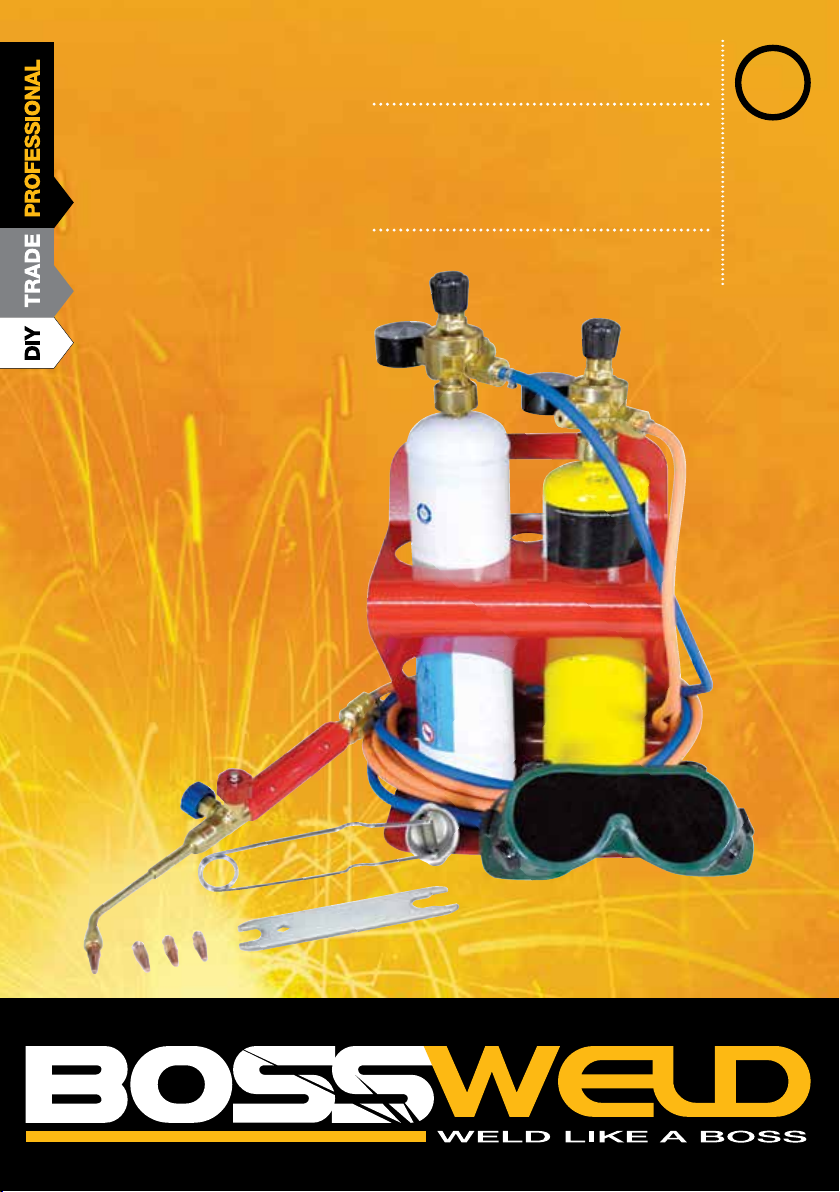

BossWeld BRAZEN 3000 User manual

PORTABLE BRAZING

AND HEATING KIT

MANUAL

BRAZEN 3000 G

GAS

2

3

INDEX PAGE

GENERAL SAFETY INFORMATION 5 3

PHYSICAL AND SAFETY PROPERTIES OF GASES 6

GAS SUPPLY 7

SAFETY 8-9

CYLINDER STORAGE, NOZZLE CHART 10

PERSONAL PROTECTIVE EQUIPMENT 11

BOX CONTENTS 12

SETUP AND LIGHTING PROCEDURE 13-15

SHUT DOWN PROCEDURE 16

WARNINGS & MAINTENANCE 17

WARRANTY 18

CONSUMABLES 19

4

BOSSWELD GAS WELDING EQUIPMENT

Dear customer,

Thank you for your purchase of our BOSSWELD BRAZEN 3000 portable

brazing & heating kit. The BOSSWELD range of gas welding and cutting

equipment has been rigorously tested by independent laboratories and

conforms to the following Australian Standards for gas welding and cutting

processes:

Small heating and brazing kits currently are not covered under the scope of

an existing Australian standard (DEC 2018), however the Brazen 3000 kit meets

the requirements of the European Standard.

