BOSSCO ZONE:1 User manual

Table of contents

Other BOSSCO Ladder manuals

Popular Ladder manuals by other brands

INNOVAPLAS

INNOVAPLAS Lumi-O BILTMOR 5005 installation instructions

Confer Plastics

Confer Plastics 635-52X Assembly and installation manual

Batavia

Batavia Professional BT-TL035W operating instructions

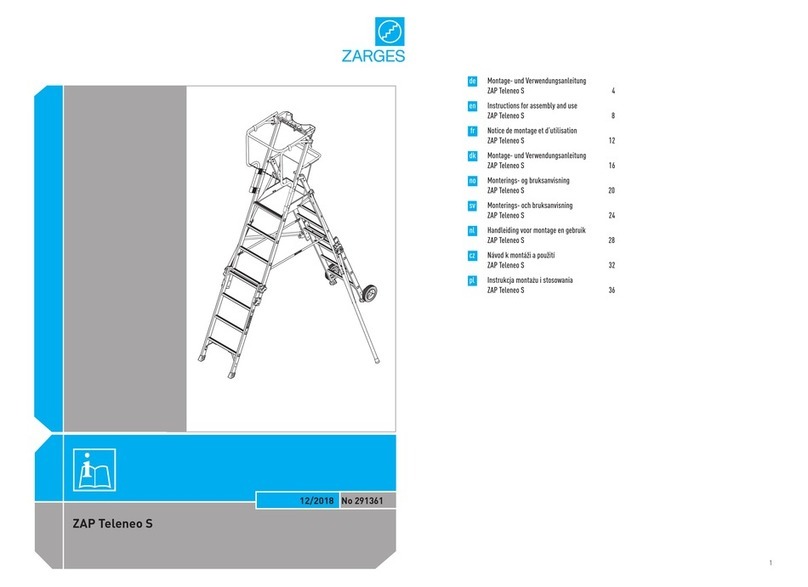

zarges

zarges ZAP Teleneo S Instructions for assembly and use

Torklift

Torklift GlowStep Revolution owner's manual

Toya

Toya VORTEL 17702 Original instructions

Hailo

Hailo TopLine TL100 Instructions for use

TUBESCA-COMABI

TUBESCA-COMABI RAPTOR 2272/182 Technical instructions

Vestil

Vestil COL-4-36-33 instruction manual

MetalTech

MetalTech E-LAD8T2 Jobsite series OPERATIONAL, SAFETY AND MAINTENANCE INSTRUCTIONS

Kargo Master

Kargo Master 40816 installation instructions

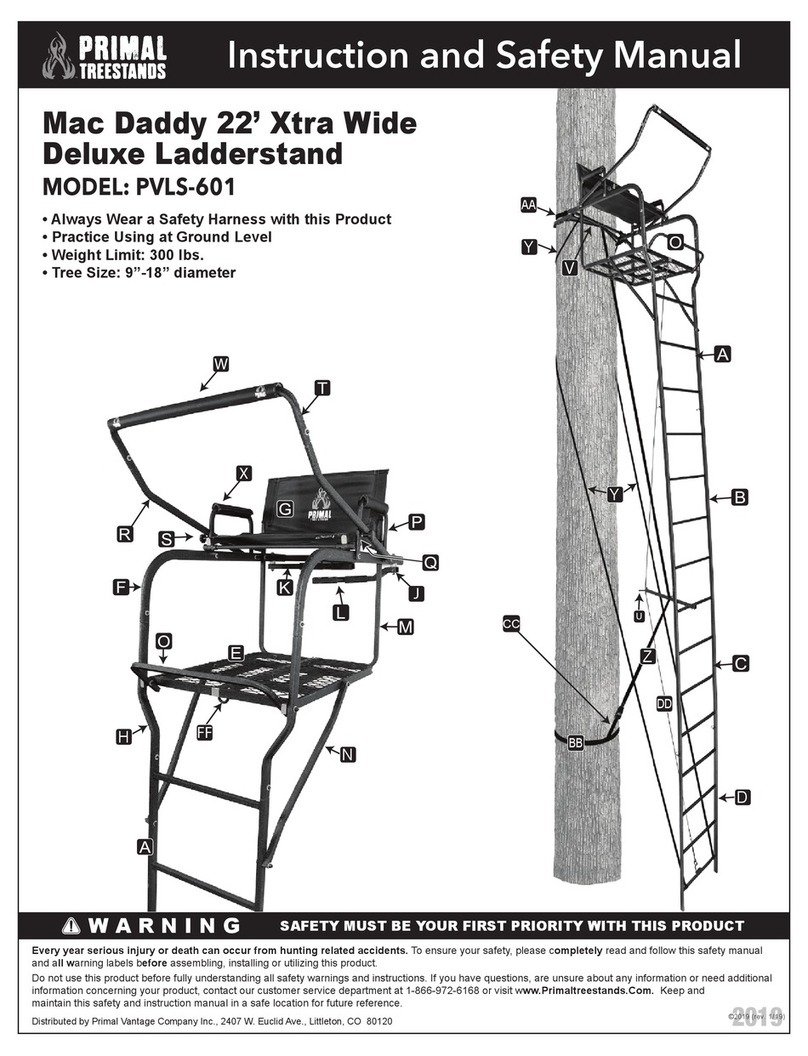

Primal

Primal Mac Daddy PVLS-601 Instruction and safety manual