Art. no.: 5090032018 Rev.: 01/2023-05-03 7

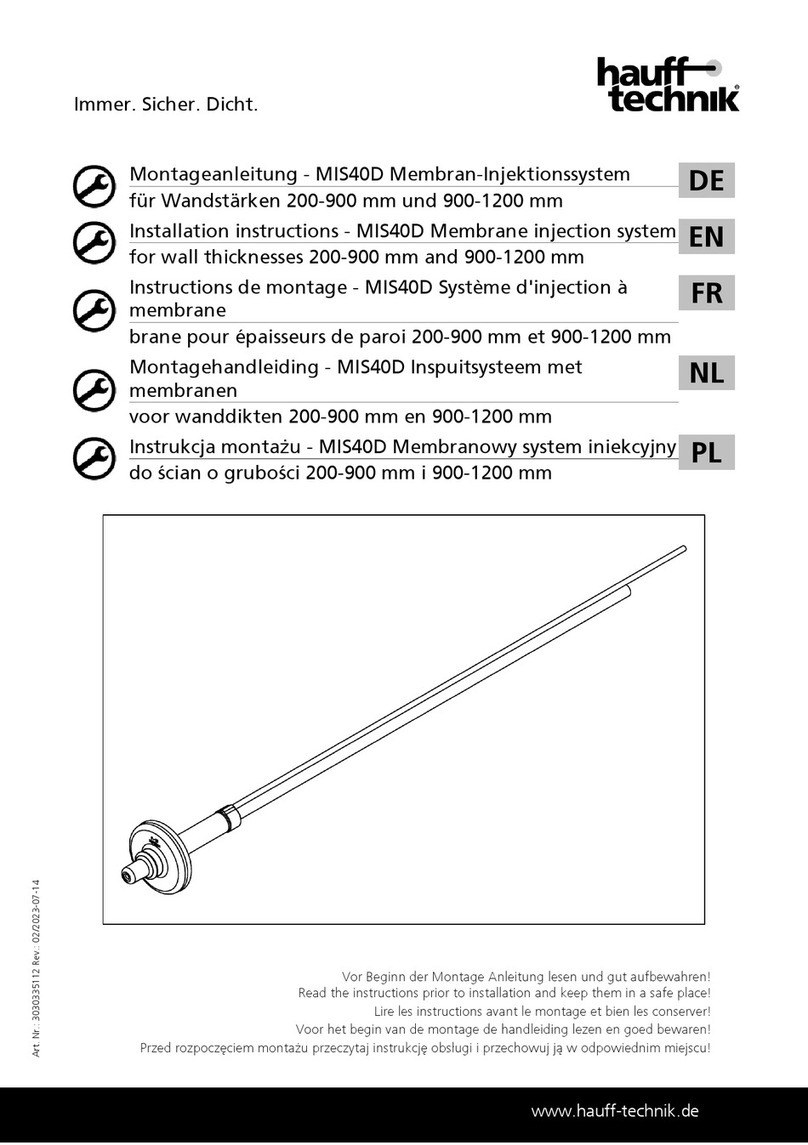

Zum Lieferumfang der MIS90D 1x24-40+3x7-13+2x5-8+2x7 für Wandstärken

200-900 mm oder 900-1200 mm gehören:

•1 Stück MIS90D K oder L inklusive vormontiertem Manschettenstopfen

•1 Stück Universal-Manschettenstopfen MS78EW 1x24-40+3x7-13+2x5-8

•1 Stück Wandabschlussrosette WAR90 1x63+2x7

Zum Lieferumfang der MIS90D 1x13-21+3x7-13+1x5-13+2x7 für Wandstärken

200-900 mm oder 900-1200 mm gehören:

•1 Stück MIS90D K oder L inklusive vormontiertem Manschettenstopfen

•1 Stück Universal-Manschettenstopfen MS78K 1x13-21+3x7-13+1x5-13

•1 Stück Wandabschlussrosette WAR90 1x63+2x7

Zum Lieferumfang der MIS90D zxd (individuelle Belegung) für Wandstärken 200-

900 mm oder 900-1200 mm gehören:

•1 Stück MIS90D K oder L inklusive vormontiertem Manschettenstopfen

•1 Stück Universal-Manschettenstopfen mit individueller Belegung

•1 Stück Wandabschlussrosette WAR90 1x63+2x7

Lieferumfang in der Standardausführung! Abweichungen bei individuel-

len Zusammenstellungen möglich!

Lagerung

Beschädigung durch unsachgemäße Lagerung!

Bei unsachgemäßer Lagerung können Sachschäden in erheblicher Höhe ent-

stehen.

•Membran-Injektionssystem vor der Montage vor Beschädigungen, Feuchte und

Verunreinigungen schützen. Es dürfen nur unbeschädigte Teile montiert wer-

den.

•Die Lagerung des Membran-Injektionssystem muss so erfolgen, dass dieser kei-

nen zu niederen Temperaturen (<5 °C) und höheren Temperaturen (>30 °C) so-

wie keiner direkten Sonneneinstrahlung ausgesetzt ist.

