See Drawing 24804 Page 8

1. Fit the Raised Platform to the stair set and truck per Views 1 & 2. The Raised

Platform bolts to the main cabin landing on one side and is supported through

isolators from the radiator enclosure on the other side. Weld the Landing Isolator

Bracket components per Detail 1.1 - the Back to the radiator enclosure and the

Cleat to the Back - in such a position as to make the Platform level and parallel to

the radiator enclosure. Do not burn the rubber isolators while welding.

2. Attach the Flooring Extension to the Raised Walkway as shown in Views 3 & 4, so

it can be folded over towards the engine hood to present a trafficable surface level

with the raised platform or stowed away on top of the raised walkway. Pg4

CAT773D 19-12-12

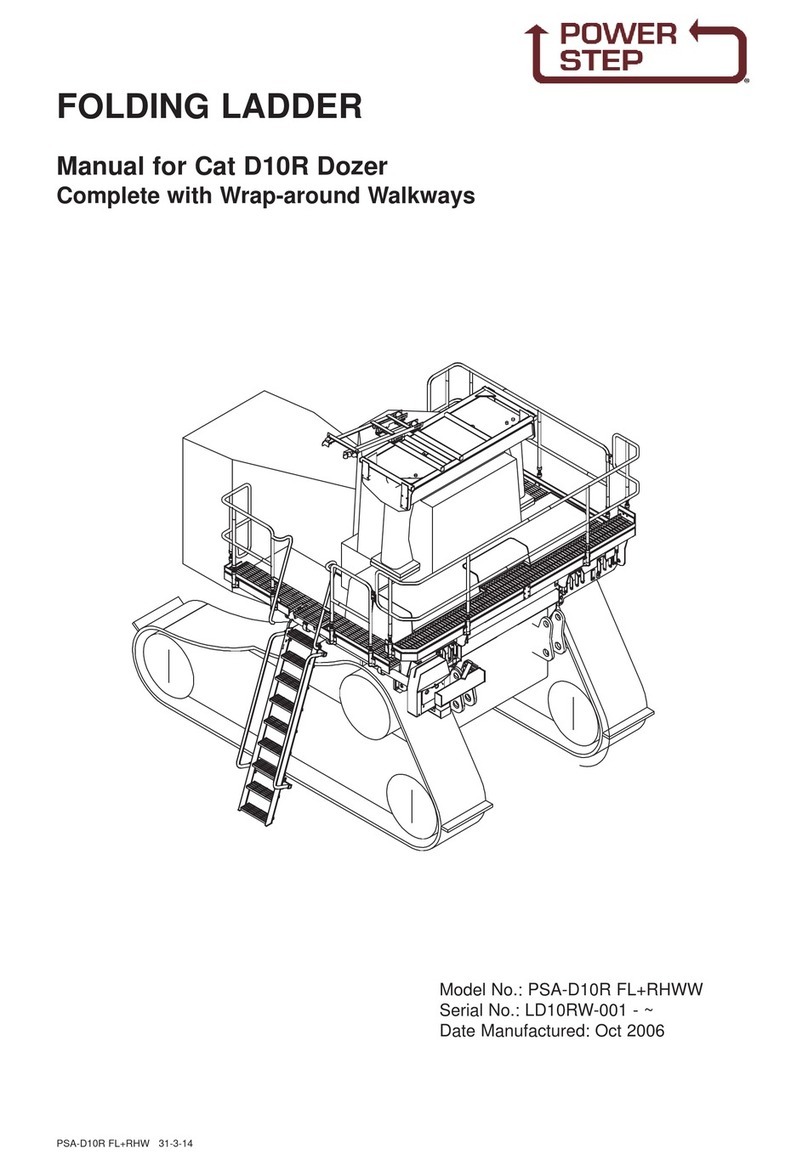

FOLDING STAIRWAY

Caterpillar 773D Truck

Section 1 Installation Instruction Drawings PS-24802/3/4

Front Bolting Pad

PROCEDURE

See Drawing 24802 Page 5

1. Mount and weld the Front Bolting Pad and Mounting Gussets to the front bumper,

located per View 1.2. Weld per Detail 3 - Preliminary Welding.

Note that this preliminary welding is required to temporarily support the stair during

early stages of the installation procedure. The welding must be upgraded to its'

final specification later in the installation.

2. Check that the dimension shown in Views 1.1 & 1.3, (the distance between the

alignments of the Return Edge of the cabin landing and the face of the Front Bolting

Pad) is measures 130 +/- 10 on the truck. If it does not measure 130 +/- 10, contact

Power Step - some rectification will be required.

3. Check that the dimension shown in View 1.2, (the distance between the alignments

of the face of the cabin landing frame where the stair fits and the end face of the

front bumper) measures 125 +/- 10 on the truck. If it does not measure 125 +/- 10,

contact Power Step - some rectification will be required.

See Drawing 24803 Page 6

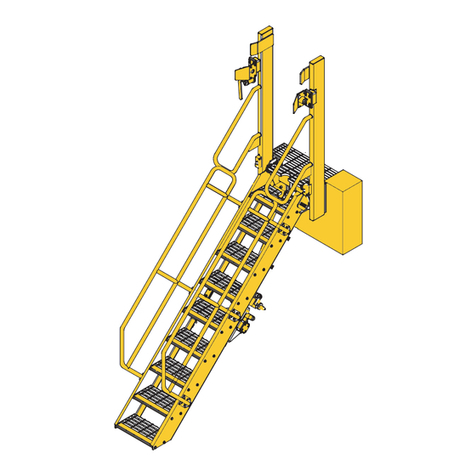

1. Fit the Stair Assembly (24 390) to the Front Bolting Pad per

View 1 Stair Installation and to the Landing per View 2.0 Stair/Landing Connection

and Detail 2.1 Isolators

2. Bolt the Support Plate underneath the top of the stair per View 3.0.

Locate the end Bolting Pad against the end of the bumper per Detail 3.1

and tack weld in place.

3. Fully weld the bolting pads to the bumper per Drg 24 389

NOTE

Follow all on-site/Mine lifting and safety procedures when installing

Power Step Landings to Truck.