BOSSCO PHAH1000 User manual

Model No.: PHAH1000, PHAH1500 and PHAH2800

OPERATING INSTRUCTIONS

Hand Pumps- 1,000- 2,000 Bar

(10,000- 14,000 psi)

WARNING

Read and follow all Safety Instructions, Warnings, Cautions and

Important information provided in this manual before using the

equipment. They are provided for the safety of those operating the

equipment and to prevent personal injury and/or damage to property

when using this equipment.

THIS EQUIPMENT SHOULD ONLY BE USED BY OPERATORS

WHO HAVE BEEN TRAINED IN THE SAFE USE OF HIGH

PRESSURE HYDRAULIC EQUIPMENT

www.bosshydraulics.com.au

Form: BM003

BM003-V2

2

WARNING:

• Always wear the correct personal

protective equipment when

operating high pressure hydraulic

tools and equipment.

• Always stay clear of loads

supported by hydraulic systems,

the load must be secured

mechanically before work can

commence.

• Always keep your hands and feet

clear of the work activity during

operation to avoid personal injury.

• Never handle pressurised

hydraulic hoses. Escaping oil

under pressure can penetrate

the skin causing serious injury.

Contact a doctor immediately if

oil is injected under the skin.

• Never operate the system above

the maximum rated output

pressure.

• Never connect to the system

components, ttings, couplers,

hoses, valves etc. that are NOT

rated to the full system operating

pressure.

• Never exceed equipment ratings.

Never attempt to lift a load

greater than the capacity of the

cylinder. Overloading causes

equipment to fail and possible

personal injury or damage to

equipment.

• Boss cylinders and pumps

are designed to operate at a

maximum of 700 bar (10,000 psi)

unless specied. Never connect a

cylinder to a pump with a higher

output pressure.

• Never use pumps and cylinders

with disconnected couplers.

Always ensure where couplers

are used that they are all fully

engaged. Failure to do so can

result in the system becoming

overloaded and can result in a

catastrophic component failure

potentially causing severe

personal injury.

• Always ensure the system has

a stable set up before operating

the equipment. Cylinders should

be located on a at surface that

has the capacity to support the

load, cylinder bases and other

supports should be used where

applicable. Avoid situations where

the load is not directly centred on

the cylinders. Loads that are o

centre place considerable strain

on the cylinder and piston. This

can result in the load slipping or

the cylinder failing with potentially

dangerous results. Always

distribute the load evenly across

the entire surface of the cylinder

saddle. Always use a saddle to

protect the cylinder rod.

BM003-V2 3

IMPORTANT:

• Never lift or carry hydraulic

equipment by the hose or

couplers. Use carry handles or

another safe method to transport

or lift components.

• High pressure hydraulic

equipment should only be

serviced, adjusted, repaired and

tested by qualied hydraulic

technicians.

• After unpacking the equipment

it should be inspected by a

qualied person to ensure

there is no shipping damage or

missing part.

• A gauge is highly recommended

to be used, so the pressure in

the hydraulic system can be

monitored.

CAUTION:

• Avoid damage to hydraulic

hoses from sharp objects,

vehicles and heavy objects

falling on them, never kink or

t hoses with a sharp bend in

them. All of these things can

cause internal damage to the

hose leading to premature

hose failure.

• Keep hydraulic equipment

away from sources of

heat and ames. Heat will

soften seals and hoses

which results in hydraulic

uid leaks. For optimum

performance, equipment

should not be exposed to

temperatures of 65° C (150°

F) or higher. Always protect

hoses from weld splatter

or sparks from cutting or

grinding tools.

• Never weld to or modify

cylinders, pumps or other

system components as

they have been engineered

and tested to meet specic

standards.

• Always immediately replace

worn or damaged parts with

genuine Boss Hydraulics

parts. The use of non-

genuine parts can result in

failure potentially causing

personal injury and/or

property damage.