Entsorgung

Sofern keine Rücknahme- oder Entsorgungsvereinbarung getroffen wurde, zer-

legte Bestandteile nach sachgerechter Demontage der Wiederverwertung zufüh-

ren:

•Metallische Materialreste nach den geltenden Umweltvorschriften verschrotten.

•Elastomere nach den geltenden Umweltvorschriften entsorgen.

•Kunststoffe nach den geltenden Umweltvorschriften entsorgen.

•Verpackungsmaterial nach den geltenden Umweltvorschriften entsorgen.

•Ausgehärtete Expansionsharzreste nach den geltenden Umweltvorschriften ent-

sorgen (Hausmüll/Gewerbeabfall).

•Restentleerte Verpackung des Expansionsharz nach den geltenden Umweltvor-

schriften entsorgen (gelbe Tonne/Sack).

EN Safety Instructions and Information

Target Group

The installation may only be carried out by technical experts.

Qualified and trained individuals carrying out installation must have

•knowledge of general safety and accident prevention regulations as amended,

•knowledge of how to use safety equipment,

•knowledge of how to use hand tools and electric tools,

•knowledge of the relevant standards and guidelines for laying pipes/cables and

for backfilling utility trenches as amended,

•knowledge of the regulations and installation guidelines of the supply company

as amended,

•knowledge of the waterproof concrete directive and building waterproofing

standards as amended.

General information and intended use

In line with their intended use, our products have been developed solely for instal-

lation in buildings made of state-of-the-art materials. Insofar as no express written

confirmation has been provided by us, we do not accept any liability for any other

purposes or purposes going beyond the above.

For warranty conditions, please see our current General Terms and Delivery Condi-

tions. We explicitly draw your attention to the fact that no warranty whatsoever

applies for any subsequent damage occurring as a result of failure to follow the

installation instructions or if our products are used incorrectly or combined with

third-party products.

