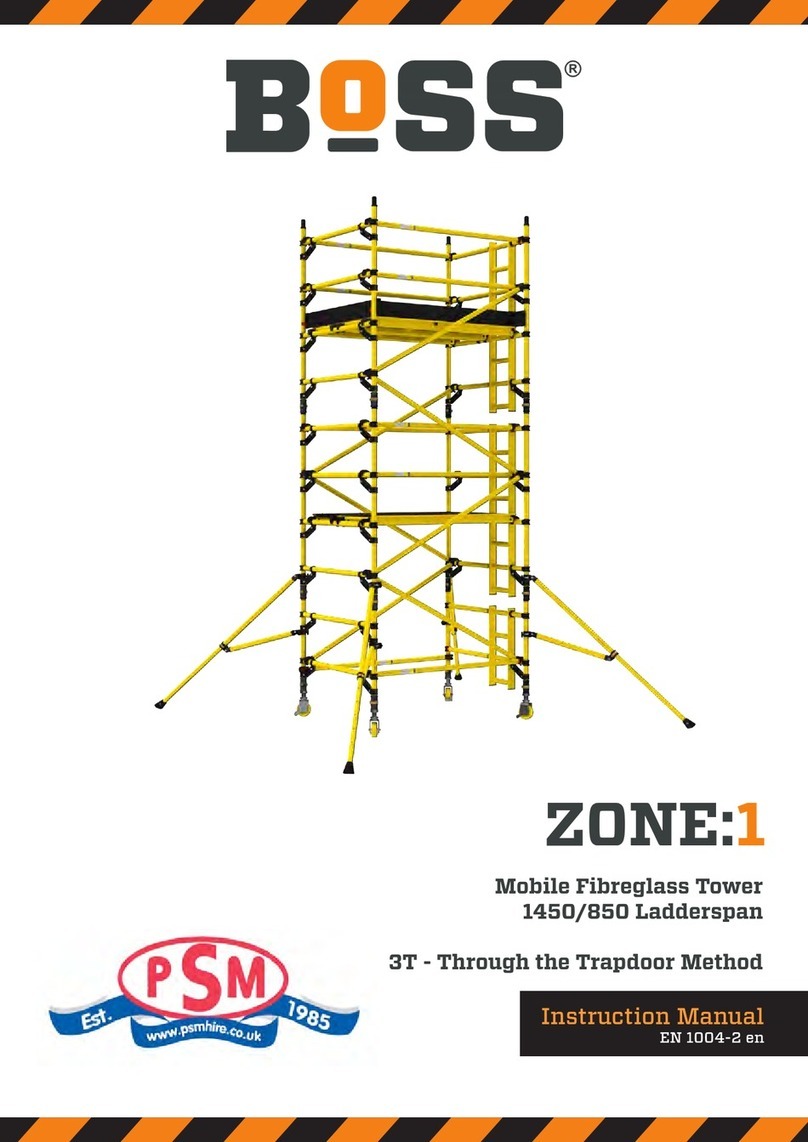

BOSSCO Ladderspan 3T User manual

Instruction Manual

Ladderspan 3T

Mobile Aluminium Tower

1450/850 Ladderspan

3T - Through the Trapdoor Method

EN 1004-2 en

BoSS Ladderspan 3T Instruction Manual

1bossaccesstowers.com

Contents

1Safety First

1.1 Introduction 2

1.2 Tower Designation 3

1.3 Maintenance - Storage - Transport 3

2Building the Tower

2.1 Pre-Assembly Checks 4

2.2 Component Diagram 6

2.3 Quantity Schedule 8

2.4 Stabilisers 11

2.5 Assembly 12

2.5.1 Assembly General: Steps to 14

2.5.2 Assembly For 1450 Towers: Steps to 15

2.5.3 Assembly For 850 Towers: Steps to 18

2.6 Dismantling 20

3 Using the Tower

3.1 Safety Checklist 21

3.2 Pre-Use Checklist 21

3.3 Use 22

3.4 Movement Of TheAssembled Prefabricated Tower Scaffold 24

1 3

4 8

4 9

2BoSS Ladderspan 3T Instruction Manual

1 Safety First

1.1 Introduction

Please read this instruction manual carefully.

