Borum BOD1906 User manual

Sep-19 Product Code: BOD1906

Made in China to TQB Brands Pty Ltd specifications

Visit us at www.tqbbrands.com.au

OWNER’S MANUAL

PRODUCT CODE: BOD1906

65 LITRE PORTABLE OIL DRAINER

Tank

Capacity

Recovery

Chamber

Capacity

Vacuum

Working

Pressure

Degree of

Vacuum

Net

Weight

Dimensions

65 Litre

9 Litre

0.04-0.06MPa

0.05-0.07MPa

37kg

480x500x1850mm

Sep-19 Product Code: BOD1906

Made in China to TQB Brands Pty Ltd specifications Page 2

Visit us at www.tqbbrands.com.au

WARNING

IMPORTANT: READ ALL INSTRUCTIONS BEFORE USE

WARNING

The instructions and warnings contained in this manual should be read and understood before

using or operating this equipment. Do not allow anyone to use or operate this equipment until

they have read this manual and have developed a thorough understanding of how this

equipment works. Failure to observe any of the instructions contained in the manual could result

in severe personal injury to the user or bystanders, or cause damage to the equipment and

property. Keep this manual in a convenient and safe place for future reference.

Whilst every effort has been made to ensure accuracy of information contained in this manual,

the TQB Brands Pty Ltd policy of continuous improvement determines the right to make

modifications without prior warning.

CONTENT

WARNING .............................................................................................................................. 2

CONTENT ............................................................................................................................... 2

SAFETY INSTRUCTIONS ........................................................................................................... 3

ASSEMBLY, OPERATION, PREVENTITIVE MAINTENANCE .......................................................... 4

TROUBLESHOOTNG ................................................................................................................ 8

PARTS LIST ............................................................................................................................. 9

WARRANTY .......................................................................................................................... 11

Sep-19 Product Code: BOD1906

Made in China to TQB Brands Pty Ltd specifications Page 3

Visit us at www.tqbbrands.com.au

SAFETY INSTRUCTIONS

SAFETY OPERATING INSTRUCTIONS

- Check for damaged parts. Before using any product, any part that appears damaged should

be carefully checked to determine that it will operate properly and perform its intended

function. Check for any broken or damaged parts and any other conditions that may affect

its operation. Replace or repair damaged or worn parts immediately.

- Do not exceed the product’s working pressure of 0.5bar.

- If compressor supplies air pressure in excess of 0.5 Bar, an inline air regulator must be used

to maintain air pressure at 0.5 Bar.

- Only use on a flat surface capable of supporting the Portable Oil Drainer and its maximum

load of 65 litres.

- Use eye and hearing protection. Always wear ANSI approved impact safety goggles, full

face shield and ANSI approved hearing protection when working with this product.

- Dress safely. Non-skid footwear or safety boots should be used when working with the

product. Do not wear loose clothing or jewellery as they can become caught in moving parts

wear a protective hair covering to prevent long hair from becoming caught in moving parts.

- Always secure the wheels and castors in place while operating the oil drainer.

- Never leave unit unattended when operating or evacuating.

- Never use near open flame or heat source.

- Always check that valve below funnel is closed before emptying

- Always disconnect air supply after emptying.

- Never use unit for handling highly volatile fuels and fluids.

- Use only the nozzle assembly provided.

- Never fill the tank over the max. Level given by the level indicator

- Keep work area clean. Cluttered areas and benches invite accidents.

- When servicing, use only Borum Industrial identical replacement parts. Use of any other

parts will void the warranty.

- Use the right product for the job. There are certain applications for which the Oil Drainer

was designed. Do not modify the Oil Drainer and do not use the Oil Drainer for a purpose

for which it was not intended.

Sep-19 Product Code: BOD1906

Made in China to TQB Brands Pty Ltd specifications Page 4

Visit us at www.tqbbrands.com.au

ASSEMBLY, OPERATION, PREVENTITIVE MAINTENANCE

1. FEATURES

The Borum Industrial Oil Drainer is a multifunction oil drainer with 2m x 25.4mm discharge

hose. Discharge is by compressed air fitted with safety valve, 18 litre steel telescopic

collection pan, oil reservoir level indicator and small parts tray; it has heavy duty castors

for easy manoeuvrability.

