a

operating

compone

n

warranty

d

If found t

o

Cryomech

are respo

n

The Puls

e

12,000 op

e

Conditi

o

Opera

in this

the sp

Failur

e

Sectio

Beca

u

perfor

m

care t

o

bent t

u

Opera

warra

n

Do no

heat

e

warra

n

Sectio

In so

m

the c

o

value

orient

a

load

o

under

If the

Cryo

m

p

rior

a

Cooli

n

the c

o

cleani

n

: Warr

a

e

nt of wa

r

that the c

u

to the speci

f

warranty on

a

hours, whic

h

n

ts of the co

m

d

oes not cov

e

o

be defecti

v

will provide

w

n

sible for all

s

e

Tube Cold

H

e

rating hours

o

ns that

c

tion of the cr

y

section will

v

ecified condi

t

e

to follow th

e

n 6.

u

se the tube

m

ance, extre

m

o

not dent or

u

bes. See Se

ting the cold

n

ty. See Sect

t

apply heat

d

e

xchanger(s))

n

ty will not

c

n 6.

m

e applicatio

n

o

ld head ori

e

specified in

a

tion other t

h

o

n the cold h

e

the warranty

.

bolt pattern

m

ech first to l

e

a

pproval from

n

g water mus

t

o

oling water

s

n

g purposes,

a

nty

r

ranty

u

stomer inst

a

f

ications and

a

ll parts and

w

h

ever comes

m

pressor pa

c

e

r user-servic

e

v

e and in

a

w

arranty repl

a

s

hipping and

h

H

ead is also

to deliver th

e

c

an void

y

orefrigerato

r

v

oid the warr

a

t

ions, contact

e

se installati

o

s in the co

m

e care mus

t

bend the tu

b

ction 6.

head in a

m

ions 6 and 7.

d

irectly to th

e

. Doing so w

c

over heatin

g

n

s, heavy co

m

nted vertical

l

Section 5.

h

an vertical

w

e

ad can da

m

.

See Sectio

n

on the heat

e

arn how to p

Cryomech

w

t

meet the r

e

s

pecifications

it will void th

e

2-1

a

lls, operate

procedures

s

w

orkmanshi

p

first. This w

a

c

kage, the c

o

e

able parts (

s

ccordance

w

a

cement par

t

h

andling cha

r

warranted f

o

e

specified te

m

the warr

a

r

in any situa

ti

a

nty. If you p

l

Cryomech.

S

o

n guidelines

ld head mu

s

t

be taken w

h

b

e assemblie

s

m

agnetic field

e

cold head (

ill damage t

h

g

of the col

d

m

ponents m

u

l

y, the maxi

m

If your appl

w

ith a load,

p

m

age the tub

e

n

6.

exchanger n

revent dama

g

w

ill

v

oid the w

a

e

quirements i

n

in Section

5

e

warranty. S

s and mai

n

s

et forth in t

h

p

for a period

arranty cove

o

ld head an

d

s

uch as fuse

s

w

ith the ter

m

t

s at no cost

t

r

ges associat

e

o

r the same

t

m

peratures

a

a

nty

t

ion that doe

s

l

an to operat

e

S

ee Section

5

could result

i

s

t have ver

y

h

en handling

s

. The warra

n

of greater t

h

e.g. solderin

g

h

e cold head

d

head over

u

st be mount

e

m

um allowab

ication requi

p

lease conta

c

e

s. This typ

e

eeds to be

c

g

e to the col

d

a

rranty. See

S

n

Section 5.

5

is introduce

d

S

ee Sec

t

ion 6

.

n

tains this

c

h

is manual,

C

of three (3)

y

rs all non-u

s

d

the helium

s

).

m

s of the li

m

t

o the custo

m

ed with warr

a

t

hree (3) yea

a

nd cooling c

a

s

not meet th

e

e

the system

5

.

i

n voiding the

y

thin walls

the cold hea

d

n

ty will not c

o

h

an 500 gau

s

g

anything to

and void the

325K (125º

F

e

d to the col

d

b

le load can

n

res a heavi

e

c

t Cryomech.

e

of damage

c

hanged, yo

u

d

head. Hole

s

S

ection 6.

If water that

d into the s

ys

.

