BOSSCO 950 User manual

Summary

Content

1. SECURITY INSTRUCTIONS FOR YOUR SAFETY AND THE GOOD USE OF PUMP

a) SAFETY..............................................................................................2

b) PUMP ENVIRONMENT.....................................................................2

c) ELECTRICSAFETY….......................................................................3

d) PERSONAL SAFETY.........................................................................3

2. GETTING STARTED...................................................................................4

3. WORKING PRINCIPLES & TECHNICAL SPECIFICATIONS.....................4

4. ACCESSORIES……...................................................................................5

5. USE AND DESTINATION OF THE PUMP….…..........................................5

6. CARE & MAINTENANCE............................................................................5

7. TROUBLESHOOTING................................................................................6

8. CERTIFICATE OF CONFORMITY.……......................................................7

9. GUARANTEE..............................................................................................7

1. SAFETY INSTRUCTIONS FOR YOUR SAFETY AND THE GOOD USE OF THE PUMP

a) SAFETY

This equipment is NOT suitable for drinking water.

Unplug the equipment from the mains before any intervention.

When the pump is running, there must be no particles in the water (clean water only).

Do not use the pump if safety devices are damaged or depleted. Never deactivate safety devices.

The pump must be used with 230V AC Power supply, as indicated on the rating plate.

Do not use the power cable for carrying the pump or for unplugging.

Make sure that electric connections are protected from humidity.

Avoid dry-running of the pump. Never use the pump if the suction hose is obstructed.

It is strictly prohibited to pump corrosive, easily combustible, aggressive or explosive liquids (such as

gasoline, petroleum or nitro thinner), saltwater and food

The temperature of the liquid must not exceed 35°C.

b) PUMP ENVIRONMENT

Do not operate pumps in explosive atmospheres, such as in the presence of flammable liquids,

gases or dust.

Keep children and unqualified persons away from the pump when it is in use

Version 1.0

BOSS™, ASHCROFT WAY, CROSS POINT BUSINESS PARK, COVENTRY, GB, CV2 2TU Created on: 04 July 2023

c) ELECTRIC SAFETY

The pump cable plug must match the socket. Never modify the plug in any way. Do not use any

adapter plugs. Unmodified plugs and matching sockets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces.

Do not abuse the electrical cord. Never use the cord for carrying, pulling or unplugging the pump.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase

the risk of electric shock.

When operating a pump outdoors, use an extension cord suitable for outdoor use.

The pump is equipped with a socket compatible with it. The power source of your country must be in

keeping with international regulations.

d) PERSONAL SAFETY

Risk of injury due to hot water. If the pump runs for an extended period when the outlet is closed,

the water in the pump can become heated so that hot water can emerge from the outlet and cause

injuries.

Stay alert, watch what you are doing and use common sense when operating a pump.

Maintain your pump. If the pump is damaged, ensure repair by a specialist before further use.

Follow these instructions to use the pump, its accessories, connectors, etc… properly. The pump

must be used only for its prescribed purpose. Any use other than those mentioned in this Manual will

be considered a case of misuse.

SYMBOL

The pump must be disposed of in accordance with local environmental regulations.

Read the instructions before use

To be checked before you start

BOSS™ 650 and BOSSTM 950 Sump Pumps have been designed to suck clear water only.

Pumps have been designed to suck clear water or dirty water with particles (max particle sizes apply)

The pump must be installed on a flat and solid surface wherever possible.

2. GETTING STARTED

1. Connect a discharge pipe with a diameter at least equal to the diameter of the pump outlet

2. Immerse the pump in the liquid to be sucked, by making an angle of 45 degrees (to reduce the

amount of air trapped in the pump body). If the pump rests on the bottom, make sure it is on a flat and

stable surface.