2. ASSEMBLY

Unpacking: after removing the packing material, make sure the product is in perfect

condition and that there are no visible damaged parts. The packaging materials

(Polyethylene bags, polystyrene etc.), must be disposed of in an appropriate refuse

collection container. These materials must not be left within the reach of children as they

are potential sources of danger.

Assembly according to the exploded drawing, all connecting parts should be well sealed by

tape or seal glue, ensure all parts are tightened.

3. BEFORE USE

Prior to each use conduct a visual inspection by checking for abnormal conditions, such as

cracked joints and damaged, loose, or missing parts.

Air Supply

To prevent explosion:

Only use clean, dry, regulated, compressed air to operate this tool. Do not use oxygen,

carbon dioxide, combustible gases, or any other bottled gas as a power source for this

tool.

Note: Air flow, and therefore tool performance, can be hindered by undersized air

supply components. The compressor air hose must be long enough to reach the work

area.

Before connecting the air compressor to pressurise the Oil Extractor, run the air

compressor to make sure it is in good working order.

- Turn on the air compressor according to the manufacturer’s directions and allow

it to build up pressure until it cycles off.

- Adjust the air compressor’s pressure regulator so that the air output is enough to

properly power the tool, but the output will not exceed the tool’s maximum air

pressure at any time. Turn the knob clockwise to increase the pressure and

counter clockwise to decrease pressure. Adjust the pressure gradually, while

checking the air output gauge to set the pressure.

- Inspect the air connections for leaks. Repair any leaks found.

- If the compressor will not be used at this time, turn off the air supply and safely

discharge any residual air pressure to prevent accidental operation.

Sep-19 Product Code: BOD1906

Made in China to TQB Brands Pty Ltd specifications Page 5

Visit us at www.tqbbrands.com.au

Check the unit meets seal specification:

- Please note that the air intake pipe connected to the quick coupler on the top of

the transparent recovery chamber must be fitted with the oil filter and air

regulator. Turn the ball valve handle under the transparent recovery chamber

to the horizontal position before testing.

- Turn off the valve of the suction probe, connect the air intake pipe with the quick

coupler, adjust the air intake pressure, the needle of the pressure gauge will

move.

- When the pressure reaches to 0.05MPa (7psi), turn off the air intake valve on the

top of transparent recovery chamber and hold pressure for 1 hour ensure the

pressure has been maintained.

- Turn off the air intake valve on the top of the tank

- Turn off the discharging oil pipe valve

- Turn off the valve under the oil tray

- Turn the valve handle under the transparent recovery chamber to the vertical

position, open the transparent recovery chamber top valve, air intake for about

3—5 minutes and then check the pressure gauge reading, the pressure should

not be less than 0.05MPa, (7psi) and should be maintained for at least 1 hour. It

the pressure reads no change the oil drainer is ready for use. If pressure has

dropped below 7psi reseal all fittings and check again.

4. OPERATION

OIL EXTRACTION

1. Position the Extractor on a flat, level surface

2. Choose the appropriate Probe (one of two choices) 2 x 6f , 1 x 8f. Remove the

dipstick and insert the probe into the engine’s dipstick port.

3. Turn off the valve under the transparent recovery chamber, turn on the air intake

valve on the top of transparent recovery chamber, connect the quick coupler on

top of the transparent recovery chamber with the air intake pipe, turn on the air

