BOSSCO 20810A User manual

Important:

-Please read these instructions carefully prior to installation.

-Check the contents of this kit before commencing fitment and report any discrepancies.

-Do not use power tools. Only tighten with the provided allen key to avoid stripping the bolt heads or cross

threading the bolts.

-Do not fully tighten bolts until the end of the assembly.

-Problems and losses which occur due to improper installation and use are not covered by our warranty

-All pictures in the instructions are for reference only, pictures may vary from product to product, however,

the installation method is the same.

-Please check regularly if all fittings connected to the car are loose to ensure safe use.

-Place these instructions in the vehicle’s glove box after installation is complete.

Flat Roof Platform SKU: 20810A, 20811 or 20812

Maximum carrying capacity: 150kg including the weight of the rack system.

Please refer to your vehicle handbook for maximum carrying capacity –many dual cab utes are roughly around 85kg carrying capacity. Always

use the lower the lower of the two figures. Load must be evenly distributed over the entire basket.

Recommendations: It is essential that all bolt connections are checked after driving a short distance when you first install your roof racks. Bolt

connections should be checked at regular intervals (once a week is enough, depending on road conditions, usage, loads and distance travelled).

You should also check the roof racks each time they are re-fitted. Always make sure to fasten your load securely. Please also ensure that the

centre of gravity is kept as low as possible. Contents must be entirely contained within the extents of the roof racks. Rack system should be

removed when using an automatic car wash.

Off-road use: Our racks can be used in off road applications, however a safety factor of 1.5 is enforced. That is, maximum permissible off-road

load is 100kg. Extreme care must be taken in off road conditions

Note for Dealers and Fitters:

Please ensure that fitting instructions are given to the end user or client.

These instructions remain the property of Bossco Auto Parts & Accessories Pty Ltd and may not be used or changed for any other purpose than

intended.

Installation Video

https://youtu.be/zhugLkbnNo8

Follow us on our youtube channel for more installation tips and content. Share your rig with us and we’ll share it on

our social medias!

@bosscoautoofficial

@bossco4x4

Assembly

1- Parts List:

NO.

NAME

QTY

SPEC

NO.

NAME

QTY

SPEC

[1]

FRONT/REAR

BAR

2

Front and rear

are the same

[8]

M6*20 ALLEN KEY

HEAD BOLT

10

M6*20mm

[2]

SIDE BARS

2

Both bars are

identical

[9]

M8*20 ALLEN KEY

HEAD BOLT

4

M8*20mm

[3]

MIDDLE BAR

4

All 4 middle

bars are

identical

[10]

SHORT PHILLIPS

HEAD SCREW

10

7mm

[4]

CROSS BAR

2

Both cross bars

are identical

[11]

LONG PHILLIPS

HEAD SCREW

16

15mm

[5]

PLASTIC SPACER

10

All plastic

spacers are

identical

[12a]

M6 SPRING

WASHERS

10

M6

[12b]

M8 SPRING

WASHERS

4

M8

[6]

END CAP

4

All end caps are

identical

[13a]

M6 FLAT WASHERS

10

M6

[13b]

M8 FLAT WASHERS

4

M8

[7]

END HEAD COVER

4

All end head

covers are the

same

[14]

CAGE NUTS

12

10

[15]