WARNING:

BM003-V2

4

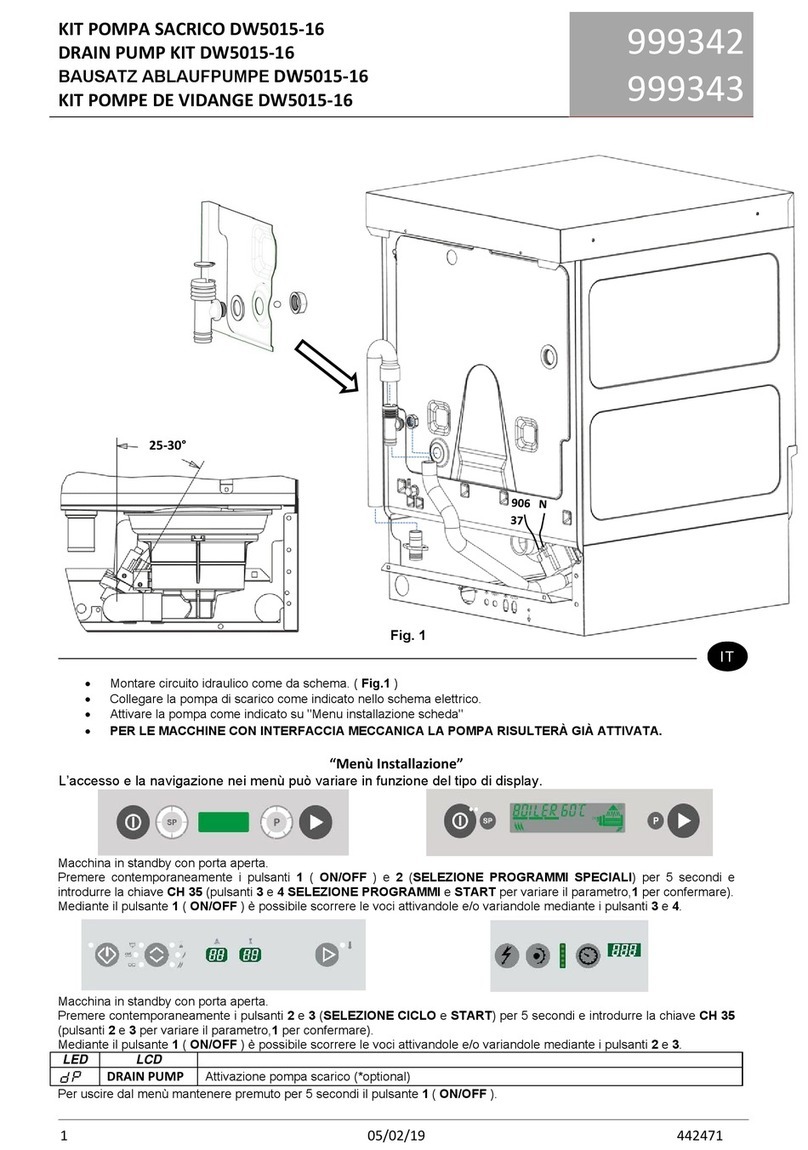

1. SETUP/ INSTALLATION

Connecting the Pump:

• Remove shipping plugs from

pump port outlets.

• Connect hoses to pump. To seal

threads, use thread sealer or

thread tape. When using seal

tape, apply tape one thread back

from end of tting to prevent

excess tape entering the hydraulic

system.

• Install a pressure gauge in the

system to monitor pressure.

• Connect the hoses to your

cylinder or tool.

• For single-acting cylinders,

connect one hose from the pump

to the cylinder; For double-acting

cylinders, connect two hoses.

Connect one hose from Port A of

the pump to the advance port of

the cylinder. Connect the second

hose from Port B of the pump to

the retract port of the cylinder.

• The pump may be used in either

the horizontal or vertical position.

When operated in the vertical

position, the hose end of the

pump must be pointed down, or

the pump will pick up air and will

not build up pressure.

• Inspect all system ttings and

connections to ensure they are

tight, rated to 700 Bar and are

leak free.

• Check oil level in the reservoir

and add oil if needed. Refer

to instructions in Maintenance

section.

IMPORTANT:

• To prevent contaminants from

entering the hydraulic system, do

not operate the pump with oil ll

plug loosened or removed.