intake valve and adjust the air intake pressure 0.03—0.05MPa (4-7psi), the

vacuum gauge pointer will move and the degree of vacuum can be adjusted

according to operator’s requirement, the Max. degree of vacuum is not less than

0.057MPa (8psi). Oil cannot exceed the STOP position

4. Lubricate the rubber O-ring of the suction plug

5. Push the suction plug to the quick coupler of the suction probes.

Sep-19 Product Code: BOD1906

Made in China to TQB Brands Pty Ltd specifications Page 6

Visit us at www.tqbbrands.com.au

6. Secure over the two rubber gaskets in the assembly.

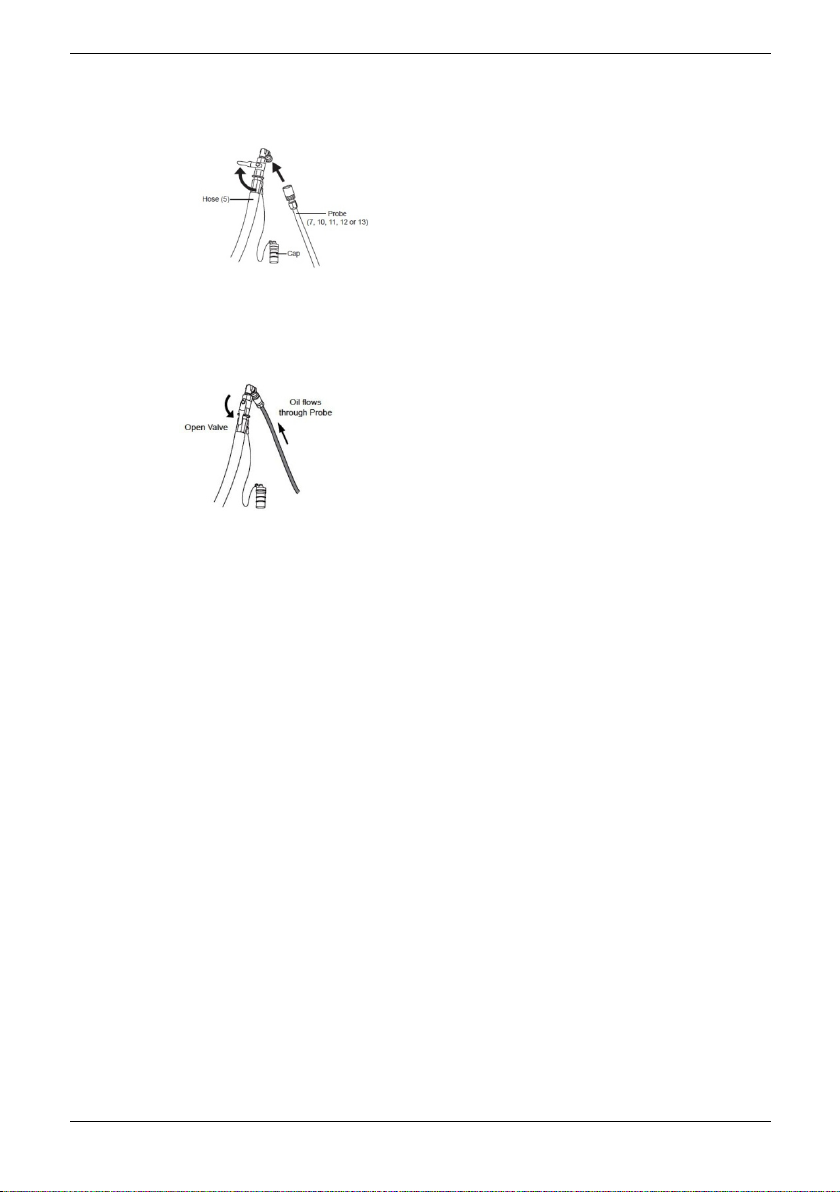

7. Remove the cap (which is attached to a chain) from the end of the hose (5) and

attach the probe to the hose.