Warran

t

c

ryorefrigerat

o

C

ryomech, In

y

ears or 12,0

0

s

er serviceab

flex lines. T

h

m

ited warran

t

m

er. Custome

a

nty repair.

rs or period

o

a

pacities.

e

specificatio

n

outside any

o

warranty. S

e

for cryogen

d

. Take speci

o

ver dented

o

s

s will vo

i

d t

h

the cold he

a

warranty. T

h

F

, 52ºC). S

e

d

surface. Wi

t

n

ot exceed t

h

e

r load or

a

A

n excessi

v

is not cover

e

u

must cons

u

s

drilled witho

does not me

e

ys

tem, even

fo

t

y

o

r

c.

0

0

le

h

e

t

y,

rs

o

f

n

s

o

f

e

e

ic

al

o

r

h

e

a

d

h

e

e

e

t

h

h

e

a

n

v

e

e

d

u

lt

ut

e

t

fo

r

A

volt

a

comp

r

that v

o

Do n

o

comm

comm

Do no

t

may o

The c

o

cold

h

return

e

When

gases

their f

r

heliu

m

servic

i

p

rem

a

warra

n

Never

warra

n

a

ge deviatio

n

r

essor motor

o

ltage range

w

o

t allow the

e

rcial cleani

n

ercial cleani

n

t

bend the fl

e

c

cur. This ty

p

o

ld head co

n

h

ead will voi

d

e

d for servici

n

adding heli

u

will result in

r

eezing tem

p

m

charge will

s

i

ng. Contam

i

a

ture failure

a

n

ty. See Sect

wet either

p

n

ty. See Sect

n

of more th

a

overheating

a

w

ill void the

c

flex lines to

n

g agent. H

n

g agents will

e

x lines to le

s

p

e of damage

n

tains no us

e

d

the warran

t

n

g. See Secti

u

m, the heli

u

the freezing

p

erature is m

u

s

everely deg

r

i

nation of th

a

nd, unless r

e

ion 8.

p

art of the

s

ion 8.

2-2

a

n 10% abov

e

a

nd possible

c

ompressor

w

come into

c

e

lium leaks

not be cover

e

s

s than 10 in

c

is not cover

e

e

r-serviceabl

e

t

y. Contact

C

on 8.

m must be

9

of the conta

u

ch higher t

h

r

ade the cold

e helium b

y

e

sulting from

s

ystem. Wat

e

e

or below t

h

failure. Indi

c

w

arranty. See

c

ontact with

caused by

r

ed under wa

r

c

h (25 cm) r

a

e

d under the

w

e

parts. Atte

C

ryomech if

t

9

9.999% pu

r

minant gase

s

h

an that of h

e

head’s functi

y

other gase

a system fa

i

e

r getting int

o

h

e voltage ra

t

c

ations of op

e

Sections 6 a

n

corrosives

o

exposure to

r

ranty. See S

e

a

dius or perm

w

arranty. Se

e

mpting to di

s

t

he cold hea

d

r

e. Contamin

s

in the cold

elium. Conta

on and it will

e

s is a com

m

i

lure, is not

c

o

the syste

m

Warran

t

t

ing can cau

s

e

ration outsi

d

n

d 7.

o

r any type

o

corrosives

o

e

ction 6.

anent dama

g

e

Section 6.

s

assemble t

h

d

needs to

b

ation by oth

e

head becau

s

minants in t

h

require facto

m

on cause

c

overed b

y

t

h

m

will vo

i

d t

h

t

y

s

e

d

e

o

f

o

r

g

e

h

e

b

e

e

r

s

e

h

e

ry

of

h

e

h

e

3.1

Section 3

Safety

Se

c

3.1

3

3

c

tion 3

Safety

a

.1.1 Equi

p

The safet

y

defined b

e

.1.2 Icon

s

Definition

s

: Safet

y

a

nd infor

m

p

ment sy

m

y

and inform

a

e

low.

A

lternating

Internal g

r

terminal.

S

any other

c

Warning I

c

The CE la

meets the

Conformit

é

maximum

(425psig).

The TUV l

a

meets the

officially r

e

CSA mar

k

Rheinland

by UL and

Power swi

t

Read the

m

equipment

,

or use. Thi

s

in the m

a

s

of Warning

a

Warning I

c

instruction

s

Electrical

W

observe in

s

humans.

y

m

ation s

y

m

bols

a

tion symbol

current. The

r

ound. This

S

uch a termin

c

onnections t

o

c

on. Refer to

t

bel is placed

safety stand

é

Européenn

e

temperature

a

bel is place

d

safety stand

a

e

cognized as

k

s. Nation

R

can test to t

h

CSA.

t

ch. This sym

m

anual or ha

n

,

the user sh

o

s

symbol is f

o

a

nual

a

nd Caution

a

c

on. A warnin

g

s

or precauti

o

W

arning Icon.

s

tructions or

3-1

y

mbols

stickers pla

c

symbol signi

symbol repr

e

al must be c

o

o

the equipm

e

t

he documen

t

on a produ

c

ards set by

t

e

.

