TUMBLE DRYER

r120085e -15/3

04.99

•Operating and display module is situated in the fascia.

•Control and power module is situated on the right frame support.

•Thermistor sensor for measuring the air temperature.

•Condensation

pump is situated in the base group underneath the belt tensioning device.

•Motor is situated on the right in the base group.

•Heater on the rear panel – under the heating duct cover.

•Bimetallic thermal cut-out (>170 °C) is situated directly on the heater.

1.1 Operating and display module

The

operating and display module is used to input and output

information. It houses all the

direct input buttons, all signalling elements, e.g. LEDs, selector switches and signal

transmitters. Models are encoded by breaking off the side bridges.

1.2 Control and power module

The module houses all the significant components, e.g. micro-controller, relays, power

supply, etc. It performs complex functions with respect to controlling drying sequences,

monitoring the temperature, ascertaining parameters and actuating the operating and

display

section. The appliance is switched over from 16 A to 10 A by means of a wire jumper

.

Wire

jumper closed 16 A – Wire jumper open 10 A. Control and power module

≥

mask V 4.00

(software

version is indicated on the processor) changes automatically from 16 A to 10 A.

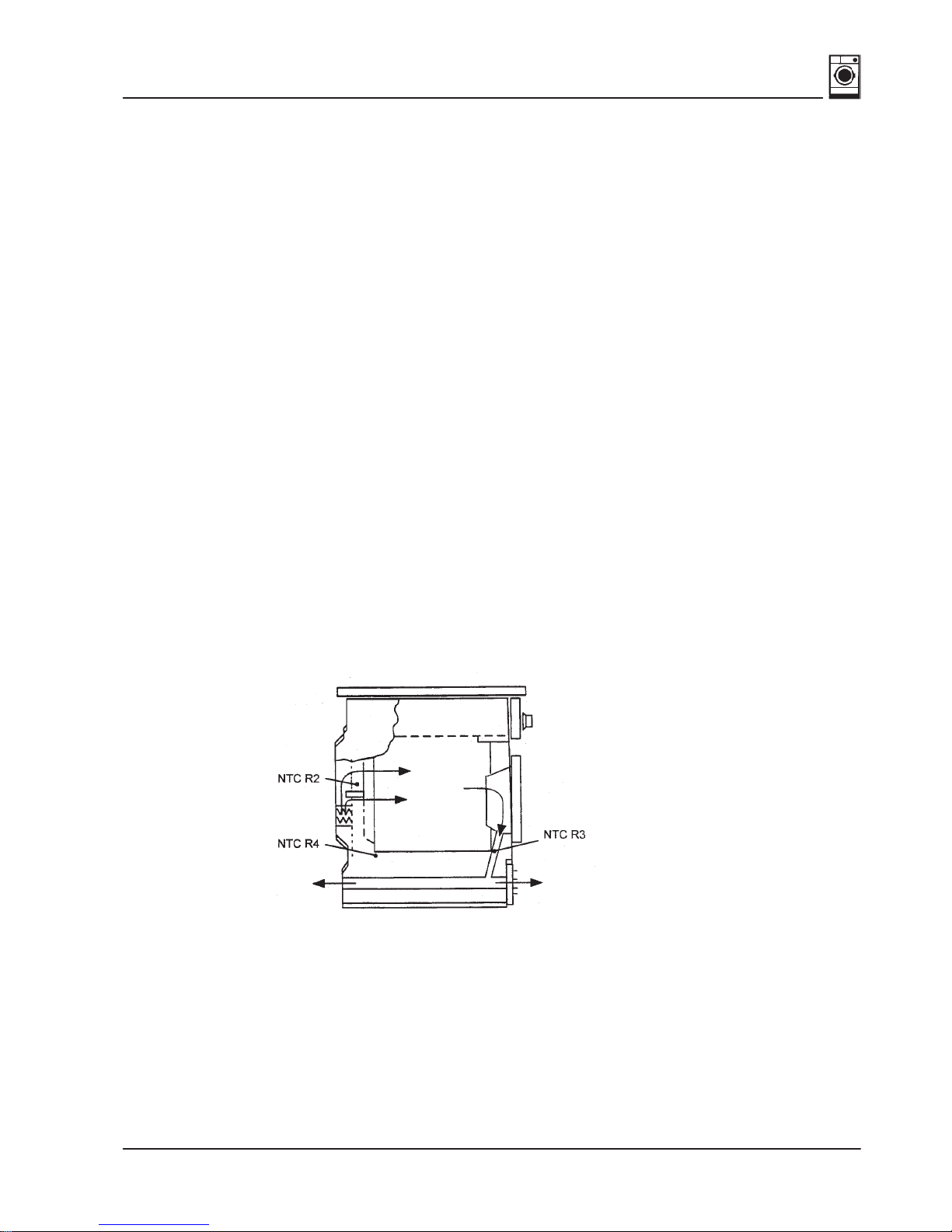

1.3 Thermistor sensor for measuring the air temperature

Thermistor

sensors measure the temperature of the process air at three dif

ferent points

in

the appliance (NTC thermistor – NTC stands for Negative Temperature Coefficient).

NTC R3

is situated in the ring insert under the door and measures the exhaust-air temperature.

NTC R4

is situated in the air current in front of the heater.