BOSSCO 8060 UBI User manual

This manual must be read carefully BEFORE installing, operating, servicing and/or

maintaining your Boss Industries Air Compressor.

Store in a safe and convenient location for future reference.

For technical support:

Phone: (800) 635-6587 (USA)

Phone: (219) 324-7776 (Outside USA)

Fax: (877) 254-4249 (USA)

service@bossair.com (email)

http://www.bossair.com (website)

309743

KWB

11-13-2014

Operator

Manual

BOSS 8060 UBI

PTO Air Compressor

This manual is for operator and maintenance personnel only.

309743

3 309743

Safety ...................................................................................................................5-12

Safety Disclaimer ................................................................................................................................6

Safety Overview .................................................................................................................................6

Safety Warnings .......................................................................................................................7-11

Welcome .............................................................................................................13-14

General Information ..........................................................................................................................14

System Overview ..............................................................................................................................14

System Specifications ........................................................................................................................14

Description of Components ..............................................................................15-18

Subsystems .............................................................................................................................16-18

Compressor Assembly .........................................................................................................16

Sump TankAssembly ...........................................................................................................16

Air Oil Manifold ...................................................................................................................17

CoolerAssembly ..................................................................................................................18

Air Filter Assembly ...............................................................................................................18

B-CANAssembly and Harnesses .........................................................................................18

Hoses and Tubing .................................................................................................................18

Operation ...........................................................................................................19-26

Compressor General Overview .........................................................................................................20

Inspection Prior to Moving Vehicle ........................................................................................20-21

Job Site Considerations ......................................................................................................................21

Starting the Compressor System ........................................................................................................21

Stopping the Compressor System ......................................................................................................22

Operating Multiple Components (if equipped) ....................................................................................22

Checking the Air Filter .......................................................................................................................22

Shutdowns ........................................................................................................................................23

Compressor Lockout ...........................................................................................................23

System Safeties ......................................................................................................................24-25

B-CAN ................................................................................................................27-32

B-CAN Overview ............................................................................................................................28

B-CAN Basic Display ...........................................................................................................28-29

Compressor Pressure Gauge ................................................................................................28

Compressor Temperature Gauge ..........................................................................................28

Hour Meter ..........................................................................................................................29

Compressor Status ..............................................................................................................29

Button Labels .......................................................................................................................29

B-CAN Basic Menu ..............................................................................................................30-32

Accessing the Menu ..............................................................................................................30

Information Screen ...............................................................................................................30

Display Options ...................................................................................................................31

Service Menu .............................................................................................................31-32

Switch to Service Mode .......................................................................................................32

Table of Contents

4309743

Table of Contents

Maintenance ......................................................................................................33-38

Overview ..........................................................................................................................................34

Recommended Spare Parts List .........................................................................................................34

How to Locate a Distributor ..............................................................................................................34

Maintenance Schedule ......................................................................................................................35

Compressor Lubrication Recommendation .......................................................................................36

Proper Compressor Oil Level ...........................................................................................................37

Draining Moisture from the System ....................................................................................................37

Warranty ............................................................................................................39-44

Warranty Statement ...........................................................................................................................40

Summary of Main Warranty Provisions ..............................................................................................41

Warranty/Return Goods Instructions ..................................................................................................42

Warranty Claims - Preparation of Part Return ....................................................................................42

Return or Warranty Claims - Filing Procedures ...................................................................................42

General ............................................................................................................................................43

Damage in Transit .............................................................................................................................43

Screw Compressor Airend Exchange Program ..................................................................................44

Drawings ............................................................................................................45-69

10G Compressor Assembly ...................................................................................................46-47

RSC9 Compressor Assembly .................................................................................................48-49

14D Compressor Assembly ...................................................................................................50-51

10G/RSC9 Sump Tank Assembly ..........................................................................................52-53

14D Sump Tank Assembly ....................................................................................................54-55

B-CANAssembly ..................................................................................................................56-57

Air Filter Assembly ................................................................................................................58-59

10G Air Oil Manifold .............................................................................................................60-61

RSC9 Air Oil Manifold ..........................................................................................................62-63

14D Air Oil Manifold .............................................................................................................64-65

10G/RSC9 Cooler Assembly .................................................................................................66-67

14D Cooler Assembly ............................................................................................................68-69

5 309743

Safety

Safety

6309743

The Boss 8060 UBI PTO compressor system is industrial equipment. This equipment is to be installed, operated,

maintained, and serviced only by trained personnel who have fully read and understand this manual and all associated

manuals. Just as you would not operate a bulldozer or excavator without training, you should never operate a Boss

compressor without training.

