BENTS KLIK User manual

APR/15

1. Check instructions before use. Mobile access working towers

may only be erected and dismantled by persons familiar with

these instructions for erection use.

2. Do not use any scaffold tower which is damaged, which has not

been properly erected, which is not firm and stable, and which

has any missing or damaged parts.

3. Do not erect a scaffold tower on unstable ground or objects such

as loose bricks, boxes or blocks. Only a sound rigid footing must

be used.

4. Ensure that the scaffold tower is always level and the adjustable

legs are engaged. Check that you have taken all necessary

precautions to prevent the tower being moved, or rolling away.

Always apply all castor brakes or use base plates.

4. Ensure that all frames, braces and platforms are firmly in place

and that all locking hooks are functioning correctly. Ensure that

all frame locking clips are engaged. If any missing, replace them.

5. Ensure that the scaffold tower is within the maximum platform

height is stated, and that the appropriate stabilizers are fitted.

6. Outdoor scaffold towers should, wherever possible, be secured to

a building or other structure. It is good practice to tie in all

scaffold towers of any height, especially when they are left

unattended, or in exposed or windy conditions.

7. A scaffold tower must not be used in winds stronger than 7.7

metres per second. Beaufort scale 4. Be cautious if erecting or

using the tower in open places, such as hangers or unclad

buildings. In such circumstances the wind forces can be

increased, as a result of the funnelling effect.

8. Do not use sheeted towers.

9. Do not erect or use a scaffold tower near un-insulated, live or

energised electrical machinery or circuits, or near machinery in

operation.

11. If an overhead hazard exists, head protection should be worn.

12. Do not lean ladders against the tower, or climb the outside of the

tower. Whatever your intended access system, it should only be

used inside the tower.

13. Never climb on horizontal or diagonal braces. Do not gain access

or descend from the working platform other than by the intended

access system.

14. Do not work from ladders or stairways, they are a means of

access only.

15. Guardrails and Toeboards must be fitted to the working

platforms.

16. Never jump on to or off platforms.

17. DO NOT exceed the safe working load of the platform or

structure by accumulating debris, material or tools on platforms

as these can be a significant additional load.

18. If you must move a tower, remove all materials and personnel.

When moving a scaffold tower, force must always be moved from

the base. The tower should only be moved manually on firm,

level ground which is free from obstacles. Normal walking speed

should not be exceeded during relocation. The ground over which

a tower is moved should be capable of supporting the weight of

the structure.

19. Should you require additional platform height, add further frames.

NEVER extend your adjustable legs to achieve extra height,

these are for levelling only. NEVER use a ladder or other objects

on the platform to achieve additional height.

20. It is not permissible to attach and use hoisting facilities on towers,

unless specifically provided for by the manufacturer.

21. It is not permissible to attach bridging sections between a

scaffold tower and a building. Refer to the tower manufacturer.

22. ALWAYS TAKE CARE OF ALUMINIUM SCAFFOLD TOWER

EQUIPMENT. REMEMBERYOUR SAFETY DEPENDS ON THE SAFE

ERECTION AND USE OF THE EQUIPMENT. RESPECT IT.

MAINTENANCE RULES USE OF STABILIZERS

1. Ensure that the scaffold tower is kept clean, especially the

spigots and sockets. These should fit together with ease and be

secured by an interlock clip.

2. Check frames and braces, adjustable legs and boards for paint,

grit, burrs etc. Remove any foreign substance with a light wire

brush. Check no slip hazards exist on the platform.

3. Where brace, ladder and platform hooks attach the frames,

ensure that the frame rungs are kept clean.

4. Ensure that all locking hooks function correctly. If necessary

lubricate with light oil.

5. The inside diameter of all hooks should be kept clean to ensure

they fit to other components without being forced.

6. If in any doubt about the proper use and maintenance of the

scaffold tower equipment, consult the manufacturer.

7. Do not misuse or abuse the scaffold tower with heavy objects,

hammers etc. Do not throw components in and out of vehicles or

to the ground when the tower is being dismantled. Such abuse

may reduce the structural integrity of the scaffold tower.

