Toro Sand Pro 3040 User manual

FormNo.3457-815RevA

QASBunkerPump

SandPro®/IneldPro®3040and5040

TractionUnit

ModelNo.08765—SerialNo.315000001andUp

ModelNo.08765—SerialNo.316000001andUp

ModelNo.08765—SerialNo.400000000andUp

ModelNo.08765—SerialNo.405560000andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3457-815*

ThebunkerpumpismountedtoaSandPromachine

andisintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Itisprimarily

designedtopumpwateroutofsandtraps.

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g008126

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

BeforeOperating................................................3

WhileOperating..................................................3

Maintenance.......................................................4

SafetyandInstructionalDecals..........................5

Setup........................................................................6

1MountingtheBunkerPumptotheTraction

Unit.................................................................6

2AdjustingtheLinkAssembly............................7

©2022—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Operation..................................................................8

AdjustingtheDischargeNozzle..........................8

BeforeOperating................................................8

OperatingtheBunkerPump...............................9

OperatingTips....................................................9

Maintenance............................................................11

PumpCleaning..................................................11

Safety

Hazardcontrolandaccidentpreventionare

dependentupontheawareness,concern,and

propertrainingofthepersonnelinvolvedinthe

operation,transport,maintenance,andstorageof

themachine.Improperuseormaintenanceofthe

machinecanresultininjuryordeath.Toreduce

thepotentialforinjuryordeath,complywiththe

followingsafetyinstructions.

BeforeOperating

•Readandunderstandthecontentsofthis

Operator’sManualandtheSandProOperator’s

Manualbeforeoperatingthemachine.Become

familiarwithallofthecontrolsandknowhowto

stopquickly.

•Neverallowchildrentooperatethemachine.Do

notallowadultstooperatemachinewithoutproper

instruction.Onlytrainedoperatorswhohaveread

thismanualshouldoperatethismachine.

•Neveroperatethemachinewhenunderthe

inuenceofdrugsoralcohol.

•Keepallbystandersawayfromtheoperatingarea.

•Keepallshieldsandsafetydevicesinplace.If

ashield,safetydevice,ordecalisillegibleor

damaged,repairorreplaceitbeforeoperationis

commenced.Alsotightenanyloosenuts,bolts,

andscrewstoensurethatthemachineisinsafe

operatingcondition.

•Donotoperatethemachinewhilewearing

sandals,tennisshoes,sneakers,orshorts.Also,

donotwearloosettingclothingwhichcouldget

caughtinmovingparts.Alwayswearlongpants

andsubstantial,slip-resistantfootwear.Wearing

safetyglasses,safetyshoes,andahelmetis

advisableandrequiredbysomelocalordinances

andinsuranceregulations.

WhileOperating

•Donotoperatetheengineinaconnedspace

wheredangerouscarbonmonoxideandother

exhaustgassescancollect.

•Themaximumseatingcapacityisoneperson.

Nevercarrypassengers.

•Sitontheseatwhenstartingtheengineand

operatingthemachine.

•Usingthemachinedemandsattention.T oprevent

lossofcontrol:

–Operateonlyindaylightorwhenthereisgood

articiallight.

–Driveslowlyandwatchforholesorother

hiddenhazards.

3

–Useextremecautionwhendrivingintoasand

trap,ditch,creek,orotherhazard.

–Reduceyourspeedwhenmakingsharpturns

andwhenturningonhillsides.

–Avoidsuddenstartsandstops.

–Beforebackingup,looktotherearandensure

thatnooneisbehindthemachine.

–Watchoutfortrafcwhennearorcrossing

roads.Alwaysyieldtheright-of-way.

•Stayawayfromthedischargeopeningwhen

themachineisoperating.Keepallbystanders

awayfromthedischargeopeninganddon’tdirect

dischargetowardbystanders.

•Iftheenginestallsorthemachinelosesheadway

andcannotmakeittothetopofaslope,donot

turnthemachinearound.Alwaysbackslowly

straightdowntheslope.

•Donottakeaninjuryrisk!Whenapersonor

petappearsunexpectedlyinorneartheoperating

area,stopoperation.Carelessoperation,

combinedwithterrainangles,ricochets,or

improperlypositionedguardscanleadtothrown

objectinjuries.Donotresumeoperationuntilthe

areaiscleared.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Donottouchtheengineormuferwhiletheengine

isrunningorsoonafteritisstopped.Theseareas

couldbehotenoughtocauseaburn.