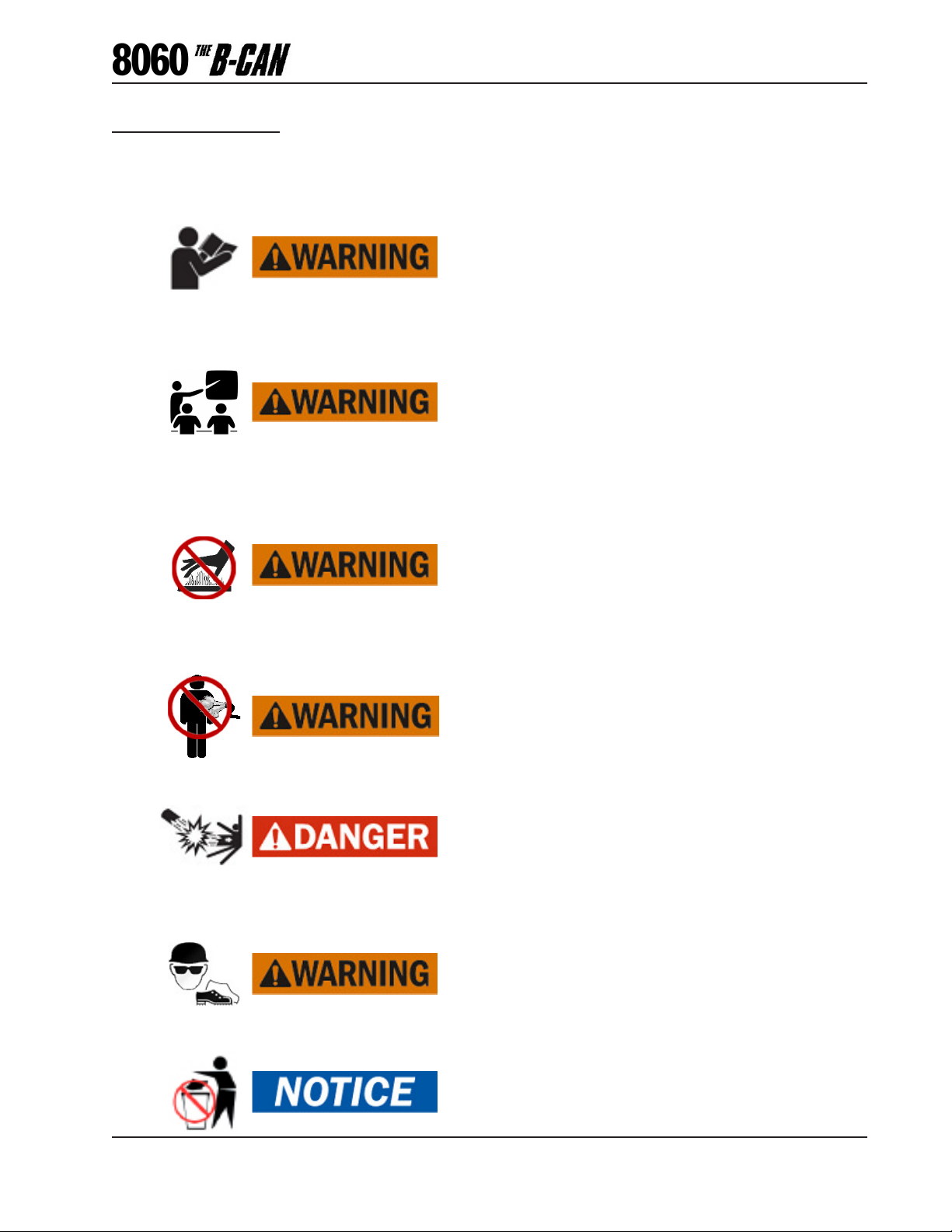

The following safety symbols are used throughout this manual to draw attention to important information. If the

information is not carefully read and the instructions are not followed, severe injury or death, and/or damage to property

and equipment may occur. The key to the safety symbols are listed below.

Safety

Safety Overview

Safety Disclaimer

The owner, lessor, and/or operator of the Boss Industries, Inc. 8060 UBI PTO compressor system are hereby notified and

forewarned that any failure to adhere to the following safety precautions may result in property damage and/or personal

injury or death.

Boss Industries, Inc. expressly disclaims responsibility or liability for any injury or damage caused by the failure to

observe the following specified precautions or by failure to exercise the ordinary caution and due care required when

operating or handling the Boss Industries, Inc. 8060 UBI PTO compressor system, even though not expressly specified.