This instruction manual shall be available at the location of use of

this mobile access tower. Instruction manuals are also available to

download at www.bossaccesstowers.com.

This product shall only be used in accordance with this manual without any

modification.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY LEAD TO

DEATH OR SERIOUS INJURY.

Mobile access towers must always be used in accordance with the national

regulations. If any aspect of these instructions conflicts with local regulations please

contact Werner UK Sales & Distribution Ltd. for advice.

Please note that diagrams are for illustrative purposes only.

User training courses are available, but must not be used as a substitute for

familiarity with this manual.

BoSS mobile aluminium towers are light-weight scaffold towers used throughout

the building and construction industry for both indoor and outdoor access solutions

where a stable and secure platform is required. Ideal for maintenance and

installation work or short-term access, the highly versatile towers provide a strong

working platform for a variety of heights.

Verification and assessment documentation is held by Werner UK Sales &

Distribution Ltd.

Compliances The BoSS Ladderspan mobile tower system has been

designed, tested, approved and certified to EN 1004-1:2020.

This instruction manual is in compliance with EN 1004-2-en.

3bossaccesstowers.com

1 Safety First

1.2 Tower Designation

EN 1004 3 8/12 XXXD H2

Design Code

Load Class (2 = 153kg/m2UDL, 3 = 204kg/m2UDL*)

Max. Platform Height Outdoors (m)

Max. Platform Height Indoors (m)

Access Method

A = Stairway, B = Stair ladder, C = Inclined Ladder, D = Vertical Ladder

Clear Height Class (H1 = 1.85m, H2 = 1.90m)

*UDL = Uniformly distributed load

1.3 Maintenance - Storage – Transport

•The BoSS mobile tower system is robust and requires little maintenance.

•All components and their parts should be regularly inspected to identify

damage, particularly to joints.

•Refer to the BoSS Inspection Guidance for detailed inspection and

maintenance advice, the guidance is available to download at:

www.bossaccesstowers.com.

•Threads, hinges, and brace latches may be lubricated with light oil. Ensure oil

does not contaminate climbing or walking surfaces.

•Safety labels should be kept legible. Replacement labels are available from

Werner UK Sales & Distribution Ltd.

•Surfaces should be kept reasonably free of dried paint, plaster etc.

•Use of solvents on wooden platform surfaces and plastic components should

be avoided.

•Components should be stored in clean, dry conditions with due care to prevent

damage.

•During transportation ensure components are not damaged by excessive

strapping forces.

4BoSS Ladderspan 3T Instruction Manual

2 Building The Tower

2.1 Pre-Assembly Checks

•Check overhead that the area into which the structure is to be erected contains

no obstructions, particularly electrical or radio radiation hazards. The structure is

conductive.

•Ensure the ground on which the mobile access tower is to be erected is capable

of supporting the tower in use.

•Check the surface is level within the 210mm range of the adjustable legs.

•Only components specified in this manual shall be used with BoSS towers.

Check all required components are onsite and in a suitable working condition.

•Damaged components shall not be used and must

be put beyond use and disposed of according to local

regulations.

•Adjustable legs should only be used for levelling purposes and never to gain

extra height.

•Ensure distance from the ground to first climbing rung is less than 400mm.

•Only climb the tower from the inside using the access

method provided.

•This tower provides a work platform. It must not be

used to access other structures.

•Tower scaffolds are not designed to be lifted or suspended.

•Ensure the safe working load on the structure is not exceeded.

•Tools and materials should be lifted using a reliable lifting material (e.g. a strong

rope) employing a reliable knot (e.g. clove hitch) to ensure safe fastening and

always lift within the footprint of the prefabricated tower scaffold (i.e. within the

area bounded by the stabilisers).

5bossaccesstowers.com

•Check this manual is available and its contents familiar to all those involved.

•If assembling outdoors; check the forecast windspeed.

| The assembled tower is certified to wind forces

equating to 27mph, but handling components under

those conditions would be hazardous.

| Also consider the wind funnelling effect of nearby

buildings.