A

ll pressu

of 94°C (2

0

d

on a prod

u

a

rds set by t

h

an equivale

n

R

ecognized

T

h

e same sta

n

bol designat

e

n

dbook sign.

o

uld read the

o

und on the

c

a

nd Informati

o

g

message is

o

ns could res

u

An electrical

precautions

c

c

ed on Cryo

m

fies that alte

r

e

sents an i

n

o

nnected to

e

e

nt.

t

s that acco

m

c

t if the prod

t

he Europea

n

re equipmen

t

0

0°F) and a

u

ct if the pro

d

h

e US and C

n

t and direct

T

esting Lab

o

n

dard and sp

e

e

s an in/out o

When this s

y

e

whole man

u

c

ompressor p

a

o

n icons in th

s

used when

f

u

lt in injury o

r

l

warning me

s

c

ould result i

n

m

ech Cryor

e

r

nating curre

n

n

ternal prote

c

e

arth ground

m

pany the eq

u

uct has bee

n

n

Communit

y

t

bearing the

maximum p

d

uct has bee

n

anada. The

c

replacemen

t

o

ratories (N

R

e

cifications

a

r push/push

s

y

mbol is fou

n

u

al before sta

ackage.

h

e manual

f

ailure to obs

e

r

death to hu

m

s

sage is use

d

n

electrical s

h

Safe

t

e

frigerators a

r

n

t is present.

c

tive ground

prior to mak

u

ipment.

n

tested for

a

y

. CE stands

CE label ha

s

ressure 29b

a

n

tested for

a

c

TUVus mar

k

t

of the UL

a

R

TL) like T

Ü

a

s those defi

n

s

witch.

n

d on a piec

e

rting installat

e

rve

m

ans.

d

when failur

e

h

ock or burn

s

t

y

r

e

ing

ing

a

nd

for

s

a

a

rg

a

nd

k

is

a

nd

Ü

V

n

ed

e

of

ion

e

to

s

to

3.2

3

3

Warnin

g

Warnings

subsyste

m

unpacking

.2.1 Sect

i

Sectio

n

Opera

specif

i

outsid

e

.2.2 Sect

i

Sectio

n

Opera

warra

n

The L

i

Main

A

adjus

t

of ver

y

Sectio

n

A

liquid re

t

used for s

h

yellow ca

u

be lowere

d

Caution Ic

o

or precauti

facilities.

Informatio

n

operator i

n

important i

n

g

s and c

a

and caution

s

m

. The same

, installation,

i

on 5. Spe

c

n

5.2 Techni

c

tion of the

i

cations in th

i

e

any of the

s

i

on 6. Inst

a

n

6.1 Reliqu

e

ting the Reli

q

n

ty.

i

quid Helium

A

ssembly is

t

without co

n

y

thin walled

s

n

6.2 Helium

t

urn line prot

e

h

ipping, pre-i

n

u

tion tape for

d

into the ap

p

o

n. A caution

o

ns could re

s

n

Icon. The a

c

n

obtaining

t

n

formation th

a

utions

s

for the Cr

y

warnings a

n

operation an

d

c

ifications

c

al specific

a

helium reli

q

i

s section wil

l

s

pecified con

d

a

llation

e

fier installa

t

q

uefier in a

m

Return Line

extremely d

e

n

tacting Cry

o

s

tainless ste

e

Reliquefier

e

ctor is attac

h

n

stallation, a

n

identification.

p

lication. Do

n

3-2

message is

u

s

ult in signific

a

c

companyin

g

t

he best pe

r

at does not i

n

y

omech Cry

o

n

d cautions

a

d

routine mai

a

tions

CA

U

q

uefier in a

n

l

void the wa

r

d

itions, conta

t

ion

CA

U

m

agnetic fiel

d

CA

U

extending o

u

e

licate. Plea

s

o

mech. The

e

l tubing with

v

Installation i

NO

h

ed to the He

n

d storage p

u

Do not rem

o

n

ot is dispos

e

u

sed when fa

a

nt damage

t

g

message c

o

r

formance fr

o

n

volve dange

o

refrigerator

a

ppear in th

e

ntenance se

c

U

TION

n

y situation

r

ranty. If you

ct Cryomech

U

TION

d

of greater t

h

U

TION

u

t of the sid

e

s

e handle

w

line is vacuu

m

very close to

l

i

nto your Cr

y

O

TE

lium Re-liqu

e

u

rposes. It is

o

ve this until

e

of this part.