EN 1326 - 1996 Gas welding equipment

- small Kits for brazing and welding

BOSSWELD strives to meet all relevant Australian Standards. Should there

be change to existing or creation of new Australian Standards, BOSSWELD

will endeavor to ensure that all products and services comply with those

standards.

This manual refers to safety measures that must be adhered to for the safe

operation of your BOSSWELD BRAZEN 3000 equipment. Please read and

understand these warnings and instructions before use. Failure to do so

could result in serious injury or death. BOSSWELD brazing and heating

equipment should only be used by operators who are properly trained and

qualied in the safe use of this type of equipment.

5

GENERAL SAFETY INFORMATION

Safety consideration for both the operator and surroundings must be given to

the heat source produced by mixing compressed oxygen with a fuel gas and

igniting the resulting mixture. When using these processes, particular safety

considerations apply with respect to:

a) Do not leave the Brazen 3000 torch unattended when lit, or put it down

b) Burns from ames, hot objects, malfunctioning hand-held equipment,

molten particles, etc.

c) Explosions from mixed gas concentrations created by fuel gas leakage

from cylinders,

d) Fire caused by ignition of ammable materials, leakage of fuel gases,

contact with hot slag, poor condition of welding equipment, etc. (Plant,

building, ship and bush res have occurred)

e) Use welding goggles when using the Brazen 3000 kit.

d) Do not breath welding fumes

e) Violent rupture or explosion of components due to pressurisation beyond

their designed working pressures

f) Asphyxiation due to the displacement of atmospheric, breathable air by

inert or toxic gases. For example, leakages in conned spaces or lack of

oxygen resulting from excessive rusting in conned spaces

g) Radiation damage (to eyes principally and other exposed surfaces)

h) Fumes originating from the particular materials being welded and heating

6

PHYSICAL AND SAFETY PROPERTIES OF GASES

a) DO NOT use oxygen to refresh air. There is often a temptation to use

oxygen to ‘sweeten’ air whilst welding or cutting operations are being

carried out in conned spaces. Large amounts of oxygen can be released

locally in a short time from gas cylinders under pressure. In one situation

where this was done, hot work in the form of ame cutting was carried out

with a subsequent ignition of worker’s clothes and fatal burns.

b) TAKE CARE in conned spaces. Do not leave blowpipes or hoses

connected to the supply gases within conned spaces overnight or during

work breaks. Slow leaks can result in very hazardous situations, with

possible re and explosion on re-ignition of the blowpipe.

c) VENTILATE conned spaces. In ame cutting not all of the oxygen

released from the cutting nozzle is necessarily used in cutting. In conned

spaces this may result in a dangerous increase in oxygen content in the air,

pointing to the need for adequate ventilation in such situations.

d) DO NOT use oxygen as a substitute for compressed air. There are

many examples of this situation where oxygen has been used, such as in

cleaning, resulting in serious and fatal accidents due to re or explosion from

spontaneous ignition. NEVER use oxygen to start engines, drive air tools

etc.

e) DO NOT use oxygen or compressed air to dust off clothes. Clothes

can become readily ammable and even self-igniting through oxygen

enrichment.

f) DO NOT kink pressure hosing. Kinking or nipping hose to interrupt gas

ows or whilst changing torches is a very dangerous practice. Gas can still

bleed through the system, or more seriously, escape rapidly should the hose

rupture or the operator lose their grip.

g) The oxygen cylinder once it is empty can devalued and the cylinder

recycled at a scrap metal merchant.

DO NOT USE BRAZEN 3000 IF THE RUBBER O-RING IS MISSING

OR DAMAGED IN THE REGULATORS

7

GAS SUPPLY

General

Your BOSSWELD gas welding and cutting equipment is designed to be used

by gases delivered to the point of use from portable compressed gas cylinders.

In all cases, gas supplies may be subject to statutory or regulatory provisions.