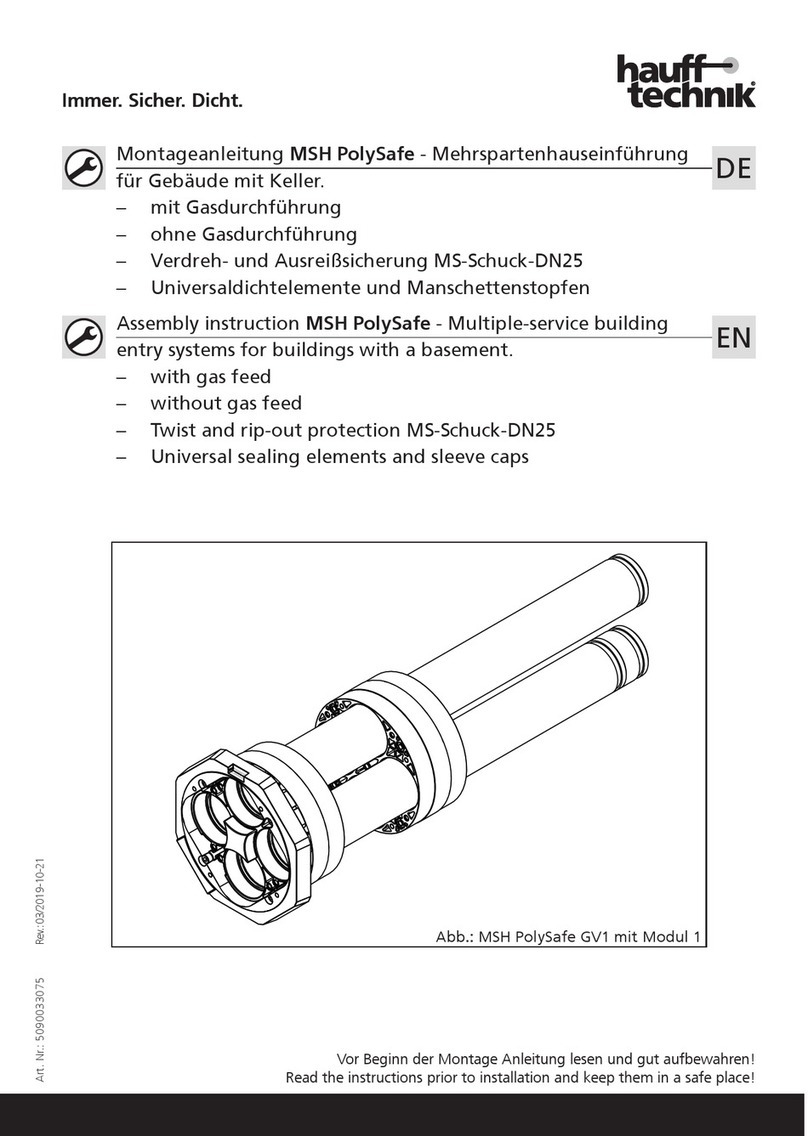

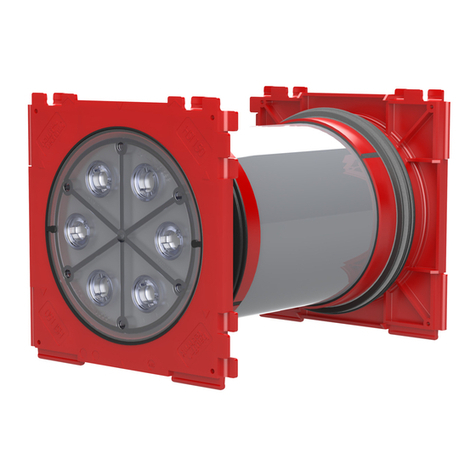

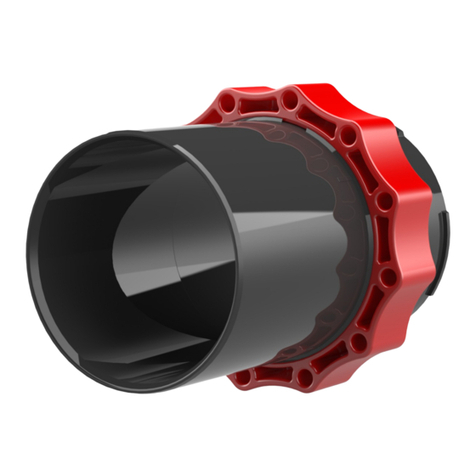

MIS90D is suitable for buildings with basements for reliable sealing of drinking

water pipes, power cables, telecommunication lines or micropipes/fibre optic

cables. A take-up of

1 cable/pipe diameter 24 - 52 mm and 2 cables with diameter 7 mm

or

1 cable/pipe diameter 24 - 40 mm and 3 cables with diameter 7-13 mm

or

1 cable/pipe diameter 13-21 mm, 3 cables diameter 7-13 mm and 1 cable 5 -13

mm

or

individual assignment diameter da mm (tolerance +1 mm/ -2 mm)

as well as up to 2 SpeedNet pipes of 7 mm (tolerance ± 0.5 mm) for wall thick-

nesses of 200 - 900 mm respectively 900-1200 mm is possible.

Safety

This section provides an overview of all the main safety aspects for optimum pro-

tection of personnel and a safe installation process.

A failure to observe the instructions and safety information set out here may re-

sult in significant hazards.

During installation of the Membrane injection system it is imperative to observe

the relevant professional association rules, the VDE provisions, the relevant natio-

nal safety and accident prevention regulations and your company’s guidelines

(work and procedure instructions).

The fitter must wear the relevant protective clothing.

Only intact components may be installed.

When dealing with expansion resin, the following points must be strictly obser-

ved:

Expansion resin: Tangit iM 3000

Component B: Contains isocyanate.

Observe manufacturer's instructions and the manufacturer's safety data sheet as

amended.

Harmful. Contains Diphenylmethane diisocyanate, isomers and homologues.

The product falls within the scope of applicability of Regulation (EC) 1907/2006

(REACH), Annex XVII, No. 74, Item 1(b). Effective 24 August 2023, appropriate

training must be conducted prior to any industrial or commercial application.

Further information at: https://www.feica.eu/PUinfo

•Harmful by inhalation

•Irritating to eyes, respiratory system and skin

•May cause sensitisation by inhalation

•Keep out of the reach of children

•In case of contact with eyes, rinse immediately with plenty of water and seek

medical advice

•After contact with skin, wash immediately with plenty of water and soap

•Wear suitable glove

•In case of accident or if you feel unwell, seek medical advice immediately (show

label on cartridge if possible)

•Processing temperature: +5 °C to +30 °C, optimum: +15 °C to +25 °C

The following instructions are to be observed prior to installa-

tion of the Membrane injection system MIS90D:

Risk of injury in the event of improper installation!

Improper installation can result in significant bodily harm and property da-

mage.

•Observe the nationally applicable laying and filling regulations for pipes and

cables.

•Seal the underground and cable substructure well prior to laying pipes or cables

so that the latter cannot subside.

No sealing due to incorrect installation!

Improper installation can result in damage.

•Diamond core bits for dry cutting are available (e.g. Hilti) for basements with

masonry walls. Handheld drills can be used.

•Before installing the MIS90D, existing breaks ( > 140 mm) in the wall surface or

paint must be properly restored according to DIN 18533 until an opening dia-

meter of 92-102 mm is achieved. In the case of small breaks (max. 140 mm),

no follow-up is required since the sealing will be covered by the expansion

resin.

•If there are breaks in the masonry or wall, we recommend using a second resin

cartridge (which is not included in the package but can be ordered separately)

to help secure the wall entry.

•The max. volume of the resin is reached after approx. 5 min. After this, the

entire resin system can be removed from the MIS. The complete curing period

is approx. 30 min.

•All surfaces must be clean, firm and free of dust and grease.

•Do not use cleaning agents containing solvents to clean the Membrane injec-

tion system. We recommend using the cable cleaner KRMTX.

•For details of other accessories and further information, see www.hauff-tech-

nik.de and the technical data sheets as well as the safety data sheet.

Personnel requirements

Qualifications