ilure to obse

r

t

o equipment

o

ntains infor

m

o

m the equi

p

r to equipme

n

system are

e

appropriate

c

tions of this

d

that does

plan to oper

a

.

h

an 500 gau

s

e

of the Heli

u

w

ith care. D

o

m

jacketed a

n

l

erances.

y

ostat

e

fier assembl

y

wrapped in

b

the Re-lique

f

Safe

t

r

ve instructio

n

and/or

m

ation to aid

t

p

ment or ot

h

n

t or humans

listed here

b

e

places in t

h

d

ocument.

not meet t

h

a

te the syste

s

s will void t

h

u

m Re-liquefi

e

o

not bend

o

n

d construct

e

y

which is

b

lack and

f

ier is ready t

o

t

y

n

s

t

he

h

er

.

b

y

h

e

h

e

m

h

e

e

r

o

r

e

d

o

Sectio

n

Failur

e

Sectio

n

The c

o

panel

Sectio

n

Cooli

n

the c

o

cleani

n

Do no

t

panel

Sectio

n

A

volt

a

comp

r

that v

o

Be su

r

One l

e

attach

hazar

d

n

6.5 Compr

e

e

to follow th

e

n

6.5.1 Prep

a

o

mpressor p

a

mounted circ

n

6.5.2 Conn

n

g water mus

t

o

oling water

s

n

g purposes,

t

apply heat t

o

f the compr

e

n

6.5.3 Conn

a

ge deviatio

n

r

essor motor

o

ltage range

w

r

e to follow al

e

ad of the

c

the compre

d

will develop

e

ssor install

a

e

se installatio

a

re the com

p

a

ckage mus

t

uit breaker.

ect the wate

t

meet the r

e

s

pecifications

it will void th

e

o

the cooling

e

ssor.

ect the com

p

n

of more th

a

overheating

a

w

ill void the

c

l local electri

c

c

ompressor

p

ssor packag

e

.

3-3

a

tion

CA

U

n

guidelines

c

p

ressor pac

k

WA

t

be position

e

r lines to th

e

CA

U

e

quirements i

n

in Section

5

e

warranty.

CA

U

water inlet a

n

p

ressor pac

k

CA

U

a

n 10% abov

e

a

nd possible

c

ompressor

w

WA

R

c

al codes an

d

WA

R

p

ackage is g

e

to an ung

r

U

TION

c

ould result i

n

k

age locatio

n

RNING

e

d to provid

e

e

compress

o

U

TION

n

Section 5.

5

is introduce

d

U

TION

nd outlet con

k

age to the

m

U

TION

e

or below t

h

failure. Indi

c

w

arrant

y

.

R

NING

d

guidelines.

R

NING

rounded. Ne

r

ounded circ

n

voiding the

n

e

easy acce

s

o

r

If water that

d into the s

ys

nectors locat

m

ain power

h

e voltage ra

t

c

ations of op

e

ver bypass

t

uit. A dang

e

Safe

t

warranty.

s

s to the fro

n

does not me

e

ys

tem, even

fo

t

ed on the fro

t

ing can cau

s

e

ration outsi

d

t

his ground

o

e

rous electric

t

y

n

t-

e

t

fo

r

nt

s

e

d

e

o

r

al

3

Sectio

n

and th

e

Follo

w

lines.

destru

Do n

o

comm

comm

Do no

t

may o

Never

relievi

n

can bl

o

.2.3 Sect

i

Sectio

n

A

volt

a

comp

r

outsid

e

Opera

the w

a

n

6.5.4 Conn

e

compress

o

w

the proced

u

Failure to fo

ction of the s

o

t allow the

e

rcial cleani

n

ercial cleani

n

t

bend the fl

e

c

cur. This ty

p

remove th

e

n

g the heliu

m

o

w off the co

u

i

on 7. Ope

r

n

7.1.1 Chec

k

a

ge deviatio

n

r

essor motor

e

that range

w

ting the heliu

a

rranty.