SLIDING CHANNEL

NUTS

4

M8

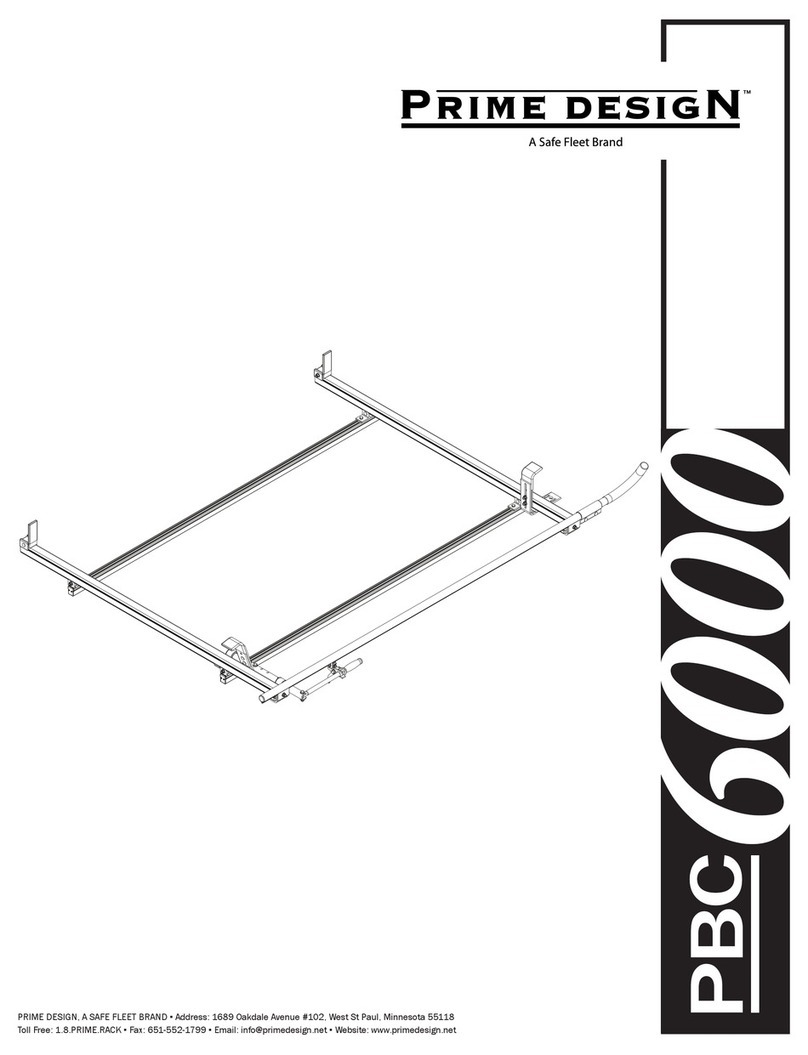

Aluminium Roof Platform Assembly Instructions

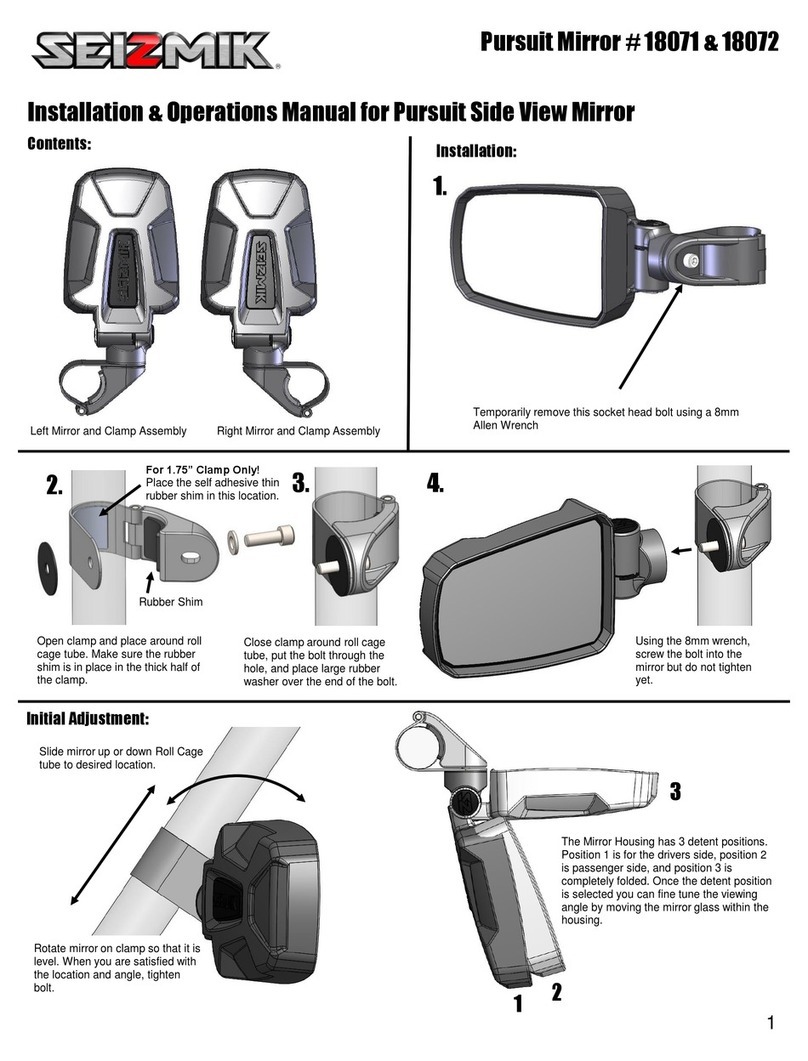

1. Prepare all parts for installation. It is recommended to start assembling loosely with the product upside-

down.

1. Connect the front/rear bars [1] with the side bars [2] using the provided end caps. Make sure the slotted

holes on the bars are facing upwards.

2. Using the 15mm Phillips head long screws, attach the flat end head covers over the corner pieces. You will

need 4 per corner.

3. Secure the 2 cross bars [4] to the front/rear bar with the sliding channel nuts [15] and M8*20mm Allen key

head bolts [9], M8 Spring Washers [12b] and M8 Flat Washers [13b]. The side with the open channel should

be facing upwards (the channel will be facing downwards once installed on the roof).

4. Insert the silver cage nuts [14] into the square slots in the cross bars.

5. Flip over the roof platform. Carefully place and align all 4 middle bars [3] perpendicular to the cross bars

along the slotted holes and hand tighten with the provided 7mm Phillips head short screws [10]. Repeat for

all 4 middle bars.

6. Bolt on the plastic spacers between the 4 middle bars using the provided M6*20 Allen key head bolts [8], M6

Spring Washers [12a] and M6 Flat Washers [13a]. Make sure that the lip of the middle bars sits in the slots of

