56 720 606 804 (02.10)

Louvers, grills and screens have a blocking effect. If the

effectivefreearea is notknown,increase the sizesofyour

openings by 75% if your louvers are wood and by 30% if

yourlouversaremetal.RefertotheNationalFuelGasCode

forcomplete information. In buildings of tight construction

all air should be taken from outside.

CLEARANCES

TheAquastar125HXisdesigncertifiedforinstallationon a

combustible wall and for installation in an alcove or closet

with the minimum clearances to combustible and non -

combustibleconstruction listed below

A. Top 12inches (306 mm)

B. Front 4 inches (102 mm)

C. Back 0 inches

D. Sides 4 inch (102mm)

E. Bottom 12 inches (306 mm)

Clearancefromventisdependentupontheclearancerating

oftheventing material used. For example:typeB-1 vent is

approvedfor1inchclearance.

Note: Minimumclearancetocombustiblematerialsshould

not be less than 6" for single wall flue pipe. Note that this

clearance can be reduced if combustible material are

protectedaspertableVIoftheNationalfuelGasCodeorif

Type B gas vent is used.

MOUNTING INSTALLATION

TheAquastar125 HX isdesign certified formounting on a

wall.

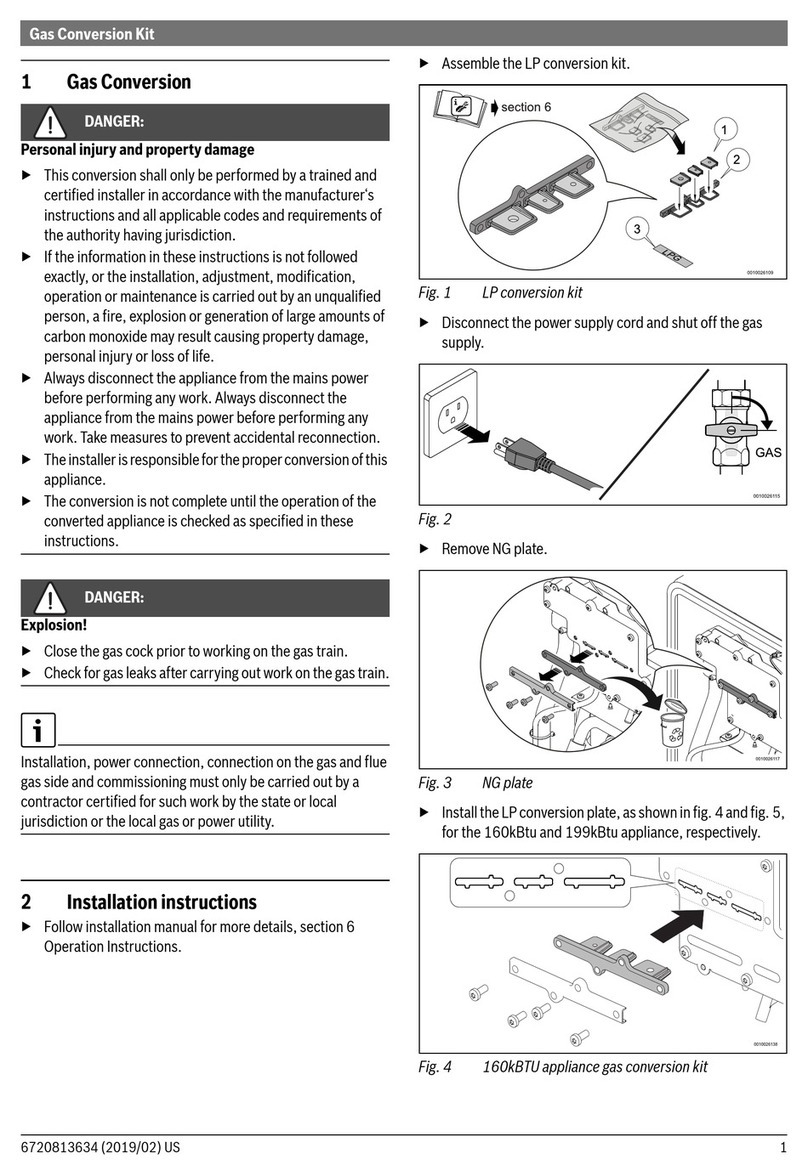

SecurethetwoLshapedhooksprovidedwiththeheaterto

a wall surface. Place them 13 ¼ inches apart as shown in

Fig1.

