BOSSCO 210 DUS JD4045 Installation and user guide

This manual must be read carefully before using your Boss Industries, Inc. Air Com-

pressor. Store in a safe and convenient location for future reference.

For technical support:

Phone: (800) 635-6587 (USA)

Phone: (219) 324-7776 (Outside USA)

Fax: (877) 254-4249 (USA)

Email: service@bossair.com

Website: http://www.bossair.com

Service and

Maintenance

Manual

210 DUS JD4045

IT4 74HP

Air Compressor

309416

05-03-2013 ARB

2309416

01/31/2012

3309416

01/31/2012

Manual Change History................................................................................................7

1.1 Revision List....................................................................................................7

Welcome........................................................................................................................8

2.1 General Information..........................................................................................8

2.2 Overview .........................................................................................................8

Safety...................................................................................................................9-13

3.1 General Safety Overview...................................................................................9

3.2 Safety Precautions..........................................................................................10

3.3 Safety and Information Decals..........................................................................12

Specifications..............................................................................................................14

4.1 Specification Sheet........................................................................................14

Description of Components..............................................................................15-18

5.1 Engine............................................................................................................15

5.2 Drive Coupling...............................................................................................15

5.3 Compressor Airend.......................................................................................15

5.4 Separator System..........................................................................................15

Separator Tank.........................................................................................15

Separator Element......................................................................................15

5.5 Pressure Relief Valve.....................................................................................16

5.6 Engine Air Filter..........................................................................................16

5.7 Compressor Air Filter.................................................................................16

5.8 Cooling Systems...........................................................................................16

Engine Radiator..........................................................................................16

Compressor Oil Cooler...............................................................................16

5.9 Compressor Oil Filter..................................................................................16

5.10 Compressor Oil Thermal Valve......................................................................16

5.11 Compressor Inlet Valve.................................................................................17

5.12 Minimum Pressure Valve...............................................................................17

5.13 Blowdown Valve..........................................................................................17

5.14 Blowdown Switch........................................................................................17

5.15 Discharge Pressure Regulator Valve...............................................................17

5.16 Instrument Panel...........................................................................................18

Engine Oil Pressure Gauge..........................................................................18

Engine Coolant Temperature Gauge............................................................18

Compressor Discharge Pressure Gauge......................................................18

Compressor Discharge Temperature Gauge................................................18

Contents

4309416

01/31/2012

Contents

Description of Components (continued)............................................................15-18

5.15 Instrument Panel (continued).....................................................................18

Hourmeter.......................................................................................18

Tachometer.........................................................................................18

Voltmeter.................................................................................18

Unloader Valve...........................................................................................18

Emergency Stop Switch.............................................................................18

Bypass Switch...........................................................................................18

Ignition Switch...........................................................................................18

Installation.............................................................................................19-23

6.1 System Installation Overview...........................................................................19

6.2 Placing the Machine........................................................................................19

6.3 Connecting the System Fuel Supply.................................................................19

6.4 Fuel Specifications..........................................................................................20

High Altitude and Low Temperature Fuel....................................................20

Cold Weather Fuel.....................................................................................20

6.5 Connecting the Air Discharge Lines...............................................................20

6.6 Pre-Startup Inspection .................................................................................20

6.7 Machine Documentation...............................................................................21

6.8 Check Fluid Levels.......................................................................................21

6.9 Initial Startup Preparation..............................................................................21

6.10 Initial Startup.................................................................................................22

Operation.............................................................................................................23-24

7.1 Routine Operating Procedures........................................................................23

Routine Startup Preparation........................................................................23

Routine Startup Procedure.........................................................................23

Routine Shutdown Procedure.....................................................................23

7.2 Emergency Shutdown Procedure..........................................................24

Maintenance........................................................................................................25-36

8.1 Maintenance Overview....................................................................................25

8.2 Maintenance Schedule....................................................................................25

8.3 Recommended Spare Parts List......................................................................26

8.4 Parts and Service Contact Information............................................................26

8.5 Maintenance Log............................................................................................27

5309416

01/31/2012

Maintenance (continued)....................................................................................25-36

8.6 Separator Element Replacement......................................................................28

8.7 Engine Air Filter Replacement..........................................................................29

8.8 Compressor Air Filter Replacement.................................................................30

8.9 Compressor Oil..............................................................................................31

Specifications.......................................................................................31

Adding Compressor Oil.............................................................................32

Changing Compressor Oil..........................................................................32

