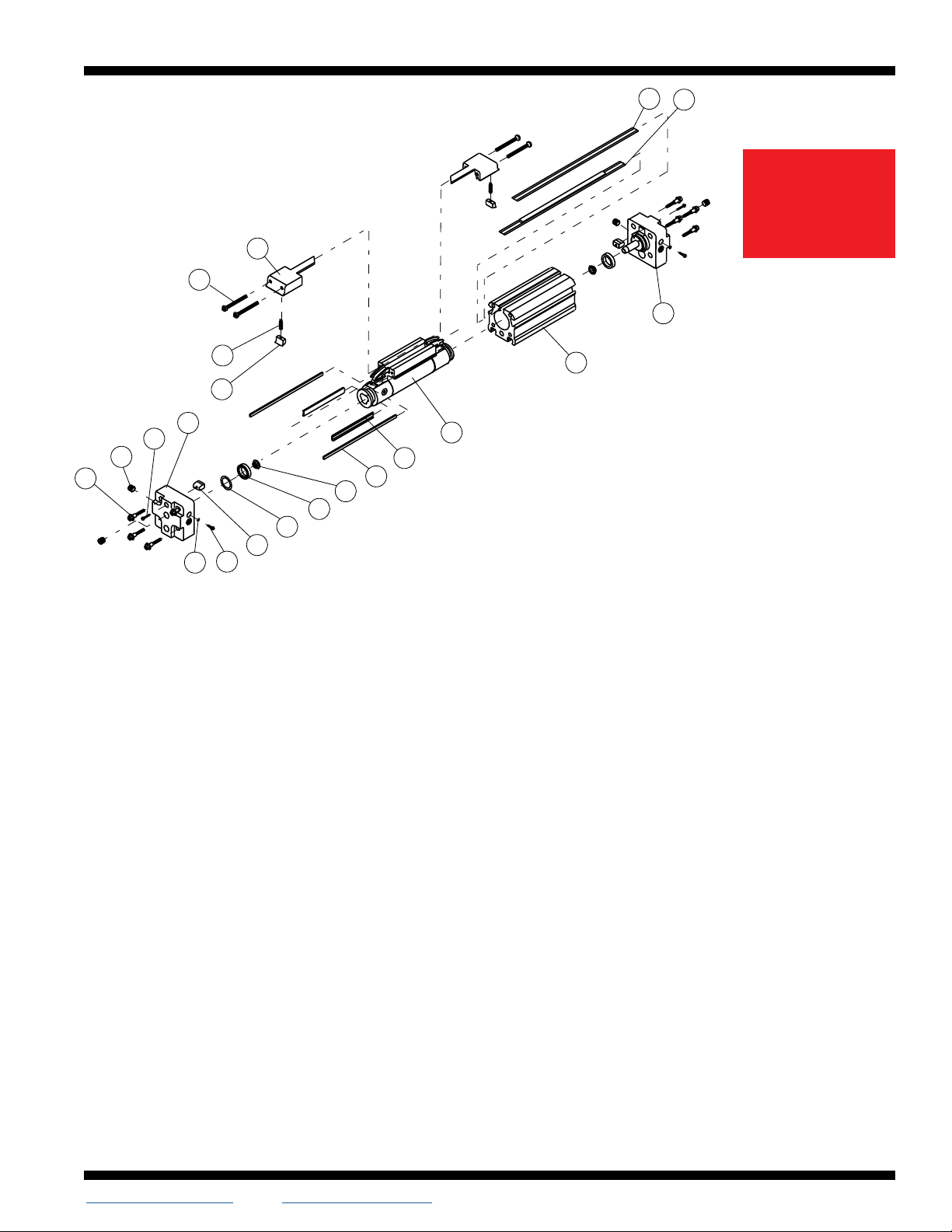

Tolomatic BC4 Series User manual

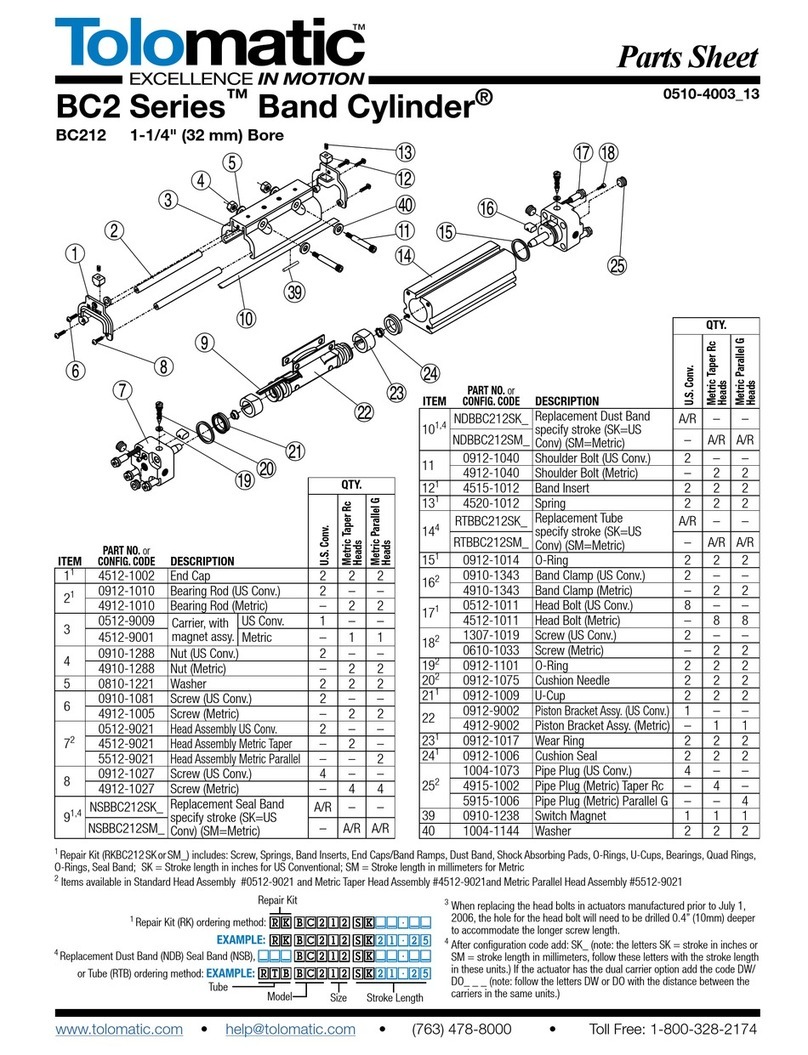

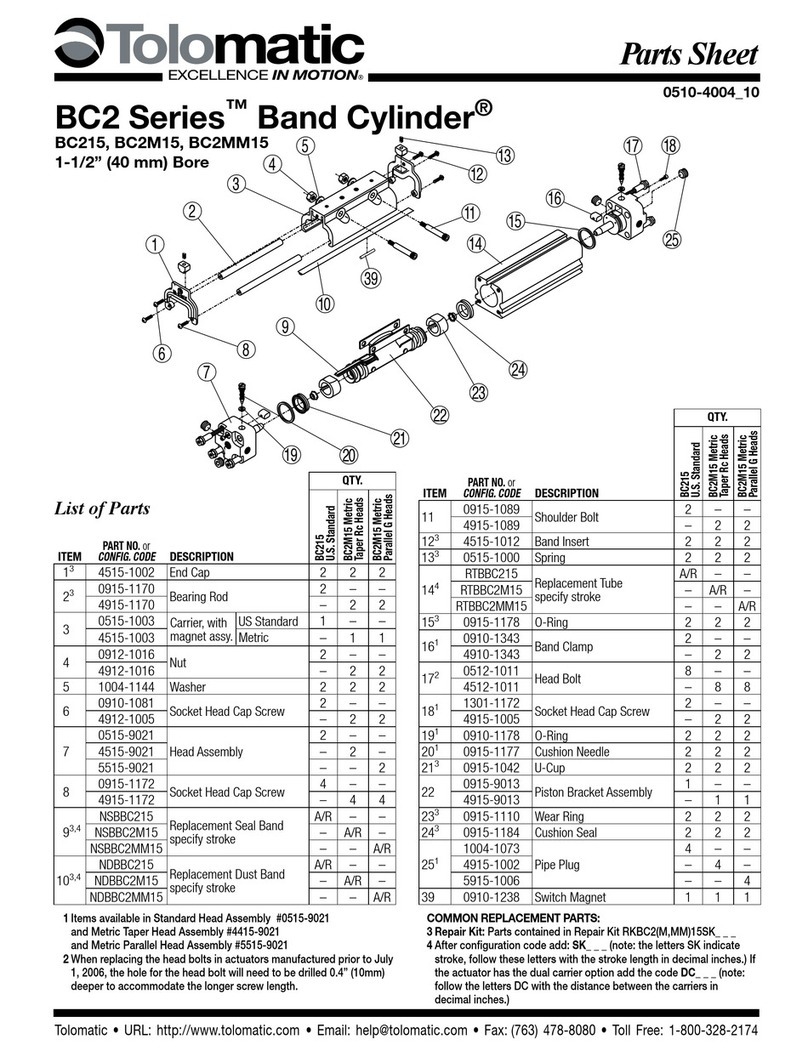

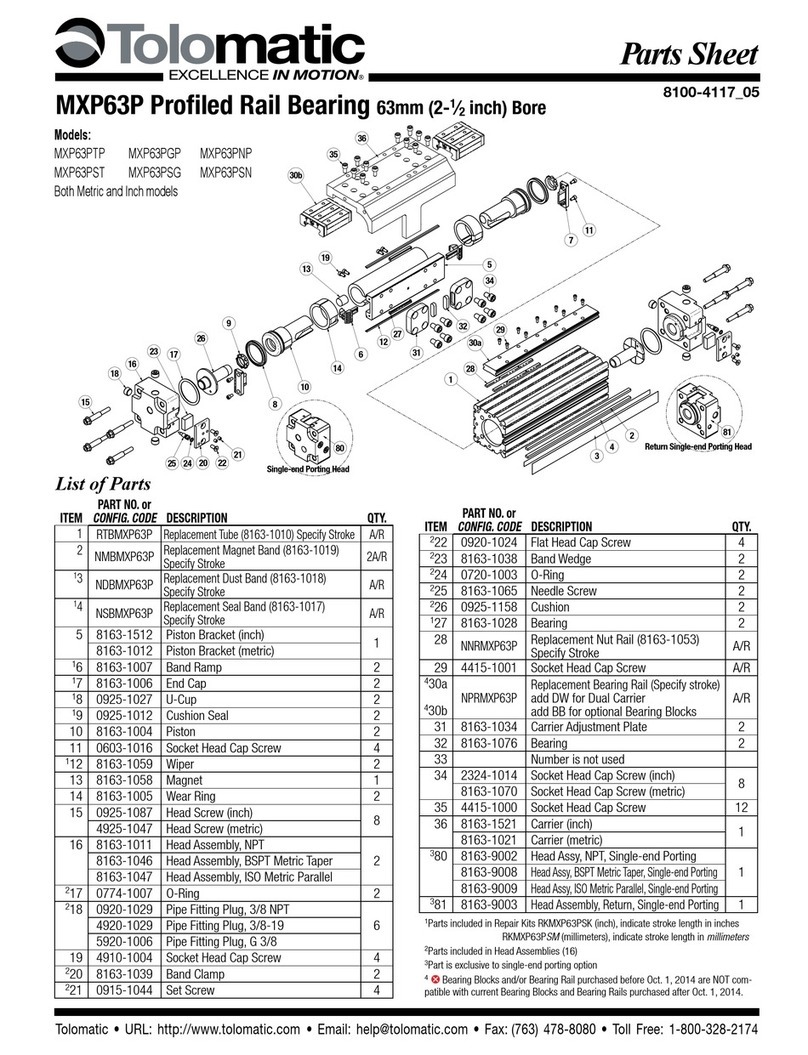

Parts Sheet

6900-4002_18_BC410ps-OBS

QTY.

ITEM

PART NO. or

CONFIG. CODE

DESCRIPTION

BC4(L)10

U.S. Standard

BC4(L)M10 Metric

Taper Heads

BC4(L)M10 Metric

Parallel Heads

1

6910-9015 Left Head Assy. US Std. 1 – –

7910-9000 Left Head Assy. Metric Taper –1–

8910-9000 Left Head Assy. Metric Parallel – – 1

231207-1027

Socket Head Cap Screw US Std.

2 – –

4,54415-1024

Socket Head Cap Screw Metric

– 2 2

3

31014-1065 Pipe Plug 4 – –

44910-1002 Pipe Plug Metric Taper – 4 –

55910-1006 Pipe Plug Metric Parallel – – 4

740910-1344 Head Bolt US Std. 8 – –

4910-1344 Head Bolt Metric – 8 8

5

1,2,3,4,50910-1178

O-Ring 2 2 2

63,4,50910-1177 Cushion Needle 2 2 2

730910-1343 Band Clamp 2 – –

4,54910-1343 Band Clamp, Metric – 2 2

81,20910-1160 O-Ring 2 2 2

91,20910-1206 U-Cup 2 2 2

10 1,20910-1184 Cushion Seal 2 2 2

11 16910-1029 Wiper, Carrier 2 2 2

16910-1053 Wiper, Carrier, LCU 2 2 2

1 Repair Kit: Parts contained in Repair Kit RKBC4(L)(M,MM)10SK_ _ _

2Seal Kit: Parts contained in Seal Kit #6910-9022

