BOSSCO Infinity User manual

BOSS MODEL INFINITY

PTO AIR COMPRESSOR

OPERATORS, MAINTENANCE

AND PARTS MANUAL

P/N: 307200

06/05/2008 MCM

4

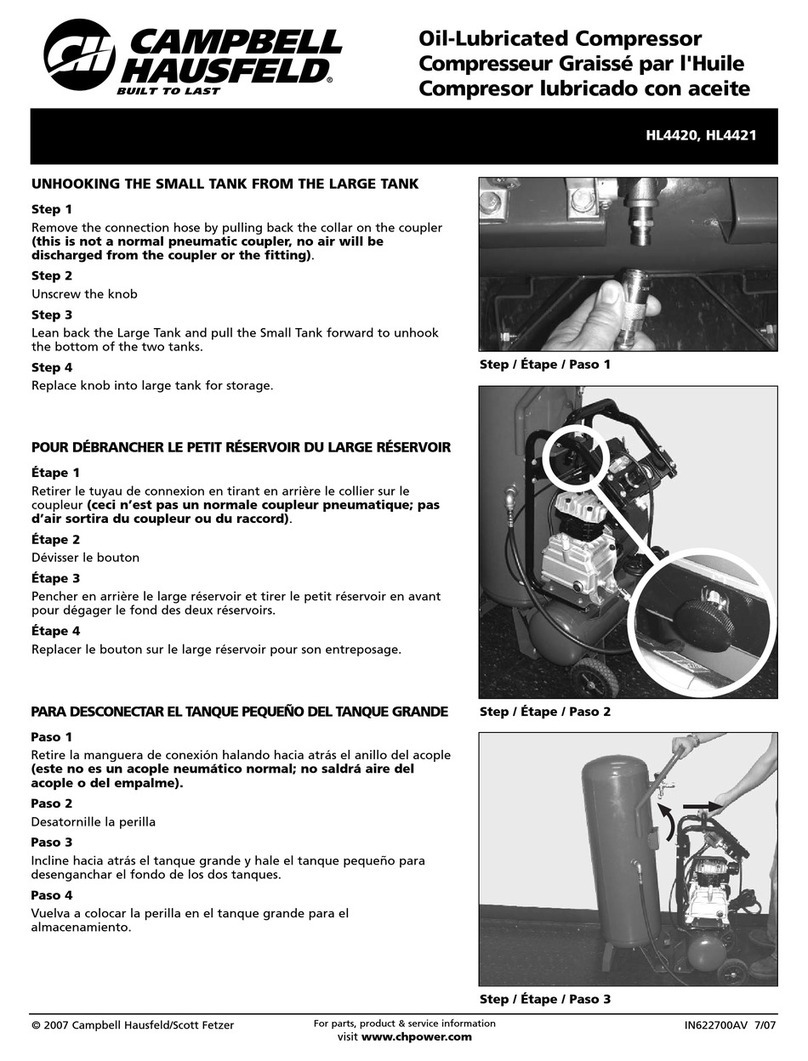

OPERATORS, MAINTENANCE, AND PARTS MANUAL

BOSS INDUSTRIES INFINITY

Operation & Maintenance Section

TABLEOFCONTENTS

Operation& Maintenance Section

Specifications...................................................................................................................... 6

Safety .................................................................................................................................. 7

CompressorTerminology .................................................................................................. 11

Description of Components............................................................................................... 12

Inspection,Lubrication,andMaintenance.......................................................................... 16

Troubleshooting................................................................................................................. 24

Compressor Operation ...................................................................................................... 27