Donotinstallthisapplianceonacarpetedwalloroverfloor

coveringwhichis combustible, such ascarpet.Theheater

must be mounted on a wall using appropriate anchoring

materials.Ifwall is a studwallsheathed with plasterboard,

it is recommended that support board(s), either 1x4’s

or 1/2" (minimum) plywood first be attached across a

pair of studs and then the heater should be attached

to the support boards. See Fig 1.

Expansionandcontractionofpipingduetochangingwater

temperature in the pipes imparts movement to the heater

which, if mounted directly to a brittle, friable board, such

asplasterboard, can cause failureof mounting.

In earthquake-prone zones, CEC recommends that

installers use a large washer and lag screw through the

existing holes used to hang the heater to affix the upper

thirdofthe heater to themountingboard.Toaffixthe lower

third of the heater, CEC recommends that two new holes

bedrilled in theheater’s frame, eachone 16 inchesbelow

the top two holes, and that washers and lag screws be

usedtosecure the lowerportionof the heatertoa spacing

board.

Before installing the unit, be certain you have the

correctheater for yourtype of Gas– Propane orNatural

Gas. Identification labels are found on the shipping

box, and on the rating plate which is located on the

right side panel of the cover.Also,each burner orificeis

stamped with a number (79 for LPG and 120 for Natural

Gas).

Thisproduct is not approved for manufactured homes

(mobile home), recreational vehicles (RV) or boats.

Reference ANSI Z21.10.3.

This product is neither designed or approved for

outside installations.

COMBUSTION AIR REQUIREMENTS

TheAquaStar water heater holds cold water in its copper

heatexchanger and water valve when not in use. Because

of this, any cold air that comes in through the unit’s vent

pipe is capable of freezing these components. This

InstallationManual specifiestheminimumvertical ventpipe

and the amount of combustion air required for this unit.

Thevent pipe must not be restricted and its 6footminimum

height(provided there are noelbows)mustterminate2feet

aboveany obstruction withina 10 footradius.

When all requirements are followed, the unit will operate

properly and safely. However, there may still be a risk of

freezingduetonegativedraftifallthecombustionappliances

inthe area arenot being suppliedwith a sufficientamount

ofmake-upair.Awood stove orfurnacecanrob the make-

upairintheAquaStar’sventpipe,leavingthecoldinfiltrating

aircapable of freezingthe cold waterin theAquaStarheat

exchanger. More make up air is the solution. Follow the

instructionsonventingandcheckingadequacyofmakeup

air. AHVAC specialist should be used to design solutions

forprovidingmoremake-up air if necessary.

Observethefollowinginstructions concerning combustion

air.

Applianceslocated in unconfinedspaces:

a) An unconfined space is one whose volume is greater

than50 cubicfeetper1000Btu per hourofthecombined

ratingofallappliancesinstalledinthe space.That would

be5850cubic feet for theAquaStar125HX alone.

b) Inunconfined spaces in buildings of conventional frame,

masonry, or metal construction, infiltration is normally

adequateto provide air forcombustion, ventilation, and

dilutionof flue gasses.

Applianceslocated inconfined spaces:

Theconfinedspace must be providedwithtwo permanent

openings,onecommencingwithin12inchesofthetopand

one commencing within 12 inches of the bottom of the

enclosure.Each openingmust have a minimum free area

ofone square inchper:

- 1000 Btu/hr if all air is taken from inside the building.

- 2000Btu/hr ifallairis takenfromtheoutsideby horizontal

ducts.

- 4000 Btu/hr if all air is taken from the outside by direct

openingsor vertical ducts.

Ortheconfinedspacemustbeprovidedwithonepermanent

openingorduct that iswithin12 inches of theceiling of the

enclosure.This opening must have a minimum free area of

onesquare inch per:

- 3000 Btu/hr if all air is taken from the outside by a direct

openingorvertical duct.