Many Australian Standards cover the subject.

a) The Brazen 3000 is fueled with Oxygen and Mapp gas cylinders, Cylinders

are generally obtained from gas suppliers.

b) Do not tamper with the markings or colour coding of cylinders. Do not use

non colour coded cylinders or those without safety and information labels.

c) The Oxygen and Mapp gas cylinders are not rellable.

d) Gas should only be used for the particular intended purpose, e.g. never

use oxygen for cleaning (dusting), or to provide ventilation or to support

breathing

e) Gases should only be identied by their correct name so as to avoid

dangerous confusion or misunderstanding.

f) Valve seats and outlets should be protected by keeping all kinds of dirt

and contamination away from cylinders, especially during connection

and disconnection. Grit, loose bers and other dirt may lodge in

connectors or valve seats causing leaks or may be picked up by high

velocity gas streams, causing hot spots in regulators, potentially resulting

in ignition. Organic matter such as oil, grease and hydrocarbon liquids

which may ignite spontaneously in high pressure oxygen is another hazard

to regulators and other downstream equipment.

g) Do not tamper with safety devices.

DO NOT CONNECT CYLINDERS BEFORE YOU HAVE READ THIS

MANUAL IN FULL AND UNDERSTAND IT.

THE BRAZEN 3000 OXYGEN BOTTLE CONNECTION ONLY

CONNECTS TO M12x1 THREAD.

THE BRAZEN 3000 MAP-PRO CONNECTION IS CGA 600.

8

SAFETY

The regulators supplied ensure a low and constant ow and pressure. Inspect

all parts of the equipment for wear or loose connection before use. If you have

a leaking hose or connection, close all valves regulators and torch handles, and

ensure you ventilate the area you are working in. and remove this equipment

from and ammable sources. Do not attempt to x any damaged parts contact

your nearest Bossweld service agent or Bossweld directly.

• Always make sure the ame is fully extinguish after use before place the

torch on any surface.

• Check hoses for kinks or bends.

• Keep ame away from cylinders, regulators, hoses and other persons.

• Only use this product in a well ventilated space - never use in a conned

area.

• Make sure the cylinder holder is on a at surface - do not drag the cylinders

or cylinder holder by the hoses.

• Ensure the work area is clean and remove all ammable objects and re

hazards.

• Always wear the appropriate PPE equipment when operating this equipment.

IN CASE OF FIRE

• In the event of a re, if it is safe to do close the oxygen valve, this should

extinguish the ame and also if safe close the fuel valve and remove the

equipment from the area.

• Extinguish the re with the appropriate equipment only if it is safe to do so.

• If you are unable to turn of the valves or extinguish the re leave the area,

warn any other persons in the area and contact emergency services

- Phone 000.

9

SAFETY SAFETY

TIP REPLACEMENT

Make sure you use the tool supplied and that tips are installed straight as not to

wear the thread, this can result in a leak.

• Ensure tip has cooled after use before replacing.

• Do not over tighten

• Ensure tip is clean and dry before installing and is not blocked.

CYLINDER REPLACEMENT

• Make sure the regulator is completely shut off before removing it from the

cylinder., Always check condition of the seal in the regulator before replacing

on a new cylinder

• Unscrew the empty cylinder and replace with a new one.

• Dispose of empty cylinder at your local recycling center

- NEVER incinerate empty cylinder.

- Do NOT puncture.

10

Storage

In the case where the Brazen 3000 should not be used for a long time or

when requiring transport by a motor vehicle, unscrew the cylinders from

the regulators, This will ensure that the contents of the cylinder will remain

contained and prevent leaks. Do not expose cylinders to a temperature higher

than 50ºC.