3 Head Assy.: Parts contained in Head Assembly #6910-9015 & 6910-9016

4 Head Assy.: Parts contained in Head Assembly #7910-9000 & 7910-9001

5 Head Assy.: Parts contained in Head Assembly #8910-9000 & 8910-9001

6

After configuration code add: SK_ _ _(note: the letters SK indicate stroke, follow these let-

ters with the stroke length in decimal inches.) If the actuator has the dual carrier option add

the code DC_ _ _(note: follow the letters DC with the distance between the carriers in

decimal inches.)

7 NOTE: When replacing the head bolts in actuators manufactured prior to July 1, 2006,

the hole for the head bolt will need to be drilled 0.4”(10mm) deeper to accommodate the

longer screw length.

8 NOTE: Repair Kits include 3 sets of color coded Slot Bearings. Select the same color

combinations as originally installed.

BC4 Series™Band Cylinder®

BC410, BC4M10, BC4MM10

BC4L10, BC4LM10, BC4LMM10

1"(25 mm) Bore

QTY.

ITEM

PART NO. or

CONFIG. CODE

DESCRIPTION

BC4(L)10

U.S. Standard

BC4(L)M10 Metric

Taper Heads

BC4(L)M10 Metric

Parallel Heads

812.

16910-1003 Bearing, Slot, Blue 2 2 2

16910-1050 Bearing, Slot, Blue 2 2 2

16910-1004 Bearing, Slot, Natural 2 2 2

16910-1051 Bearing, Slot, Natural 2 2 2

16910-1005 Bearing, Slot, Black 2 2 2