3. Make sure that all persons are clear of the liquid to be pumped

4. Plug the pump to the mains

Version 1.0

BOSS™, ASHCROFT WAY, CROSS POINT BUSINESS PARK, COVENTRY, GB, CV2 2TU Created on: 04 July 2023

3.WORKING PRINCIPLES & TECHNICAL SPECIFICATIONS

Model

BOSS™ 650

BOSS™ 950

Float Switch

Float Switch

ON level

550mm

530mm

OFF level

200mm

190mm

Power

650W

950W

230V 50HZ

230V 50HZ

Flow

12500 l/h

13000 l/h

Head

7.5m

9m

Max. Particle

15mm

3mm

Max.Submersible depth

7m

7m

Outlet

G1 - ¼”

G1 - ½”

Cable length

9.8m

10m

Working Model

Version with float switch

The pump has a loose float which

start and stop the pump

automatically, depending on the

water level

Version with float switch

The pump has a loose float which start and

stop the pump automatically, depending on

the water level

4. ACCESSORIES

- Hose adapter :1 pc

5. USE AND DESTINATION OF THE PUMP

Your pump is designed to remove or transfer clean water

Your pump must not be used in following situations:

- Water temperature to be sucked greater than 35°C

- Continuous run

- Drinking water supply or washing machines for dishes supply

- Corrosive, easily combustible, aggressive or explosive liquids (such as gasoline, petroleum or

thinners), saltwater, oils and greases must not be pumped

- Permanent submersion under 3 metres or more water

6. CARE & MAINTENANCE

- In case of temporary installation, the pump must be cleaned up with clear water after use.

- In case of permanent installation, it is necessary to check every 3 months that the start mechanism is

working properly (float switch)

- Regularly remove dirt that may accumulate in the sump.

- Do not expose to frost.

- Avoid dry running.

- Do not abuse the electrical cord. Never use the cord for carrying, pulling or unplugging the pump.

- Clean the pump regularly if aspirated liquid causes sediments.

- Avoid shocks, do not let the pump fall.

Version 1.0

BOSS™, ASHCROFT WAY, CROSS POINT BUSINESS PARK, COVENTRY, GB, CV2 2TU Created on: 04 July 2023

7. TROUBLESHOOTING

Trouble

Check

Should do

The pump motor does not

start and does not make

noise.

Is the pump plugged in?

Is the pump float switch in

the start position when fully

submerged?

Check your electrical

installation.

Check that the float can

move freely.

Pump does not discharge.

Does the impeller rotate?

Is it in good condition?

Is the pump inlet free?

Does the delivery head

exceed the capability of the

pump discharges?

Eliminate the reason for

blocking

Replace the impeller

Clean the pump inlet.

Use the pump in accordance

with its technical capabilities.

Increase the pipe diameter.

The pump stops suddenly

Is there a sufficient water

level to suck?

Did the pump run for a

long time without

stopping?

Check inlet is not

obstructed?

Do the power of the mains

match the rating plate?

Is the temperature of the

liquid less than 35°C?

Disconnect the pump from

the mains and let it cool.

Clean the pump inlet

Use a power supply matching

the rating plate.

Observe the maximum

allowable temperature

Flow decreases

Is the pump inlet clean?

Is the impeller clean?

The discharge pipe is not

partially clogged?

Clean the area or areas in

question (s)

Low flow or insufficient

Are you sure that the pump inlet

is not obstructed?

Is the impeller clean?

Are you sure that the outlet pipe

is not obstructed?

Is the diameter of the discharge

pipe enough?

Clean the zone (s) concerned

and verify check valve, if

applicable

Connect a pipe with a suitable

diameter and suppress reduction

of the water passage.

Version 1.0

BOSS™, ASHCROFT WAY, CROSS POINT BUSINESS PARK, COVENTRY, GB, CV2 2TU Created on: 04 July 2023

8. CERTIFICATE OF CONFORMITY

Declares that following pumps:

BOSSTM 650

BOSS™ 950

Comply with the following directives

LVD Directive: 2014/35/EU

EMC Directive: 2014/30/EU

Directive ROHS 2011/65/EU

Tests executed in accordance with following regulations:

EN55014-1: 2006+A1+A2

EN55014-2: 1997+A1+A2

EN60335-1: 2012+A11+A13

EN60335-2-41 : 2003+A1+A2

EN61000-3-2: 2006+A1+A2

EN61000-3-3: 2013

9. GUARANTEE

This pump is guaranteed for 1 year from the date of purchase.