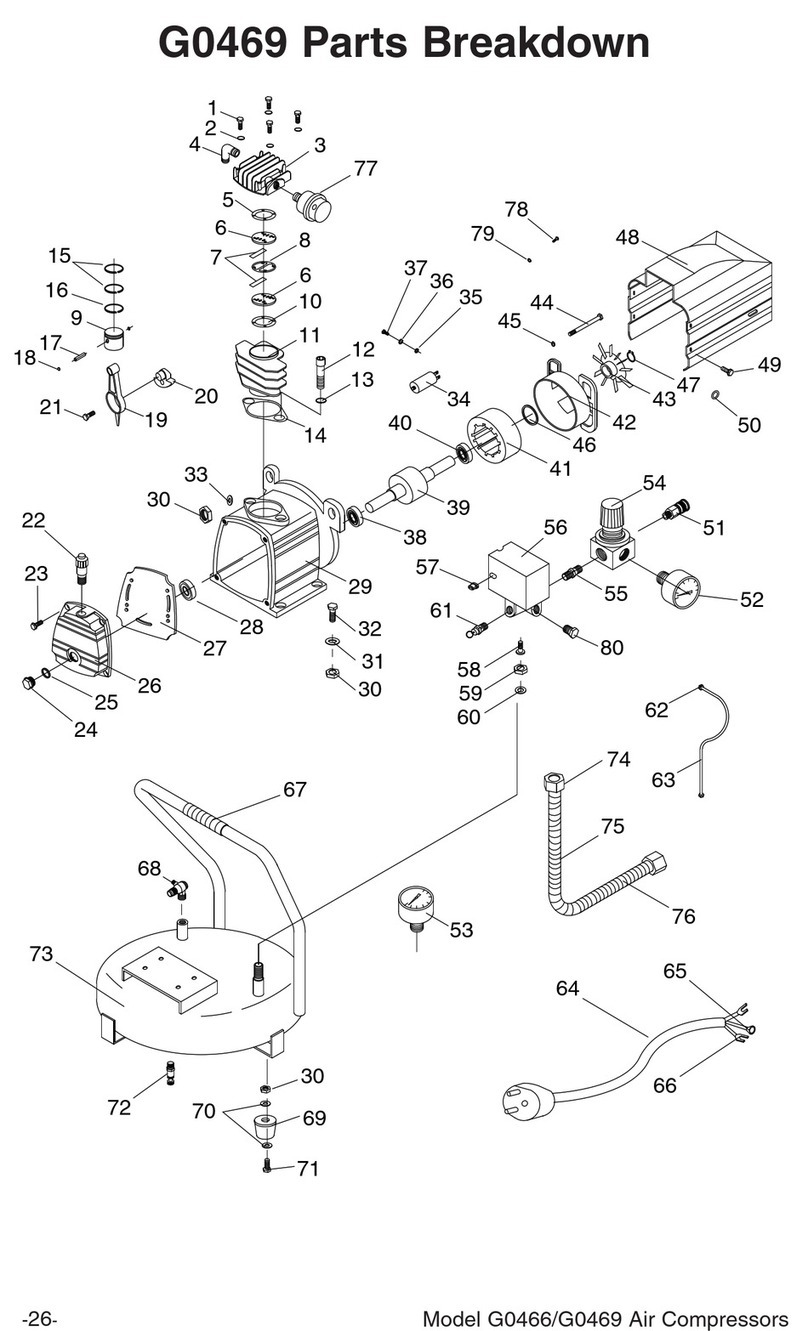

Parts and Illustration Section ............................................................................................. 29

RecommendedSpare Parts ................................................................................................ 36

ServiceQuestionnaire........................................................................................................ 37

Instructional Procedures for Installation ........................................................................... 38

Warranty Section

WarrantyInformation ........................................................................................................ 43

6

SPECIFICATIONS

GISP051@YREVILEDMFC5406

rosserpmoCotdeepStupnI MPR MPG

0051 @01 ISP0742

1591 @31 ISP0742

rosserpmoC-yticapaCdiulF )

ciluardyhton( metsySsnollaG0.1 pmuSrosserpmoC57.

metsySrosserpmoC-stnenopmoC )snoisnemiDllarevO( wolebees

)