16910-1052 Bearing, Slot, Black 2 2 2

13

16910-9025 Carrier/Piston Assy 1 – –

16910-9028 Long Carrier/Pist Assy 1 – –

1 7910-9025 Carrier/Pist. Assy, Metric – 1 1

1 7910-9028 Long Carrier/Pist Assy, Metric – 1 1

14

6RTBBC4(L)10 Replacement Tube (6910-1010)

specify stroke

A/R – –

6RTBBC4(L)M10

– A/R –

6RTBBC4(L)MM10

– – A/R

15

6910-9016 Right Head Assy. US STd. 1 – –

7910-9001 Right Head Assy. Metric Taper –1–

8910-9001

Right Head Assy. Metric Parallel

– – 1

16

1,6NSBBC410 Replacement Seal Band(6910-

1046) specify stroke

A/R – –

1,6NSBBC4M10 – A/R –

1,6NSBBC4MM10

– – A/R

1,6NSBBC4L10 Replacement Seal Band; Long

Carrier(6910-1064) specify

stroke

A/R – –

1,6NSBBC4LM10 – A/R –

1,6NSBBC4LMM10

– – A/R

17

1,6NDBBC410 Replacement Dust Band(6910-

1045) specify stroke

A/R – –

1,6NDBBC4M10 – A/R –

1,6NDBBC4MM10

– – A/R

1,6NDBBC4L10 Replacement Dust Band; Long

Carrier(6910-1065) specify

stroke

A/R – –

1,6NDBBC4LM10 – A/R –

1,6NDBBC4LMM10

– – A/R

18 16910-1025 Screw, Pan 4 4 4

19 16910-1006 End Cap 2 2 2

20 10605-1008 Spring, Compression 2 2 2

21 16910-1007 Wiper, Band 2 2 2

18

1

2

3

4

5 6

7

8

9

10

11

12

13

14

19

15

20

21

17 16

DISCONTINUED

PRODUCT STYLE

OR SIZE. PARTS

SHEET IS FOR

REPAIR USE ONLY.