Maintenance

•Removethekeyfromtheignitionswitchtoprevent

accidentalstartingoftheenginewhenservicing,

adjusting,orstoringthemachine.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

AuthorizedT oroDistributor.

•Toreduceapotentialrehazard,keeptheengine

freeofexcessivegrease,grass,leaves,and

accumulationsofdirt.Neverwashawarmengine

oranyelectricalpartswithwater.

•Besurethatthemachineisinsafeoperating

conditionbykeepingnuts,bolts,andscrewstight.

•Makesurethatallhydrauliclineconnectorsare

tightandallhydraulichosesandlinesareingood

conditionbeforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksinhydrauliclinesthatejecthighpressure

hydraulicuid.Usecardboardorpapertond

hydraulicleaks.Hydraulicuidescapingunder

pressurecanpenetrateskinandcauseinjury.

Fluidaccidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursbyadoctor

familiarwiththisformofinjuryorgangrenemay

result.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystem

mustberelievedbystoppingtheengineand

loweringthepumptotheground.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,

clothing,andotherpartsofthebodyawayfrom

thefanandothermovingparts.

•Donotoverspeedtheenginebychangingthe

governorsettings.Tobesureofsafetyand

accuracy,haveanAuthorizedT oroDistributor

checkthemaximumenginespeedwitha

tachometer.

•Theenginemustbeshutoffbeforecheckingthe

oiloraddingoiltothecrankcase.

•Toensureoptimumperformanceandsafety,

alwayspurchasegenuineTororeplacementparts

andaccessoriestokeepthemachineallT oro.

Neveruse“will-t”replacementpartsand

accessoriesmadebyothermanufacturers.

LookfortheT orologotoensuregenuineness.

Usingunapprovedreplacementpartsand

accessoriescouldvoidthewarranty.

4

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

decal106-5517

106-5517

1.Warning–DoNottouchthehotsurface.

5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Bunkerpumpassembly1Mountthebunkerpumptothetraction

unit.

2Nopartsrequired–Adjustthelinkassembly.

MediaandAdditionalParts

DescriptionQty.Use

Partscatalog1Usetoreferencepartnumbers

Operator'sManual1Readbeforeoperatingthemachine

Certicateofconformity1Declarationofconformity

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Note:Tooperatethebunkerpump,thetractionunit

mustbeequippedwiththeRearRemoteHydraulics

Kit,Model08781ortheFrontRemoteHydraulicsKit,

Model08782.

1

MountingtheBunkerPump

totheTractionUnit

Partsneededforthisprocedure:

1Bunkerpumpassembly

Procedure

1.Removeanyattachmentfromthemachines

adapter.

2.Movethemachineintopositionbehindthe

attachmentadapter.

Note:Makesurethelockinglever(Figure3)is

pivotedtotheleft(unlockedposition)asviewed

fromtherearofthemachine.

g008164

Figure3

1.Attachmentadapter2.Lockinglever

3.Raisethemachineadapterintotheattachment

adapter.

4.Pivotthelockinglevertotherighttolockthe

adapterstogether.

5.Makesuretheengineandtheremotehydraulics

kitareOFF .

6.PlugthehydraulichosesintotheSandPro

machineremotehydraulics.Positionthehoses

inthehoseguide(Figure4).Avoidkinksand

sharpbendstothehydraulichoses.

6

g008127

Figure4

1.Hoseguide

Important:Wheneverthehydraulichose

couplersaredisconnected,makesure

thedustplugsareinstalledtoprevent

contaminationfromenteringeitherhydraulic

system.

7.Duringoperationthebunkerpumphydraulic

hoseswilldisplaceasmallamountofthe

machine'shydraulicoil.Checkthehydraulicoil

levelinthemachineasfollows:

A.Startthemachineengineandtheremote

hydraulics.

B.Startthebunkerpumpandallowittorun

afewseconds.Itdoesnothavetobe

submergedinwater.

C.Stopthepump,theremotehydraulicsand

theengine.

D.Checkthehydraulicoillevelinthemachine

andreplenishasrequired.Referto

machineOperator'sManualforhydraulicoil

requirements.