8.10 Compressor Oil Cooler.................................................................................33

8.11 Compressor Oil Filter....................................................................................33

8.12 Engine Cooling System Maintenance..............................................................34

Engine Coolant...........................................................................................34

Engine Radiator..........................................................................................34

Engine Fan.................................................................................................35

Engine Serpentine Belt...............................................................................35

8.13 Battery..........................................................................................................35

8.14 Standby Pressure Adjustment (For 100 PSI System).....................................35

8.15 Idle Speed Adjustment..................................................................................36

8.16 Rated Speed Adjustment...............................................................................36

Troubleshooting...................................................................................................37-40

9.1 Troubleshooting Chart....................................................................................37

9.2 Parts and Service Contact Information............................................................40

Warranty..............................................................................................................41-45

10.1 Warranty Policy............................................................................................41

10.2 Summary of Main Warranty Provisions..........................................................42

10.3 Warranty/Return Goods Instructions.............................................................43

10.4 Warranty Claims - Preparation of Part Return.................................................43

10.5 Return or Warranty Claims - Filing Procedures...............................................43

10.6 Warranty Claims Provisions..........................................................................44

10.7 Damage in Transit..........................................................................................44

10.8 Screw Compressor Airend Exchange Program..............................................45

Parts and Illustration Section...........................................................................46-63

11.1 Frame System...............................................................................................46

11.2 Engine System..............................................................................................48

11.3 Compressor System.....................................................................................50

11.4 Discharge System..........................................................................................52

Contents

6309416

01/31/2012

Parts and Illustration Section (continued)........................................................46-63

11.5 Cooling System..........................................................................................54

11.6 Electrical System.......................................................................................56

11.7 Canopy System.......................................................................................58

11.8 Decal System..............................................................................................60

11.9 Hose System......................................................................................62

11.10 System Wiring Diagram..............................................................................63

Contents

7309416

01/31/2012

Manual Change History

ETAD NOITACOL EGNAHCFONOITPIRCSED SLAITINI

1.1 Revision List

8309416

01/31/2012

Welcome

2.2 Overview

The 210 DUS Air Compressor is a compact, strategically designed system. It integrates all major

components on a single frame, which is enclosed in a tough, weather-resistant canopy.

The 210 DUS Air Compressor’s rotary screw

design guarantees continuous air output of up to

210 CFM (cubic feet per minute) at 100 PSI

(pounds per square inch). With remote fluid

drains and removable doors, virtually all

components are accessible for maintenance and

service. The instrument panel clearly displays

pressures, temperatures, and hours of operation.

Other features, including a spin-on compressor oil

filter and a drop-in separator element, reduce the

time and costs associated with routine

maintenance.

The 210 DUS Air Compressor also has enhanced

safety features to protect your valuable resources:

minimum pressure valve, high compressor oil

temperature shutdown, high discharge pressure

shutdown, automatic blowdown device, pressure

relief valve, high engine coolant temperature, low

engine oil pressure, and clearly displayed warning/

information decals.

2.1 General Information

Thank you for choosing the 210 DUS Air Compressor. Before operating

this system, read over this manual and become well acquainted with your

new machine. Doing this will increase your safety and maximize the life

of the machine.

While this manual is written to be as accurate as possible, Boss Indus-

tries, Inc. strives to continually improve the efficiency and performance of

its machines. As a result, sometimes there may be slight differences

between a given version of the manual and the machine.

This manual must be read carefully before using your Boss Industries, Inc. Air Com-

pressor. Store in a safe and convenient location for future reference.

For technical support:

Phone: (800) 635-6587 (USA)

Phone: (219) 324-7776 (Outside USA)

Fax: (877) 254-4249 (USA)

Email: service@bossair.com

Website:http://www.bossair.com

Service and

Maintenance

Manual

210 DUS JD4045

IT4 74HP

Air Compressor

309416

01/31/2012

9309416

01/31/2012

Safety

3.1 General Safety Overview

Indicate[s] an imminently hazardous situation, which, if

not avoided, will result in death or serious injury.

Indicate[s] a potentially hazardous situation, which, if not

avoided, could result in death or serious injury.

Indicate[s] a potentially hazardous situation, which, if not

avoided, could result in minor or moderate injury.

Indicate[s] a potentially unsafe situation or practice,

which, if not avoided, can result in property and/or

equipment damage only.