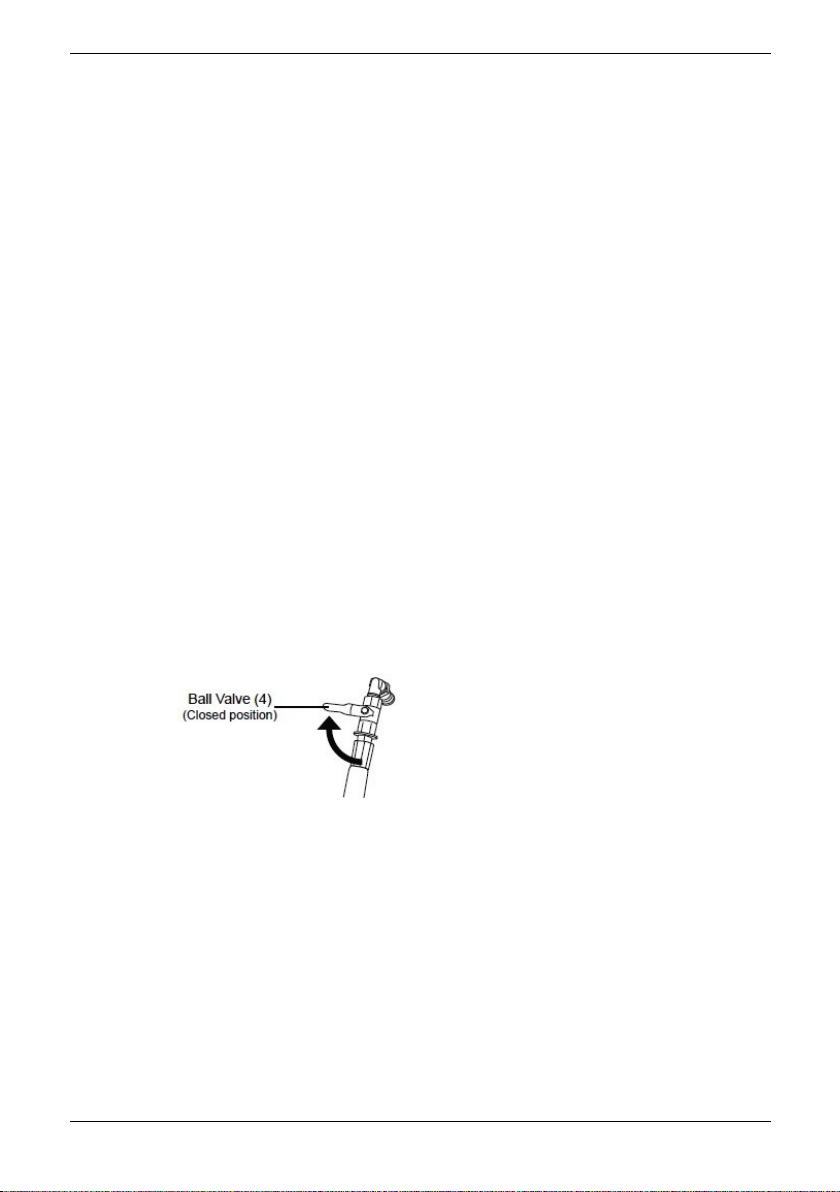

8. Open the Ball Valve (4) by aligning it with the hose; oil will begin to flow

9. Oil should always be removed when it is hot, otherwise personal injury or property

damage may result. The oil level tube (see figure F) will show how much oil is in

the tank. Keep the probe near the bottom of the sump.

10. When done, close the Ball Valve Lever (4) (horizontal position). Remove the Probe

from the vehicle.

11. Turn on the probe under the transparent recovery chamber, the oil will flow from

the transparent recovery chamber to the main oil tank.

DISCHARGING OIL

1. Turn Off the valve under the transparent recovery chamber before discharging oil, to

avoid damaging the transparent recovery chamber.

2. Turn On the control valve of oil discharge opening under the tank, place the steel

elbow of the oil pipe on the opening of the oil storage tank.

3. Turn Off the valve under the oil tray.

4. Connect the air intake pipe (requires fitting pressure regulator) with the quick coupler

on the top of tank

- Turn On the air intake valve, adjust the air intake pressure to 0.5Bar, (7psi), then fill the air

and the oil will be discharged out to the oil storage tank. If compressor supplies air pressure

in excess of 0.5 Bar, an inline air regulator must be used to maintain air pressure at 0.5 Bar.

Sep-19 Product Code: BOD1906

Made in China to TQB Brands Pty Ltd specifications Page 7

Visit us at www.tqbbrands.com.au

OIL COLLECTION

1. Turn Off the valve under the transparent recovery chamber.

2. Turn On the valve under the oil tray and the air intake valve on the top of tank, adjust

the oil tray to suitable height, move the portable drainer to the position under the oil

discharging vehicle, open the Ball Valve (9).

5. STORAGE

This Oil Drainer should always be stored in a dry location on a level surface. Disconnect air

supply and empty air and waste oil.

6. MAINTENANCE

Disconnect air prior to any maintenance

Inspect the general condition of the Oil Drainer checking:

- for loose hardware

- misalignment of binding or parts, cracked, bent, or broken parts, and

- any other condition that may affect the Oil Drainers safe operation

7. SERVICE & REPAIR

Any Oil Drainer found damaged in any way, or found to be worn or operates abnormally

should be removed from service until repaired by an authorised service agent. Owners and

/ or operators should be aware that repair of this product may require specialised

equipment and knowledge. Only authorised parts, labels and decals shall be used on this

equipment. Annual inspection of the Oil Drainer is recommended and can be made by an

authorised repair facility to ensure that your equipment is in optimum condition and that

the equipment has the correct decals and safety labels specified by the manufacturer.