the plastic spacers.

7. Flip the roof platform over. Using the 7mm Phillips head short screws, secure the 4 middle bars to the outer

edges of the platform.

8. Fully tighten all bolts - start with the plastic spacers then flip over and tighten the rest. For an even finish,

make sure to align all bolts in the middle of the slotted holes before tightening.

M6*20 ALLEN KEY HEAD BOLT

Parts List

NO.

QTY

IMAGE

NO.

QTY

IMAGE

[1]

1

Roof Tray/Basket

[8]

8

M6*40mm Socket Head Cap Screw

[2]

4

Backbone bracket

[9]

4

M8*30mm Socket Head Screw

[3]

4

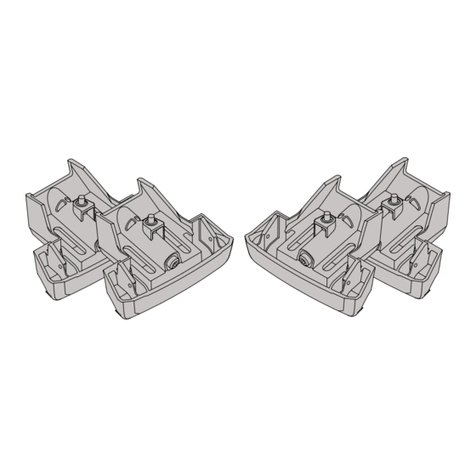

Triangle Base Brackets

[10]

4

M8*20mm Hex Bolt

[4]

4

Full Spacers

[11a]

8

M6 Spring Washers

[11b]

8

M8 Spring Washers

[5]

4

Half Spacers

[12a]

8

M6*12mm Flat Washers

[12b]

8

M6*18mm Flat Washers

[12c]

8

M8*20mm Flat Washers

[6]

16

Sliding Channel Nuts

[13a]

8

M6 Serrated Flange Nut

[13b]

4

M8 Serrated Flange Nut

[7]

8

M8*15mm Rubber Flat Washers

[14]

1

Instruction Manual

Backbone & Aluminium Roof Platform Instructions

1. Please see ‘special cars’ list below for any extra notes specific to your car.

2. Access behind roof lining by pulling down door trim rubber. You may have to uninstall grab handles and/or

sun visors to give sufficient access into roof lining. You only need about 1 hand’s depth up to where the black

rubber roof moulding would be.