8. Under no circumstances use a scaffold tower which damaged,

has not been properly erected, is it not rigid and which has any

missing parts.

9. REMEMBER YOUR SAFETY DEPENDS ON THE SAFE

ERECTION AND USE OF THIS EQUIPMENT. RESPECT IT.

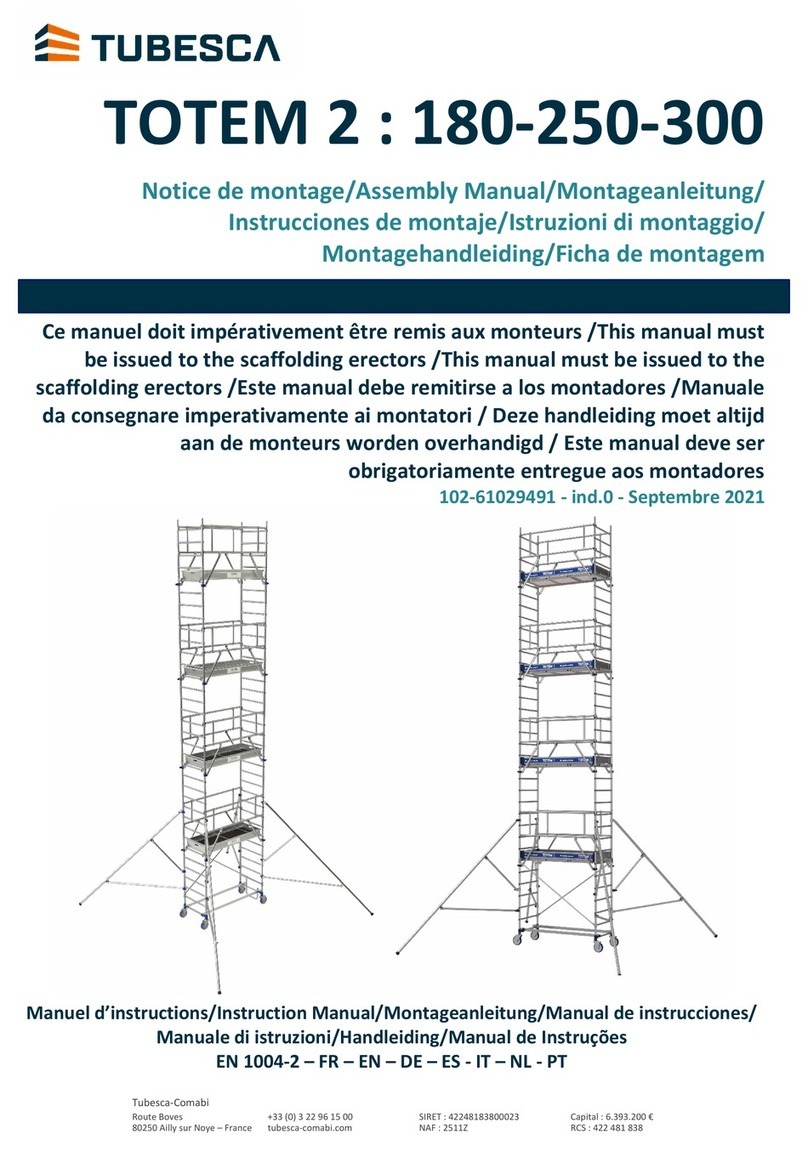

Stabilizers increase the EFFECTIVE BASE dimensions and

improve the STABILITY of the tower.

Position the stabilizers symmetrically to obtain the MAXIMUM

BASE DIMENSION, use the full adjustment of the telescopic

stabilizers.