•Towers greater than 8.2m platform height are for indoor use only.

•This structure is designed to be self-supporting under the loading condition

requirements of EN 1004-1:2020 and does not require tying in. Consideration

should be given to potential wind conditions if the tower is left unattended.

2 Building The Tower

6BoSS Ladderspan 3T Instruction Manual

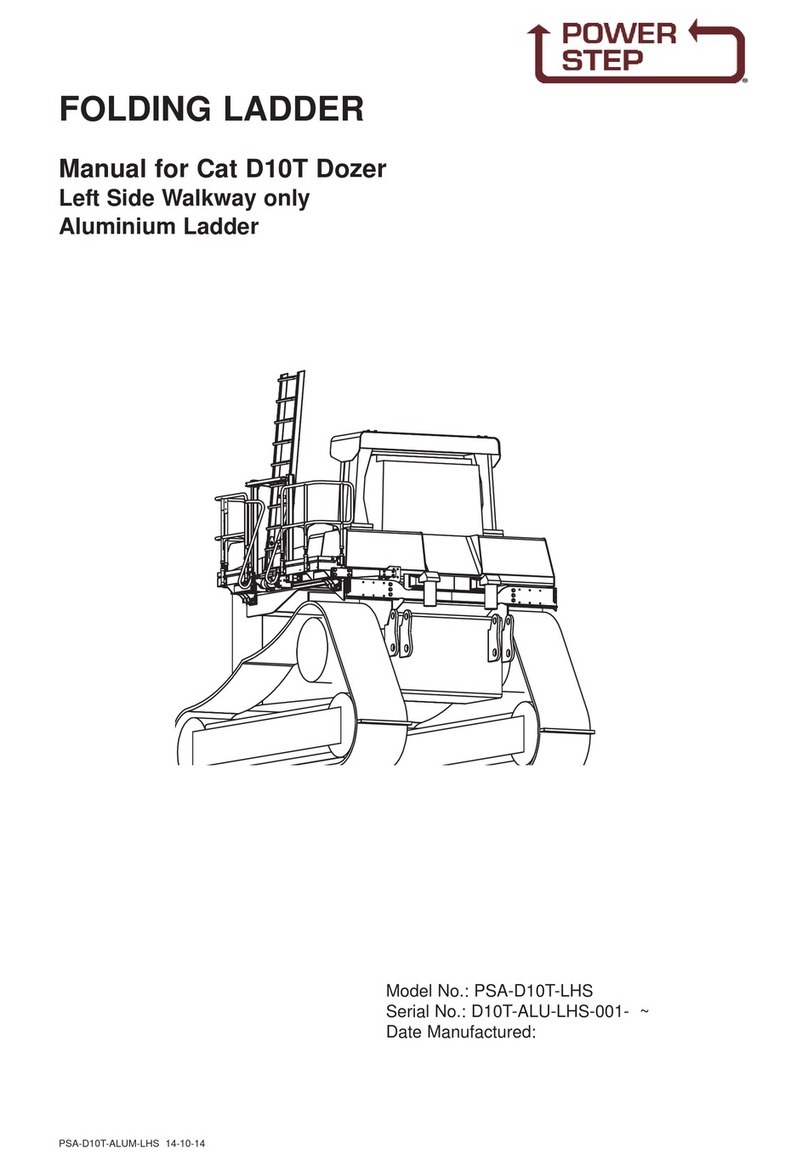

2.2 Component Diagram

2 Building The Tower

Instruction

Manual

Horizontal

Brace

Span

Frame

4 Rung

Platform

(Fixed and

Trapdoor

Platforms)

Ladder Frame

4 Rung

End Toe

Board

Stabiliser

Span

Frame

2 Rung

Ladder Frame

2 Rung

Adjustable Leg

Castor

Diagonal

Brace

Side

Toe

Board

7bossaccesstowers.com

Component Weights

2 Building The Tower

Component

Code Name Weight (kgs)