yrd(thgieW .sbl003

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT PRIOR NOTICE

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

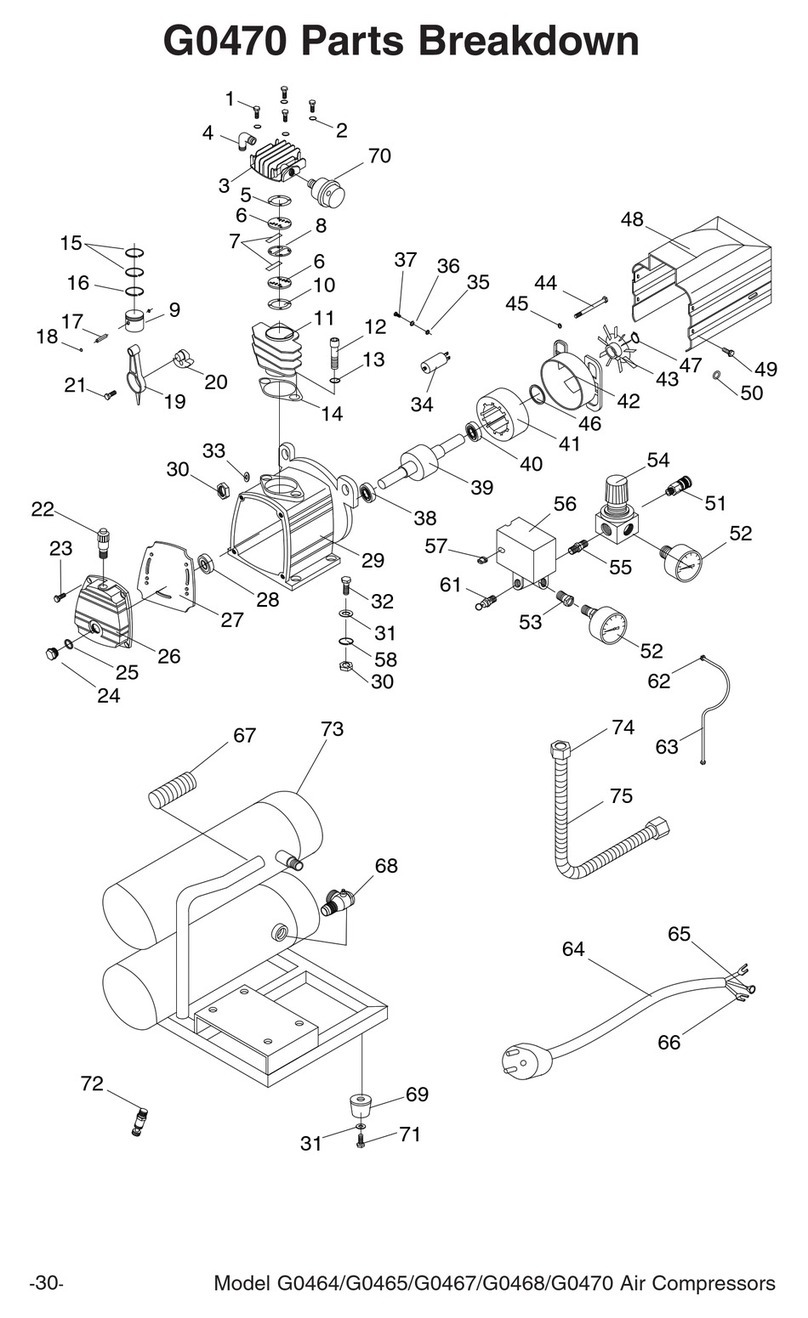

Parts List

DESCRIPTIONPART NUMBERQTYITEM

COMPR MTG SYS, INFINITY 45-60-150 SCI8G 0820035311

ELEC SYS, INFINITY 45-60-150 SCI8G 08200355-99912

OIL-AIR-HYD CLNG SYS, INFINITY SCI8G 08200356-99913

CANOPY SYS, INFINITY 45-60-150 SCI8G 0820035414

SHEET

20054-001

11

OF

REV

1

INFINITY 45-60 SCI8G 08

BOSS INDUSTRIES

1761 GENESIS DR.

LA PORTE, IN 46350

N/A

PATH

MATERIAL

G:\Inventor Files\20k\20054-001.dwg

12/3/2007

12/3/2007

DCL

DRAWN

NDD

CHECKED

1=4

D

DESCRIPTION

DWG NO

R

SCALE

SIZE

UNMACHINEDSURFACES

FRACTIONAL

`

1/16

DECIMAL

`

.03

ANGULAR

`

1°

DO NOT SCALE

TOLERANCES

UNLESS NOTED

MACHINEDSURFACES

NOMINALDIM.

0.000 TO 1.000

`

.010

1.001 TO 5.000

`

.015

5.001 TO 10.000

`

.020

10.001 & OVER

`

.025

THIS DRAWING AND ALL ITS

CONTENTS ARE PROPERTY

OF BOSS INDUSTRIES, INC.

AND MUST NOT BE COPIED

OR MADE PUBLIC. IT IS

LOANED AN D IS SUBJEC T TO

RETURN UPON DEMAND . THE

INFORMATION CONTAINED IN

THIS DRAWING IS

CONFIDEN TIAL AND MUST

NOT BE USED, DIRECTLY OR

INDIRECTLY, IN ANY WA Y

DETRIMENTAL TO THE

INTEREST OF BOSS

INDUSTRIES, INC.

PROPRIETARY INFORMATION

34 3/4 in

[882.7 mm]

32 1/4 in

[819.2 mm]

17 3/4 in

[450.9 mm]

6 3/8 in

[163.2 mm]

5 in

[127.0 mm]

19 in

[481.4 mm]

20 1/4 in

[514.4 mm]

DIMENSIONS OF MOUNTING HOLES

REVISION HISTORY

REV DESCRIPTION DATE ENG

1UPDATED 200353 TO REV 1, 200354 TO REV 1 5/22/2008 MCM

7

WARNING

AIR COMPRESSOR SAFETY PRECAUTIONS

Safety is basically common sense. While there are standard safety rules, each situation has its own

peculiarities that cannot always be covered by rules. Therefore with your experience and common

sense, you are in a position to ensure your safety. Lack of attention to safety can result in:

accidents, personal injury, reduction of efficiency and worst of all - Loss of Life. Watch for safety

hazards. Correct them promptly. Use the following safety precautions as a general guide to safe

operation:

Do not attempt to remove any compressor parts without first relieving the entire system of

pressure.

Do not attempt to service any part while machine is operating.

DANGER

Do not operate the compressor at pressure(s) or speed in excess of its rating as indicated in

“Compressor Specifications”.

Periodically check all safety devices for proper operation.

Do not play with compressed air. Pressurized air can cause serious injury to personnel.

Exercise cleanliness during maintenance and when making repairs by covering parts and exposed

openings.