OPTIMUM MAX HEIGHTS STABILZER TYPE

BASE DIMENSION

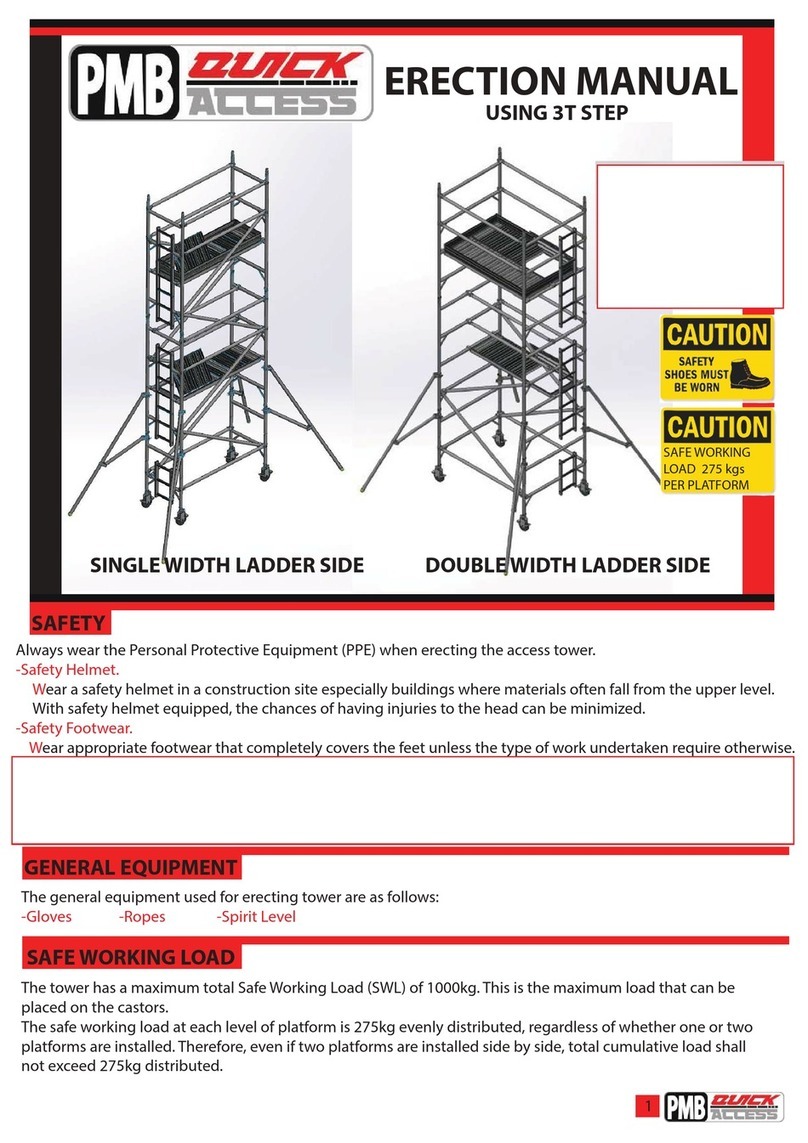

SINGLE WIDTH TOWER

Single Width 1.41M NONE

1.88M 5.13M STANDARD

5.59M 7.91M TELESCOPIC

*Due to general tower rigidity it is recommended that the

maximum platform height of a single width tower is 8.0m unless

the tower is tied in.

GENERAL SAFETY RULES

SINGLE WIDTH ALUMINIUM SCAFFOLD TOWER EQUIPMENT

KLIK 2.5m SINGLE WIDTH LADDER FRAME

ERECTION INSTRUCTION MANUAL

TUV CERTIFIED QUALITY SYSTEM

TO ISO9001:2008

GS PRODUCT APPROVAL

TO BS.EN.1004 3 8/12 XXXD

MANUFACTURED BY EURO TOWERS LTD

MAX SAFE WORKING LOAD FOR STRUCTURE 750KG

MAX SAFE WORKING LOAD FOR PLATFORM 250KG

NEVER CLIMB SCAFFOLD ON

THE OUTSIDE OF THE FRAME

INSTRUCTIONS FOR USE TO

BE FOLLOWED CAREFULLY

Horizontal Brace

2M Black / Green / Red

2.5M Black / Green / Yellow

3M Black / Green / Blue

End Toeboard

Trapdoor Platform

Side Toeboard

Plain Frame

3,4 or 5 Rung

Diagonal Brace

2M White / Green / Red

2.5M White / Green / Yellow

3M White / Green / Blue

Ladder Frame

3,4 or 5 Rung

Stabilizer

Castor / Adjustable

Leg

KLIK 2.5m LADDER FRAME SCAFFOLD TOWER SINGLE WIDTH KIT LIST APR/15

This range of Single Width Tower gives an exceptional versatile system ideal for working in narrow and confined spaces such as stairwells, corridors, alleyways