Indicates a practice which, if not avoided, could result in

property and/or equipment damage only.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Call Boss Industries, Inc. if there are any discrepancies with the listed safety

precautions and your company policies and procedures.

This equipment is to be installed, operated, maintained, and serviced

only by trained personnel who have fully read and understand this

manual and all associated documentation for the Boss 8060 UBI PTO

compressor system. Failure to adhere to this warning could result in

death or serious injury, damage to property and equipment or both.

7 309743

The following safety warnings and precautions must be observed at all times for the Boss 8060 UBI PTO compressor

system:

Safety

Safety Warnings

Do not discard this manual. This manual should be kept

in a location that can be easily accessed at all times.

Proper attire is required at all times when installing,

operating, maintaining, and/or servicing the Boss 8060

UBI PTO air compressor system. This includes, but is

not limited to, safety glasses, work gloves, and steel toe

footwear. Company policies and procedures must be

followed.

Do not direct compressed air discharged from the system

at any person, including yourself. Failure to follow

warning could result in personal injury or death and/or

damage to equipment and property.

Do not disable, override, or remove system safeties or

controls, either temporarily or permanently. Overriding

safeties will result in serious injury, death, and/or damage to

equipment.

Fully read and understand this manual and all other

associated documents before installing, operating,

maintaining, and/or servicing this equipment. Failure to

comply could result in personal injury or death and/or

damage to equipment and property.

The Boss 8060 UBI PTO compressor system is to be

installed, operated, maintained, and serviced only by

trained personnel. An untrained individual could suffer

personal injury or death and/or damage to equipment

and property.

The Boss 8060 UBI PTO compressor system contains

hot oil that is circulated through this system during opera-

tion. Do not touch any compressor system components

until the system has been shut off and allowed to cool to

ambient temperature. Failure to follow warning could

result in personal injury or death and/or damage to

equipment and property.

8309743

Do not use flammable solvents for cleaning compressor

parts as this can cause the unit to ignite and/or explode

during operation. Failure to comply could result in

personal injury or death and/or damage to equipment

and property.

This compressor is designed to compress air only. Do

not attempt to compress other gases. Compression of

other gases may create a situation where an explosion or

fire may occur. This will result in serious injury, death,

and/or damage to equipment.

Do not use air from this compressor system for breathing

or food processing. Air discharged from this compres-

sor system contains small particles of oil that must not be

ingested. This will result in serious injury, death, and/or

damage to equipment.

Never adjust the pressure regulator to increase the

system pressure above 125 PSIG.If pressure require-

ments are higher, contact Boss Industries, Inc. for

necessary component changes. Failure to comply could

result in personal injury or death and/or damage to

equipment and property.

Prior to every use check all safety devices for proper

operation. Failure to comply could result in personal

injury or death and/or damage to equipment and prop-

erty.

Do not install a shut-off valve in any oil lines throughout

the Boss 8060 UBI PTO compressor system. Failure to

comply will result in serious injury, death, and/or damage

to equipment.

Safety

Safety Warnings (cont.)

9 309743

Safety

Safety Warnings (cont.)

Connect air hoses only in full compliance with OSHA

Standard 29 CFR 1926:302(b)(7). The required safety

devices (velocity fuses) should be tested in accordance

with their manufacturer’s recommendations to verify that

they reduce pressure in case of hose failure and will not

nuisance trip with the hose and tool combinations in use.

Failure to comply could result in personal injury or death

and/or damage to equipment and property.

Never leave the machine running unattended or leave a

tool connected to an air hose when not in use. Failure to

comply could result in personal injury or death and/or

damage to equipment and property.

Use only Boss Industries, Inc. approved

replacement parts. Not all components have the same

specifications. Only Boss approved replacement parts

are safe to use when servicing a Boss 8060 UBI PTO

compressor system. Failure to comply could result in

personal injury or death and/or damage to equipment and

property.

The Boss 8060 UBI PTO compressor system contains

ASME certified pressure vessels. Never attempt to

repair or modify any pressure vessel. Failure to comply

could result in personal injury or death and/or damage to

equipment and property.

Do not attempt to service or maintain any part of the

compressor system while the vehicle is running. Failure to

comply could result in personal injury or death and/or

damage to equipment and property.

The Boss 8060 UBI PTO compressor is a

pressurized system. Do not attempt to remove any

compressor system part without first completely relieving

entire system of pressure. Failure to comply will result in

serious injury, death, and/or damage to equipment.