SAFETY

ALLUNITSARE SHIPPEDWITHADETAILEDOPERATORSAND PARTS

MANUAL. THISMANUALCONTAINSVITALINFORMATION FORTHE SAFE

USEANDEFFICIENTOPERATIONOFTHISUNIT. CAREFULLYREAD

THEOPERATORSMANUALBEFORESTARTINGTHEUNIT. FAILURETO

ADHERE TO THE INSTRUCTIONS COULD RESULT IN SERIOUS BODILY

INJURYORPROPERTYDAMAGE.

CHECKTHECOMPRESSORSUMPOILLEVELONLYWHENTHECOMPRESSOR

ISNOTOPERATINGAND SYSTEMISCOMPLETELYRELIEVEDOFPRESSURE.

OPENSERVICEVALVETOENSURERELIEFOFSYSTEMAIRPRESSUREWHEN

PERFORMINGMAINTENANCEONCOMPRESSORAIR/OILSYSTEM. FAILURE

TOCOMPLYWITHTHISWARNINGMAYCAUSEDAMAGETOPROPERTY

AND SERIOUS BODILYHARM.

8

SAFETY

Do not install a shut-off valve between the compressor and compressor oil sump.

DANGER

Do not disconnect or bypass safety circuit system.

Do not install safety devices other than authorized BOSS INDUSTRIES, INC. replacement

devices.

Close all openings and replace all covers and guards before operating compressor unit.

Tools, rags, or loose parts must not be left on the compressor or drive parts.

Do not use flammable solvents for cleaning parts. This can cause the unit to ignite during operation.

Keep combustibles out of and away from the Compressor/Inlet and any associated enclosures.

The owner, lessor, or operator of the Compressor are hereby notified and forewarned that any

failure to observe these safety precautions may result in damage or injury.

BOSS INDUSTRIES, INC. expressly disclaims responsibility or liability for any injury or damage

caused by failure to observe these specified precautions or by failure to exercise that ordinary

caution and due care required when operating or handling the Compressor, even though not

expressly specified above.

DO NOT USE BOSS INDUSTRIES COMPRESSOR SYSTEMS TO PROVIDE

BREATHINGAIR. SUCHUSAGE,WHETHERSUPPLIEDIMMEDIATELYFROM

THE COMPRESSOR SOURCE, OR SUPPLIED TO BREATHING TANKS FOR

SUBSEQUENTUSE,CANCAUSE SERIOUSBODILYINJURY.

BOSSINDUSTRIES,INC.DISCLAIMSANYANDALLLIABILITIESFORDAMAGE

FOR LOSS DUE TO PERSONAL INJURIES, INCLUDING DEATH, AND/OR

PROPERTYDAMAGEINCLUDINGCONSEQUENTIALDAMAGESARISINGOUT

OFANYBOSSINDUSTRIES,INC.COMPRESSORSUSEDTOSUPPLYBREATHING

AIR.

9

SAFETY

A compliment of warning decals is supplied with each unit. These decals must be affixed to the

comressor package in the locations noted in this manual. If for any reason a safety decal is

removed it is the owners responsibility to make sure it is replaced.

10

SAFETY

11

COMPRESSOR TERMINOLOGY

AIR/OILCOALESCER- Performs second stage separation of oil from compressed air feeding

air tools. Sometimes referred to as the separator element.

CFM - Refers to the volume of compressed air being produced, expressed as cubic feet of air per

minute.

COMPRESSOR LUBRICANT - DEXTRON IIIATF.

GPM- Refers to the amount of gallons per minute of hydraulic fluid flowing through the pump.

OILSUMP - The first stage of oil separation from compressed air. Also serves as reservoir area

for compressor lubricant and sometimes referred to as the receiver tank.

PSI - Refers to the operating pressure the system is set up at, expressed as pounds per square

inch.

SAFETYVALVE-Avalve located on the oil sump which opens in case of excessive pressure.

Sometimes referred to as the pop-off or pressure relief valve.

12

DESCRIPTION OF COMPONENTS

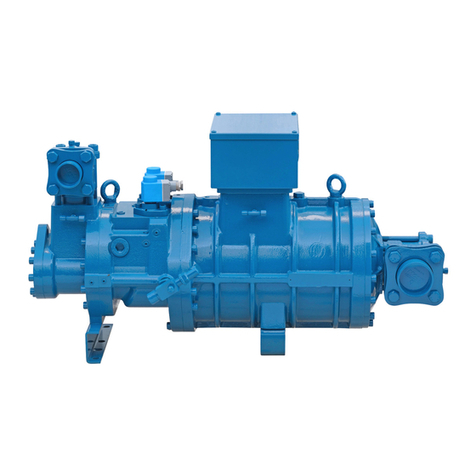

COMPRESSORASSEMBLY

The BOSS INDUSTRIES hydraulic drive compressor assembly is a positive displacement, oil

flooded, rotary screw type unit employing one stage of compression to achieve the desired

pressure. Components include a housing (stator), two screws (rotors), bearings, and bearing

supports. Power from the hydraulic motor shaft is transferred to the male rotor through a drive

coupling. The female rotor is driven by the male rotor. There are five lobes on the male rotor

while the female rotor has six roots.