- Always transport in a well ventilated vehicle never transport in a closed

vehicle

- It is dangerous to use damaged or incorrectly functioning equipment

CYLINDER STORAGE

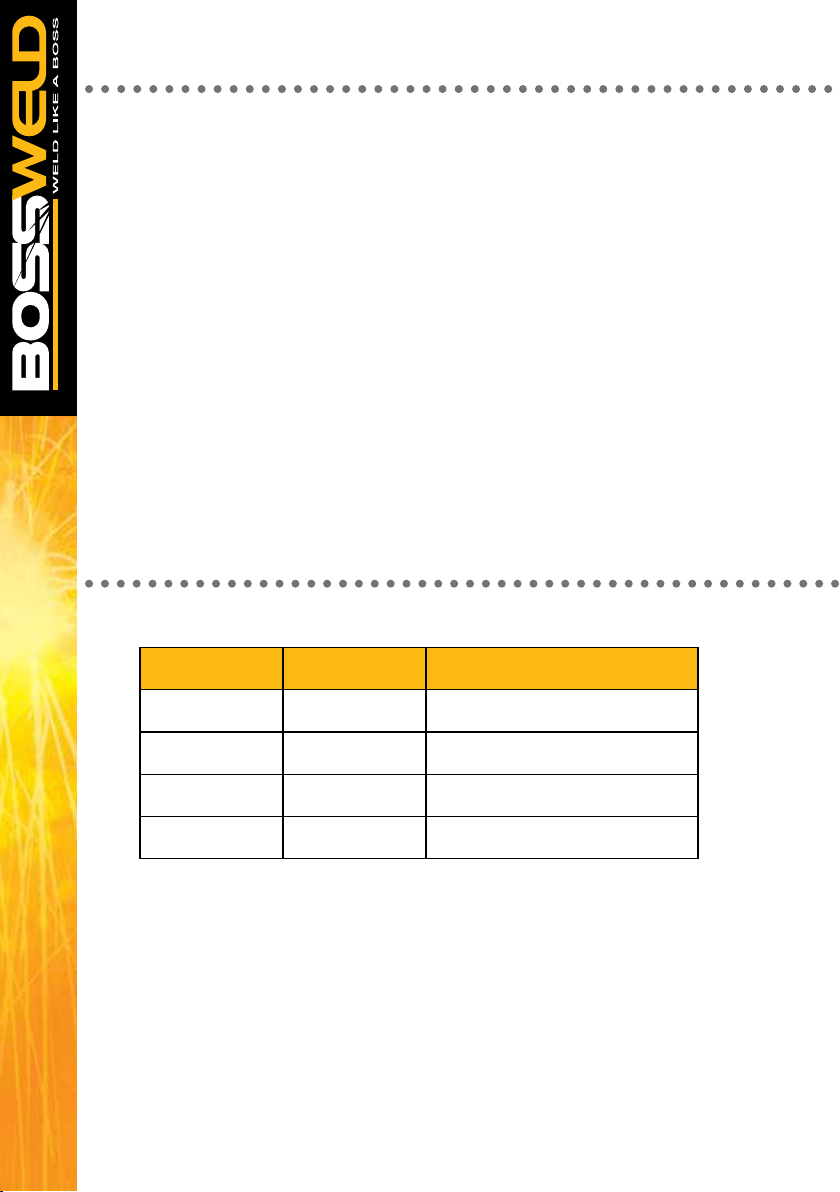

NOZZLE CHART

TIP SIZE ORIFICE WELDING RANGE

0# 0.7mm 0.5mm - 1mm

1# 0.8mm 1mm - 2mm

2# 0.9mm 2mm - 3mm

3# 1.0mm 3mm - 4mm

11

Personal protective equipment should be used by all operators of oxy-fuel gas

equipment to ensure their protection of body and clothing from:

a) The heat from the work

b) Burns which may result from contact with hot components or small

globules of hot metal

c) Radiation which may burn the skin or eyes

This protection is achieved by the use of ame resistant clothing, gloves

and footwear that is suitable to prevent the entry of hot particles or objects.

Aprons, sleeves, shoulder covers, leggings or spats of pliable ame resistant

leather and other suitable materials may also be required where the areas of

the body will encounter hot metal. Protection of the eyes from radiation is also

very important. The recommended minimum shade numbers are listed below,

however if any discomfort is felt, darker lters may be used.