32842300 Castor 150mm 3.3

33551300 Adjustable Leg 1.1

60851300 Ladder Frame 850 2 Rung 4.7

60251300 Span Frame 850 2 Rung 2.7

60751300 Ladder Frame 850 3 Rung 6.7

60151300 Span Frame 850 3 Rung 3.4

60651300 Ladder Frame 850 4 Rung 8.7

60051300 Span Frame 850 4 Rung 4.1

61151300 Ladder Frame 1450 2 Rung 5.4

60551300 Span Frame 1450 2 Rung 4.0

61051300 Ladder Frame 1450 3 Rung 8.0

60451300 Span Frame 1450 3 Rung 5.6

60951300 Ladder Frame 1450 4 Rung 10.4

60351300 Span Frame 1450 4 Rung 7.1

30151100 Fixed Platform 1.8m 11.8

30251100 Fixed Platform 2.5m 16.0

30451100 Trapdoor Platform 1.8m 12.7

30551100 Trapdoor Platform 2.5m 16.3

31251300 Horizontal Brace 1.8m (red) 2.0

34851300 Horizontal Brace 2.5m (red) 2.4

31351300 Diagonal Brace 2.1m (blue) 2.1

31451300 Diagonal Brace 2.7m (blue) 2.5

30450900 Side Toe Board 1.8m 3.2

30550900 Side Toe Board 2.5m 4.4

30250900 End Toe Board 0.85m 1.0

30350900 End Toe Board 1.45m 2.1

30150900 Toe Board Holder 0.3

31751300 SP7 Fixed Stabiliser 3.8

31851300 SP10 Telescopic Stabiliser 8.8

31951300 SP15 Telescopic Stabiliser 12.8

8BoSS Ladderspan 3T Instruction Manual

2.3 Quantity Schedule

BoSS 1450 Ladderspan to EN 1004: Available in 2 lengths - 1.8m and 2.5m

Internal or External Use Internal Use

Component Working

Height (m) 3.2 3.7 4.2 4.7 5.2 5.7 6.2 6.7 7.2 7.7 8.2 8.7 9.2 9.7 10.2 10.7 11.2 11.7 12.2 12.7 13.2 13.7 14.2

Code Name Platform

Height (m) 1.2 1.7 2.2 2.7 3.2 3.7 4.2 4.7 5.2 5.7 6.2 6.7 7.2 7.7 8.2 8.7 9.2 9.7 10.2 10.7 11.2 11.7 12.2

