Troglotech T815 Instruction manual

Troglotech T815 Crawler Workshop Manual Page 1

WORKSHOP MANUAL — T815 CRAWLER

Troglotech Ltd Phone +44(0)1730 711240

Unit 1, 3 Penns Road Phone +44(0)1730 711240

Petersfield Fax +44 (0)1730 711240

Hampshire Email info@troglotech.com

GU32 2EW Web www.troglotech.com

Troglotech T815 Crawler Workshop Manual Page 2

T815 CRAWLER - OVERVIEW

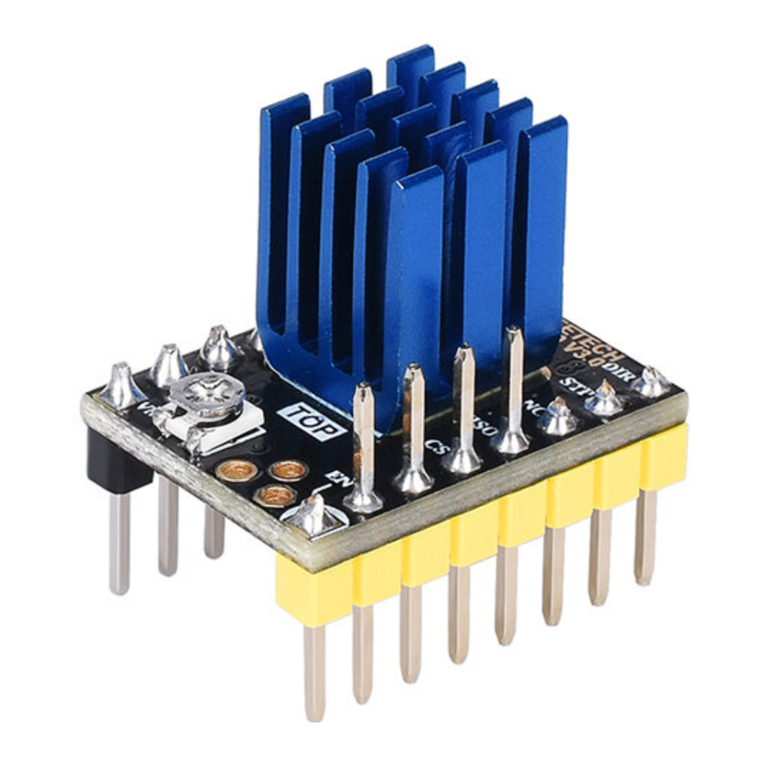

T815 Crawler Overview—Motor Drives

MECHANICS:

The mechanical construction of the T815 crawler enables quick disassembly and

is simple to repair and maintain. NOTE: See https://youtu.be/H5bHqfwd2yg for

video of assembly instructions

The diagram above shows the plain chassis and the two motor/gearbox drive

units. These are manufactured by Troglotech and are not serviceable, in the

unlikely case of malfunction they can be replaced as assemblies and the failed

unit returned to Troglotech for investigation.

The motor drives contain a 3-phase brushless motor and a Troglotech-designed

cycloid gearbox to attain the torque requirements and available volume.

The drive units can be replaced by removing the side metalwork (containing the

drive axles, seals and idler gear) and PCB’s—Note that the drive units are

connected to the Motor Drive PCB’s by a flexible Kapton lead with a ZIF

receptacle at the end—this is disconnected by sliding the lock on the PCB—this

is best done with the Motor Drive PCB still fitted to the chassis

Troglotech T815 Crawler Workshop Manual Page 3

T815 CRAWLER- OVERVIEW

T815 Crawler Overview—PCB’s

The diagram above shows the PCB positions the numbered balloons show the

order in which the PCB’s must be removed, they are connected in such a way

that only the correct order will allow them to be removed without damage.

NOTE: Removal of the Motor Drives (3 and 8) requires the disconnection of the

Kynar flexible connection from the ZIP sockets—be careful as these can be

damaged easily. Disconnection requires that the clasp is pushed towards the

flexible ribbon by around 2mm before it can be removed.