Relieve Boss 8060 UBI PTO compressor system of all

stored air pressure after every use. Failure to comply

could result in personal injury or death and/or damage to

equipment and property.

10309743

Safety

Hot oil under pressure will cause severe personal injury or

death. Do not remove valves, caps, plugs, or piping when

compressor is running or pressurized. Shut down com-

pressor and relieve system of all pressure before removing

valves, caps, plugs, or piping. Failure to comply will result

in serious injury, death, and/or damage to equipment.

Do not operate compressor without the fan guard in place.

Failure to comply could result in personal injury or death

and/or damage to equipment and property.

The driveline rotates. Switch off engine and disconnect

battery or electrical supply before attempting to work or

perform maintenance on the compressor package. Failure

to comply could result in personal injury or death and/or

damage to equipment and property.

Read the operators manual before starting this unit.

Failure to adhere to instructions can result in severe

personal injury. Replacement manuals can be purchased

from Boss Industries, Inc.

The B-CAN is not a touch screen unit. To operate, use

the buttons below the screen.

Safety Warnings (cont.)

Operators must not tamper with engine governed speed.

High operating speeds are dangerous and increase the

risk of personal injury or damage to equipment.

Never weld to truck chassis, as this will cause damage to

many electrical or electronic components grounded to

vehicle’s chassis.

Gasoline and natural gas are highly flammable, and their

vapors are explosive. Do not permit smoking, open

flames, sparks, or heat in the vicinity while exposed to

these gases.

11 309743

Safety

Safety Warnings (cont.)

This compressor is designed for outdoor use only. Do not

use this compressor inside any building or enclosure.

Deadly carbon monoxide gas may cause fatal injuries. In

addition a fire or an explosion may occur. No user-

performed modifications, including venting of exhaust and/

or cooling ventilation, will eliminate the danger.

The Boss 8060 UBI PTO compressor system requires an

adequate flow of cooling air for its continued operation.

Never operate the unit inside any room or enclosure where

the free flow of cooling air into and out of the unit might be

obstructed. Without sufficient cooling air flow, the com-

pressor quickly overheats, damaging the unit and nearby

property. Maximum compressor capacity may be reduced

where ambient temperatures exceed 100°F.

Do not pressure wash or apply excessive force to the face

of the B-CAN module. Doing so may break the water

resistant seal, causing failure to the B-CAN panel. Failure

to comply could result in personal injury or death and/or

damage to equipment and property.

12309743

Safety

13 309743

Welcome

Welcome

14309743

General Information

Welcome

System Specifications†

Thank you for choosing the Boss 8060 UBI PTO Air Compressor System. Before

installing, servicing, maintaining, or operating this compressor, read over this manual

and become well acquainted with this system. Doing this will increase your safety

and maximize the life of the compressor system.

While this manual is written to be as accurate as possible, Boss strives to continu-

ally improve the efficiency and performance of its products. As a result, sometimes

there may be slight differences between a given version of the manual and the

system.

System Overview

The Boss 8060 UBI PTO air compressor package is comprised of unique

subsystems that are independently mounted to fit a wide range of vehicles. This

subsystem design allows components to be mounted in the location that works

best for your specific vehicle.

The 8060 UBI PTO air compressor system is controlled by the Boss B-CAN. The

B-CAN is the most advanced, user friendly, digital compressor controller available

for the PTO compressor market. The dynamic on-screen display will simplify the

operation, service, and maintenance processes.

** Hydraulic calculations include 85% mechanical efficiency and 96% volumetric efficiency.

†Specifications subject to change without prior notice.

GISP011@yrevileD MFC 06 58 001 521 061 581

)1:50.3(rosserpmoCotMPRdeepStupnI MPR 057 0101 0021 0541 5781 0612

**IBHU-0608rofISP0022@MPGtupnI MPG 2.51 5.02 4.42 4.92 0.83 8.34

)1:05.2(rosserpmoCotMPRdeepStupnI MPR 519 0521 5741 5771 0532 X

)1:69.1(rosserpmoCotMPRdeepStupnI MPR 0011 5751 0681 0032 X X

)9CSR(rosserpmoCotMPRdeepStupnI MPR X X 0002 0052 X X

)D41(rosserpmoCotMPRdeepStupnI MPR X X X X 5222 0052

yticapaCdiulF snollaG57.4

)yrD(thgieW .sbl324

This manual must be read carefully BEFORE installing, operating, servicing and/or

maintaining your Boss Industries Air Compressor.

Store in a safe and convenient location for future reference.