32842300 Castor 150mm 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

33551300 Adjustable Leg 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

61151300 Ladder Frame 1450 2 Rung - 1 1 - - 1 1 - - 1 1 - - 1 1 - - 1 1 - - 1 1

60551300 Span Frame 1450 2 Rung - 1 1 - - 1 1 - - 1 1 - - 1 1 - - 1 1 - - 1 1

61051300 Ladder Frame 1450 3 Rung - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 -

60451300 Span Frame 1450 3 Rung - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 -

60951300 Ladder Frame 1450 4 Rung 1 - 1 1 2 1 2 2 3 2 3 3 4 3 4 4 5 4 5 5 6 5 6

60351300 Span Frame 1450 4 Rung 1 - 1 1 2 1 2 2 3 2 3 3 4 3 4 4 5 4 5 5 6 5 6

30151100/

30251100

Fixed Platform 1.8m

and 2.5m 1 1 1 2 1 1 1 2 1 1 1 2 1 1 1 2 1 1 1 2 1 1 1

30451100/

30551100

Trapdoor Platform 1.8m and

2.5m 1 1 1 1 2 2 2 2 3 3 3 3 4 4 4 4 5 5 5 5 6 6 6

31251300/

34851300

Horizontal Brace 1.8m

and 2.5m (red) 6 6 6 10 10 10 10 14 14 14 14 18 18 18 18 22 22 22 22 26 26 26 26

31351300/

31451300

Diagonal Brace 2.1m

and 2.7m (blue) 2 4 4 6 6 8 8 10 10 12 12 14 14 16 16 18 18 20 20 22 22 24 24

30450900/

30550900

Side Toe Board 1.8m

and 2.5m 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

30350900 End Toe Board 1.45m 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

30150900 Toe Board Holder 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

31751300 SP7 Fixed Stabiliser 4 4 4 4 4 4 4 - - - - - - - - - - - - - - - -

31851300 SP10 Telescopic Stabiliser - - - - - - - 4 4 4 4 4 4 - - 4 4 4 4 4 4 4 4

31951300 SP15 Telescopic Stabiliser - - - - - - - - - - - - - 4 4 - - - - - - - -

Tower Total Self-weight 1.8m (kgs) 103 113 116 145 149 159 163 211 216 226 230 258 263 288 292 304 309 319 323 351 356 366 369

Tower Total Self-weight 2.5m (kgs) 116 127 131 165 170 180 184 239 243 254 257 292 296 323 327 346 350 360 364 399 403 414 418

Max. Exerted Leg Load 1.8m (kgs) 150 150 150 150 160 170 180 190 200 210 220 240 255 270 300 300 300 310 310 310 320 320 320

Max. Exerted Leg Load 2.5m (kgs) 160 160 170 170 180 180 190 190 200 200 210 260 305 310 320 330 340 350 360 370 380 390 400

2 Building The Tower

9bossaccesstowers.com

BoSS 850 Ladderspan to EN 1004: Available in 2 lengths - 1.8m and 2.5m

Internal or External Use Internal Use

Component Working

Height (m) 3.2 3.7 4.2 4.7 5.2 5.7 6.2 6.7 7.2 7.7 8.2 8.7 9.2 9.7 10.2 10.7 11.2 11.7 12.2 12.7 13.2 13.7 14.2

Code Name Platform

Height (m) 1.2 1.7 2.2 2.7 3.2 3.7 4.2 4.7 5.2 5.7 6.2 6.7 7.2 7.7 8.2 8.7 9.2 9.7 10.2 10.7 11.2 11.7 12.2

32842300 Castor 150mm 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

33551300 Adjustable Leg 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

60851300 Ladder Frame 850 2 Rung - 1 1 - - 1 1 - - 1 1 - - 1 1 - - 1 1 - - 1 1

60251300 Span Frame 850 2 Rung - 1 1 - - 1 1 - - 1 1 - - 1 1 - - 1 1 - - 1 1

60751300 Ladder Frame 850 3 Rung - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 -

60151300 Span Frame 850 3 Rung - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 - 1 -

60651300 Ladder Frame 850 4 Rung 1 - 1 1 2 1 2 2 3 2 3 3 4 3 4 4 5 4 5 5 6 5 6

60051300 Span Frame 850 4 Rung 1 - 1 1 2 1 2 2 3 2 3 3 4 3 4 4 5 4 5 5 6 5 6

30151100/

30251100

Fixed Platform 1.8m

and 2.5m - - - 1 - - - 1 - - - 1 - - - 1 - - - 1 - - -

30451100/

30551100

Trapdoor Platform 1.8m and

2.5m 1 1 1 1 2 2 2 2 3 3 3 3 4 4 4 4 5 5 5 5 6 6 6

31251300/

34851300

Horizontal Brace 1.8m

and 2.5m (red) 6 6 6 10 10 10 10 14 14 14 14 18 18 18 18 22 22 22 22 26 26 26 26

31351300/

31451300

Diagonal Brace 2.1m

and 2.7m (blue) 2 4 4 6 6 8 8 10 10 12 12 14 14 16 16 18 18 20 20 22 22 24 24

30450900/

30550900

Side Toe Board 1.8m

and 2.5m 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

30250900 End Toe Board 0.85m 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

30150900 Toe Board Holder 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

31751300 SP7 Fixed Stabiliser 4 4 4 4 4 4 4 - - - - - - - - - - - - - - - -

31851300 SP10 Telescopic Stabiliser - - - - - - - 4 4 4 4 4 4 - - 4 4 4 4 4 4 4 4

31951300 SP15 Telescopic Stabiliser - - - - - - - - - - - - - 4 4 - - - - - - - -

Tower Total Self-weight 1.8m (kgs) 84 93 96 122 126 135 138 184 188 197 200 226 230 255 257 284 288 297 299 310 314 323 325

