10/68 Safety instructions

Bosch Rexroth AG, APAS assistant K1100-10i V01.00.00 - V01.00.99, 3 842 565 050/2019-11

2 Safety instructions

2.1 About this section

The product has been manufactured in accordance with the generally accepted rules

of current technology. Nevertheless, there is a risk of personal injury and property

damage if you do not read this section and follow the safety instructions in this

document.

Read this documentation carefully and completely before you start working with

the product.

Keep the documentation accessible to all users at all times.

Always include them when giving the product to a third party.

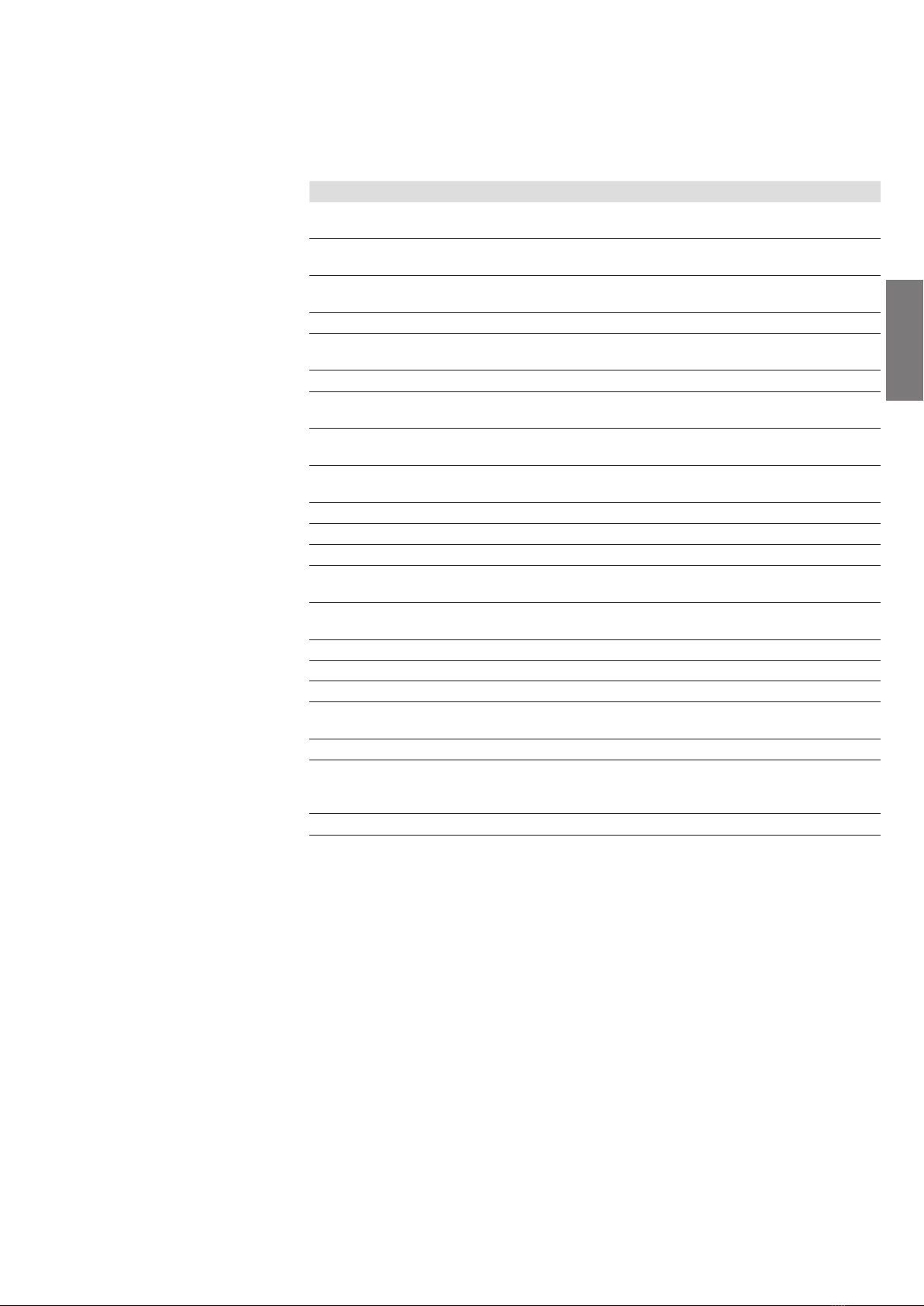

2.2 Intended use

The APAS assistant K1100-10i is a robot system based on the industrial robot

KUKA Agilus KR10 R1100-2. The robot system is additionally equipped with

a capacitive sensor skin, an SRS and an SRS for collaborative operation. These safety

functions ensure that persons and detectable objects are detected safely and a safe

stop is triggered before a collision occurs. This makes safe human/robot collaboration

possible without a protective fence. The robot system constitutes a partly completed

machine and is exclusively intended for the following intended use:

• Independent performance of changing handling tasks with attached or gripped tools

in assembly as well as support of the operator in monotonous repetitive tasks.

• Installation on various substructures or in an existing system.

• Use exclusively in industrial applications and indoors.

• To prevent head and eye injuries,

– movements of the APAS assistant with adapted end effector, tool and gripped

workpiece, if applicable, are only permitted at a height less than 1.40 m above

all oors on which the personnel is standing, and

– work on the robot is only permitted when standing or walking upright.

• The exact ambient conditions in which the product may be used

(see Ambient conditions on page 42).

• The workpiece must be suitable for handling by the APAS assistant and for

collaborative operation. It must not have any points, cutting edges or similar

dangerous features.

• The product must be installed, set up, maintained and operated

according to these installation instructions and further documentation

(see Further documentation on page 6).

• The product may only be integrated, set up, maintained and

operated by an adult with the appropriate specialist knowledge

(see Personnel qualications on page 11).

• The product is strictly intended for professional use and not for private use.

The intended use also includes having read and understood these instructions,

especially section 2 "Safety instructions".