2

AdjustingtheLink

Assembly

NoPartsRequired

Procedure

1.Withthebunkerpumpmountedandsecuredon

themachine,raisetheattachment.

2.Measurethegapbetweenthetopwasher

andthespacerinthelinkassemblyonthe

attachmentadapterasshowninFigure5.

Note:Ensurethegapbetweenthewasherand

theshoulderisbetween1.52to2.03mm(0.060

to0.080inch).

g008163

Figure5

1.1.52to2.03mm(0.060to

0.080inch)

3.Adjustmentnut

2.Jamnut

7

Operation

AdjustingtheDischarge

Nozzle

Thedischargenozzle(Figure6)canbeadjustedup

anddownorfromsidetosidetodirecttheowtothe

desiredlocation.

1.Toadjusttheowdistance,proceedasfollows

•Rotatethelockuphandle(Figure6)tounlock

thepivottower.

g008121

Figure6

1.Lockuphandle2.Dischargenozzle

•Rotatethepivottowerfrontorbacktothe

desiredposition.

•Tightenthelockuphandle.

Note:Whenthepumpismountedtothe

frontofthemachine,thelockuphandle

shouldberemovedandreinstalledonthe

oppositesideoftheframe.

CAUTION

Donotmovethelockuphandletothe

oppositesideoftheframewhenthe

pumpismountedtotherearofthe

machine.

2.Toadjusttheowdirection,rotatethenozzle

handle(Figure7)tothedesiredposition.

Note:Theresistanceonthehandlenozzle

(Figure7)maybeincreasedordecreasedby

adjustingthetorqueonthelargenutontopof

thepivottower.

g008120

Figure7

1.Nozzlehandle

BeforeOperating

1.Measurethewaterdepthinthelowestpartof

thebunker.Ifthewaterdepthislessthan63.5

mm(2–1/2inches)(halfwayuptheslotsonthe

pump),diga30.5cmx30.5cmx5to7.6cm(1

ftx1ftx2to3inches)deepholetolowerthe

pumpintothehole(Figure8).

g008139

Figure8

1.Waterlevel(63.5cm(2-1/2inches))

2.Makesurethepumpclamp(Figure9)andthe

lockuphandle(Figure10)aresecurebefore

commencingoperation.

8

g008122

Figure9

1.Pumpclamp

g008121

Figure10

1.Lockuphandle2.Dischargenozzle

3.Checkandadjustthepumpdischargedirection.

RefertoAdjustingtheDischargeNozzle.

OperatingtheBunkerPump

1.StarttheSandPromachineandslowlybackinto

theshallowestpartofthebunker.Donotdrive

intowaterthatisdeeperthanthewheelhubsof

theSandPromachine(Figure11).

g008236

Figure11

Note:IftheSandPromachinecannotbe

movedintothedesiredposition,thepumpcan

beremovedfromthehousingandplacedinto

thewater.Toremovethepump,pivotthepump

clampforward,slidethepumptotherearofthe

frameandliftthepumpoutwiththehandle.

2.Starttheremotehydraulicstoactivatethepump

beforeinsertingthepumpintothewater.This

preventsdebrisfromstallingthepumpimpeller

tothehousingifdebrisgetslodgedinthepump.

3.Lowerthepumpintothewater.

Note:Ifthepumpdoesnotstartpumpingonce

itisinthewater,cycletheremotehydraulicson

for1secondandofffor2secondstohelpthe

pumpprime.

4.Checktheowandredirectasrequired.

OperatingTips

WARNING

Dischargedoutputhasconsiderableforce

andcouldcauseinjuryorlossoffooting.

•Stayawayfromdischargenozzlewhen

machineisoperating.

•Keepbystandersawayfromdischarge

nozzlewhenmachineisrunning.

•Makesurenozzlecollarisfreeofdebrissoit

drainsproperly.

•Donotusethebunkerpumpinsaltwater.

9

Maintenance

PumpCleaning

Ifforeignmattergetsintothebunkerpump,theow

maydecreaseorstop.Ifthisoccurs,thepumpwill

havetoberemovedfromtheframe,disassembled,

cleaned,reassembledandinstalledbackintothe

frame.

1.StoptheSandPromachine,applytheparking

brakeandremovethekeyfromtheignition

switch.

2.Disconnectthepumphydraulichosesfromthe

machine.Insertdustcapsontotheexposed

hydrauliccouplers.