Sep-19 Product Code: BOD1906

Made in China to TQB Brands Pty Ltd specifications Page 8

Visit us at www.tqbbrands.com.au

TROUBLESHOOTNG

PROBLEM

POSSIBLE CAUSE

ACTION

Degree of vacuum doesn’t

meet requirement

1. Air leaking

2. Steel ball corroded

1. Test the degree of vacuum

of transparent recovery

chamber, if the chamber

passes test it will show no

signs of leaking. Check tank

seal tape and seal glue.

2. Replace the steel ball and

the upper cover

3. Check all valves are turned

off

The pointer of vacuum

gauge flow down quickly

after vacuumise

1. Air leaking

1. As above

Vacuum gauge has pressure

drop but cannot suck oil

1. The oil temperature

is too low

2. The suction plug seal

has worn out

3. The oil suction

probe cover is

distorted

4. Check the valve of

oil suction turning is

not worn out

5. Check the oil suction

pipe is not jammed

or touching the

bottom of the tank

1. Let the oil reach normal

temperature and retry

2. Replace the seal ring of the

suction plug

3. Change the oil suction probe

cover

4. Turn on valve of oil suction

pipe

5. Clean oil suction pipe

Sep-19 Product Code: BOD1906

Made in China to TQB Brands Pty Ltd specifications Page 9

Visit us at www.tqbbrands.com.au

PARTS LIST

Part

#

Description

QTY

Part

#

Description

QTY

1

Oil suction probe

1

27

1/8” safety valve

1

2

Vacuum recovery chamber

1

28

Air intake connector

1

3

Oil tray

1

29

Air intake pipe connector

1

4

O-ring

2

30

1/4” ball valve

3

5

Oil tray’s connector

1

31

Quick coupler

1

6

O-ring

2

32

Handle

1

7

Oil tray’s connector

1

33

Hex nut

1

8

Hex nut

1

34

Pipe Clipper

1

9

25mm Ball valve

1

35

Hex nut

2

10

Upper connector of drain tube

1

36

Clipper

2

11

Hex nut

2

37

Oil discharging connector

1

12

Fixing ring

1

38

1/2” Ball valve

1

13

Inlay screw

1

39

Oil discharging pipe connector

1

14

Clipper

1

40

Reinforced nylon hose

1

15

O-ring

1

41

Oil discharging elbow

1

16

Drain tube

1

42

Right angle connector

2

17

Tool tray

1

43

Flexible hose connector

2

18

Bush for oil suction probe

1

44

Oil lever

1

19

Self-tapping nut

1

45

Clipper

2

20

Rivet

1

46

Cap screw

2

21

25mm elbow

1

47

Washer

2

22

Oil intake connector

1

48

75mm Castor

2

23

Clipper

2

49

O-ring

1

24

Pressure Hose

1

50

Drain plug

1

25

Down connector

1

51

Circlip

2

26

Tank

1

52

125mm wheel

2

Sep-19 Product Code: BOD1906

Made in China to TQB Brands Pty Ltd specifications Page 10

Visit us at www.tqbbrands.com.au

Sep-19 Product Code: BOD1906

Made in China to TQB Brands Pty Ltd specifications Page 11

Visit us at www.tqbbrands.com.au

WARRANTY

Borum Industrial products have been carefully tested and inspected before shipment and are

guaranteed to be free from defective materials and workmanship for a period of 12 months

from the date of purchase except where tools are hired out when the guarantee period is ninety

days from the date of purchase.

Should this piece of equipment develop any fault, please return the complete tool to your

nearest authorised warranty repair agent or contact TQB Brands Pty Ltd Warranty team –

If upon inspection it is found that the fault occurring is due to defective materials or

workmanship, repairs will be carried out free of charge. This guarantee does not apply to normal

wear and tear, nor does it cover any damage caused by misuse, careless or unsafe handling,

alterations, accident, or repairs attempted or made by any personnel other than the authorised

TQB Brands Pty Ltd repair agent.

This guarantee applies in lieu of any other guarantee expressed or implied and variations of its

terms are not authorised.

Your TQB Brands Pty Ltd guarantee is not effective unless you can produce upon request a dated

receipt or invoice to verify your proof of purchase within the 12 month period.

Consumer Guarantee

Our goods come with a guarantee that cannot be excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for a major failure and compensation for any other

reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or

replaced if the goods fail to be of acceptable quality and the failure does not amount to a major

failure.