Tower Total Self-weight 2.5m (kgs) 93 103 106 139 142 152 154 208 211 220 223 256 259 285 288 305 308 318 321 354 357 367 369

Max. Exerted Leg Load 1.8m (kgs) 150 150 155 155 155 155 155 160 160 160 160 160 185 210 235 260 285 310 325 330 335 340 345

Max. Exerted Leg Load 2.5m (kgs) 140 140 140 140 150 150 150 150 160 160 170 170 175 200 230 230 240 250 260 270 280 285 285

2 Building The Tower

10 BoSS Ladderspan 3T Instruction Manual

Assembly Variations

This section lists the permitted component variation from the Quantity Schedule.

Note: These substitutions must be made before assembly.

Stabilisers

Stabilisers with Universal

Clamps may be substituted:

Castors

Other Castor sizes and types

may be substituted:

High Clearance Frame If side walk-through access is required at the base

of 4.2m, 6.2m, 8.2m, 10.2m or 12.2m platform

height towers, high clearance frames may be used

in place of the four lower diagonal braces and two

lower horizontal braces.

High clearance frames must not be used in

conjunction with walk-through frames.

Component

Code Description Weight

(kg)

30051500 High Clearance Frame

1.8m 10.0

30151500 High Clearance Frame

2.5m 12.0

2 Building The Tower

Component

Code Description Weight

(kg)

31842300 Diameter 150mm (Tyred) 3.2

32942300 Diameter 200mm 3.9

31942300 Diameter 200mm (Tyred) 3.9

Component

Code Description Weight

(kg)

31751400 SP7 4.0

31851400 SP10 9.0

31951400 SP15 13.1

11bossaccesstowers.com

Walk-through Frame

If side walk-through access is required at the base of

4.2m, 6.2m, 8.2m, 10.2m or 12.2m platform height

towers, high clearance frames may be used in place

of the four lower diagonal braces and two lower

horizontal braces.

High clearance frames must not be used in

conjunction with walk-through frames.

If end walk-through access is required at the base

of 2.2m, 4.2m, 6.2m, 8.2m, 10.2m or 12.2m platform

height, 1450 wide towers, walk-through frames may

be used.

In this case the 1m ladder frame and span frame

must be tted above the walk-through frames.

Walk-through frames must not be used in addition to

high clearance frames.

Component

Code Description Weight(kg)