Gas Welding - Low heat input Shade 3

- Light fusion welds Shade 4

- Heavy fusion welds Shade 5

PERSONAL PROTECTIVE EQUIPMENT

12

8

10

7

3

4

6

21

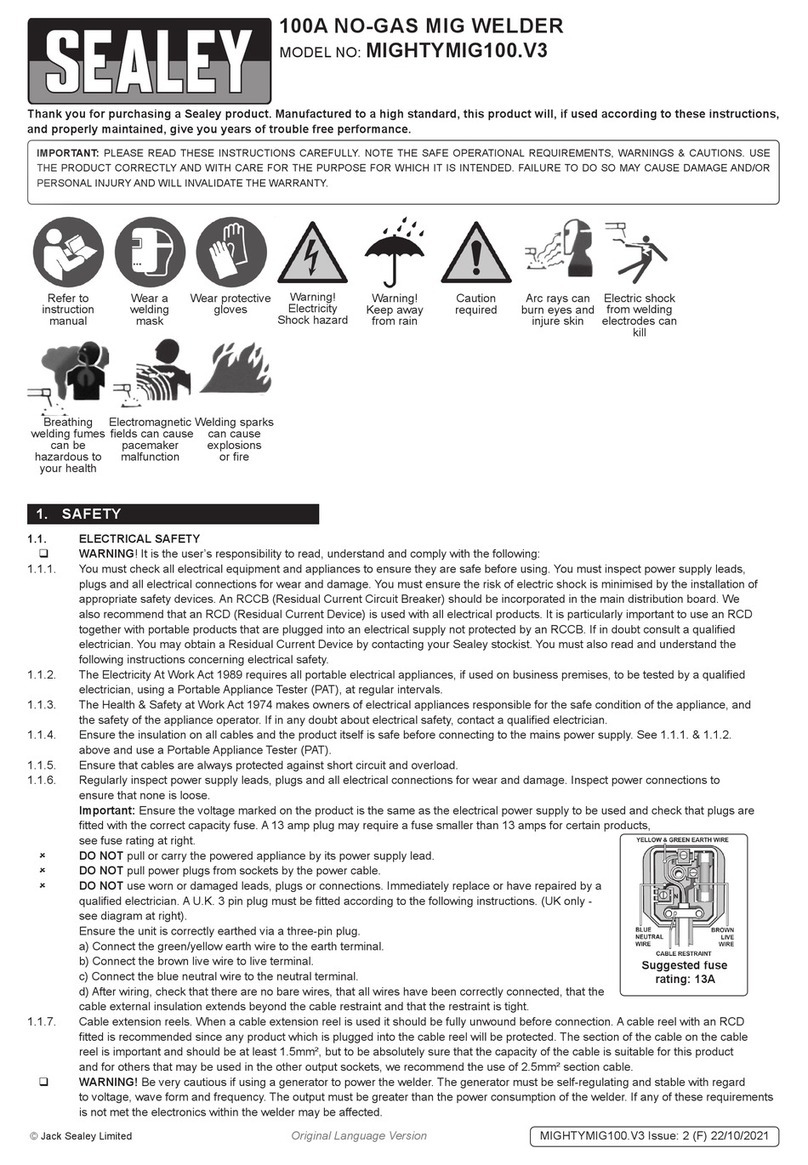

BOX CONTENTS

Kit Contains

1. Fuel gas regulator with gauge.

2. Oxygen regulator with gauge with M12x1mm connection.

3. Hand piece with adjustment values

4. Blowpipe.

5. 2.5m Oxygen / Fuel hose set.

6. Light weight & heavy duty carry case.

7. Flint Lighter.

8. Combination Spanner

9. Brazing nozzle size: 0, 1, 2, 3.

10. Brazing goggles.

Disposable gas cylinders sold separately

9

5

• OXYGEN REGULATOR

- CONNECTS TO M12x1 THREAD.