All images and illustrations shown are for reference purposes only. All information, specifications and

illustrations in this manual are based on the latest information available at the time of publication and are

subject to change without notice. The information in this manual is periodically revised to ensure the latest

information is included. Download the latest version of this manual and other related technical

documentation from www.tqbbrands.com.au.

Table of contents

Other Borum Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

CleaverBrooks

CleaverBrooks CB-LE Series Operation, service and parts manual

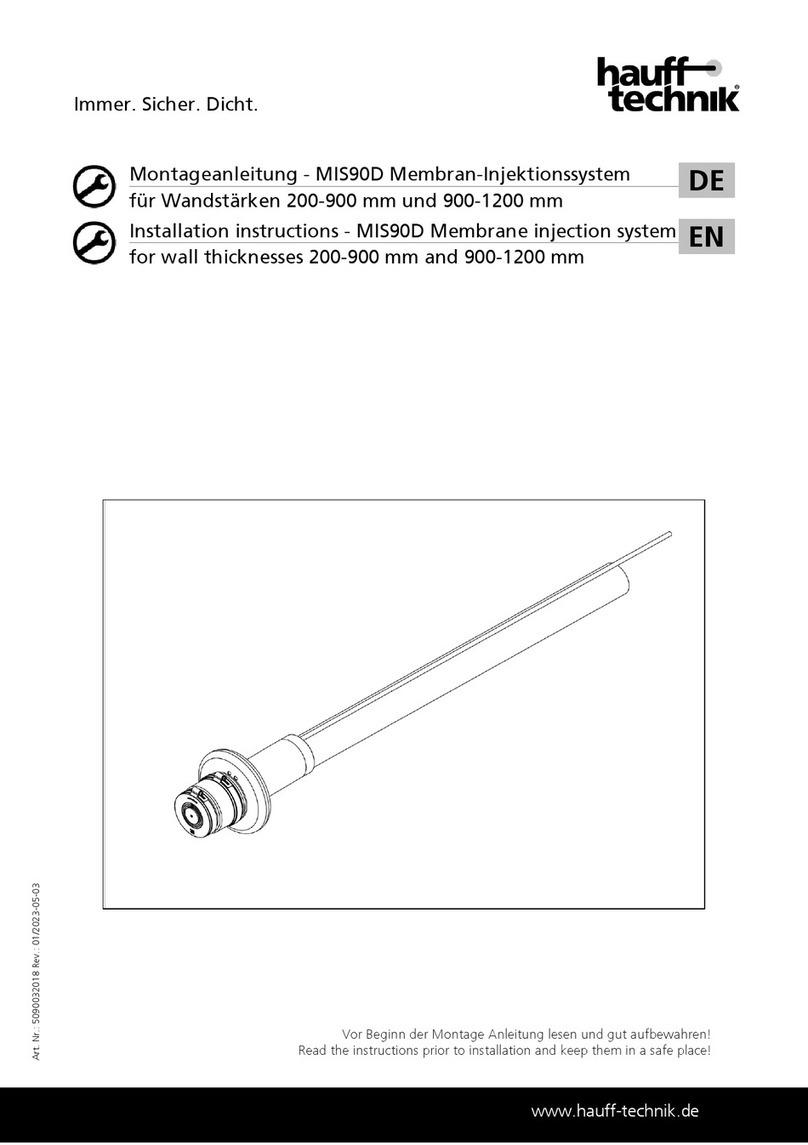

Haufftechnik

Haufftechnik MIS90D installation instructions

Carbatec

Carbatec TH-B317P owner's manual

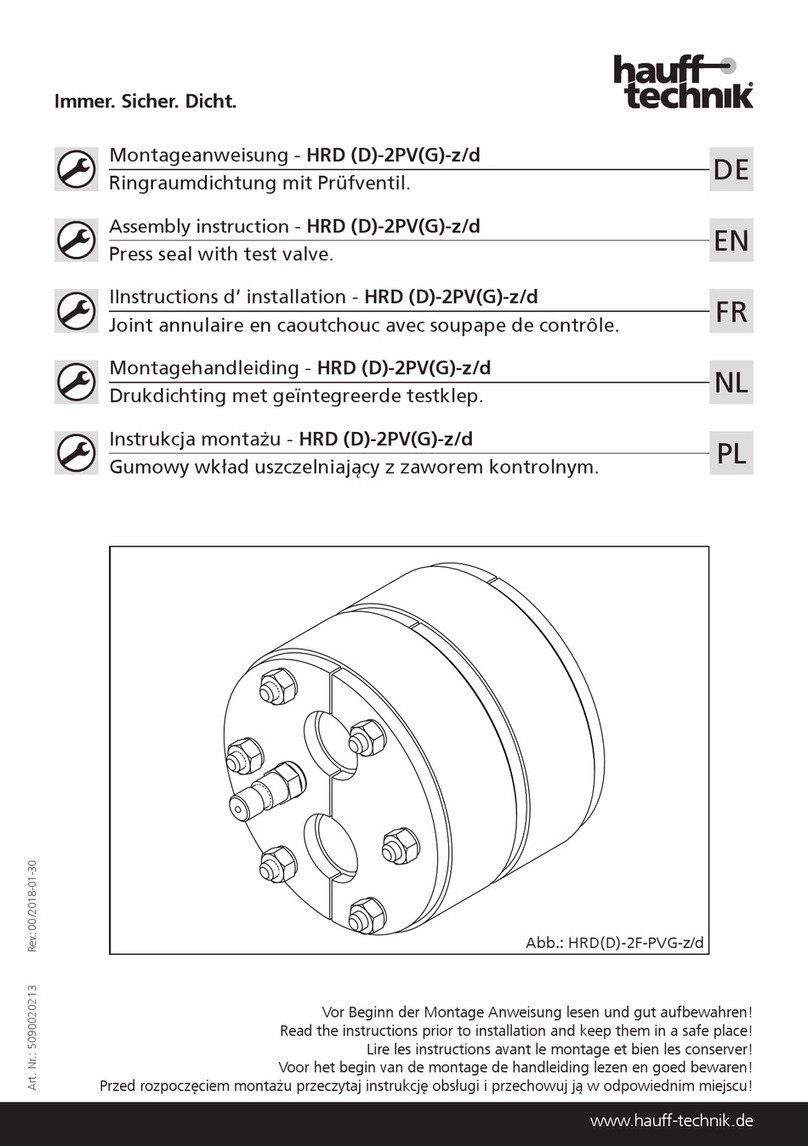

Haufftechnik

Haufftechnik HRD Series Assembly instruction

Ditch Witch

Ditch Witch 1CM Operator's manual

Hoffmann&Hoffmann