Remember, safety is basically common sense. While there are standard safety rules, each situation has

its own peculiarities that cannot always be covered by rules. Therefore with your experience and

common sense, you are in a position to ensure the safety of yourself and others. Lack of attention to

safety can result in: accidents, personal injury, reduction in efficiency, and worst of all – Loss of Life.

Watch for safety hazards and correct them promptly.

Understanding the proper operation of this equipment is critical to its safe operation. The owner, lessor,

and/or operator of this equipment is hereby notified and forewarned that any failure to observe the

safety and operating guidelines may result in injury and/or damage. Boss Industries, Inc. expressly

disclaims responsibility or liability for any injury or damage caused by failure to observe these specified

precautions or by failure to exercise the ordinary caution and due care required while operating or

handling this equipment, even though not expressly specified.

In addition to following these safety guidelines, the operator should follow any company specific guide-

lines and procedures. Consult your immediate supervisor for specific company safety guidelines and/or

procedures.

The following safety symbols are used throughout this manual to draw attention to important information.

If the information is not carefully read and the instructions are not followed, severe injury, death, and/or

damage to property and equipment may occur.

10 309416

01/31/2012

Safety

3.2 Safety Precautions

This is a pressurized system. Do not attempt to remove

any part of this machine without first completely relieving

entire system of pressure. Do not attempt to service any

part of the equipment while in operation. Never attempt

to repair or modify any pressure vessel or device.

The system is designed to compress air. Do not attempt

to compress other gases. Compression of other gases

may create a situation where an explosion or fire may

occur.

Do not use flammable solvents for cleaning system com-

ponents as this can cause the unit to ignite or explode

during operation. Keep combustibles out of and away

from system inlets and any associated enclosures.

Never disable, override, or remove safeties, either tempo-

rarily or permanently.

The following safety precautions are a general guide to safe operation of the equipment.

System contains hot oil. The system must be shut off prior

to servicing. Then permit system to cool down prior to

adding compressor oil or servicing the unit.

Do not use air from this system for breathing or food

processing. Air from this system will cause severe injury

or death if used for breathing or food processing.

Do not modify systems to operate equipment at a higher

pressure than specified.

Never operate the machine in an enclosed area.

11 309416

01/31/2012

Safety

3.2 Safety Precautions (continued)

Read and understand this manual and all other safety

instructions before using this equipment. Failure to follow

operating instructions and/or failure to follow maintenance

procedures and intervals could result in personal injury,

death, and/or damage to equipment and property.

Use only Boss Industries, Inc. approved replacement

parts.

Check engine’s operator manual for required service

and maintenance intervals.

Never place machine on a grade more than 15 degrees.

Keep doors closed on the machine during operation.

This machine is equipped with safety unloading

system to prevent damage to the compressor drive

coupling. Should an attempt be made to start this

system improperly, the machine will run unloaded for

60 seconds. Likewise, if an attempt is made to

shutdown the system improperly, the unit will con-

tinue to run until the compressor system pressure

unloads below 50 PSI.

12 309416

01/31/2012

Safety

3.3 Safety and Information Decals

Hot Exhaust Pressurized System

Electrical ShockHot Pressurized Oil

Close Doors Oil Level

This machine is supplied with a full complement of safety and identification decals. These decals are

affixed to the unit during final assembly. These decals must be clearly visible and undamaged. Should

any of these decals become illegible or damaged, immediately replace the decal.