3.Releasethelatchesanduncouplethedischarge

hosefromthepump(Figure13).

g008123

Figure13

1.Dischargehose2.Latch

4.Pivotthepumpclampforward(Figure14).

g008122

Figure14

1.Pumpclamp

5.Slidethepumptotherearoftheframeandlift

thepumpoutwiththehandle.

Disassembly(Figure15)

6.Removethe(5)coverplatemountingscrews

andremovethecover.

7.Trytoturntheimpellertofreeanydebrisfrom

thepumpimpellerandhousing.Ifthedebris

cannotbefreed,proceedtothenextstep.

8.Removethe(3)screwssecuringthesuction

angeandremovethesuctionange.

9.Removethe(2)handlescrewsandremovethe

handle.

10.Removethe(4)hydraulicmotorscrewsand

removethehydraulicmotorcover,gerotor

elementwithdrivepin,andthethrustplate.

11.Whileholdingtheimpeller,unthreadtheimpeller

fromtheshaftusingawrenchontheatsatthe

ballbearing.Thethreadisalefthandthread

thatrequiresoppositerotationforremoval.

12.Removetheshaftandbearingassemblybyrst

removingtheretainingring,thenapplypressure

toslidetheshaftandbearingoutofthemotor

sideofthepumphousing.

13.Removethe(2)lipsealsbypushingtheseals

outthroughthemotorsideofthepumpbody.

Inspectthepumpcomponents

•Cleanallforeignmaterialofftheparts.Donotuse

abrasivecleaningmethodsonthehydraulicparts

orshaft.

•Checkthemotorshaftforwearatthelipseal

surface.Ifithasgroovesgreaterthan0.076mm

(.003inches)deep,theshaftshouldbereplaced.

•Checkthehydraulicmotorpartsforwear.Any

appearanceofdisplacedmetalorsurface

11

smearingwillrequirereplacingallofthemotor

parts.

•Checktheimpellerbladesurfacebetweenthe

impellerandthesuctionange.Ifthesurfacesare

severelyworn,ortheimpellerbladesarebent,

replaceeachitem

•Cleanthepartsthataretobereusedusinga

solventormildcleaner.Removeabrasivematerial.

Cleanlinessofthehydraulicmotorpartsisvery

important.

g008138

Figure15

1.Coverplate3.Impeller5.Pumphousing7.Hydraulicmotor

2.Suctionange4.Shaft6.Thrustplate8.Handle

Reassembly(Figure15)

1.Pressthenewlipsealsintothepumphousing

usingasuitablebushingorsocket.Alight

lubricantmaybeusedtoaidtheassembly.The

properassemblyistoinstallthesealsbackto

back,installingonesealatatime.

2.Pressthenewballbearingontotheshaftby

pressingagainsttheinnerfaceofthebearing

untilitisseatedagainsttheshaftshoulder.The

rstlipsealshouldbeinstalledopenfacedown

andatsidefacingout.Thesecondlipseal

shouldbeinstalledatsidein.

3.Lubricatetheimpellersideoftheshaftwithoil.

Pushtheshaft/bearingintothebodyusingcare

toaligntheshaftatthecenterofthelipseal

untilitisatthebottomoftheshoulderinthe

body.Installthesnapringtosecuretheshaft

assembly.

12

4.Securetheshaftwithawrenchontheatsof

theshaftandthreadtheimpellerontotheshaft

(notelefthandthread).Tightentheimpelleruntil

itshouldersontotheshaft.

5.Placenewquadringsontothethrustplate.

Useasmallamountofgreasetoholdthequad

ringsfrommovingoutofposition.Placethe

thrustplateovertheshaftwiththekidneyslotup

awayfromthebearing.Kidneyshouldbeonthe

pressuresideofthemotor.

6.Placethedrivepinontotheshaftslotandhold

itinpositionwithascrewdriverwhileslidingthe

gerotorovertheshaftandstoppingatthethrust

plate.Lineupthegerotorandthrustplate.

7.Installthecoverontotheshaft;somesideways

movementofthegerotorisnecessary.The

dowelpinsshouldgothroughthethrustplate

andintothebody.Donotforcethisassemblyby

usingahammerorpress,itwillslidetogether

whenitisinposition.