PRINCIPLES OF OPERATION

In operation, two helical grooved rotors mesh to compress air. Inlet air is trapped as the male

lobes roll down the female grooves, pushing trapped air along, compressing it until it reaches the

discharge port in the end of the stator and delivers smooth-flowing, pulse-free air to the receiver.

During the compression cycle, oil is injected into the compressor and serves these purposes:

1. Lubricates the rotating parts and bearings.

2. Serves as a cooling agent for the compressed air.

3. Seals the running clearances.

LUBRICATION SYSTEM

Oil from the compressor at discharge pressure, is directed into its integral housing, through the

thermal valve and filter, and then out of the integral housing to the oil cooling system, and then back

to the side of the compressor stator, where it is injected into the compressor. At the same time oil

is directed internally to the bearings and shaft seal of the compressor.

OIL SUMP

Compressed, oil-laden air enters the sump from the compressor. As the oil-laden air enters the

sump, most of the oil is separated from the air as it passes through a series of baffles and diffusion

plates. The oil accumulates at the bottom of the sump for recirculation. However, some small

droplets of oil remain suspended in the air and are passed on to the Coalescer.

13

DESCRIPTION OF COMPONENTS

SAFETYVALVE

The pop safety valve is set at 200 PSI and is located at the top of the air/oil sump. This valve acts

as a backup to protect the system from excessive pressure that might result from a malfunction.

AIR/OIL COALESCER

The coalescer is self-contained within a spin-on housing. When air is demanded at the service line,

it passes through the coalescer which efficiently provides the final stage of oil separation.

OIL RETURN LINE

The oil that is removed by the coalescer accumulates and is returned through an internal oil return

line leading to the compressor.

MINIMUM PRESSUREVALVE

The minimum pressure valve is located at the outlet of the coalescer head and serves to maintain a

minimum discharge pressure of 75 PSIG in operation, which is required to assure adequate

compressor lubrication pressure.

OILFILTER

The compressor oil filter is a removable and cleanable screen built into the side of the compressor

housing. Screen replacement may be necessary after several cleanings.

COMPRESSOR OILAND HYDRAULIC OIL COOLING SYSTEMS

The compressor cooling system consists of a combination hydraulic cooler and compressor cooler

mounted on the common frame. Compressor oil temperature is controlled by a thermal valve

located down stream of the oil filter. The thermal valve maintains the compressor oil temperature

at 185ºF. Cool air is drawn through the vented end panel and across the combo cooler. The air is

heated by the coolers and the hot air exits out the back vented panel . Allow for adequate

clearance (12”) for the air to exit. Also, the package location should not be subjected to above

ambient air temperatures.

14

DESCRIPTION OF COMPONENTS

INSTRUMENTATION

TheBOSSINDUSTRIEShydraulic drivecompressorunitincorporates agaugepanelthat monitors

temperature,pressure and hoursof operation.

HOURMETER

Thehourmeterrecords thetotalnumberof operatinghours. Itserves as aguidein following the

recommendedinspectionandmaintenanceschedule. Thehourmeterwillonly run when thereis pressure

inthesystem.

COMPRESSORDISCHARGEAIR/OILTEMPERATURESWITCHGAUGE

Thisswitchgaugeindicatescompressorairdischargetemperature. Theswitchgauge ensures safety

shutdownincaseof excessive operatingtemperatures,preventingcompressor damage, bystopping

hydraulicflowtothecompressor motor.

ELECTRICALANDSAFETYSYSTEM

TheBOSSINDUSTRIES compressor’s standardelectricalsystem consistsof:

-Gaugepanelwithatemperatureswitchgauge, hourmeterand dischargepressure switchgauge.

-Compressorandhydraulicoil coolerfanassemblyand relay.

-Compressoraftercooler/oil coolerfanassemblyand relay.

-3-waypressure switch andrelay tocontrolhourmeter andblowdown.

-12VDCN.O. hydraulic solenoidand relay.

-Switchrelayforcustomerequipmentinterface during compressoroperation.

-Differentialpressureswitchforairfiltermaintenance.

-Opticaloillevelswitchandrelay.

15

DESCRIPTION OF COMPONENTS

CONTROL SYSTEM

The prime component of the compressor control system is the compressor inlet valve. The control

system is designed to match air supply to air demand and to prevent excessive discharge pressure

when compressor is at idle. Control of air delivery is accomplished by the inlet valve regulation

and modulation as directed by the discharge pressure regulator.

NORMALLYOPEN REGULATOR SOLENOID

A closed Furnas air pressure switch will energize the normally open regulator solenoid, thus closing

it. When the normally open regulator solenoid is closed, air pressure will rise. When it is open air

pressure falls only in the compressor sump.

NOTE: Most air tools operating pressure range is between 90 and 125 psi. Operating

above the tools recommended pressures will decrease the life of the tool. Higher

operating pressure can also over torque nuts and bolts fatiguing the fastener and mating

parts. Strictly adhere to tool operating pressures and torque standards set forth by the

tool manufacturer and the specifications of the equipment that work is being performed

on.