Parts Sheet #6900-4002_18_BC410ps-OBS

BC4(L)10, BC4(L)M10, BC4(L)MM10 Instructions – 2

Drawing repeated for reference

18

1

2

3

4

5 6

7

8

9

10

11

12

13

14

19

15

20

21

17 16

CYLINDER DISASSEMBLY INSTRUCTIONS FOR INSTALLATION OF

REPAIR KITS ONLY

1. Remove Band Cylinder from machinery.

2. Remove any foot mounting hardware external shock absorbers or switches if present.

Remove the four Head Bolts(#4) and loosen the SHCS(#2) on each cylinder Head(#1, #15).

Remove Heads.

3. Remove Screws(#18) from End Caps(#19) and slide End Caps off Carrier(#13). Remove top

Dust Band(#17). Remove the Carrier Assembly(#13) from the Tube(#14).

4. Dislodge the inner Sealing Band(#16) from its groove by gently pressing down on the band

with an O-ring Pick or similar tool.(When doing so, take care that NO SCRATCHES are made

in the tube bore slot.) Remove Sealing Band(#16).

CYLINDER ASSEMBLY INSTRUCTIONS

1. CLEAN AND LUBRICATE

Thoroughly clean all components, particularly the tube bore slot and bands. Thoroughly lubri-

cate the tube with RheoGel TEK664 grease. Apply light coat of grease to Sealing Band(#16)

and Dust Band(#17).

2. ASSEMBLE SEALING BAND

CAUTION: Metal edges of Sealing Band are sharp. Exercise caution

to avoid injury to yourself of the Band and Tube when inserting.

Carefully install Sealing Band(#16) by passing it sideways though the slot in the tube. Position

Sealing Band, rubber up, on the bottom of the tube with equal length of band extending out

both ends of the tube.

3. INSTALL PISTON/CARRIER ASSEMBLY

Lubricate and install new U-Cups(#9)(lip seals facing out) onto Piston ends(#13). Lubricate

and install new Cushion Seals(#10)(small end facing out) into Piston ends and rotate to seat

them in their grooves.

NOTE: If the cylinder will be used with optional shock absorber packages, do not install the

Cushion Seals. Doing so will adversely affect

shock performance.

4. INSTALL CARRIER BEARINGS

Repair Kits include 3 sets of color coded Slot Bearings(#12). Select the same color combina-

tion Slot Bearings as originally installed. Insert

Piston/Carrier Assembly(#13) and Slot Bearings into

tube and manually push the Carrier the full length of the

Tube(#14). As this is done check that the fit of the Carrier is firm.

NOTE: A tight fit will result in higher cylinder break-

away. Use your own discretion in determining perfor-

mance requirements for your application. It fit is insufficient, select the

next size bearing, larger or smaller as needed. Repeat until

fit is correct.

Remove Piston/Carrier Assembly(#13) and place a small amount of RheoGel TEK664 into the

Cushion Seals(#10) then fill both sides of Piston completely with grease. Install Piston/Carrier

Assembly into Tube(#14) with Magnet facing the die mark that is located in the

switch groove and feed the Sealing Band(#16) between the Piston

and the bracket.

NOTE: Take care that the U-Cup(#10) is not cut as the first end of the Piston is inserted into

the Tube.

a. Manually slide Piston/Carrier Assembly(#13) the length of the Tube(#14) to seat the

Sealing Band(#16) into the groove until end of piston is present at other end of tube. As

the end of the Piston exits the Tube, grease should be present on the Piston. If not, the

tube was not properly greased. Wipe off any excess grease. DO NOT REMOVE

THE PISTON FROM THE TUBE, doing so will require installing new sealing band. Leaving

the piston in place, proceed to(b.) below.

b. The Sealing Band is intentionally cut longer than the tube to elim-

inate indentations caused when U-cup on piston assembly

enters the tube to seat the sealing band. To remove these indentations,

carefully pull the Sealing Band(#16) out the end of the tube where the piston was first

inserted to reveal indentation(s) in the

band caused by the U-cup. Inspect the band and cut to remove

all indentations.

5. TRIM SEALING BAND

With a razor blade, remove rubber from extended band until flush with the end of tube. With tin

snips, trim band to length indicated.

Cylinder Size Trim Length From Tube

1”(25 mm) .656” (16.7 mm)(Tolerance of +/- .032”)

6. INSTALL HEADS

Lubricate and install new O-Rings(#8) onto Heads(#1, #15). Remove Cushion Needle

Valve(#6) and lubricate and install new O-Rings(#5) onto Cushion Needle Valves. Insert

Cushion Needle Valves(#6) back into Heads(#1, #15). Insert Heads into Tube(#14) using a

slight rocking motion. DO NOT TWIST. Twisting the Head during installation may cut the O-Ring

resulting in excessive leakage during operation.

NOTE: When inserting heads, make sure band does not get pushed backwards into tube.

Rubber on band must remain flush to the tube after head installation.

Install Head Bolts(#4) into Heads(#1, #15).(†When replacing the head bolts in actuators

manufactured prior to July 1, 2006, the hole for the head bolt will need to be drilled 0.4”

[10mm] deeper to accommodate the longer screw length.)