For technical support:

Phone: (800) 635-6587 (USA)

Phone: (219) 324-7776 (Outside USA)

Fax: (877) 254-4249 (USA)

service@bossair.com (email)

http://www.bossair.com (website)

309743

BSM

11/7/2012

Operator

Manual

BOSS 8060 UBI

PTO Air Compressor

This manual is for operator and maintenance personnel only.

15 309743

Description of

Components

Description of Components

16309743

Subsystems

Description of Components

The Boss 8060 UBI PTO air compressor system is a group of subsystems that are shipped loose to be mounted in open

spaces on the vehicle’s frame and body. The subsystems are connected using hoses and tubing that are also shipped in

the kit. Not all vehicles are capable of being equipped with a Boss 8060 UBI PTO air compressor system. Please contact

your local distributor to verify your vehicle is capable of supporting the Boss 8060 UBI PTO air compressor system.

The images shown below are for reference only and may not match your exact system.

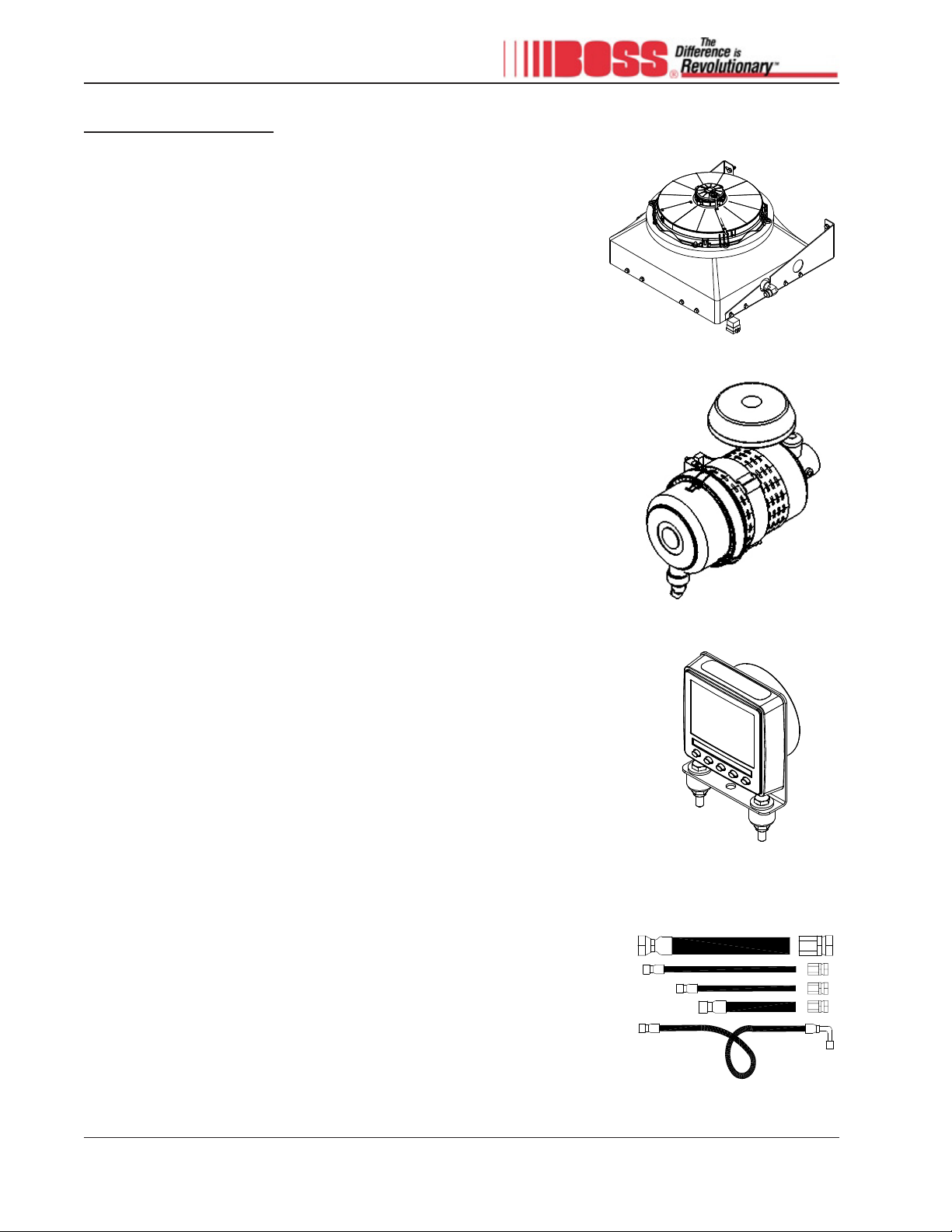

Sump Tank Assembly

The air oil mixture leaving the compressor assembly flows into the

sump tank assembly. The sump tank is the first stage of oil

separation in the 8060 UBI PTO compressor system. The sump

tank also acts as an oil reservoir to ensure there is plenty of oil

capacity to handle continuous air compressor operation.