FURNAS SWITCH DESCRIPTION

The Furnas switch is a N.C. electrical switch set to open at 150 PSI and set to close at 115 PSI.

The Furnas switch controls the N.O. regulator solenoid. If service air pressure is under 150 PSI,

the Furnas switch will not trip keeping the N.O. inlet valve open and the compressor making air. If

the service valve is closed or the tool using the air is off, service line pressure will rise over 150

PSI. This will trip the Furnas switch to open. The regulator solenoid will open and send air

pressure to the inlet valve to close. With the inlet valve closed, the compressor will stop making

air. If the tool is turned on or the service valve is opened, the service line pressure will drop.

When the pressure falls to 115 PSI the Furnas switch will close energizing the N.O. regulator

solenoid closing off the air supply to the inlet valve. This will allow the inlet valve to open, and the

compressor will start making air to meet the demand.

INLETVALVE

The compressor inlet valve is a piston operated disc valve that regulates the inlet opening to control

capacity and serves as a check valve at shutdown.

16

INSPECTION, LUBRICATION, AND MAINTENANCE

Thissection contains instructionsfor performing theinspection, lubrication, and maintenance

procedures required to maintain the compressor in proper operating condition. The importance of

performing the maintenance described herein cannot be over emphasized.

The periodic maintenance procedures to be performed on the equipment covered by this manual

are listed below. It should be understood that the intervals between inspections specified are

maximum interval. More frequent inspections should be made if the unit is operating in a dusty

environment, in high ambient temperature, or in other unusual conditions. Aplanned program of

periodic inspection and maintenance will help avoid premature failure and costly repairs. Daily

visual inspections should become a routine.

The LUBRICATIONAND MAINTENANCE CHART lists serviceable items on this compressor

package. The items are listed according to their frequency of maintenance, followed by those

items which need only “As Required” maintenance.

The maintenance time intervals are expressed in hours. The hourmeter shows the

total number of hours your compressor has run. Use the hourmeter readings for determining your

maintenance schedules. Perform the maintenance at multiple intervals of the hours shown. For

example, when the hourmeter shows “100” on the dial, all items listed under “EVERY10 HOURS”

should be serviced for the tenth time, and all items under “EVERY50 HOURS” should be

serviced for the second time, and so on.

DANGER

COMPRESSOR MUST BE SHUT DOWN AND COMPLETELY RELIEVED OF

PRESSUREPRIOR TOCHECKINGFLUID LEVELS. OPEN SERVICEVALVETO

ENSURERELIEFOFSYSTEMAIRPRESSURE. FAILURETOCOMPLYWITHTHIS

WARNINGMAYCAUSEDAMAGETOPROPERTYANDSERIOUSBODILYHARM.

17

LUBRICATION AND MAINTENANCE CHART

NOTE: Compressor oil and filter is to be changed after the first 50 hours of operation. After this,

normal intervals are to be followed.

LAVRETNINOITCA

YLLACIDOIREP GNIRUD NOITAREPO

egnahcynaetoN.sgnidaereguagllaevresbO.1 ehtenimreteddnasgnidae

rlamronehtmorf :ETON(.edamsriaperyrassecenevaH.esuac nehwgnidaereguaglausuehtsi"LAMRON" yadotyadanosnoit

idnocralimistagnitarepo ).sisab

YLIAD

.levelliorosserpmocehtkcehC.1 rotacidniporderusserP.retlifriakcehC.

2.gnitareposirosserpmocelihw .skaelriadnaliorofkcehC.3 .sehctiwstiucricytefaskcehC.4

SRUOH52YREVE YLHTNOM

RO .liorosserpmocmorfretawniarD.1

005YREVE 6ROSRUOH SHTNOM

neercsecalperdnaliorosserpmocegnahC.1 .egakaelro

flaestfahsrosserpmockcehC.2 .spmalcdnasgnittif,gnipipretlifriakcehC.3 .stroppusrosserpmockcehC.4 retrohS

(.tnemeleretlifriawenllatsnI.5 ytsudrednuyrassecenebyamlavretni ).snoitidnoc .evlavytefaspmuskcehC.6

0001

YREVE 1ROSRUOH RAEY .tnemelegnicselaocegnahC.1

ROYLLACIDOIREP DERIUQERSA

.tnemeleretlifrianaelcdnatcepsnI.1 recselaocno-nipsecalperdnatcepsnI.2 .yrassecenfitnemele .snifrelooclionaelcdnatcepsnI.3

18

LUBRICANT RECOMMENDATIONS

WARNING

The following are general characteristics for a rotary screw lubricant. Due to the impossibility of

establishinglimits on allphysical and chemicalproperties of lubricants which canaffect their

performance in the compressor over a broad range of environmental influences, the responsibility

forrecommending and consistentlyfurnishing a suitableheavy dutylubricant must restwith the

individual supplier if they choose not to use the recommended BOSS INDUSTRIES rotary screw

lubricant. The lubricant supplier’s recommendation must, therefore, be based upon not only the

following general characteristics, but also upon his own knowledge of the suitability of the

recommended lubricant in helical screw type air compressors operating in the particular

environmentinvolved.