8.Installthefourmotorcoverscrewsandtorque

to23.0N-m(17ft-lb)inacrosspatternwiththe

rsttorqueat13.6N-m(10ft-lb).

9.Installthesuctionangeandscrews.

10.Installthehandleandscrews.

11.Checkforfreerotationbyrotatingtheimpeller

byhand.Ifitdoesnotrotate,removethemotor

cover,cleanthemotorparts,andreassemble.

Dustanddirtgranuleswillimpedemotorrotation.

12.Installthecoverplateusingvescrewsand

lockwashers.

13.Insertthepumpintotheframeandslideit

forwarduntilthekeepertabtsintotheslotsof

thepump(Figure16).

g008124

Figure16

1.Keepertab

14.Pivotthepumpclamprearwardontothepump

(Figure14).

15.Couplethedischargehosetothepumpand

securethelatches(Figure13).

16.Connectthehydraulichosestothemachine.

CheckingtheNozzleSleeve

Thenozzlesleeve(Figure17)inthehandleassembly

isslottedtoallowwateranddebristodrainwithout

backowingintothehose.Makesuretheslotand

holearefreeofdebris.

g008125

Figure17

1.Nozzlesleeve3.Hole

2.Slot

GreasingtheAttachmentAdapter

Ifthelockingleverontheattachmentadapterdoes

notpivotfreelyandeasily,applyalightcoatofgrease

totheareashowninFigure18.

g008165

Figure18

13

Notes:

DeclarationofIncorporation

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionDirective

08765315000001andUp

QASBunkerPump,Sand

Pro/IneldPro3040and

5040TractionUnit

QASBUNKERPUMPBunkerPump2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

TomLangworthy

EngineeringDirector

8111LyndaleAve.South

Bloomington,MN55420,USA

September23,2022

UKDeclarationofIncorporation

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionRegulation

08765315000001andUp

QASBunkerPump,Sand

Pro/IneldPro3040and

5040TractionUnit

QASBUNKERPUMPBunkerPumpS.I.2008No.

1597

RelevanttechnicaldocumentationhasbeencompiledasrequiredperSchedule10ofS.I.2008No.1597.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Thisdeclarationhasbeenissuedunderthesoleresponsibilityofthemanufacturer.

TheobjectofthedeclarationisinconformitywithrelevantUKlegislation.

AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroU.K.Limited

SpellbrookLaneWest

Bishop'sStortford

CM234BU

UnitedKingdom

TomLangworthy

EngineeringDirector

8111LyndaleAve.South

Bloomington,MN55420,USA

September23,2022

InternationalDistributorList

Distributor:Country:PhoneNumber:Distributor:Country:Phone

Number:

AgrolancKftHungary3627539640MaquiverS.A.Colombia5712364079

BalamaPrimaEngineeringEquip.HongKong85221552163MaruyamaMfg.Co.Inc.Japan81332522285

B-RayCorporationKorea82325512076Mountelda.s.CzechRepublic420255704

220

CascoSalesCompanyPuertoRico7877888383Mountelda.s.Slovakia420255704

220

CeresS.A.CostaRica5062391138MunditolS.A.Argentina54114821

9999

CSSCTurfEquipment(pvt)Ltd.SriLanka94112746100NormaGardenRussia74954116120

CyrilJohnston&Co.NorthernIreland442890813121OslingerTurfEquipmentSAEcuador59342396970

CyrilJohnston&Co.RepublicofIreland442890813121OyHakoGroundandGarden

Ab

Finland35898700733

EquiverMexico525553995444ParklandProductsLtd.NewZealand6433493760

FemcoS.A.Guatemala5024423277PerfettoPoland48618208416

ForGarderOUEstonia3723846060PratoverdeSRL.Italy390499128

128

G.Y .K.CompanyLtd.Japan81726325861Prochaska&CieAustria4312785100

GeomechanikiofAthensGreece30109350054RTCohen2004Ltd.Israel97298617979

GolfinternationalTurizmTurkey902163365993RiversaSpain34952837500

GuandongGoldenStarChina862087651338LelyTurfcareDenmark4566109200

HakoGroundandGardenSweden4635100000SolvertS.A.S.France331308177

00

HakoGroundandGardenNorway4722907760SpyprosStavrinidesLimitedCyprus35722434131

HayterLimited(U.K.)UnitedKingdom441279723444SurgeSystemsIndiaLimitedIndia911292299901

HydroturfInt.CoDubaiUnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

HydroturfEgyptLLCEgypt2025194308T oroAustraliaAustralia61395807355

IrrimacPortugal351212388260ToroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India0091442449

4387

ValtechMorocco21253766

3636

JeanHeybroekb.v.Netherlands31306394611VictusEmakPoland48618238369

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(Toro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalTorocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIVACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.T oromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailat[email protected].