33151700 Walk-through Frame

2.0m 10.8

2 Building The Tower

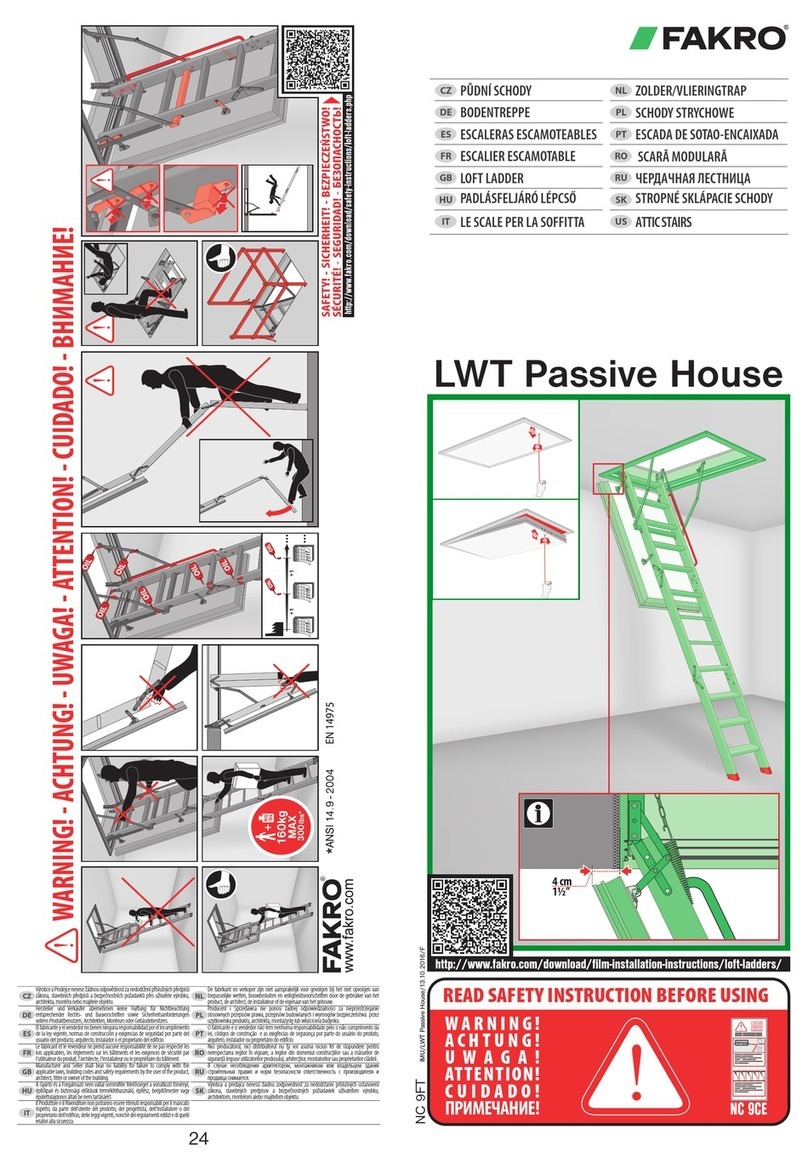

2.4 Stabilisers

X

Y

90%

Double Width 1450

Tower Single Width 850 Tower

1.8m 2.5m 1.8m 2.5m

X & Y X & Y X & Y X Y

SP7 3351 3629 2294 3201 3201

SP10 4789 5100 4458 4734 3734

SP15 5520 5838 5195 5485 6074

SP10 and SP15 stabilisers must always be fully extended.

Position the lower clamp so that the arm is as close to horizontal as possible. Adjust

the position of the top clamp to ensure the stabiliser foot is in firm contact with the

ground. Ensure the clamps are secure.

12 BoSS Ladderspan 3T Instruction Manual

2 Building The Tower

2.5 Assembly

This tower structure must be assembled, and components oriented, in accordance

with this instruction manual. Deviation from this instruction manual is not permitted.

•No tools are required for assembly.

•The assembly uses the 3T (Through the Trapdoor) method that provides

collective fall protection.

•The tower may be assembled by a single person, but it is recommended that

two or more are used to pass up components on the taller assemblies.

•Components must be lifted within the footprint of the tower using a reliable

method such as a strong rope with a clove hitch knot.

•Castor brakes should be locked as soon as the tower base is in position.

•The tower base should be levelled to within 0.6° before continuing the assembly.

•The adjustable legs are for levelling the tower only and not to be used to gain

extra height.

•Ensure when the base is levelled the distance from the ground to the rst

climbing rung is less than 400mm.

•Stabilisers of the size specied in the quantity schedule should be tted at the

earliest opportunity.

13bossaccesstowers.com

2 Building The Tower

•Always start assembly with the smallest end frames at the base.

Platform Height (m) Frame at Base

1.7, 2.2, 3.7, 4.2, 5.7, 6.2, 7.7, 9.7, 10.2, 11.7,12.2 2 Rung

2.7, 4.7, 6.7, 8.7, 10.7 3 Rung

1.2, 3.2, 5.2, 7.2, 9.2, 11.2 4 Rung

•Where all three frames are specied, start with the 2 rung, 3 rung next and

4 rung on top. Refer to the quantity schedule for details.

Platform heights:

1.2m, 3.2m, 5.2m, 7.2m, 9.2m, 11.2m Platform heights:

2.2m, 4.2m, 6.2m, 8.2m, 10.2m, 12.2m

Platform heights:

1.7m, 3.7m, 5.7m, 9.7m, 11.7m Platform heights:

2.7m, 4.7m, 6.7m, 8.7m, 10.7m, 12.7m

14 BoSS Ladderspan 3T Instruction Manual

2.5.1 Assembly General

Push castor into adjustable

leg. Push castor/adjustable leg

assemblies into a span frame. Lock

castors. Repeat procedure with a ladder

frame.