CAUTION

IT IS IMPORTANT THAT THE COMPRESSOR OIL BE OF A RECOMMENDED

TYPE AND THAT THIS OILAS WELLAS THE AIR FILTER, OIL FILTER, AND

COALESCERELEMENTS BEINSPECTEDANDREPLACEDASSTATED INTHIS

MANUAL.

THE COMBINATION OFACOALESCER ELEMENT LOADED WITH DIRTAND

OXIDIZEDOILPRODUCTSTOGETHERWITHINCREASEDAIRVELOCITYASA

RESULTOFTHISCLOGGEDCONDITIONMAYPRODUCEACRITICALPOINT

WHILETHEMACHINEISINOPERATIONWHEREIGNITIONCANTAKEPLACE

ANDCOULDCAUSEAFIRE INTHE OILSUMP.

FAILURE TO COMPLY WITH THIS WARNING MAY CAUSE DAMAGE TO

PROPERTYAND SERIOUS BODILYHARM.

MIXING DIFFERENT TYPES OR BRANDS OF LUBRICANTS IS NOT

RECOMMENDED DUE TO THE POSSIBILITY OF A DILUTION OF THE

ADDITIVESORAREACTIONBETWEENADDITIVESOFDIFFERENTTYPES.

19

LUBRICANT RECOMMENDATIONS

LUBRICANT CHARACTERISTICS

1. Flashpoint 400°Fminimum.

2. Pour point -40°F.

3. Contains rust and corrosion inhibitors.

4. Contains foam suppressors.

5. Containsoxidation stabilizer.

NOTE

NOTE

DUETOENVIRONMENTALFACTORSTHE USEFULLIFEOFALL“EXTENDED

LIFE”LUBRICANTSMAYBE SHORTERTHAN QUOTEDBYTHELUBRICANT

SUPPLIER. BOSS INDUSTRIES, INC. ENCOURAGES THE USER TO CLOSELY

MONITOR THE LUBRICANT CONDITION AND TO PARTICIPATE IN AN OIL

ANALYSISPROGRAM WITHTHE SUPPLIER.

NO LUBRICANT, HOWEVER GOOD AND/OR EXPENSIVE, CAN REPLACE

PROPERMAINTENANCEANDATTENTION. SELECTANDUSE ITWISELY.

20

MAINTENANCE

If some of the maintenance intervals in the schedule outlined in this manual seem to be rather short,

it should be considered that one hour’s operation of a compressor is equal to about 40 road miles

on an engine. Thus, eight hours operation is equal to 320 road miles, 250 hours is equal to 10,000

road miles, etc.

COMPRESSOR OILSUMPFILL, LEVEL,AND DRAIN

Before adding or changing compressor oil make sure that the compressor is completely relieved of

pressure. Oil is added at the fill cap on the side of the compressor body. Adrain valve/hose

assembly is provided at the bottom of the compressor body. The proper oil level is between the

top and the midpoint of the oil sightglass, when the unit is shut down and has had time to settle.

The truck must be level when checking the oil. DO NOT OVERFILL. The oil sump capacity is

givenin “Compressor Specifications”. DANGER

AIR INTAKE FILTER

The air intake filter is a heavy-duty dry type high efficiency filter designed to protect the

compressor from dust and foreign objects. Optional two-stage available.

Optional filter is equipped with an evacuator cup for continuous dust ejection while operating and

when stopped.

Frequency of maintenance of the filter depends on dust conditions at the operating site. The filter

element must be serviced when clogged (maximum pressure drop for proper operation is 15” of

water). The filter is equipped with a pressure drop indicator, and the element should be changed

based on its reading first and then by the maintenance intervals outlined.

DO NOTATTEMPT TO DRAIN CONDENSATE, REMOVE THE OILLEVELFILL

PLUG,OR BREAKANYCONNECTIONINTHEAIR OROILSYSTEMWITHOUT

SHUTTINGOFFCOMPRESSORANDMANUALLYRELIEVINGPRESSUREFROM

THESUMP. FAILURETOCOMPLYWITHTHISWARNINGMAYCAUSEDAMAGE

TOPROPERTYAND SERIOUSBODILYHARM.

21

MAINTENANCE

AIR/OIL COALESCER

The air/oil coalescer employs an element permanently housed within a spin-on canister. This is a

single piece unit that requires replacement when it fails to remove the oil from the discharge air, or

pressure drop across it exceeds 15 PSI. Dirty oil clogs the element and increases the pressure

drop across it.