Torque Head Bolts(#4) to 100-110 in.-lbs(11.30-12.43 Nm).

7. SINGLE END PORT HEADS(Optional)

Grease and install O-Ring into gland. Procedure is now the same as for standard Heads.

DISCONTINUED

PRODUCT STYLE

OR SIZE. PARTS

SHEET IS FOR

REPAIR USE ONLY.

Parts Sheet #6900-4002_18_BC410ps-OBS

BC4(L)10, BC4(L)M10, BC4(L)MM10 Instructions – 3

Drawing repeated for reference

18

1

2

3

4

5 6

7

8

9

10

11

12

13

14

19

15

20

21

17 16

8. INSTALL DUST BAND

Clean Dust Band(#17) thoroughly with a clean cloth. Remove any rubber residue on the solid

steel surface with a razor blade. Strip rubber from steel on end of Dust Band(#17) flush with

the end of the Tube. With a tin snips, trim Band to the proper length.

Cylinder Size Trim Length From Tube

1”(25 mm) .656” (16.7 mm)(Tolerance of +/- .032”)

Insert trimmed Band into Head. Position Band above Band Clamp(#7). Tighten screw(#2) and

press into groove in Tube.

9. INSTALL END CAPS

Lightly lubricate the Band Wiper(#21). Place a Spring(#20) into the hole of the Band Wiper

and insert the Band Wiper into the End Cap(#19). Compress the Band Wiper and insert the

End Cap onto the Carrier(#13). While pressing down on the End Cap tighten End Cap fasten-

ers(#18).

NOTE: The top surface of the End Cap must be below the top surface of the Carrier.

Work the slack out of both the Sealing Band(#16) and Dust Band(#17) by moving the

Carrier by hand, from the Head with the Bands retained to the opposite Head. Trim rubber, cut

to length and secure the free end of Bands as described in steps 5 and 8.

CAUTION: Improper cut length of Band may introduce slack into Band when free end is

secured.

10. CHECK ASSEMBLY

Run the Carrier(#13) back and forth along the full stroke to make certain the cylinder is properly

assembled before applying air. Before mounting cylinder back in application, check the cylin-

der’s internal cushions.(If optional shock absorber kits are being used, this step can be elimi-

nated as Cushion Seals(#10) were not installed.) Push the Carrier(#13) to one end. You

should feel the Cushion decelerate the Carrier before the Cushion bottoms out. If the Carrier

slams into the end of the cylinder, either the Cushion Seals have not been properly installed or

the Cushion Needle Valve(#6) is adjusted too far out.

11. REMOUNT THE CYLINDER ONTO MACHINERY

OPTIONAL ACCESSORY ASSEMBLY INSTRUCTIONS

1. SHOCK

ABSORBERS

Using Loctite #242 screw

Impact Bolts(#70) into Shock Stop

Plate(#71) and Shock Stop Plate onto

Carrier. Secure Shock Mounting

Plate(#69) to Heads with SHCS(#67)

and Loctite #242. Screw the Shock

Absorber(#68) into the Shock Mounting Plate.

Attach the cylinder to air lines and under low pressure

cycle the Carrier to one end of the cylinder. Adjust the Shock

Absorber nearest the Carrier to bottom out the Shock at its fullest

stroke. Then back out the Shock one full turn and tighten the Jam Nut.

Repeat for the other end of the cylinder.

2. FOOT MOUNTS

Apply Loctite #242 to Screws(#65) and secure Foot Mount(#64) to each Head.

3. TUBE SUPPORTS

Four T Nuts(#61) are required on the bottom of Tube. Tube Supports should be secured

at the required distances determined for the application to prevent Tube deflection. Apply

Loctite #242 to Screws(#63) and secure Tube Supports(#62) to tube aligning holes in T

Nuts with holes in Tube Supports.

4. FLOATING MOUNT

Place Pin(#73), flat side towards carrier, between the two center holes as shown. Place

Floating Mount Clamp(#74) over pin and secure to the Carrier with Screws(#75) and

Loctite #242. Place Floating Mount Bracket

(#76) over pin.

5. SWITCHES

NOTE: Form A Reed Switches should not be used in TTL logic circuits.A voltage drop

caused by the L.E.D. indicator will result.For applications where TTL circuits are used, please

contact the factory.

WARNING: An ohmmeter is recommended for testing Reed Switches. NEVER use an

incandescent light bulb as a high current rush may damage the switch.

Reed and TRIAC switches are only recommended for signalling position, not directly powering

soleniods. For shifting a solenoid, a relay or resistor is recommended between it and the Reed

Switch. Switch ratings must not be exceeded at any time.

Christo-Lube

®

is a registered trademark of Lubrication Technology, Inc., www.lubricationtechnology.

com

Loctite

®

is a registered trademark of the Loctite Corporation, www.loctite.com

DISCONTINUED

PRODUCT STYLE

OR SIZE. PARTS

SHEET IS FOR

REPAIR USE ONLY.

Parts Sheet #6900-4002_18_BC410ps-OBS

BC4(L)10, BC4(L)M10, BC4(L)MM10 Instructions – 4

4 – Options BC4(L)10, BC4(L)M10, BC4(L)MM10

QTY.

ITEM

PART NO.

DESCRIPTION

BC410

U.S. Standard

BC4M10 Metric

Taper Rc Heads

BC4M10 Metric

Parallel G Heads

TUBE SUPPORTS1

KIT16910-9002

Tube Support Kit1US Standard

A/R – –

7910-9002 Tube Support Kit1Metric – A/R A/R

61

3410-1013 T-Nut US Std.