ect the heli

u

o

r package

u

re carefully

llow the pro

c

ealing O-ring

flex lines to

n

g agent. H

n

g agents will

e

x lines to le

s

p

e of damage

e

Aeroquip

m

charge in t

h

u

pling with s

u

r

ation

k

s before o

p

n

of more th

a

overheating

a

w

ill void the

c

m reliquefier

3-4

u

m flex lines

CA

U

when conne

c

c

edure can

c

, and helium

CA

U

come into

c

e

lium leaks

not be cover

e

CA

U

s

s than 10 in

c

is not co

v

er

e

WA

couplings f

r

h

e line to acc

e

u

fficient force

p

erating

CA

U

a

n 10% abov

e

a

nd possible

c

ompressor

w

CA

U

in a magneti

c

to the heliu

m

U

TION

c

ting and di

s

c

ause accid

e

loss.

U

TION

c

ontact with

caused by

r

ed under wa

r

U

TION

c

h (25 cm) r

a

e

d under the

w

RNING

r

om the heli

e

ptable level

s

to cause inju

U

TION

e

or below t

h

failure. Indi

c

w

arrant

y

.

U

TION

c

field of gre

a

m

reliquefie

r

s

connecting t

e

ntal couplin

g

corrosives

o

exposure to

r

ranty.

a

dius or perm

w

arranty.

um flex line

s

. The press

u

u

ry.

h

e voltage ra

t

c

ations of vo

l

a

ter than 500

Safe

t

r

assembly

t

he helium fl

e

g

disassembl

o

r any type

o

corrosives

o

anent dama

g

s without fi

r

u

re in the ho

s

t

ing can cau

s

l

tage operati

o

gauss will vo

t

y

e

x

y,

o

f

o

r

g

e

r

st

s

e

s

e

o

n

o

id

3.2.4 Sect

i

Sectio

n

The h

e

the he

CON

T

RETU

Sectio

n

A

t no

replac

press

u

remo

v

The i

n

remo

v

Sectio

n

Venti

n

impro

p

be re

q

Sectio

n

When

gases

their f

r

heliu

m

servic

i

Conta

m

and,

u

i

on 8. Rou

t

n

8.3 Cold h

e

e

lium relique

f

lium reliquefi

e

T

ACT CRY

O

RNED FOR

S

n

8.4 Replac

e

time should

ing the ads

o

u

re since th

e

v

al.

n

put power m

v

ing side pan

e

n

8.5

V

ent e

x

n

g more than

p

er oil migrat

q

uired.

n

8.6 Recha

r

adding heli

u

will result in

r

eezing tem

p

m

charge will

s

i

ng.

m

ination of t

h

u

nless resulti

n

t

ine maint

e

e

ad

f

ier contains

n

e

rwill void th

O

MECH IF

S

ERVICING.

e

the adsor

b

the

A

eroqui

p

o

rber. Repla

c

e

adsorber

ust be disco

n

e

ls.

x

cess heliu

m

5 PSIG (.34

ion within th

e

r

ge helium

u

m, the heli

u

the freezing

p

erature is m

u

s

everely deg

r

h

e helium by

n

g from a sys

t

3-5

e

nance

CA

U

n

o user-servi

e warranty.

THE HELI

U

b

er

CA

U

p

coupling

s

c

ement can

is equipped

WA

R

n

nected from

m

CA

U

bar

/

34 kilo

p

e

system. If t

CA

U

m must be

9

of the conta

u

ch higher t

h

r

ade the cold

other gases

t

em failure, i

s

U

TION

ceable parts.

U

M RELIQ

U

U

TION

s

be remove

be complete

d

with Aeroq

u

R

NING

the helium

c

U

TION

p

ascals) of h

e

his condition

U

TION

9

9.999% pu

r

minant gase

s

h

an that of h

e

head's functi

is a commo

n

s

not covered

Attempting

t

U

EFIER NE

E

d from the

a

d without re

u

ipcouplin

c

ompressor

p

e

lium per min

occurs, fact

o

r

e. Contamin

s

in the cold

elium. Conta

on and it will

n

cause of pr

e

by the warra

Safe

t

t

o disassemb

E

DS TO

B

a

dsorber wh

e

lieving syste

gs for seal

e

p

ackage befo

r

ute will lead

t

o

ry service

w

ation by oth

e

head becau

s

minants in t

h

require facto

e

mature fai

l

u

r

nty.