13 309416

01/31/2012

Safety

3.3 Safety and Information Decals (continued)

Overfill Negative Ground System

Serial Tag

Compressor Oil

Hot Coolant

Breathing Air

14 309416

01/31/2012

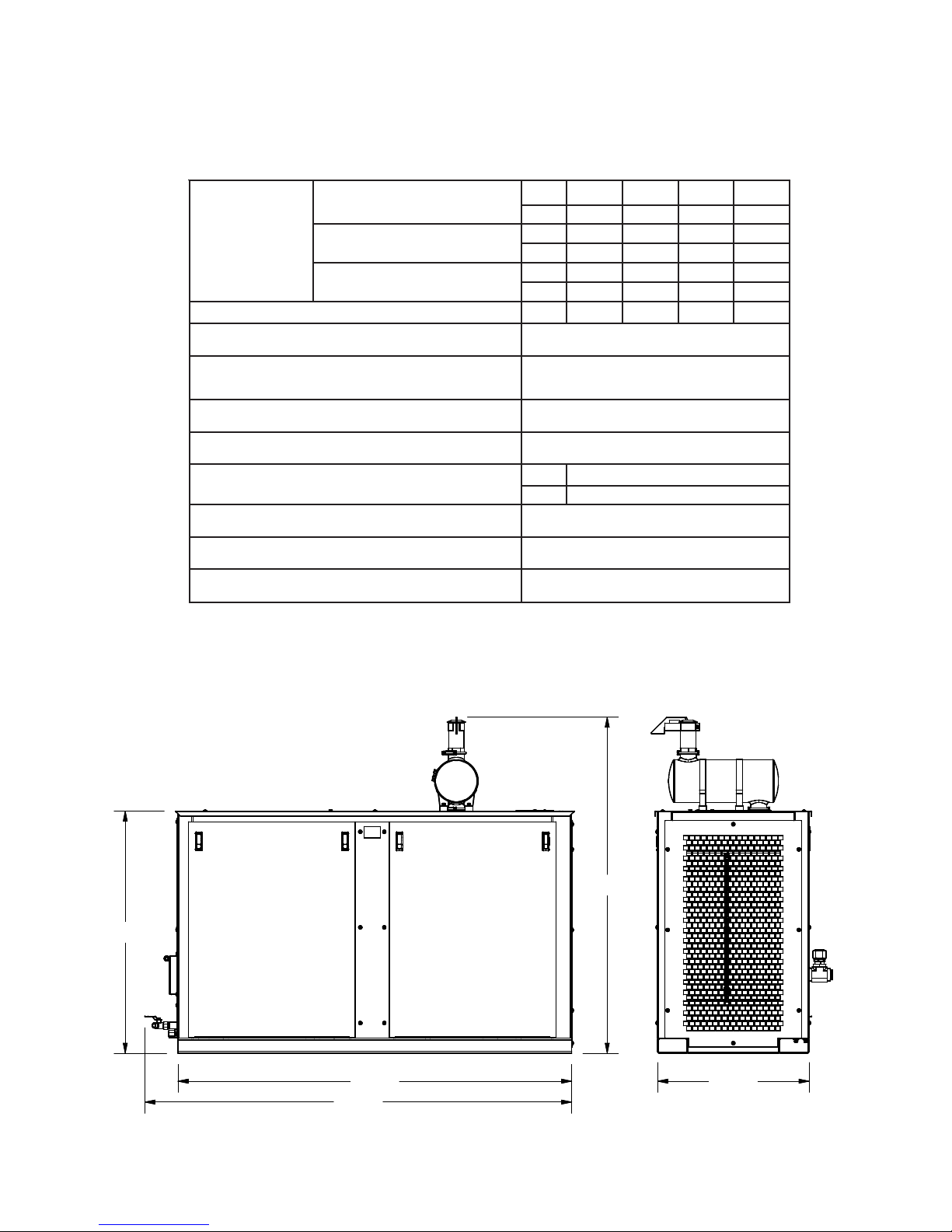

Specifications

*SPECIFICATIONS SUBJECT TO CHANGE WITHOUT PRIOR NOTICE*

4.1 Specification Sheet

yticapaC

ISP001@ MFC 571 581 002 012

PH 83 14 54 74

ISP521@ MFC 471 481 991 902

PH 44 74 25 55

ISP061@ MFC 071 181 891 402

PH 84 15 65 75

deepStupnIrosserpmoC MPR 0002 5212 5232 0042

dneriArosserpmoC oitaRraeG50.3htiwG01ACS

enignE 47

PH

DJ

5404

MIRTNI

REIT

4

EAS/W

B

EVIRDXUA

metsySlacirtcelEenignE CDV21

snoisnemiDesaB "2/107X"03X"8/548

knaTleuFleseiDlanoitpO PAC L041,.LAG73

MID "5.6X"03X"87

elgnAgnitarepOenihcaM mumixam°51

elcyCytuD suounitnoC

snoitidnoCtneibmA F°521otF°04-

66.77

48.07

78.00

84.55

30.00

15 309416

01/31/2012

Description of Components

The 210 DUSAir Compressor contains a John Deere, 4 cylinder diesel engine. This engine has been

selected to handle the rugged duty required for its operation. The engine speed is regulated by a

pneumatic throttle control.

5.1Engine

5.2Drive Coupling

Power from the engine is transmitted to the compressor input shaft through a specially designed drive

coupling. The drive coupling consists of a highly torsionally flexible rubber disc that mates with an

engine flywheel flange. The coupling provides a torque limitation to protect from system overloads.