4 – –

4410-1013 T-Nut Metric

–4 4

62

6910-1013 Bracket, Tube Support

1 1 1

63

6910-1022

Flat Head Screw 4 – –

4410-1016

Flat Head Screw(Metric) –4 4

FOOT MOUNT

KIT26910-9003 Foot Mount Kit2US Standard A/R – –

7910-9003 Foot Mount Kit2Metric – A/R A/R

64

6910-1066

Foot Mount 2 2 2

65

0915-1016

Socket Head Screw 2 – –

4910-1004

Socket Head Screw(Metric) –2 2

SINGLE END PORTING

66

6910-9018 Head Assy, Single End Prtg

1 – –

7910-9006 Head Assy, Single End Prtg

–1–

8910-9002 Head Assy, Single End Prtg

– – 1

SHOCK ABSORBERS5

QTY.

ITEM

PART NO.

DESCRIPTION

BC410

U.S. Standard

BC4M10 Metric

Taper Rc Heads

BC4M10 Metric

Parallel G Heads

KIT36910-9024

Shock Mount

Kit3(Hardware Only)

US Standard

Metric

Shock

Absorber

Kit4

Heavy

Duty

US Standard

Metric

Light

Duty

US Standard

Metric

A/R – –

7910-9024 – A/R A/R

KIT4

6910-9020 A/R – –

7910-9020 – A/R A/R

6910-9005 A/R – –

7910-9005 – A/R A/R

67

0707-1010

Socket Head Screw 4 – –

4910-1004

Socket Head Screw(Metric) –4 4

68

0910-1480

Heavy Duty Shock 1 – –

4910-1338

Heavy Duty Shock(Metric) –1 1

0910-1479

Light Duty Shock 1 – –

4910-1337

Light Duty Shock(Metric) –1 1

69

6910-1017 Shock Mounting

Plate

US Standard

Metric

1 – –

7910-1017

–1 1

70

6910-1024

Shock Impact Bolt 2 2 2

71

6910-1019 Shock Stop Plate US Standard

Metric

1 – –

7910-1019

–1 1

72

0915-1016

Socket Head Screw 4 – –

4910-1004

Socket Head Screw(Metric) –4 4

FLOATING MOUNT

KIT 6910-9004

Floating Mount Kit US Standard

1 – –

7910-9004 Floating Mount Kit Metric – 1 1

73

6910-1021

Floating Mount Pin 1 1 1

74

6910-1059

Floating Mount Clamp 1 1 1

75

0801-1198

Socket Head Screw 4 – –

6910-1060

Socket Head Screw(Metric) –4 4

76

6910-1020

Floating Mount Bracket 1 1 1

SWITCHES

77

CONFIG. CODE ORDERING

Mounting Hardware & FE conn. included

CODE

DESCRIPTION

BT

Switch Kit, Reed, Form C, 5m

BM

Switch Kit, Reed, Form C, Male Conn.

RT

Switch Kit, Reed, Form A, 5m

RM

Switch Kit, Reed, Form A, Male Conn.

CT

Switch Kit, Triac, 5m

CM

Switch Kit, Triac, Male Conn.

KT

Switch Kit, Hall-effect, Sinking, 5m

KM

Switch Kit, Hall-effect, Sinking, Male Conn.

TT

Switch Kit, Hall-effect, Sourcing, 5m

TM

Switch Kit, Hall-effect, Sourcing, Male Conn.

NOTE: When ordered female connector & all mounting hardware is included

79 0510-1018 Shock Stop Spacer 2 2 2

Service Parts Ordering NOTES:

1A minimum of 2(two) Tube Supports required per cylinder

2Foot Mount Kit contains two foot mount brackets and

mounting hardware

3Shock Mount Kit contains one set of mounting hardware only

4Shock Absorber Kit contains one Shock Absorber and

mounting hardware

5Standard end-of-stroke shock absorbers are designed to oper-

ate without the assistance of the standard band cylinder cushion.

To ensure proper shock absorber performance, make sure the air

cushion is disabled.

A/R = As Required

Switch Ordering NOTES:

To order field retrofit switch and hardware kits for all Tolomatic actuators:

SW(Then the model and bore size, and type of switch required)

Example: SWB C 410 RT

(Hardware and Form A Reed switch with 5 meter lead for 1" bore BC4

band cylinder)

65

64

63 62

61

77

68

67

79

69 66

70

76

72

73 74 75

71

Shock

Stop Plate

Floating

Mount

Shock

Absorber

Tube

Support

Switches

Foot

Mount

DISCONTINUED

PRODUCT STYLE

OR SIZE. PARTS

SHEET IS FOR

REPAIR USE ONLY.

Parts Sheet #6900-4002_18_BC410ps-OBS

BC4(L)10, BC4(L)M10, BC4(L)MM10 Switches / Maintenance – 5

3800 County Road 116, Hamel, MN 55340 USA

http://www.Tolomatic.com • Email: Help@Tolomatic.com

Phone: (763) 478-8000 • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

© 2021 Tolomatic 202112070913

All brand and product names are trademarks or registered trademarks of their

respective owners. Information in this document is believed accurate at time of print-

ing. However, Tolomatic assumes no responsibility for its use or for any errors that

may appear in this document. Tolomatic reserves the right to change the design or

operation of the equipment described herein and any associated motion products

without notice. Information in this document is subject to change without notice.

Visit www.tolomatic.com for the most up-to-date technical information

LUBRICATION AND MAINTENANCE

All Tolomatic BC4 Band Cylinders are prelubricated at the factory. To ensure maximum cylinder life,

the following guidelines should be followed.