Conditions of validity of the warranty: The unit must always be handled properly according to the

instructions of this manual. The unit must not have been modified and only repaired by a suitable

specialist.

Warranty no longer applies in the following cases:

- Non-compliance with the instructions (especially non-protection against freezing, pumping sand, dry

running, incorrect electrical connection ...)

- Attempting to repair the pump

- Changes in the technical elements of the pump

- Use of replacement parts

- Damage / malicious (fall or dents on the unit).

- Inappropriate use, and in particular passage of hard and heavy particles (stones), passage of an

excessive amount of sand, salt water, water with high lime content ...

- Lack of maintenance or cleaning

Parts not covered by the warranty (if these parts are supplied with the pump)

Rope suspension, fitting.

A repair or exchange with a new product during the warranty period does not extend the original

warranty period.

Version 1.0

BOSS™, ASHCROFT WAY, CROSS POINT BUSINESS PARK, COVENTRY, GB, CV2 2TU Created on: 04 July 2023

Other manuals for 950

1

This manual suits for next models

1

Table of contents

Other BOSSCO Water Pump manuals

Popular Water Pump manuals by other brands

DAB

DAB E.SYBOX MINI 3 Instruction for installation and maintenance

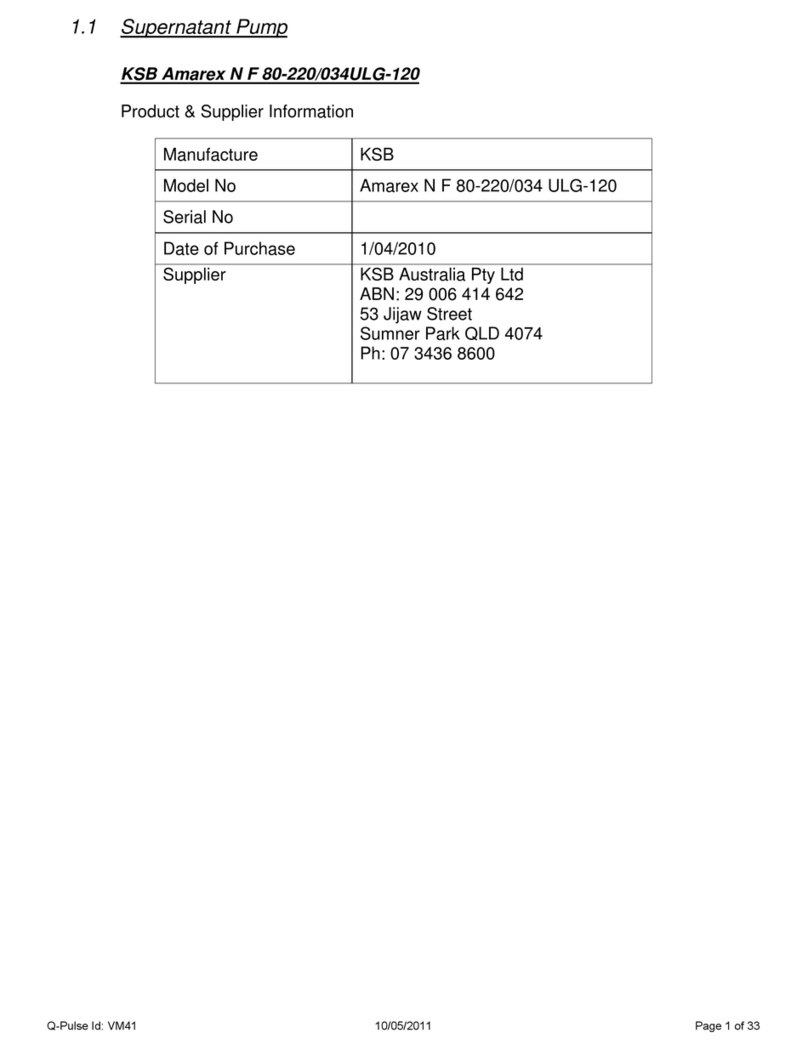

KSB

KSB Amarex N F 80-220/034U LG-120 manual

ITC

ITC DOSmart AC S50-D50 manual

caprari

caprari K Series Use and maintenance instructions

Dover

Dover PSG Wilden GP Series Engineering, operation & maintenance

Homa

Homa Sensoflat C 270 WF Original instruction manual

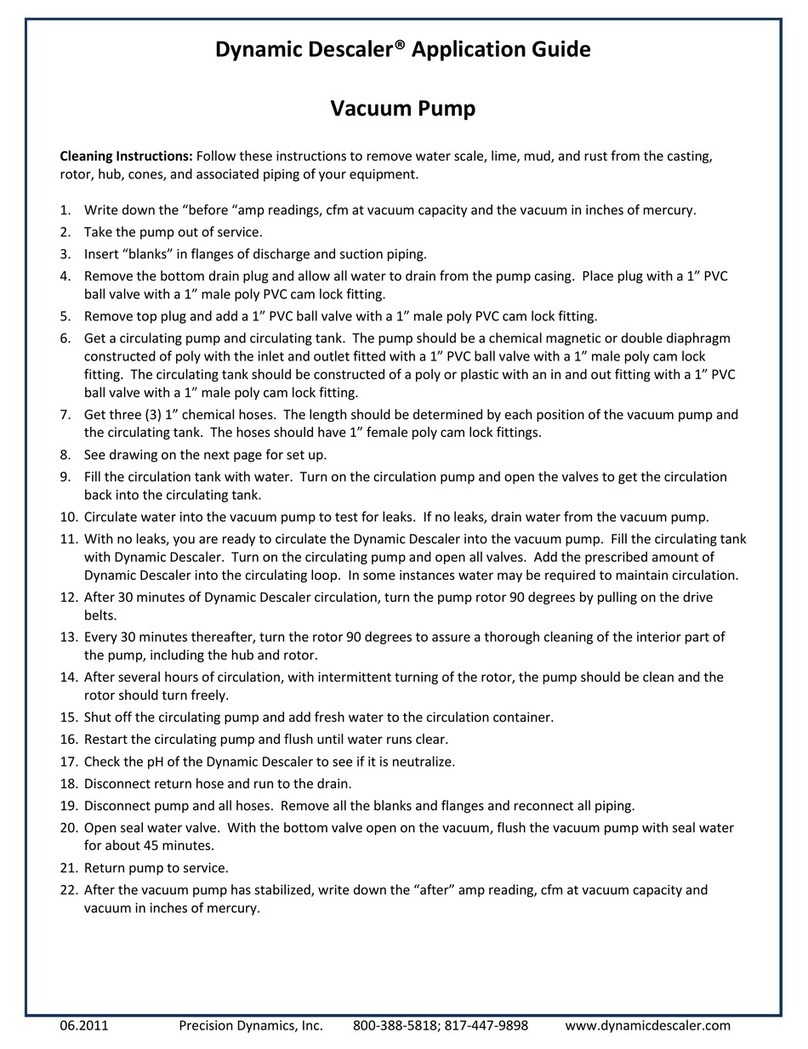

Precision Dynamics

Precision Dynamics Dynamic Descaler Application guide

AirTech

AirTech 3AV95 Repair instructions

Ryobi

Ryobi RY20WP18BTL Operator's manual

Wilo

Wilo Star-Z NOVA T Installation and operating instructions

Gardena

Gardena PTU 3000/4 Operator's manual

EINHELL

EINHELL GE-PP 18 RB Li Original operating instructions