• MAP-PRO REGULATOR

- CONNECTS TO CGA 600 THREAD

13

BOX CONTENTS BRAZEN 3000 SETUP

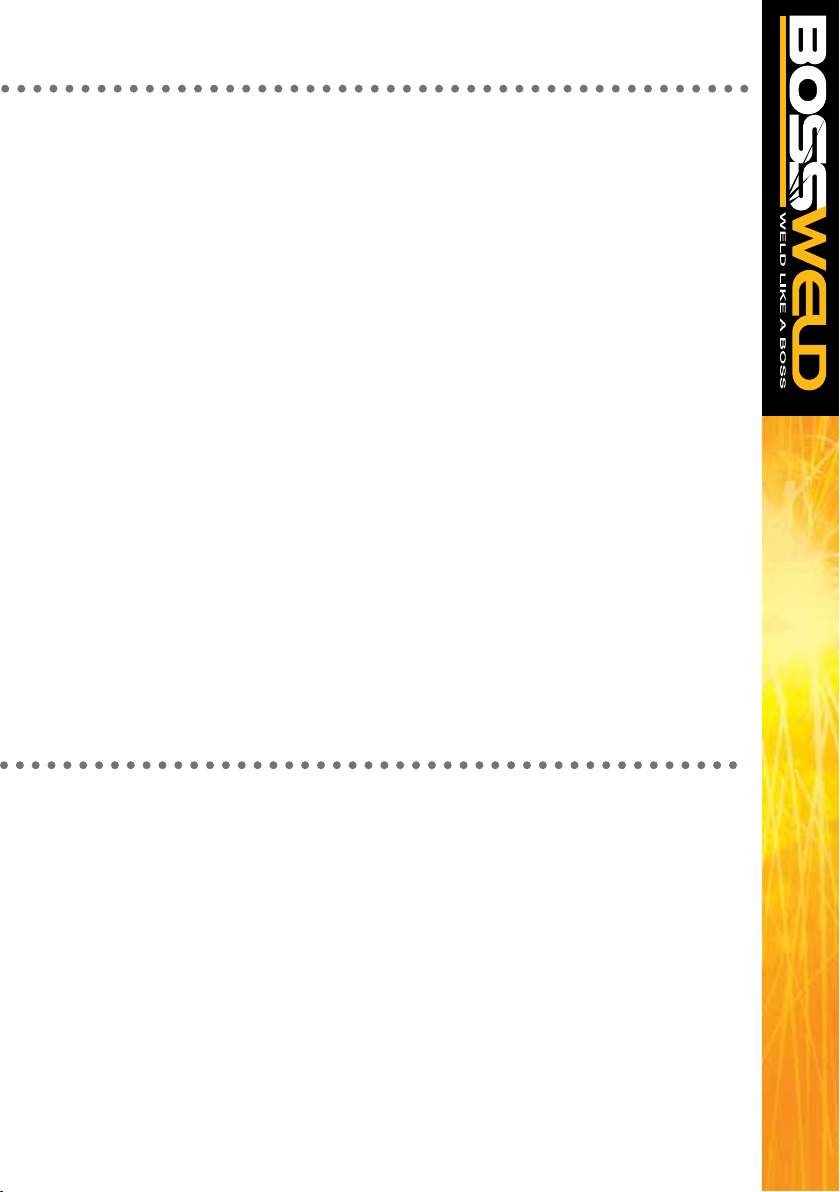

1. Make sure you have the valve on

the fuel regulator in the off position.

4. Make sure you have the valve

on the Oxygen regulator in the off

position.

2. Check the seal in the regulator is

seated properly and not kinked or

raised.

5. Check the seal in the regulator is

seated properly and not kinked or

raised.