5.3 Compressor Airend

The Boss Industries, Inc. compressor airend is a positive displacement, oil flooded, rotary screw type

unit employing one stage of compression to achieve the desired pressure. Components include a

housing (stator), two screws (rotors), bearings, and bearing supports. Power from the engine flywheel

is transferred through a gear set to the male rotor. The female rotor is driven by the male rotor. There

are five lobes on the male rotor while the female rotor has six roots. In operation, two helical grooved

rotors mesh to compress air. Inlet air is trapped as the male lobes roll down the female grooves,

pushing trapped air along, compressing it until it reaches the discharge port at the end of the stator which

delivers smooth-flowing, pulse-free air. Being an oil flooded system, the oil serves three purposes:

lubricates the rotating parts and bearings, serves as a cooling agent for the compressed air, and seals the

running clearances.

5.4 Separator System

I. Separator Tank

From the compressor airend, the compressed air and hot oil flow into a steel, ASME coded,

pressure vessel, rated at 250 PSI, that acts as an oil reservoir. This tank is the first of two stages in

separating the oil and compressed air mixture. From the bottom of the separator tank, oil is forced

to the oil filter.

II. Separator Element

At the top of the separator tank is the separator element. The separator element removes the oil

mist from the air as it is passed on to the minimum pressure valve. As the air/oil mist passes through

the outside of the media, oil gathers on the interior walls and settles to the bottom of the element.

Collected oil is returned to the compressor airend through the oil return line. The separator will filter

the oil concentration in the air to less than 3 parts per million.

16 309416

01/31/2012

5.10 Compressor Oil Thermal Valve

The compressor oil thermal valve is a thermostatically controlled by-pass valve that allows varying

amounts of oil, depending upon the temperature, to by-pass the oil cooler. The oil thermal valve directs

oil flow back to the compressor airend until the system reaches 170°F. Once at system operating

temperature, the valve shifts, directing the flow through the oil cooler before returning to the compressor

airend.

Description of Components

5.5 Pressure Relief Valve

This valve vents separator tank pressure to atmosphere should the pressure inside the tank exceed 200

PSI.

5.6 Engine Air Filter

The engine air filter is a two stage, dry type intake filter with a gravity evacuator and replaceable internal

element. On the outlet of the engine air filter is an air filter restriction indicator. This indicator serves as

a maintenance tool.

5.7 Compressor Air Filter

The compressor air filter is a two stage, dry type intake filter with a gravity evacuator and replaceable

internal element. On the outlet of the compressor air filter is an air filter restriction indicator. This

indicator serves as a maintenance tool.

5.8 Cooling Systems

I. Engine Radiator

The radiator is designed to dissipate the heat load of the engine and is mounted in front of the

specially selected engine fan. Hot engine coolant is passed through the interior of the radiator and

heat is transferred to the air that passes across the cooling fins.

II. Compressor Oil Cooler

The compressor oil cooler is designed to dissipate the heat created during the compression of air.

The oil cooler is mounted beside the engine radiator. This works similar to the engine radiator but is

designed to withstand the full compressor system working pressure.

5.9 Compressor Oil Filter

The compressor oil filter is a full flow, spin-on canister. It has been specially designed to handle 200

PSI. The oil filter is mounted downstream of the separator tank to ensure all contaminants are pre-

vented from being passed on to the compressor oil cooler.

17 309416

01/31/2012

Description of Components

5.12 Minimum Pressure Valve

To ensure there is adequate pressure to produce proper oil flow throughout the system, a spring loaded,

normally closed minimum pressure valve is set to maintain at least 80 PSI in the separator tank.

5.11 Compressor Inlet Valve

The compressor inlet valve is a normally open air intake valve bolted to the compressor airend. When

the system is shut down, this valve also acts as a check valve that prevents the air/oil mixture within the

compressor airend from entering the inlet piping.

5.13 Blowdown Valve

The blowdown valve is a shuttle valve that vents system pressure to atmosphere when the system is shut

down. This is done to prevent the high torque load that would be required to overcome the static

pressure. The blowdown valve is stamped with an “I” and a “P”. The “I” side is connected to dry air

from the separator tank, and the “P” side is the pilot signal coming from the compressor inlet valve.

5.15 Discharge Pressure Regulator Valve

This valve, located downstream of the separator element, is used to set the desired discharge pressure.