Hoffmann&Hoffmann Dripmaster EDD-4C user guide

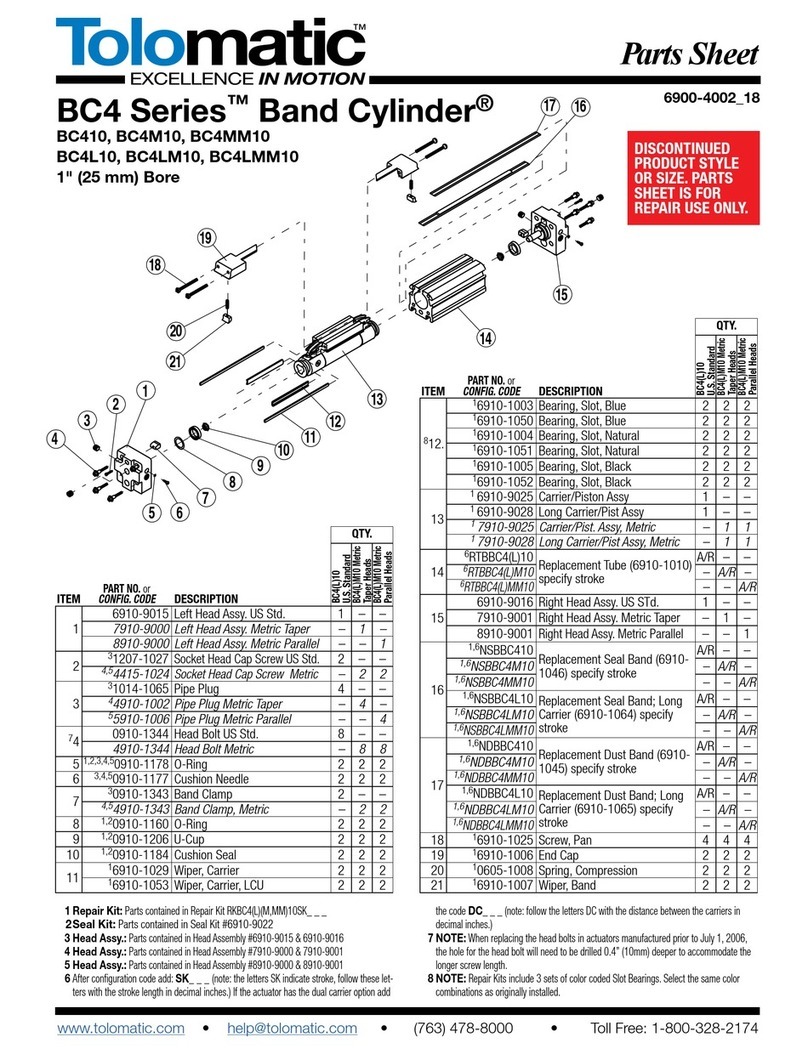

Tolomatic

Tolomatic BC4 Series quick start guide

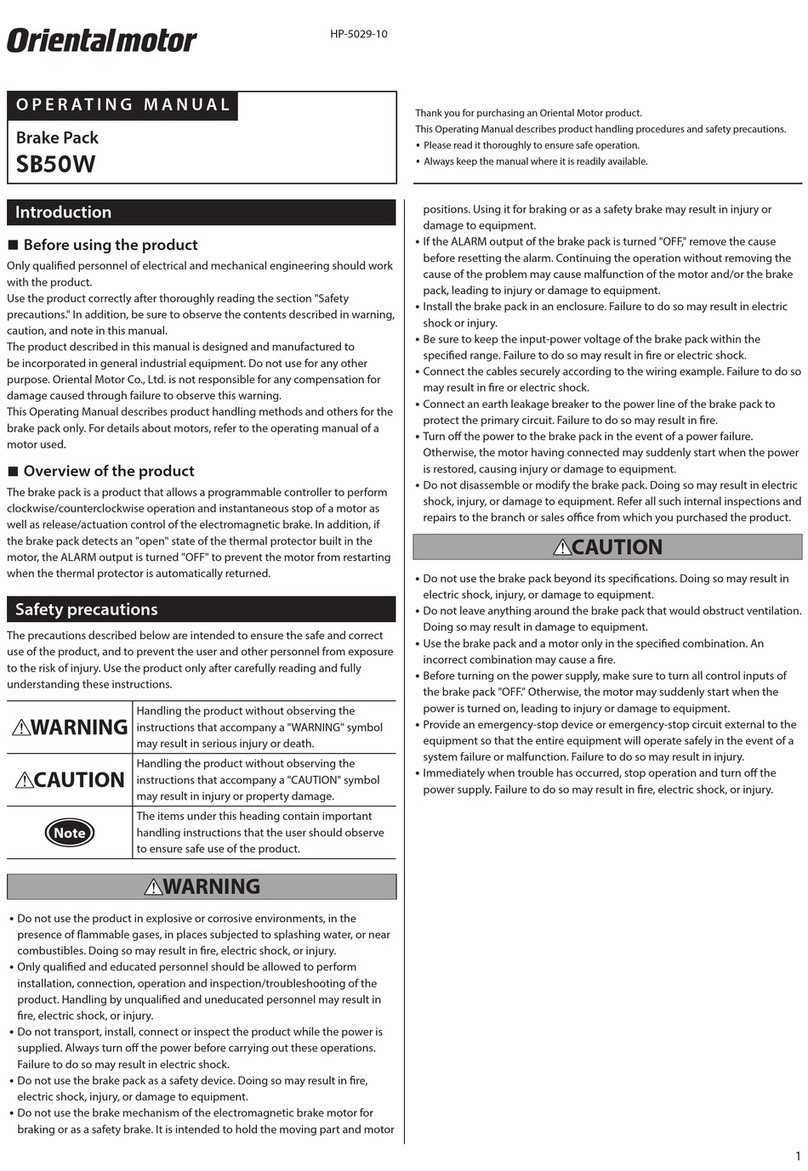

Oriental motor

Oriental motor SB50W operating manual

KEBCO

KEBCO COMBISTOP 38 Instructions for use

Avantco

Avantco Leguan 50 Operator's manual for Attachment

Flex-A-Seal

Flex-A-Seal 85 Installation, operation, maintenance guide

Haufftechnik

Haufftechnik HRD SG b40 installation instructions