3. Screw the Fuel regulator onto the

fuel bottle in a clockwise direction

to tighten. And place into the carry

case. CONNECTS TO CGA 600 THREAD

6. Screw the Oxygen regulator onto

the Oxygen bottle in a clockwise

direction to tighten, and place into

the carry case

CONNECTS TO M12x1 THREAD

Disposable gas cylinders sold separately - Oxygen Reg has a M12x1mm Connection

- Map-Pro Reg has CGA 600 Connection

14

BRAZEN 3000 SETUP - CONTINUED

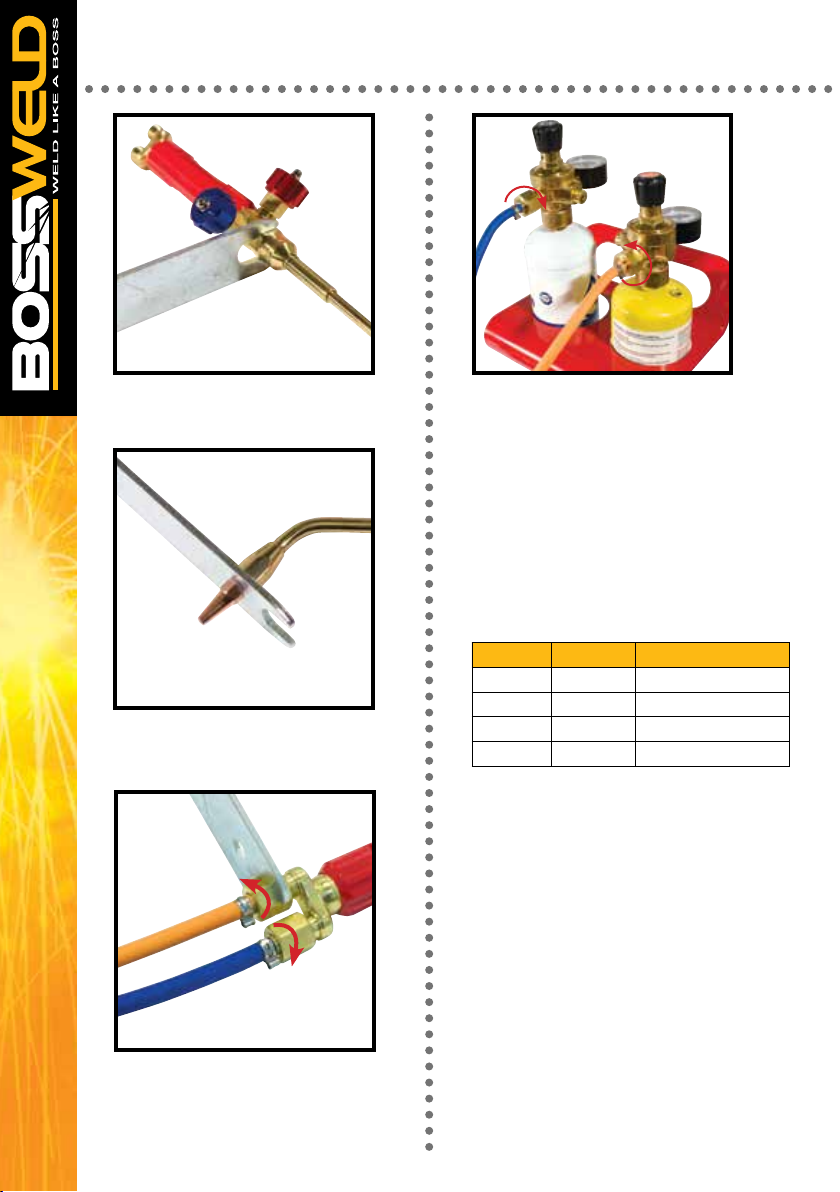

7. Attach the blowpipe to the handle

using the spanner supplied, do not

over tighten

8. Screw the required tip onto

the blowpipe. Using the spanner

supplied, do not over tighten

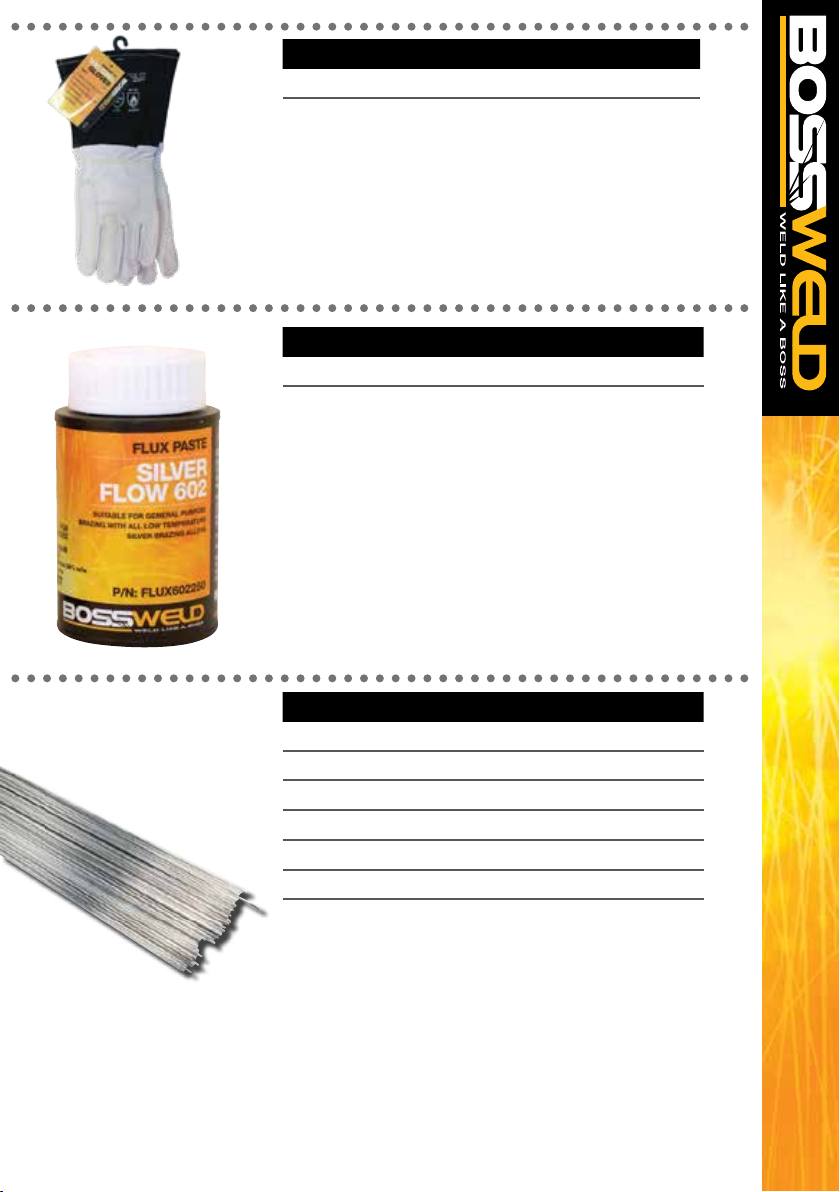

9. Attach the hose to the handle

with the numbers facing up, orange

hose on the left, tighten anti-clockwise

and blue hose on the right tighten

clockwise using the spanner supplied,

do not over tighten

10. Attach the hose to the fuel and

oxygen regulators

• Orange hose connected to the fuel

regulator tighten anti-clockwise using

the spanner supplied, do not over

tighten

• Blue hose to the Oxygen regulator

tighten clockwise using the spanner

supplied, do not over tighten

TIP SIZE ORIFICE WELDING RANGE

0# 0.7mm 0.5mm - 1mm

1# 0.8mm 1mm - 2mm

2# 0.9mm 2mm - 3mm

3# 1.0mm 3mm - 4mm

15

BRAZEN 3000 SETUP - CONTINUED BRAZEN 3000 IGNITING PROCEDURE

1. Make sure the valves on the torch

handle are closed

4. Adjust the fuel dial on the torch

until the yellow ame ows right from

the tip of the nozzle.

2. Turn the Oxygen regulator on until

it is fully open, and Turn the Fuel

regulator on until it is fully open.

5. Turn the blue dial on the torch

handle anti-clockwise to introduce

oxygen to the ame.

NOTE:

• Not enough oxygen will produce a

orange ame

• Excess oxygen will produce a

transparent ame.

• The ideal ame is a blue ame

with a cone shape.

3. Turn the Red Fuel dial

anti-clockwise to open the ow of

fuel, and immediately light the torch

using the int lighter provided in the

kit

√X

√

16

SHUT DOWN PROCEDURE

1. Turn The Fuel dial off from the

torch handle, This will extinguish the

ame.

2. Turn the Oxygen dial off from the

torch handle.

3. Shut the Fuel regulator off and

Shut the Oxygen regulator off.

NOTE:

In the case where the Brazen 3000

should not be used for a long time or

when requiring transport by a motor

vehicle, unscrew the cylinders from the