etc. All frames can be used as uppers or lowers, simply place the platform on the third rung below the top of the tower and the correct guardrail height is achieved.

BASE SET UPS:

BASE SET UP: You must get your base set up correct in order to achieve safe guardrail

heights on rest and working platforms. Safe guardrails require 2 rungs above every

platform.

PLATFORM POSITIONS:Fit platforms every 4 rungs, Temporary platforms enable safe

assembly, if temporary platforms are used in assembly they must be repositioned during

dismantling. Trapdoors must be fitted at the ladder frame end.

ALTERNATIVE FRAMES AND BRACE PATTERN:Where 2 x 4 rung frames are stated,

these can be replaced by 1 x 5 rung and 1 x 3 rung, Ladder or Plain frame. Diagonal braces

should be in a continuous pattern from rung to rung except where interrupted by a rest

platform, diagonal braces can be stepped up/down 1 rung.

These changes do not compromise the towers structural integrity.

WORK HEIGHT 3.41m 3.88m 4.34m 4.81m 5.27m 5.73m 6.20m 6.66m 7.13m 7.59m 8.05m 8.52m 8.98m 9.45m 9.91m

OVERALL TOWER

HEIGHT 2.66m 3.13m 3.59m 4.06m 4.53m 4.98m 5.45m 5.91m 6.38m 6.84m 7.30m 7.77m 8.23m 8.70m 9.16m

PLATFORM HEIGHT 1.41m 1.88m 2.34m 2.81m 3.27m 3.73m 4.20m 4.66m 5.13m 5.59m 6.05m 6.52m 6.98m 7.45m 7.91m

PARTS LIST

CASTOR 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

ADJUSTABLE LEG 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

3 RUNG FRAME 2 1 2 1 2 1 2 1

3 RUNG LADDER FRAME 2 1 2 1 2 1 2 1

4 RUNG FRAME 1 2 1 1 2 3 2 2 3 4 3 3 4

4 RUNG LADDER FRAME 1 2 1 1 2 3 2 2 3 4 3 3 4

5 RUNG FRAME 1 1 1 1

5 RUNG LADDER FRAME 1 1 1 1

DIAGONAL BRACE 2 2 3 3 4 4 5 5 6 6 7 7 8 8 9

HORIZONTAL BRACE 6 6 6 10 10 10 10 10 10 10 14 14 14 14 14

TRAPDOOR PLATFORM 1 1 2 2 2 2 2 2 2 2 3 3 3 3 3

STANDARD STABILIZER 4 4 4 4 4 4 4

TELESCOPIC STABILIZER 4 4 4 4 4 4 4

TOEBOARD ASSEMBLY 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

TOWER WEIGHT (Kgs)