The tank safety relief valve is located at the top of the sump tank.

This valve acts as a backup to protect the system from excessive

pressure buildup as a result of a system malfunction.

Also in the tank assembly is the oil fill cap and oil level sightglass.

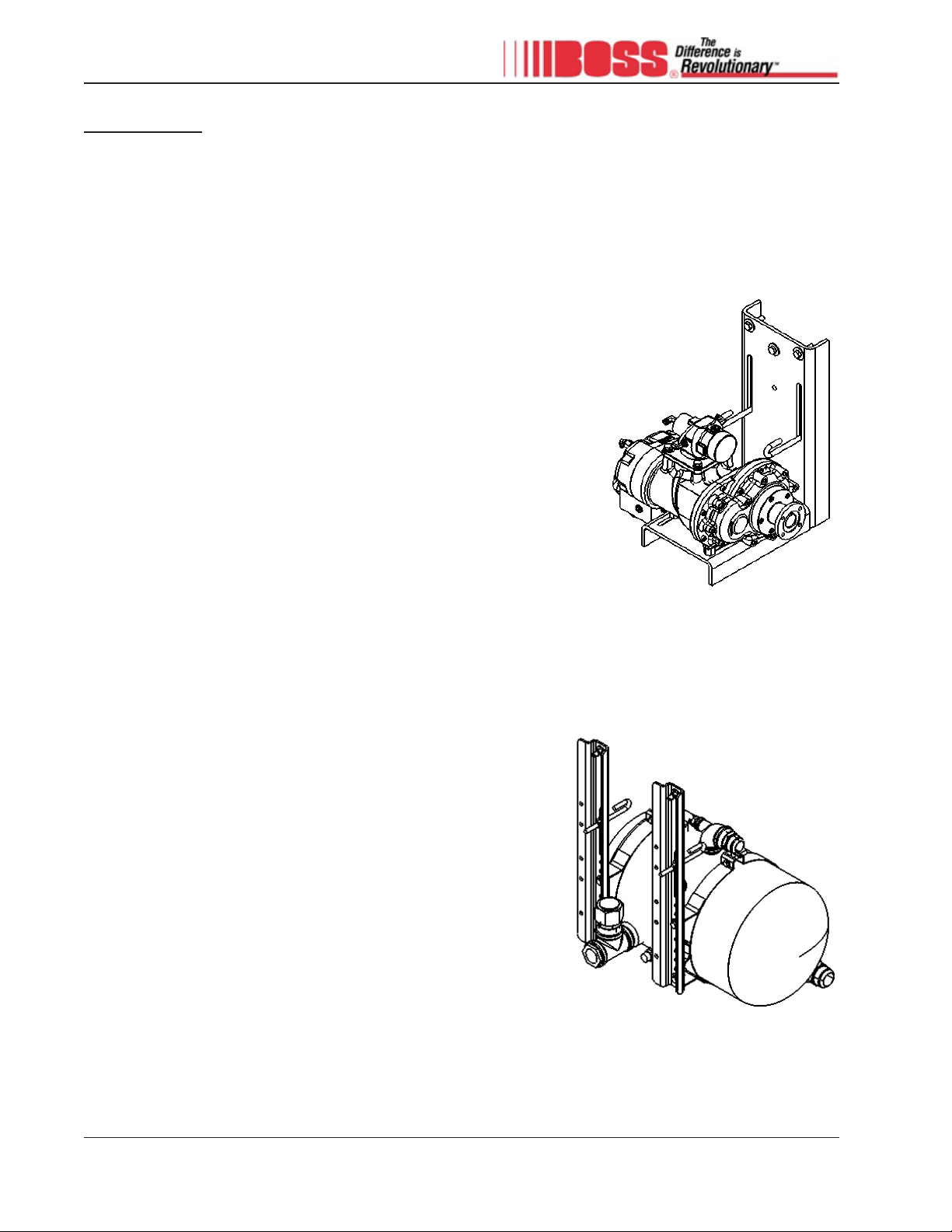

Compressor Assembly

The heart of the Boss 8060 UBI PTO air compressor system is the rotary

screw airend. The rotary screw is a positive displacement, oil flooded

device employing one stage of compression to achieve the desired

pressure. In operation, two helically grooved rotors mesh to compress air.