Pump Position:

Before Using The Pump:

WARNING:

• In certain situations the pump

handle can “spring back”. Always

keep your body to the side of the

pump, away from the line of force

of the handle.

• When operating the pump, keep

hands and gures away from the

pinch point area between the

pump and the lifting handle.

• Never add extensions to pump

handle. Extensions may cause

the pump to become unstable

during operation.

• To prevent mechanical damage,

do not use the pump handle

to carry the pump. Use the

designated carry handle.

BM003-V2 5

• With no load on the pump,

the pump operates in the high

ow stage for fast advance of

the cylinder. When the load is

increased, the pump changes

automatically to the low ow stage

to allow for higher pressures. After

the pump changes, less force is

required on the handle.

• Except for PHD models, all

other models are designed

for use with single-acting

cylinders and are equipped

with an integral release valve.

1. Close the release valve by

turning the knob clockwise until it

stops. DO NOT OVERTIGHTEN.

2. Open the release valve by

turning knob counter-clockwise

to release the pressure and allow

the oil to ow back to the reservoir

Two Stage Pumps:

• If release valve knob is dicult to

turn or becomes stuck, discontinue

using pump immediately. Have

pump inspected and repaired by a

BOSS authorised dealer.

WARNING:

• Loosen oil plug several turns to

allow reservoir venting during

operation.

• Position the pump in the

horizontal position at a higher

level than the cylinder.

• Put cylinder in horizontal position

with port facing upwards.

• Advance and retract the cylinder 2

to 3 times to full stroke.

• Repeat steps 2 to 4 as needed to

ensure smooth operation of the

cylinder.

• Check the oil level of the reservoir

and add oil if necessary. See

section on Maintenance.

Air Bleeding:

BM003-V2

6

2. MAINTENANCE:

Adding Oil to the Pump:

Check oil regularly and add oil if

required. Refer to procedure below:

• Place pump in the horizontal

position on a level surface.

• Remove oil ll plug from reservoir.

• Check oil level (see gure below).

If oil level is low, add additional oil

until level is touching the bottom

on the thread.

• Reinstall the oil l plug into the

reservoir. Ensure the plug is fully

tightened.

• Remove air from the system if

necessary and recheck the oil

level.

IMPORTANT:

• Always add oil with the cylinders

fully retracted (extended with

pull Cylinders) or the pump will

contain more oil than reservoir

capacity.

• Do not overll! There must be an

air space in the reservoir to allow

proper operation. If the reservoir

contains too much oil, a vacuum

will form preventing oil from

owing into the piston of the pump

when operating.

Pump oil should be changed twice

a year. The following conditions

require more frequent oil changes:

• Rigorous duty, where oil may leak

out or become contaminated.

• Highly humid environment and

extreme changes in temperature

that can result in condensation

inside the reservoir.

• Dirty or dusty environments that

may contaminate the oil.

Flushing the Pump:

If you suspect your pump has been

contaminated or discover sludge or

other deposits on internal

components, you should thouroghly

ush the pump.

• Remove the old oil from the

reservoir, then thoroughly clean

and rell with nonammable

ushing oil.

• Reasemble the pump head to the

reservoir and pump the handle

approx 50 times with the release

screw open.

• Empty the reservoir and rell

with clean hydarulic oil (BOSS

recommends and uses grade 46

oil).

BM003-V2 7

3. TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Pump loses

pressure

System components

leaking

Repair or replace leaking

components as necessary

Pump not

delivering uid

Low oil level in reservoir Check oil level and add oil is

required

Check ball seats are

worn or damaged

Repair or replace check ball

seats or replace pump body

Pump doesn’t

acheive rated

pressure

Low oil level in reservoir Check oil level and add oil is

required

System components

leaking

Repair or replace worn or

damaged components

Fluid leaking past inlet

or outlet checks Repair inlet or outlet checks

Piston seal leaking Replace piston seal

Relief valve faulty or set

wrong

Replace or re adjust relief

valve

Pump handle has

“spongy” feel

Air trapped in system Bleed air from system, Refer

Air Bleeding

Too much oil in

reservoir Check oil level

4. SPECIFICATIONS

PH SERIES:

Model

Pressure Rang

(bar)

1st Stage / 2nd Stage

Oil Cap.