To replace element proceed as follows:

1. Shutdown compressor and wait for complete blow down (zero pressure).

2. Turn element counterclockwisefor removal (viewingelement from bottom).

3. Apply a film of fluid directly to seal on the new element.

4. Rotate element clockwise by hand until element contacts seal (viewing element from

bottom).

5. Rotate element approximately one more turn clockwise with band wrench near the top

ofelement.

6. Run system and check for leaks.

WARNING

COALESCER OIL RETURN

This originates at the bottom of the air/oil coalescer and flows through a special recovery pipe and

venturi nozzle. If the coalescer starts to fill with oil there is a good chance the venturi or pipe has

been plugged. Consult factory for cleaning instructions.

DO NOT SUBSTITUTE ELEMENT. USE ONLYA GENUINE BOSS INDUSTRIES

REPLACEMENT ELEMENT. THIS ELEMENT IS RATEDAT 200 PSI WORKING

PRESSURE. USEOFANYOTHERELEMENTMAYBEHAZARDOUSANDCOULD

IMPAIR THE PERFORMANCE AND RELIABILITY OF THE COMPRESSOR,

POSSIBLY VOIDING THE WARRANTYAND/OR RESULTING IN DAMAGE TO

PROPERTYAND SERIOUS BODILYHARM.

Table of contents

Other BOSSCO Air Compressor manuals

BOSSCO

BOSSCO 210 DUS JD4045 Installation and user guide

BOSSCO

BOSSCO 8060 UBI User manual

BOSSCO

BOSSCO RCL-10 User manual

BOSSCO

BOSSCO 36 BHP PISTON Installation and user guide

BOSSCO

BOSSCO BA440 PISTON User manual

BOSSCO

BOSSCO K36BP PISTON Installation and user guide

BOSSCO

BOSSCO BA435 PISTON Installation and user guide

Popular Air Compressor manuals by other brands

Frascold

Frascold R-TSH8 40 120 Y Installation and start-up instruction

Atlas Copco

Atlas Copco XAHS365 Md instruction manual

Turanair

Turanair K-150 user manual

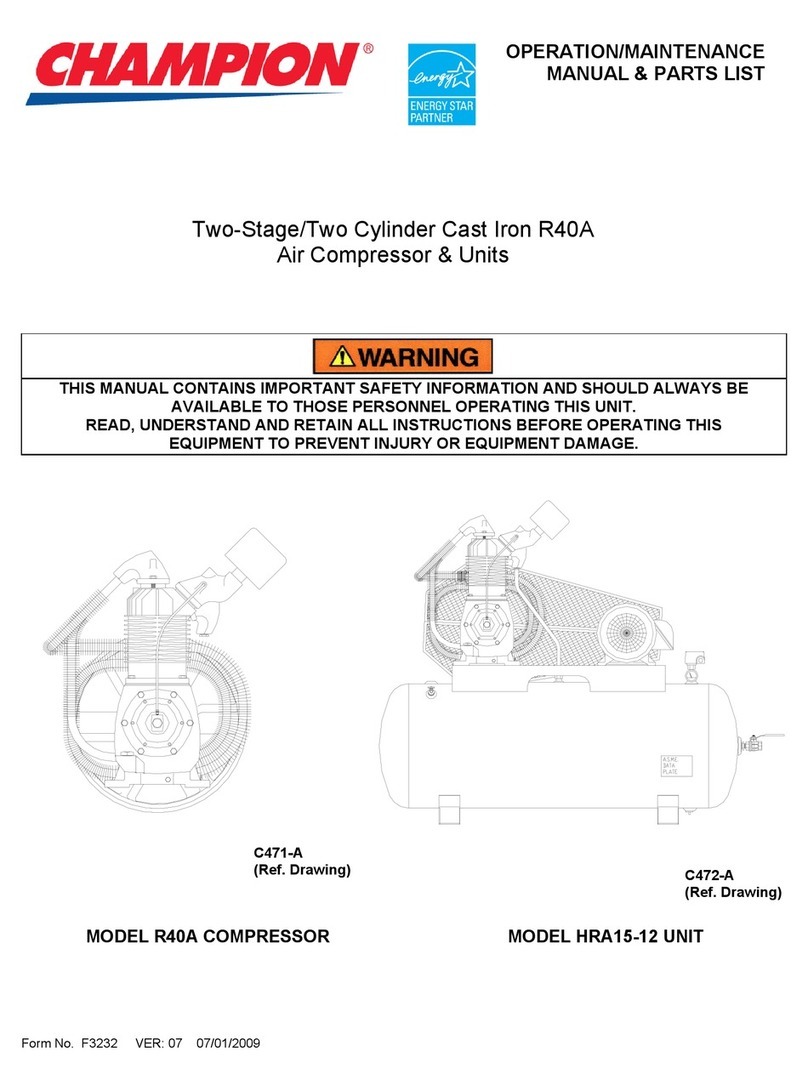

Champion

Champion R40A Operation maintenance manual & parts list

Neilsen

Neilsen CT3745 Original instructions

Industrial Air Contractor

Industrial Air Contractor C032I manual