Intake air is trapped as the male lobes roll down the female grooves,

pushing trapped air along, compressing it until it reaches the discharge

port in the end of the stator. This delivers smooth-flowing, pulse-free air

to the sump tank.

The oil in a rotary screw airend serves three purposes:

• Lubricates the rotating parts and bearings.

• Serves as a cooling agent to remove the heat from compression.

• Seals the running clearances.

Mounted to the airend is a companion flange, intake valve, and mounting bracket.

17 309743

Description of Components

Subsystems (cont.)

The spin-on coalescer is the second and final stage of oil separation in the Boss 8060 UBI PTO

compressor system. As the oil laden air passes through the filter media, oil gathers on the walls and

collects at the bottom of the element. The oil that is separated is then returned to the rear of the

compressor assembly.

On the upstream side of the coalescer is the pressure transducer. This transducer provides precise

feedback to the B-CAN on the status of the compressor system.

On the downstream side of the coalescer is the regulator valve. The regulator valve is a proportional

control valve that sends a signal to close the intake valve when the system pressure has reached the

correct level.

Also mounted downstream of the coalescer is the blowdown valve. The blowdown valve’s function is

to relieve the system of air pressure when the 8060 UBI PTO compressor system is shut off. This

valve is piloted by a signal from the intake valve and vents the system pressure to atmosphere.

The most overlooked component in the Boss 8060 UBI PTO compressor system is the minimum

pressure orifice. This orifice is designed to maintain adequate pressure in the system to ensure proper

oil circulation.

Air Oil Manifold

The air oil manifold is a common point for senders and switches

along with filters and control valves. The air oil manifold is

divided into two sides: air and oil.

The air side contains the following:

• Spin-On Coalescer

• Pressure Transducer

• Regulator Valve

• Blowdown Valve

• Minimum Pressure Orifice

The oil side of the manifold contains the following:

• Spin-On Oil Filter

• Temperature Sender

• Thermal Valve

As oil is pushed out the bottom of the sump tank, it is directed to the spin-on oil filter. After the filter

is the thermal valve. The thermal valve bypasses the cooler at start-up to minimize the time to elevate

the system to proper operating temperature.

Lastly, on the oil side is the temperature sender. This sender provides feedback to the B-CAN on the

status of the compressor system.

18309743

1

1

2

2

3

3

4

4

A A

B B

C C

D D

Subsystems (cont.)