NOTE: Add a small amount of silicon grease between the motor drive PCB and

the pocket in which it is housed to conduct heat away from the driver whenever a

motor drive PCB is replaced

Troglotech T815 Crawler Workshop Manual Page 4

T815 CRAWLER - OVERVIEW

T815 Crawler Overview—PCB’s

The diagram above shows the PCB positions the numbered balloons show the

order in which the PCB’s must be removed, they are connected in such a way

that only the correct order will allow them to be removed without damage.

NOTE: Removal of the Motor Drive (3) requires the disconnection of the Kynar

flexible connection from the ZIP sockets—be careful as these can be damaged

easily. Disconnection requires that the clasp is pushed towards the flexible ribbon

by around 2mm before it can be removed

NOTE: Add a small amount of silicon grease between the motor drive PCB and

the pocket in which it is housed to conduct heat away from the driver whenever a

motor drive PCB is replaced

Troglotech T815 Crawler Workshop Manual Page 5

T815 CRAWLER- OVERVIEW

T815 Crawler Overview—PCB’s

The diagram above shows the PCB positions the numbered balloons show the

order in which the PCB’s must be removed, they are connected in such a way

that only the correct order will allow them to be removed without damage.

NOTE: Removal of the Motor Drive (4) requires the disconnection of the Kynar

flexible connection from the ZIP sockets—be careful as these can be damaged

easily. Disconnection requires that the clasp is pushed towards the flexible ribbon

by around 2mm before it can be removed

NOTE: Add a small amount of silicon grease between the motor drive PCB and

the pocket in which it is housed to conduct heat away from the driver whenever a

motor drive PCB is replaced

Troglotech T815 Crawler Workshop Manual Page 6

T815 CRAWLER - OVERVIEW

T815 Crawler Overview—Drivetrain and External Parts

DRIVETRAIN:

The picture below shows the T815 drivetrain and external parts. The drivetrain

consists of six individual axles with integral gears and two Idler Gears. These parts

are attached to, or held in place by the Tractor Sides which are secured by 12

Allen bolts

To release the Tractor Sides it is good practice to loosen the Front Cover as this

can put force on the sides. The Rear Cover contains the Swivel Connection and

the Sonde Transmitter, it also has apertures for the rear camera and lighting

(both of which are fitted to the Processor/VID PCB)

The Front Cover contains the Camera Pogo PCB, this connects to the camera

(which can be either the T812 Pan & Tilt or the Forward View Camera)

The Connector Block connects to the inserted battery pack and is the input for

all electronics within the Tractor. This, along with the sonde assembly are the

only wired components, all other connections are connector pairs

Troglotech T815 Crawler Workshop Manual Page 7

T815 CRAWLER- OVERVIEW

T815 Crawler Overview—Electronic Operation

The electronic operation of the Crawler is controlled by the Processor/VID PCB

(TC81511011). With a Battery Pack fitted to the Crawler the battery power is

disconnected from all PCB’s apart from the Processor and the TC81510011

Power Control PCB. The latter provides power to the Processor PCB via a 1K

resistor called ‘BAT SAFE’

BAT SAFE is regulated on the Processor PCB to provide a low-current 5V supply

for a sensing circuit as seen below. When the Display Unit is switched ON the

small voltage on Video+ve that is present at the end of the cable is detected by

this circuit. The detected voltage produces a HIGH level on ‘WAKE’ and this is

conducted to the Power Control PCB to switch ON the battery supply to the

complete electronics.

At switch ON the 5V power supply becomes active and is used to keep ‘WAKE’ at

a high level for a few seconds via C89—this period is long enough to allow the

Processor to start and hold ‘KEEP AWAKE’ high whilst the cameras produce video

and TTDS communications are established to ensure that the power remains ON.

Once the 5V supply is operational Video+ve will drop in DC voltage as the video

signal is transmitted.

Troglotech T815 Crawler Workshop Manual Page 8

T815 CRAWLER - OVERVIEW

T815 Crawler Overview—Electronic Operation Continued

The picture below shows the battery switching section of the Power Control PCB.

If there is a high level on ‘WAKE’ then power is made available at Motor+ve via

IC11 which supplies power for the complete crawler including the Motor Drive

PCB’s and the PSU which provides the 5V and 15V supplies.