2.5m WEIGHT 82 104 127 139 145 151 157 160 172 178 210 214 219 225 231

GS PRODUCT APPROVAL

TO BS.EN.1004 3 8/12 XXD

INSTRUCTIONS FOR USE TO

BE FOLLOWED CAREFULLY

NEVER CLIMB SCAFFOLD ON

THE OUTSIDE OF THE FRAME

MANUFACTURED BY EURO TOWERS LTD

Horizontal Brace

Black / Green / Yellow

End Toeboard

Trapdoor Platform

Side Toeboard

Plain Frame

3, 4 or 5 Rung

Diagonal Brace

White / Green / Yellow

Castor / Adjustable Leg

Ladder Frame

Stabilizer

MAX SAFE WORKING LOAD FOR STRUCTURE 750KG

MAX SAFE WORKING LOAD FOR PLATFORM 250KG

Produced by Pollards. Tel: 01392 445333 www.pollardsprint.co.uk B.0013.051 11/17

11, 12 Manchester Way

Dagenham

RM10 8PN

V.A.T. Reg’n No. 232 1741 01 Company Reg’n No. 1011913 England

t. 020 8525 8686

e. sales@bentsplant.co.uk

www.bentsplant.co.uk

11, 12 Manchester Way

Dagerham

RM10 8PN

t. 020 8535 8686

www.bentsplant.co.uk

11, 12 Manchester Way

Dagenham

RM10 8PN

V.A.T. Reg’n No. 232 1741 01 Company Reg’n No. 1011913 England

t. 020 8525 8686

e. sales@bentsplant.co.uk

www.bentsplant.co.uk

KLIK SINGLE WIDTH LADDER FRAME ERECTION INSTRUCTION MANUAL

APR/15

The tower requires a minimum of 2 people for assembly; do not attempt to assemble a tower by yourself

Facing the ladder frame, fit a trapdoor platform on

appropriate rung* inside the brace hook as near to

the ladder as possible (*see base set up Fig 1 for

guide).

Facing the plain frame, fit a trapdoor platform on

appropriate rung* over the brace hook as near to the

frame vertical as possible, trapdoor to ladder frame

end (*see base set up Fig 1 for guide).

Insert two adjustable legs and castors into frames.

Fit in 2 horizontal braces to the vertical member of

the frames, as low as possible, below the 1st rung.

All horizontal braces fit on from inside the tower

facing out.

Facing the plain frame fit 1 diagonal to the bottom

rung as close to the right hand frame vertical as

possible. Facing the ladder frame fit 1 diagonal to

the bottom rung as close to the ladder as

possible.

From a sitting position through the trapdoor (3T) fit four

horizontal braces to the frame verticals above the

rungs pushing from inside to out.

Secure stabilizers as soon as possible to increase

tower stability, the lower arm as close to horizontal

as possible.

To add frames, stand on platform and offer frame up

to the spigots ensuring ladder runs continuously.

After adding frames, engage interlock clips.

Facing the plain frame fit 1 diagonal to the rung next to

the platform* as close to the right hand frame vertical as

possible. Facing the ladder frame fit 1 diagonal starting

2 rungs above the platform as close to the right hand

ladder as possible. (*see Brace Patterns for guide)

From a sitting position through the trapdoor (3T) fit

four horizontal braces to the frame verticals above

the rungs pushing from inside to out.

Fit Toeboard’s in the correct position.

Dismantling is the reverse of assembly except to

remove guardrail braces. Unclip the far end hooks and

then from a sitting position through the trapdoor (3T)

remove the guardrail braces. Do not remove the

handrails whilst standing on the platform; this would

put you at risk.

Lock castors and level tower.

PLEASE NOTE - If temporary platforms are used during

assembly reposition them during dismantling. Single

width towers have 2 braces at the base and singular

thereafter on alternate sides.

Continue erecting tower to final tower height, repeating

steps 8-12.

MOVING A TOWER Remove people and materials from

the tower, and reduce the height of the tower to 4.2m.

Adjust and raise the stabilizers 25mm from the ground,

ensure the couplers are tight, and push from at or near

the base by manual effort only, never use mechanical

means. Recheck level and reposition stabilizers before

use.

Castor Unlocked

Castor Locked, note

castor wheel has

swivelled in line

Popular Ladder manuals by other brands

Best Choice Products

Best Choice Products SKY3139 instruction manual

Tripp Lite

Tripp Lite SmartRack SRCABLELADDER18 owner's manual

avenli

avenli LD-24-CZ user manual

GIERRE

GIERRE Multipla AL900 Operating and maintenance instructions

SPORTNOW

SPORTNOW A00-018V00 Assembly instructions

WENKO

WENKO 601010100A Instructions for use