Description of Components

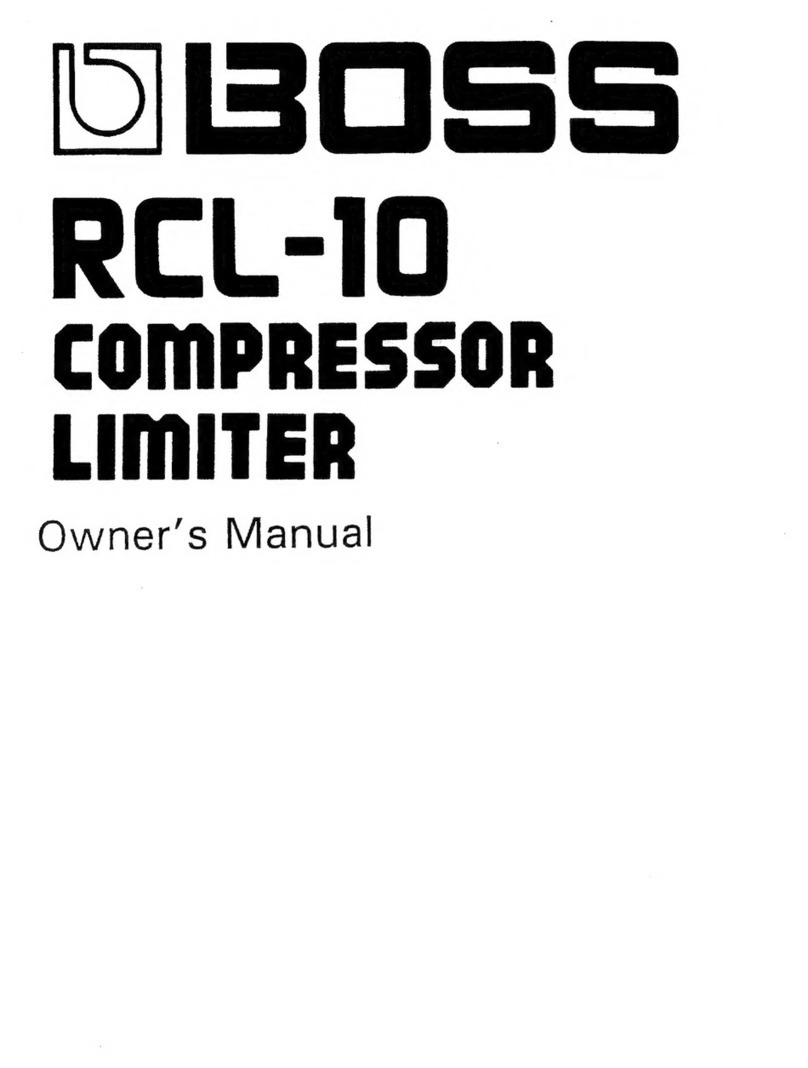

B-CAN Assembly and Harnesses

The B-CAN controller is the brain behind the Boss 8060 UBI PTO air

compressor system. The B-CAN is a compact, durable, and convenient

controller. It allows all system components, including a compressor,

generator, and hydraulic pump, to be controlled from one location with the

touch of a button. This controller receives feedback from the compressor

system to ensure proper performance. Utilizing the vehicle’s on-board

Controller Area Network (CAN), the B-CAN communicates with the vehicle

and PTO compressor systems. Along with the B-CAN controller are simple

plug and play harnesses to greatly reduce installation time.

Air Filter Assembly

The air filter assembly is the entrance for ambient air to the Boss 8060 UBI

PTO compressor system. Air is drawn through this assembly and into the

intake valve on the compressor assembly. The air filter assembly is a two

stage system that is capable of handling medium to high dust environ-

ments. The system incorporates an acoustical rain cap and corrosion

resistant housing. The air filter assembly also includes a service indicator

that shows the life of the filter even when the compressor system is off.

Cooler Assembly

The cooler assembly is an aerodynamically designed cooling package that

utilizes an electric fan that cycles on and off based on oil temperature to

ensure the temperature stays in the correct range.

Hoses and Tubing

The 8060 UBI PTO compressor system is shipped with all the hoses and

tubing required for standard installations. The hoses and tubes are rated at

the pressures and temperatures required for safe operation. All hoses are

single wire braid hose with 37° JIC ends. The color and size differentiated

tubing uses push-on connections.

19 309743

Operation

Operation

20309743

Compressor General Overview

Operation

Inspection Prior to Moving Vehicle

At the start of your shift, before taking the vehicle to the job site in the morning, the following inspections should be

performed. This simple one-minute check will help to ensure you don’t drive to the job site with an inoperable compres-

sor.

1. With vehicle on a level surface check to ensure the oil level is at least halfway on the sightglass. If not, see

maintenance section for proper filling procedure.

Operation of the 8060 UBI PTO compressor system should only be performed by trained operators. Carefully read the

entire Operation section of this manual before attempting to operate the system. Be sure to follow all company policies

and procedures.

Operation of the compressor is controlled with the first button on the B-CAN. The color and text of the button changes

with the current state of operation. The possible states are:

If the system has a generator (GEN) or hydraulic pump (HYD)

installed, the 5th button will be used to control it. Engagement is the

same as for the compressor.

A green ENGAGE COMPR button indicates all safeties have been

met. Press this button to engage the compressor.

A yellow COMPR button indicates not all safeties have been met.

Press this button to display the reason(s) engagement cannot

occur.

A dark grey COMPR LOCKED button indicates the compressor is

locked and service is required. Press this button to display the

service that is needed.

A red STOP COMPR button indicates the compressor is currently

engaged. Press this button to disengage the compressor.

Table of contents

Other BOSSCO Air Compressor manuals

BOSSCO

BOSSCO Infinity User manual

BOSSCO

BOSSCO RCL-10 User manual

BOSSCO

BOSSCO BA435 PISTON Installation and user guide

BOSSCO

BOSSCO K36BP PISTON Installation and user guide

BOSSCO

BOSSCO 210 DUS JD4045 Installation and user guide

BOSSCO

BOSSCO BA440 PISTON User manual

BOSSCO

BOSSCO 36 BHP PISTON Installation and user guide

Popular Air Compressor manuals by other brands

TOOLCRAFT

TOOLCRAFT 2149347 operating instructions

Truper

Truper COMP-50LT manual

SHARKS

SHARKS Airstation SHK 476 Instruction for operation and maintenance

Challenge

Challenge T609 instruction manual

Craftsman

Craftsman 919.167620 owner's manual

Utile

Utile L240 Installation, operation & maintenance instructions