(cc)

Oil Volume per Stroke

(cc)

1st Stage / 2nd Stage

Weight

(kg)

PHAH1000 13.8 / 1000 1000 12.9 / 1.65 3.5

PHAH1500 13.8 /1500 2000 12.9 / 1 6.7

PHAH2800 14 / 2800 1000 12.9 / 0.5 5.3

• To prevent personal injury, release pump pressure and disconnect

the hose from the pump before commencing repairs.

WARNING:

BOSS HYDRAULICS:

Head Ofce: 19 Ricketts Road, Mt Waverley VIC 3149 I P: 1300 BOSS HYD (1300 267 749)

E: [email protected] I W: www.bosshydraulics.com.au

This manual suits for next models

2

Table of contents

Other BOSSCO Water Pump manuals

Popular Water Pump manuals by other brands

Pentair

Pentair Fairbanks nijhuis 2800 Installation, operation and maintenance

Zoeller

Zoeller AQUANOT 508 Fit installation instructions

Linkstyle

Linkstyle Smart Air Pump Full user guide

SUN RUN

SUN RUN SPE-200RI operating instructions

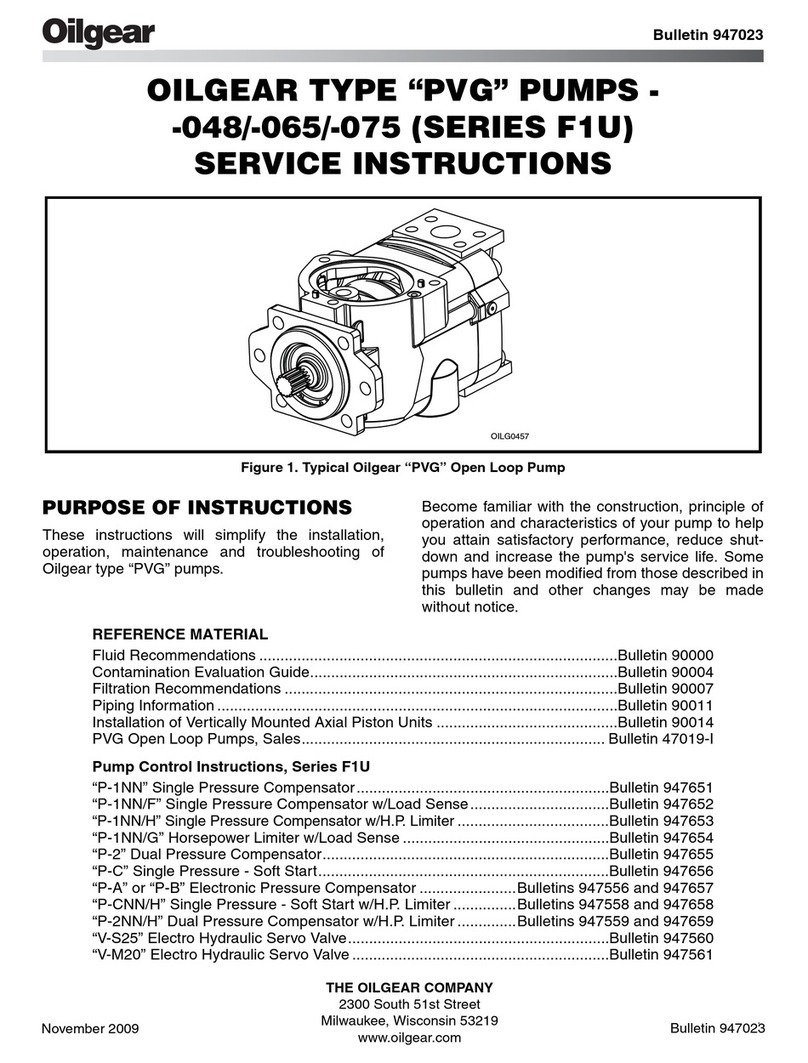

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS T2A60 B Installation, operation, and maintenance manual with parts list

Tacony

Tacony TRUVOX MW340/PUMP/B user manual