The picture below shows the Power Supply (TC81509011) which produces 5V and

15V from the Power+ve rail—it’s source is the Motor+ve supply from the Power

Control PCB—Motor+ve and Power+ve are kept separate through the Interconnect

PCB’s from the Power Control PCB to reduce electronic noise which may affect the

video picture.

This Power Supply is the voltage source for all the electronics and cameras on the

crawler, however the Motor+ve supply is used as a raw supply for the Motor Drives

and additional lighting (large lighthead and reversing lights). The voltage from the

battery can drop below 13V which is unsuitable for the T815 camera head which is

why a separate 15V supply is available.

Troglotech T815 Crawler Workshop Manual Page 9

T815 CRAWLER- OVERVIEW

T815 Crawler Overview—Electronic Operation Continued

Once the Power Supply is established, the Processor continually communicates

with the Display Unit of the Cable Drum via TTDS signals that are present on

Video+ve. As long as TTDS data is stable and the data contains the

’KEEP_ALIVE_BIT’ (this is set as long as the Display Unit has the correct crawler/

drum software) the processor will hold ‘KEEP AWAKE’ high, which, in turn, holds

‘WAKE’ high. TTDS only works when either the front or rear camera is in

operation, TTDS needs a video signal to operate.

If data is not available the crawler will switch back OFF again. If this cycling

continues, it indicates that the voltage on Video+ve is present but TTDS data is

incorrect or missing. This behaviour will be seen if the software for the Display Unit

(both MAIN and COMMS) has not been updated; pre-T815 software does not

include the ’KEEP_ALIVE_BIT’ bit on TTDS data.

Once TTDS communications are established and the correct data is received the

processor will start communicating with the internal parts via IIC serial bus

The processor has a number of tasks:

Continually send/receive TTDS data

Initialise all IIC devices

Initialise the T812 camera head (if fitted)

Initialise the two motor drives to a safe state

Communicate with the Display Unit via TTDS

Select the video source between front and rear cameras

Switch ON/OFF rear lights

Switch ON/OFF large lighthead

Initialise the accelerometer

Read the accelerometer to get inclination data

Transmit the inclination to Display Unit via TTDS

Switch sonde ON/OFF

Read EEPROM to get calibration data

Get pressure sensor data and calculate true pressure

Get IIC data from current/voltage monitors

Calculate true voltage/current

Transmit voltage/current to Display Unit via TTDS

Calculate crawler orientation for auto-steering

Determine maximum motor speed from voltage data

Troglotech T815 Crawler Workshop Manual Page 10

T815 CRAWLER - OVERVIEW

T815 Crawler Overview—Electronic Operation Continued

Once the processor has initialised all PCB’s and the T812 camera it will operate

the crawler speed, direction and camera orientation and selection via commands

from the Display Unit via TTDS:

Continually send/receive TTDS data

Control the T812 camera head

Control the motor drives speed and direction

Select the video source between front and rear cameras

Switch ON/OFF rear lights

Switch ON/OFF large lighthead

Read the accelerometer to get inclination data

Switch ON/OFF the sonde

Get pressure sensor data and calculate true pressure

Get IIC data from current/voltage monitors

Return Voltage/Current data via TTDS

Calculate crawler orientation for auto-steering

Determine maximum motor speed from voltage data

T815 Crawler Integration with AUTO DRUM:

The T850 Auto Drum system is designed to be a transparent addition to a

standard crawler system. However, the crawler changes its behaviour if the

Auto Drum is set to ‘AUTO’ and the crawler direction is set to reverse:

The Auto Drum sends a ‘crawler passive’ command via TTDS

The Display Unit accepts the ‘crawler passive’ command

The Display Unit sends out a ‘crawler passive’ command to the crawler

The crawler does not engage reverse and switches OFF the brakes

The behaviour above requires software to be upgraded in:

The Crawler

The MAIN Display Unit software

The COMMS Display Unit software

Without these software upgrades the crawler will enable its motor drives in reverse

and the Auto Drum will pull the crawler slightly faster than the wheel speed, this

substantially increases the Auto Drum current demand.

Troglotech T815 Crawler Workshop Manual Page 11

T815 CRAWLER– FAULT FINDING

T815 Crawler—Fault Finding—appears completely dead

Fault finding of the crawler can be simplified by understanding the behaviour at

start-up.