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

374-0269RevH

ToroGeneralCommercialProductWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:[email protected]

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.Toromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.374-0253RevC

Other manuals for Sand Pro 3040

8

This manual suits for next models

4

Table of contents

Popular Water Pump manuals by other brands

Graco

Graco saniforce 2150 Operation guide

GEA

GEA CA8 Series Operation manual and installation instructions

VARO

VARO POWERPLUS POWEW67915 manual

Parkside

Parkside PKA 20-Li B2 Translation of the original instructions

Ebsray

Ebsray RC SERIES Installation, operation & maintenance instructions

VERDER

VERDER VERDERAIR VA15 Instructions - parts

HEISSNER

HEISSNER FPU7200-00 Instructions for use

EINHELL

EINHELL GC-DP 7835 Original operating instructions

Graco

Graco ChemSafe 307 Instructions - parts

Walrus

Walrus TPR Series Replacing

DROPSA

DROPSA Mini-SUMO User Operating and Maintenance Manual

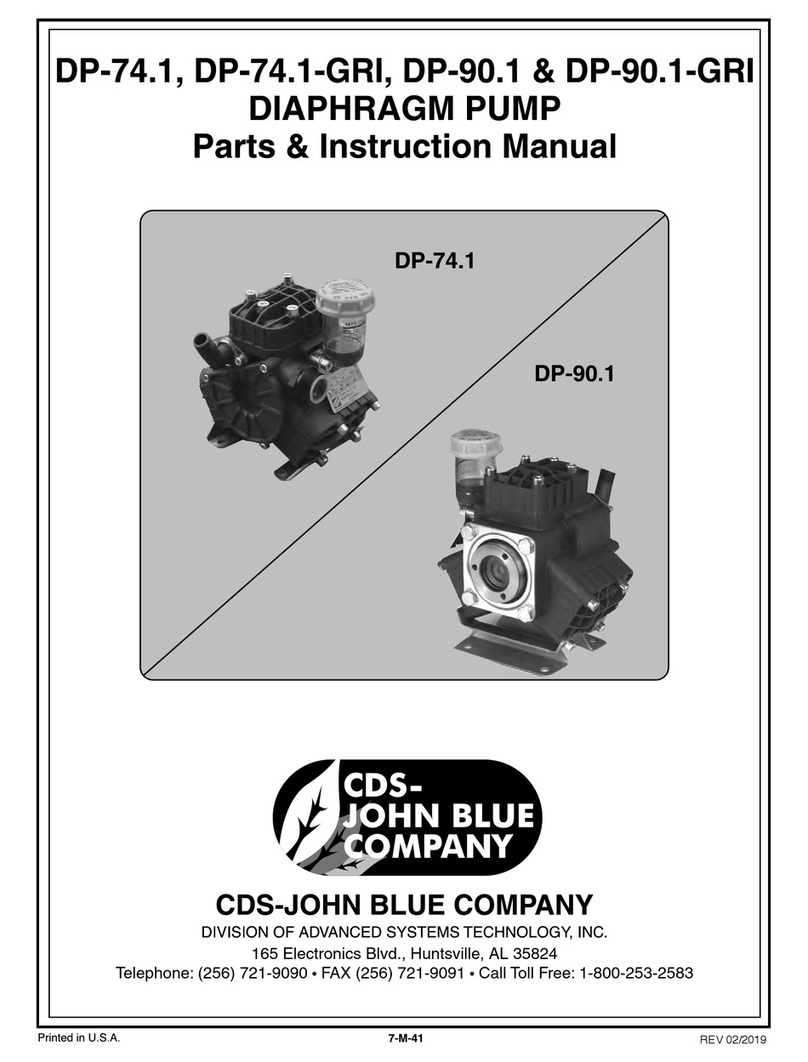

CDS-JOHN BLUE COMPANY

CDS-JOHN BLUE COMPANY DP-74.1 instruction manual