t

y

le

B

E

e

n

m

e

d

r

e

t

o

w

ill

e

r

s

e

h

e

ry

r

e

Sectio

n

Never

warra

n

Never

comp

r

comp

o

n

8.7 Cleani

n

wet either

p

n

ty.

remove an

r

essor witho

u

o

nents can bl

o

n

g

p

art of the

s

Aeroquip

u

t first relievi

o

w off the co

u

3-6

CA

U

s

ystem. Wat

e

WA

coupling fro

m

ng the heliu

m

u

pling with s

u

U

TION

e

r getting int

o

RNING

m

the heliu

m

m

charge. T

u

fficient force

o

the syste

m

m

flex lines,

he pressure

to cause inj

u

Safe

t

m

will void t

h

cold head

o

in any of t

h

u

ry.

t

y

h

e

o

r

h

e

4.1

Section 4

Inspection and

Unpacking

Table of contents

Other Cryomech Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

JMA

JMA SUPRACODE user manual

Siemens

Siemens 3VM9 0JB1 Series operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley Guardmaster Minotaur MSR178DP Quick start guide - Troubleshooting

Gerber

Gerber SABRE 408 Replacement procedure

CDL

CDL The Traditional user manual

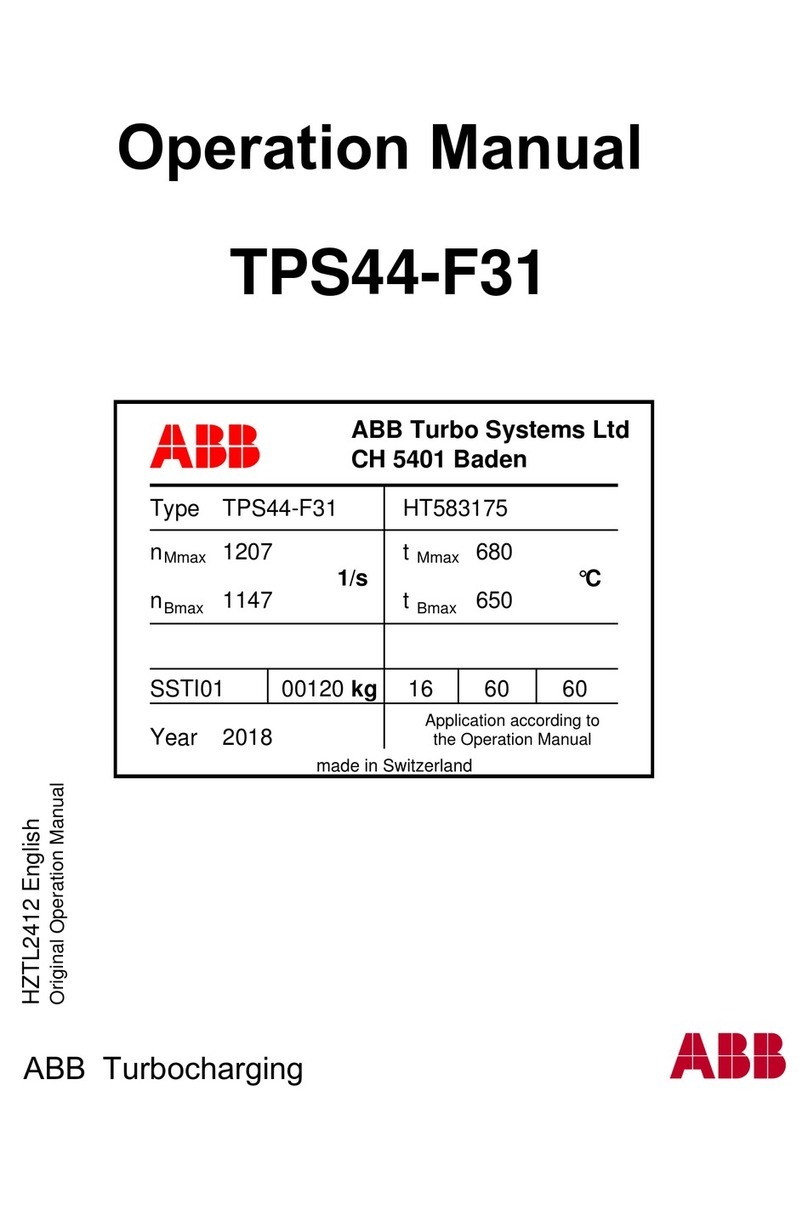

ABB

ABB HT583175 Operation manual