If a crawler does not respond when connected to the cable:

1. Check that there is 5V available between the inner and outer sliprings on

the cable. The Display Unit must be switched ON for a voltage to be

present. A lack of 5V on the cable means that there is a problem with the

above-ground equipment or the cable.

2. If the sliprings do have a 5V signal then try pushing the crawler—as long as

the crawler battery has some charge, pushing the crawler with the large

wheels fitted usually generates enough voltage to start the crawler. If the

crawler does not initialise then remove the battery and check for a voltage

at the pins as shown below:

Be careful with the meter probes as it is easy to short between the probe and the

metal case of the battery. Neither of the battery terminals is connected to the

battery metalwork—check for an infinite resistance between all pins and the battery

metalwork

If a voltage over 14V is present on the crawler battery then further investigation of

the crawler will be necessary, but ensure the battery is fully mated with the

connector block and there is no debris around the connectors

Troglotech T815 Crawler Workshop Manual Page 12

T815 CRAWLER - FAULT FINDING

T815 Crawler—Fault Finding—appears completely dead—continued

If the battery has a good charge, the cable has 5V available, all connections are

clean and the battery is pushed fully home, then the crawler will need dismantling

to find the cause.

The most likely cause of failure is always water ingress, whether this is from

a damaged cable or the crawler being pressurised with an air-supply that

contains moisture. The most likely point of access is the swivel-connection on

the rear cover of the crawler

The rear cover is simply held on with four large

Allen bolts as shown to the right.

Be aware that there is a connector pair

between the rear cover and the processor

PCB—do not apply any sideways force

when removing the rear cover.

The picture to the bottom-right shows the

crawler with the rear cover removed. The

Processor is the outer PCB as shown. SK5 is the black 10-way connector that can

be seen at the bottom centre of the picture. If any moisture is present then this

socket will show damage, possibly with black burn-marks around the pins.

If the Processor PCB is damaged then it will need to be replaced. Where severe

water ingress is seen, other PCB’s may need to be replaced, it is usually the lower

part of each PCB that has water damage.

Where any PCB is damaged it is possible

that the battery voltage (13V—17V) has

been conducted to other PCB traces.

The length of time that the crawler has been

operated with water ingress will determine

the amount of damage done to other PCB’s

and the camera head.

In severe cases of water ingress where the

battery voltage has been conducted to the

IIC Bus traces or to the 5V traces then both the crawler PCB’s AND the camera

head PCB’s may all be damaged beyond repair.

Water ingress nullifies the warranty as this indicates use without pressurisation.

Troglotech T815 Crawler Workshop Manual Page 13

T815 CRAWLER– FAULT FINDING

T815 Crawler—Fault Finding—appears completely dead—continued

If no moisture is found on the Processor PCB try pushing the Crawler again with

the battery fitted and watch the two LED’s on the Processor:

If the two small LED’s D5 and D6 start flashing that indicates that the 5V supply is

operational and the processor PCB has started initialising. If no flashing is shown

start by replacing the Processor PCB and try pushing the Crawler again for signs

of life at the LED’s.

Where the LED’s do flash but nothing else happens check the voltage between

pins 1 and 2 of PL8—whilst the LED’s are flashing there should be the battery

voltage across these two pins:

If no battery voltage is detected then it is possible that the Power Control PCB or

the traces between that PCB and the Processor PCB are damaged (this includes

all three Interconnect PCB’s and the Power Supply PCB).

At this point if no progress is being made then remove all PCB’s and inspect for

damage from water ingress or signs of any burning or malfunction.

Troglotech T815 Crawler Workshop Manual Page 14

T815 CRAWLER - FAULT FINDING

T815 Crawler—Fault Finding—appears completely dead—continued

The next tests need to be performed on the Power Control PCB—disassemble in

the correct order as shown below:

If there is no visible damage to any of the PCB’s then check the voltage at the

battery connector from the upper connection block on the crawler. This is reached

by removing the front cover.

There are five wires:

1. Battery Positive

2. Battery Positive

3. Battery Negative

4. Battery Negative

5. Power to large

lighthead

If power is available on the Power Control PCB then replace the Power Control

PCB.