1. Filtration

We recommend the use of dry, filtered air in our products.“Filtered air” means a level of 10

Micron or less. “Dry” means air should be free of appreciable amounts of moisture. Regular

maintenance of installed filters will generally keep excess moisture in check.

2 External Lubricators(optional)

The factory prelubrication of Tolomatic Band Cylinders will provide optimal performance with-

out the use of external lubrication. However, external lubricators can further extend service life

of pneumatic actuators if the supply is kept constant.

Oil lubricators,(mist or drop) should supply a minimum of 1 drop per 20 standard cubic feet

per minute to the cylinder. As a rule of thumb, double that rate if water in the system is sus-

pected. Demanding conditions may require more lubricant.

If lubricators are used, we recommend a non-detergent, 20cP @ 140˚F 10-weight lubricant.

Optimum conditions for standard cylinder operation is +32˚ to +150˚F(+0˚ to 65.5˚C).

NOTE: Use of external lubricators may wash away the factory installed lubrication. External

lubricants must be maintained in a constant supply or the results will be a dry actuator prone

to premature wear.

3. Sanitary environments

Oil mist lubricators must dispense “Food Grade” lubricants to the air supply. Use fluids with

ORAL LD50 toxicity ratings of 35 or higher such as Multitherm

®

PG-1 or equivalent.

Demanding conditions can require a review of the application.

4. Bearing lubrication

The bearing system is prelubricated at the factory with a high quality RheoGel TEK664 grease.

Relubrication is recommended every .5-1 million cycles using RheoGel TEK664 grease.

5. Cushion Adjustment

Adjust the cushion needles in the cylinder heads carefully to obtain a smooth, hesitation free deceler-

ation for your particular application. If there are questions on proper adjustment, please consult

Tolomatic, Inc.

Some actuators may require

switch mounting on a spe-

cific side of the assembly.

Call Tolomatic for details.

REPLACEMENT OF QD SWITCHES

MANUFACTURED BEFORE JULY 1, 1997: It will be

necessary to

replace or rewire

the female end

coupler.

Female Connector 5M

DISCONTINUED

PRODUCT STYLE

OR SIZE. PARTS

SHEET IS FOR

REPAIR USE ONLY.