This valve will send a pneumatic signal to the inlet valve to start closing when the pressure exceeds the

setpoint. This signal will also adjust the speed of the engine. This system has a maximum operating

pressure of 160 PSI.

Most air tools operating pressure range is between 90 and 125

PSI. Operating above the tools recommended pressures will

decrease the life of the tool. Strictly adhere to tool operating

pressures and torque standards set forth by the tool

manufacturer.

5.14 Blowdown Switch

The system is equipped with a blowdown switch. This switch will sense pressure in the pilot signal to

the blowdown valve. If the system contains pressure, the switch will prevent the machine from starting.

This will prevent premature damage to the drive coupling.

18 309416

01/31/2012

Description of Components

5.16 Instrument Panel

The 210 DUSAir Compressor incorporates an instrument panel that includes numerous gauges and

controls in a single, easy to access location.

I. Engine Oil Pressure Gauge

This feature displays the oil pressure inside the engine block. When the pressure drops below 20

PSI, the system will shut down. During operation, the engine oil pressure should be approximately

60 PSI to 80 PSI.

II. Engine Coolant Temperature Gauge

This feature displays the temperature of the engine coolant. When the temperature reaches 235°F,

the system will shut down. During operation, the temperature should be approximately 190°F to

210°F.

III. Compressor Discharge Pressure Gauge

This feature displays the pressure downstream of the airend.

IV.Compressor Discharge Temperature Gauge

This feature displays the compressor discharge temperature. When the temperature reaches 245°F,

the system will shut down. During operation, the discharge temperature should be approximately

170°F to 190°F.

V. Hourmeter

The hourmeter records the total number of operating hours. It serves as a guide in following the

recommended maintenance schedule. The hourmeter will only run when the engine is operating.

VI. Voltmeter

This feature displays the voltage of the battery. The voltmeter will display when the ignition switch is

in the “RUN” position. During operation, the voltmeter should be approximately 14 VDC.

VII. Unloader Valve

This turn valve is used to limit the compressor system pressure. When the valve is in the loaded

position, the system will build to the regulator setting. If the valve is set to unloaded, the system will

build to approximately 45 PSI.

VIII. Emergency Stop Switch

The system is equipped with an emergency stop switch to immediately shutdown the machine.

IX. Bypass Switch

The bypass switch will temporarily disable the engine oil pressure shutdown during startup.

X. Ignition Switch

The ignition switch is used for starting and stopping the machine.