It is recommended that for ease of

levelling a gap of 50mm is left between

the bottom of the leg and the adjustable

nut.

Fit one horizontal brace (red) onto

the vertical of a span frame, just

above the bottom rung, with the claw

facing outwards. The frame will now be

self-supporting.

All locking claws must be opened

before tting.

Position the ladder frame as

shown and fit the other end of the

horizontal brace on to the vertical (just

above the bottom rung).

Fit a second horizontal brace between

the bottom rungs on the other side of the

frames to square the tower.

1

2 Building The Tower

2

Unlocked

Locked

Locked

Assembly for 1450 towers, see page 15 for following steps.

Assembly for 850 towers, see page 18 for following steps.

3

15bossaccesstowers.com

2 Building The Tower

2.5.2 Assembly For 1450 Towers

The procedure illustrated shows a 4.2m platform height tower starting with a 2 rung

end frame.

Fit two additional end frames,

ensuring the frame interlock

clips are engaged.

Fit two diagonal braces (blue) in

opposite directions between the 1st

and 3rd rungs.

Ensure the frames are vertical and

level by checking with a spirit level and

setting the adjustable legs as required.

Only use the adjustment on the legs

to level the tower and not to gain

extra height.

Fit the next pair of diagonal braces

in opposite directions between the

3rd and 5th rungs. Fit a trapdoor platform

on the 4th rung (2.0m) with the trapdoor

next to the ladder. Ensure the trapdoor

is positioned with the hinges towards the

outside of the tower as shown.

Climb the ladder from the protected

trapdoor position, fit the horizontal

braces on the 5th and 6th rungs (in that

order) on both sides of the platform.

When horizontal braces are fitted as

guardrails, they should be 0.5m and

1.0m (1 and 2 rungs) above the platform

level in all cases.

Do not climb onto the platform until

all guardrails are in place.

4

INTERLOCK CLIP

Locked

Unlocked

5

16 BoSS Ladderspan 3T Instruction Manual

2 Building The Tower

Fit stabilisers (see notes

on page 11).

Continue the procedure until the

required height is reached, adding

additional pairs of end frames, diagonal

braces and fitting trapdoor platforms,

as shown on previous steps. At every

platform level, add horizontal braces as

guardrails from the protected position

within the trapdoor (as shown in Step 5).

At the required platform height, fit the

fixed platform and a trapdoor platform

alongside it. Fit the final guardrails (as

shown in Step 5).

6

7

18 BoSS Ladderspan 3T Instruction Manual

2 Building the Tower

2.5.3 Assembly For 850 Towers

The procedure illustrated shows a 3.2m platform height tower starting with a 4 rung

end frame.

Fit a trapdoor platform on the 2nd

rung. Fit the horizontal braces on

both sides of the tower. When horizontal

braces are fitted as guardrails, they

should be 0.5m and 1.0m (1 and 2

rungs) above the platform level in all

case.

Fit two diagonal braces in

opposite directions between the

1st and 3rd rungs.

Ensure that the frames are vertical

and level by checking with a spirit level

and setting the adjustable legs as

necessary.

Only use the adjustment on the legs

to level the tower and not to gain

extra height.

Fit stabilisers (see notes on page 11).

Fit the next pair of end frames and

check the frame interlock clips are

engaged.

4

5

INTERLOCK CLIP

Locked

Unlocked

Other manuals for Ladderspan 3T

2

This manual suits for next models

2

Table of contents

Other BOSSCO Ladder manuals

Popular Ladder manuals by other brands

Arke

Arke 5199 Assembly instructions

Outwater

Outwater architectural products E-GLIDE EG.300 Series instruction manual

USTEPS

USTEPS Prime Line instruction manual

Roto

Roto Quadro 2 Installation manual and operating instructions

EBCO

EBCO Smart Step Ladder 1 Step quick guide

Vestil

Vestil LAD-TRS Series instruction manual