This manual suits for next models

6

Table of contents

Other Tolomatic Industrial Equipment manuals

Tolomatic

Tolomatic MXP63PTP User manual

Tolomatic

Tolomatic LS10 User manual

Tolomatic

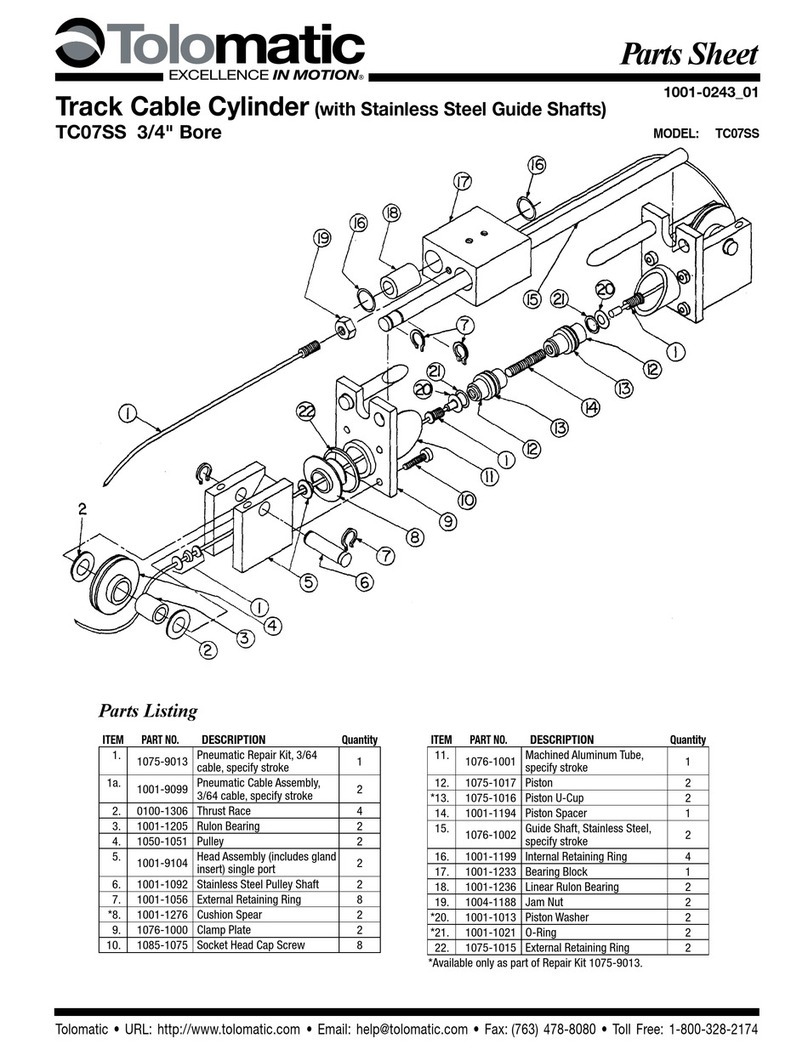

Tolomatic TC07SS Use and care manual

Tolomatic

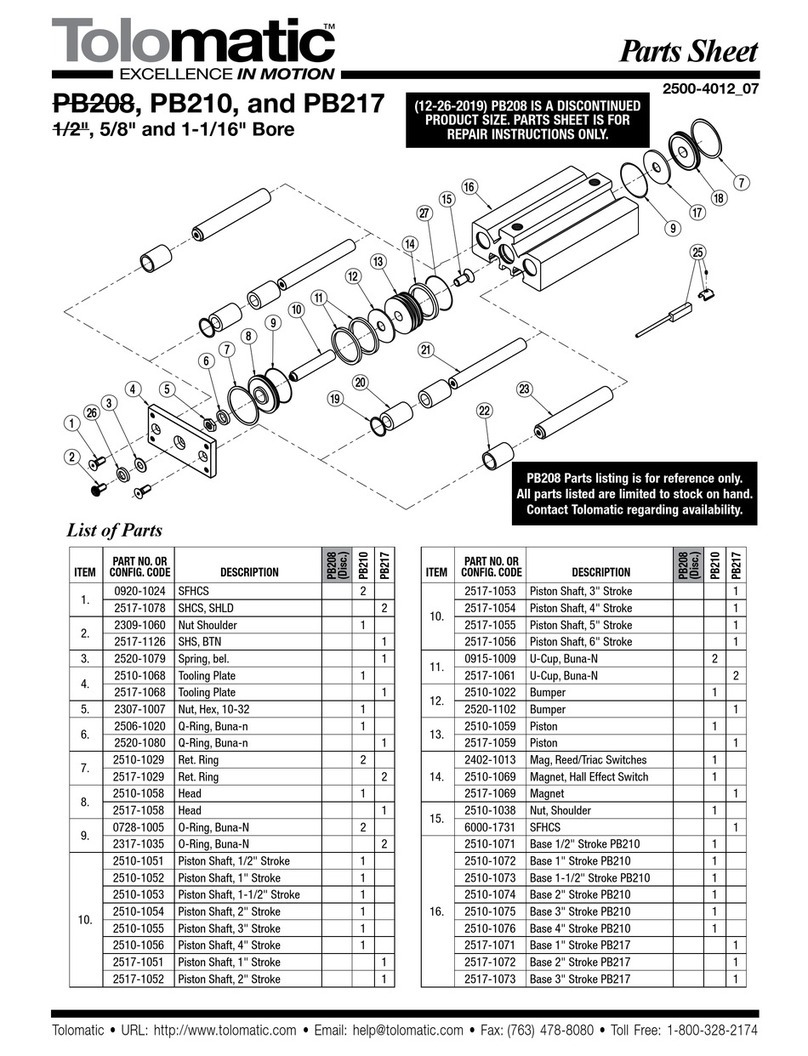

Tolomatic PB208 User manual

Tolomatic

Tolomatic MXP50N User manual

Tolomatic

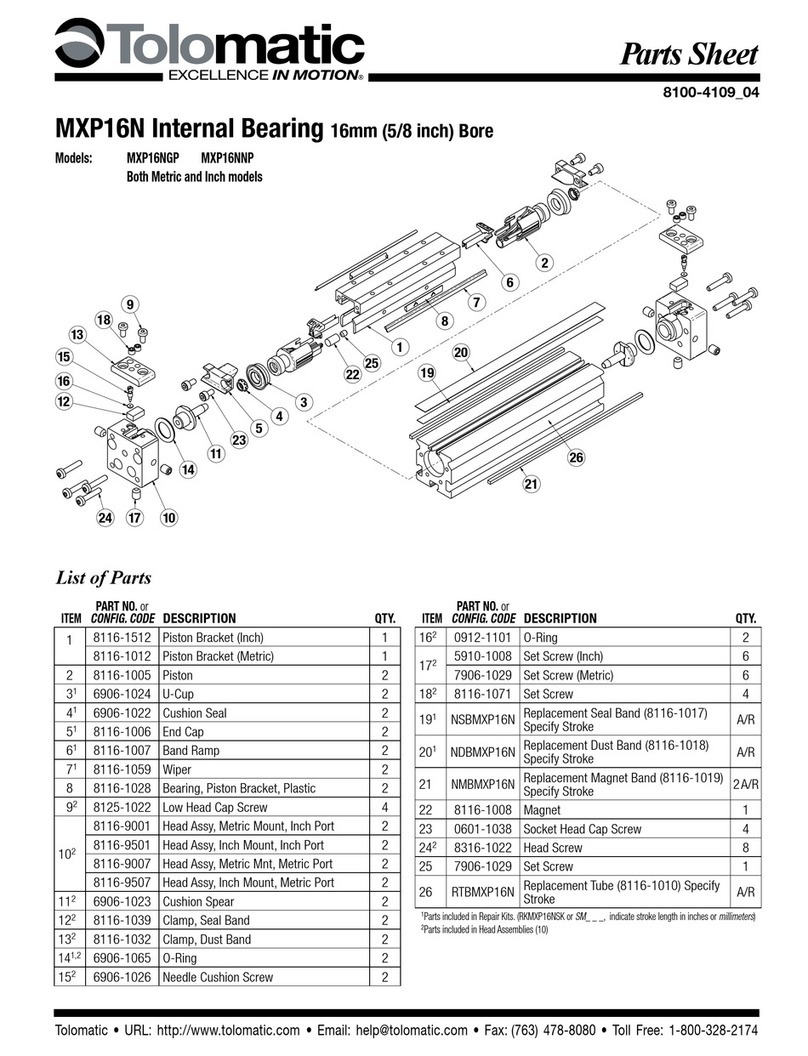

Tolomatic MXP16N User manual

Tolomatic

Tolomatic TC15 User manual

Tolomatic

Tolomatic BC3 Series User manual

Tolomatic

Tolomatic MXP25PTP User manual

Tolomatic

Tolomatic MXP32N Series Use and care manual