Pin 1 is always as shown in the picture to the right on

Picoblade connectors no matter how many ways is

present

Troglotech T815 Crawler Workshop Manual Page 15

T815 CRAWLER– FAULT FINDING

T815 Crawler—Fault Finding—One Drive fails to operate

Where one motor drive fails to operate it is most likely that the connection to the

motor driver has failed rather than the Motor Driver itself being at fault.

Alternatively the motor/gearbox may have failed, in this case listen to the crawler

whilst it is placed on the bench with the faulty side uppermost (with the crawler on

its side the lower drive will NOT operate by design). Now it is possible to listen to

the upper drive without the other drive operating.

If the motor can be heard but the axles are not rotating then the Cycloid gearbox

has failed and will need replacing.

If the motor cannot be heard, display the current demand on the Display Unit

(press ‘D’ in VIEW MODE). When the motor is commanded to run check the

current demand, if it does not increase then this is probably an electronic problem

(PCB connectors damaged).

If the current increases substantially then the motor/gearbox is mechanically

jammed and will need investigation and probable replacement

NOTE: The FORWARD Motor Driver controls the RIGHT AXLES

The REAR Motor Driver controls the LEFT AXLES

Troglotech T815 Crawler Workshop Manual Page 16

T815 CRAWLER - FAULT FINDING

T815 Crawler—Fault Finding—Other Problems

Crawler switches ON but T812 head does not initialise, no control over

motors.

This indicates an IIC problem—and this can either be a connection problem

between PCB’s or damage to PCB’s that use IIC to communicate. Sometimes this

can be diagnosed further by selecting reverse on the Display Unit: If the camera

view switches between front and rear views then the IIC Bus IS operational but

connection is lost somewhere on the Interconnect PCB’s (1, 2 and 3).

If no control of anything is possible but the crawler stays awake permanently

(rather than cycling OFF and ON) then it can be assumed that the IIC bus is

shorted to ground somewhere OR that a high voltage has been present between

the Battery Positive supply (or the 15V supply) and components on the IIC Bus

have been damaged.

This situation is always due to mechanical damage or water ingress, usually

starting with the Processor PCB.

It is advised that all PCB’s are removed from the crawler and the PCB set

inspected and then re-assembled without the metalwork on the bench

With the PCB’s in this configuration power can be supplied from a Bench Supply

to SK8 on the Processor PCB (see page 13)

Pin 1 = 12V Current Limit 500mA

Pin 2 = 0V

Pin 3 = Leave open

Troglotech T815 Crawler Workshop Manual Page 17

T815 CRAWLER– FAULT FINDING

Crawler switches ON but T812 head does not initialise, no control over

motors—continued

With power applied as detailed overleaf ensure the current does not exceed

100mA @ 12V. Power demand over this value indicates a short circuit on one of

the PCB’s.

To fault-find the damaged PCB switch OFF and start removing the PCB’s one at a

time starting at the front with the Power Control PCB, then switch back ON again

and check if the current has reduced.

Carry on checking in this fashion with the order: Power Control, Forward Motor

Drive, Interconnect 3, Interconnect 2, Interconnect 1 and finally Rear Motor Drive. If

the current remains high at this point then either the Processor or the Power

Supply PCB is at fault.

IIC BUS CHECKS USING METER OR OSCILLOSCOPE

The IIC Bus is available to be

measured on the Processor

PCB as shown to the right on

pins 1 and 2 of IC16. With

the Processor PCB powered

(LED’s D5 and D6 flashing)

then the IIC Bus should be

operational and at a voltage

of around 3V.

Using a meter connected

between 0V and the pins (0V

can be found on Pin 2 of PL8

seen in the picture) it is expected to see a voltage of 3V, an oscilloscope should

also see bursts of activity on the Bus every 20mS.

If the IIC Bus voltage is at 0V then it is possible that the Processor PCB is

damaged OR that the IIC Bus is shorted to ground somewhere in the PCB set.

Disconnect the battery and use a meter to check the resistance between SDA/SCL

to 0V, the resistance should be over 10,000 Ohms.