3. Check under the roof (where drilling will take place) for obstructions such as grab handle mounts, airbags or

centre light wires.

4. Assemble [2] backbone bracket with [3] triangle base brackets loosely attached using the [9,11b,12c,13b]

M8*30 Socket Head bolt and nuts.

5. Using the assembled backbone bracket, find a suitable spot clear of obstructions for drilling. Make sure to

check for windscreen overhang and antenna position.

6. Mark holes and drill 2x M6 holes using the [3] triangle base bracket as a template.

7. Vacuum out drill shavings.

8. Apply some paint or anti-rust to exposed metal surface.

9. Squeeze Sikaflex 227 on and around drilled holes.

10. Disassemble backbone bracket and install lower triangle brackets. Pushing the (8,11a,12b) M6*30 bolt

through the layer of Sikaflex will help spread it around the hole and saturate the thread of the bolt. This will

prevent water leaks. The [13a] M6 flange nuts go on the inside of the car roof lining. No washers are used as

the flange nut must bite into metal to secure tightly.

11. Reassemble backbone bracket using [9,11b,12c,13b] M8*30 Socket Head bolt and nuts.

12. Loosely thread the M8*20 Hex Bolts [10, 11b, 12c] into the sliding channel nuts at each of the 4 top holes of

the backbone brackets. This is what connects the roof platform to the backbone.

13. Rest roof tray/basket on backbone and line up the previously assembled sliding channel nuts into the Cross

Bars of the platform. As you tighten the bolt & channel nut assembly, the rounded edge will allow the

channel nut to turn sideways and tightly lock the platform into place. A small screwdriver may be useful to

help turn the channel nut.

14. Tighten all bolts starting with the bolts in the roof and working your way up.

15. Complete

Special cars:

Car

Special instructions

Mitsubishi Triton MQ, MR

2015+

-Use factory mounting holes hidden under black rubber roof moulding

-1x M8 bolt per triangle base bracket (separately packaged)

-Drilling an M8 sized hole in the rubber trim allows for cleaner install (the way we

recommend). Make sure to cut out thin aluminium piece running inside trim to

allow for a clean hole to be drilled

-Use the 2 closer holes on the backbone bracket as they are made to size

Holden Colorado RG 12+

-Some Colorado’s have factory mounting holes. They are hidden under roof trim

and may have some body paint covering it.

-1x M8 bolt per triangle base bracket (separately packaged)

-There are 4 holes per side of the car. Our brackets use the 2 inner holes.

-If there are no holes, new holes will have to be drilled

Isuzu D-Max 12+

-Some D-Max’s have factory mounting holes. They are hidden under roof trim and

may have some body paint covering it.

-1x M8 bolt per triangle base bracket (separately packaged)

-There are 4 holes per side of the car. Our brackets use the 2 inner holes.

-If there are no holes, new holes will have to be drilled

Volkswagen Amarok

-Uses factory mounting holes inside ‘pop off’ section

-1x M6 bolt & 1x 3-nut-plate per triangle base bracket (separately packaged)

-3-nut-plate is used a spacer to fill void in the roof so that the base bracket can sit

flush. Base bracket is not able to sit inside the void by itself. The bolt does not

thread into the 3-nut-plate.

Toyota Hilux 2015+

-This car has a very narrow roof moulding. If you were to remove the roof

moulding and try to fit the triangle base bracket in the gap, it would not fit.

-The solution is to make a hole in the roof moulding and sit the triangle base

bracket on top of the roof moulding so that it is raised up and flush with the roof.

This also looks a lot neater and cleaner.

-A bit of clear 3M tape is recommended so that the edge of the triangle base

bracket is not scratching the paint

This manual suits for next models

2

Other BOSSCO Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Aries

Aries 363006-2 installation manual

Agcen

Agcen C01 product manual

Performance Accessories

Performance Accessories 4073 installation instructions

Blaupunkt

Blaupunkt TPMS HN1.0 Operating and installation instructions

Marlon

Marlon Xplore Pro II SxS Owner’s Manual Assembly & Installation Instructions

Yakima

Yakima K1200W instructions