19 309416

01/31/2012

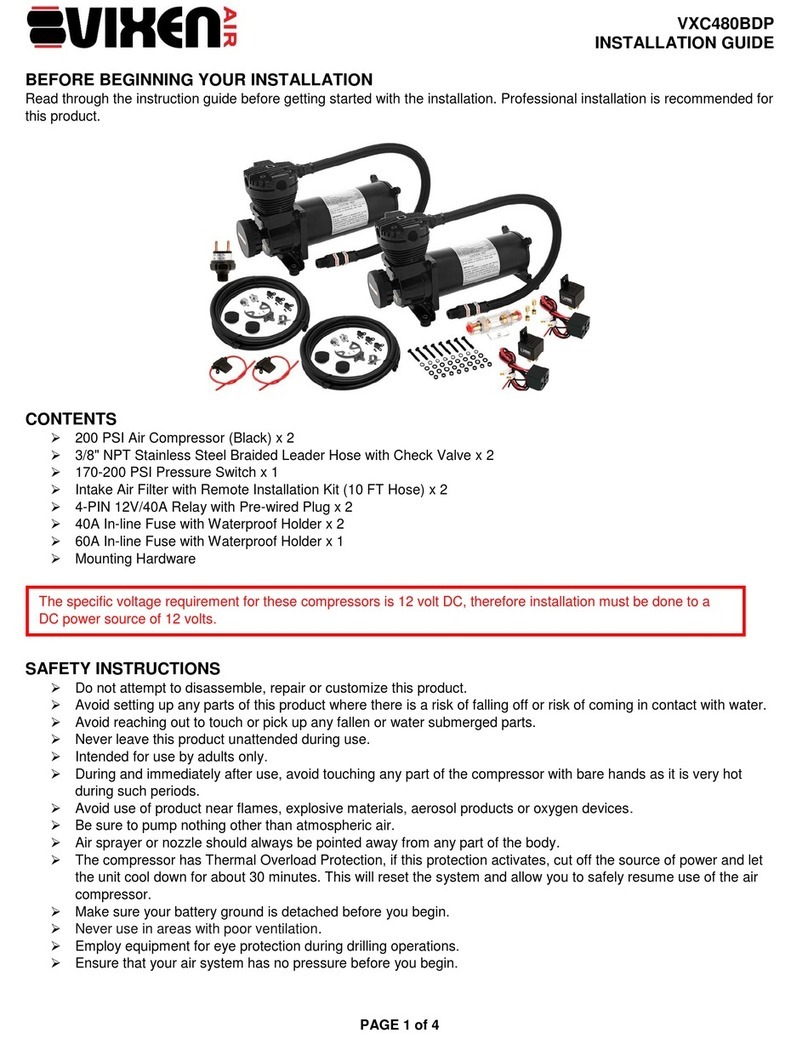

6.3 Connecting the System Fuel Supply

Connect the fuel supply line to the 1/4” tube port on the starter side of the engine. Connect the fuel

return line to the 5/16” tube port, near the air inlet side of the turbo. Both tubes need to be SAE

30R7 rated fuel lines.

Installation

6.1 System Installation Overview

The 210 DUS Air Compressor should be installed only by those who have been delegated to do so,

trained, and who have read and understand this manual. Failure to follow the instructions, procedures,

and safety precautions in this manual may result in accidents and injuries.

Install, use, and operate this system only in full compliance with all pertinent O.S.H.A., Federal, State,

and Local codes or requirements, in addition to Boss Industries, Inc. and any company’s regulations.

Do not modify this system except with written factory approval.

6.2 Placing The Machine

The first step in installing the 210 DUS Air Compressor is placing the system on a solid, level surface.

This machine is designed to run at up to a 15° grade maximum. The machine must be supplied ample

ambient air, as the system will overheat if the cooling air intake’s temperature exceeds ambient condi-

tions.

Do not mix gasoline or alcohol with diesel fuel. This mix-

ture can cause an explosion.

Due to the precise tolerances of diesel injection systems, it is

extremely important that the fuel be kept clean and free from

dirt or water. Dirt or water in the system can cause severe

damage to both the injection pump and the injection nozzle.

1/4" TUBE

FUEL SUPPLY

(2) 3/4" MNPT AIR

SERVICE VALVES

5/16" TUBE

FUEL RETURN

20 309416

01/31/2012

6.5 Connecting the Air Discharge Lines

Connect the customer supplied air discharge lines, designed to handle a minimum of 200 PSI continu-

ously, to the two 3/4” MNPT air discharge ports.

6.4 Fuel Specifications

I. HighAltitude and Low Temperature Fuels

Fuels with cetane numbers higher than 40 may be needed in high altitudes or extremely low ambient

temperatures to prevent misfires and excessive smoke.

II. Cold Weather Fuel

At operating temperatures below 32° F, use a blend of No. 1D and No. 2D fuels, also known as

“Winterized” No. 2D.

Use a low sulfur content fuel having a cloud point that is at least 10 degrees below the lowest

excepted fuel temperature. Cloud point is the temperature at which wax crystals begin to form in

diesel fuel.

The viscosity of the fuel must be kept above 1.3 centistoke to provide adequate fuel system lubrica-

tion.

Use ASTM No. 2D fuel with a minimum cetane number of 40.

No. 2 diesel fuel gives the best economy and performance

under most operating conditions. See engine manufactures

operators/instruction manual for the proper engine fuel for the

brand engine in your Boss Industries, Inc. Air Compressor.

Installation

6.6 Pre-Startup Inspection

This inspection must be done prior to initial system startup.

I. Check all assemblies, clamps, fittings, hose connections, nuts, and bolts to ensure they are properly

tied and secured.

II. Remove all tools, rags, and installation equipment from the area.

III. Verify the air discharge valves are closed.

No. 1D fuel can be used; however, fuel economy will suffer.

This manual suits for next models

1

Table of contents

Other BOSSCO Air Compressor manuals

Popular Air Compressor manuals by other brands

Synairgy

Synairgy SACBD-100 operating instructions

ABAC

ABAC B6000/270 CT7.5 V400 SUPRA Instructions for use manual

Ingersoll-Rand

Ingersoll-Rand R30 Product Maintenance Information

VacuumChambers

VacuumChambers PC2123S operating manual

Rolair

Rolair FC2002HBP6 owner's manual

EKOM

EKOM DK 50 4X2VT/M user manual