If there is a short, remove the Processor PCB and perform the same test—if the

resistance increases the problem is elsewhere in the PCB set

Troglotech T815 Crawler Workshop Manual Page 18

T815 CRAWLER - FAULT FINDING

T815 Crawler—Fault Finding—Other Problems

Crawler switches ON but as soon as the T812 camera head has centralised

the power switches back OFF again. The crawler will continue this behaviour

until the Display Unit is switched OFF (VIDEO PICTURE PRESENT):

This indicates that TTDS data is not being received by the Processor PCB

(possibly main cable damage) or the Processor PCB is not responding to the data.

In this case replace the Processor PCB and see if this cures the problem.

If this fails to repair the crawler then suspect the Display Unit or main cable.

The TTDS amplitude at the crawler must be at a minimum of 600mV above sync

pulses.

Crawler switches ON but as soon as the T812 camera head has centralised

the power switches back OFF again. The crawler will continue this behaviour

until the Display Unit is switched OFF (VIDEO PICTURE NOT PRESENT):

If no video picture is present when the crawler switches ON then suspect the T812

head (or Forward View Camera if fitted). The crawler cannot receive TTDS data

without a video picture being present. If possible try another T812 head or

Forward View camera. If neither is available then try replacing the Processor PCB.

Alternatively, the Processor PCB Video Output Stage may be damaged—replace

the Processor PCB to see if this cures the problem—this damage is usually due to

water ingress in the cable or cable connector at the swivel joint.

Inspect the Processor PCB for water ingress and any burning or contamination of

SK5. This socket is the only connector that has high voltages available (over 50V)

as this is the voltage at which the sonde coil operates. High voltages and moisture

will always cause burns around the connector and Processor PCB.

If there are burns then replace the Processor PCB AND the TC81516011 Swivel

Slipring assembly as this will also be damaged with possible contamination of the

sliprings and pogo’s on the swivel connector.

Troglotech T815 Crawler Workshop Manual Page 19

T815 CRAWLER– MECHANICAL

Water Damage at the rear of the Crawler—Swivel Assembly Removal

To change the PCB first remove the Rear Cover from the Crawler (4 large Allen

bolts) and carefully pull the cover straight back and avoid damaging the mating

connectors. Disconnect the 2-way connector from the sonde from the PCB and

then rotate the swivel connector unit one of the grub screws (17) can be seen as

shown on the bottom right. Completely remove the grub screw and then rotate

the swivel assembly so the next grub screw can be seen and removed. There

are six (6) grub screws that must be removed.

With all 6 grub screws remove the swivel connector. The PCB is held on with

two 1.2 x 3 mm screws. Replace the PCB and replace the o-ring 18 (21 x 1.5)

and liberally grease before replacing the swivel connector. NOTE: The swivel

ring must be placed on the PCB before screwing the PCB in place.

With the Swivel Ring in place and the Swivel Assembly dropped into position

with its o-ring onto the Swivel Ring, refit one grub screw and ensure it fits into

one of the holes in the Swivel Ring. Fully fit the grub screw and then loosen by

1/2 a turn. NOTE: Do not tighten any of the grub screws fully at this stage.

Make sure the Swivel Assembly can be rotated without the grub screw

fouling the PCB. Repeat this for all 6 grub screws and then go around all 6 fully

tightening each grub screw. Refit the Sonde connector.

Grease the large o-ring liberally before refitting the rear cover.

Troglotech T815 Crawler Workshop Manual Page 20

T815 CRAWLER - MECHANICAL

Crawler Disassembly:

The Crawler is simple to disassemble as long as a few precautions are taken:

1. Never use power tools—they can damage the Brass threads

2. Keep the disassembly area clean and dry

3. Have receptacles for any PCB that is removed, they are delicate

4. Have receptacles for all fixings

5. Only disassemble the PCB’s in the order given in earlier sections

6. Take care assembling the rear cover—there are delicate mating connections

and there is wiring to the sonde that can be damaged

7. Have an idea what you want to reach—often removal of one cover is all that

is required

Other manuals for T815

1

Other Troglotech Robotics manuals

Popular Robotics manuals by other brands

adept technology

adept technology Viper s650 user guide

QB Robotics

QB Robotics qb SoftHand RESEARCH user guide

MantaroBot

MantaroBot TeleMe 2 Assembly instructions & quick start guide

SuperDroid Robots

SuperDroid Robots SGT-32P Assembly and operation

Hitbot

Hitbot Z-Arm 2140 instructions

iRobot

iRobot PackBot Accessories