regulators,

17

SHUT DOWN PROCEDURE WARNING

• Do not ignite the torch near your body, combustible material or close to

regulators and cylinders.

• Caution: the torch can become very hot during and after use, keep away

from skin and combustible materials, lay at on a clean surface after use.

• Make sure you follow the correct shutdown procedures.

• This equipment uses compressed gas cylinders, do not disassemble

cylinders, puncture or incinerate.

• Always wear the appropriate personal protective equipment when using this

equipment.

• Do not disassemble the regulators, if regulator stops working, contact your

Bossweld agent or Bossweld directly.

• Use only recommended parts with this equipment, altering removing or

using non genuine part can be very dangerous.

• Only use fuel and oxygen cylinders that pass the AS/NZS standards,

compress cylinders can be very dangerous, make sure you follow

manufactures operating instructions.

MAINTENANCE

• Only use Bossweld approved replacement parts

• Do not use this equipment if you are unshore of any procedures outline in

this manuals, contact your Bossweld agent or Bossweld directly.

• Do not use this equipment if part is damage, replace any damaged parts

before use.

• Regularly inspect all parts before use, ensure valves are clean and dry

before connecting to the cylinders.

• Do not disassemble any part of the equipment unless stated in this manual.

• Check equipment for any leaks before ignition of the ame.

18

WARRANTY

BOSSWELD undertakes to repair or replace, at its option, any new

BOSSWELD product which fails due to a defect in materials or workmanship

during the 12 month warranty period. Any repair work must be carried out by

an authorised BOSSWELD repair agent.

This warranty does not apply to, or in any way cover:

1. Normal everyday wear and tear.

2. Failure due to improper use.

3. Failure of, or caused by, parts or components which are not original

BOSSWELD parts.

4. Failure arising from accident, abuse, re, vandalism, contaminated uids

or neglect or failure to store or use the BOSSWELD product in

accordance with the instructions provided in this manual.

Note:

The following items are not included in the 12 month warranty period:

Welding tips, welding goggles and int lighter

DISCLAIMER

Whilst the above information is provided in good faith, BOSSWELD does

not warrant the accuracy of the information provided or assume any legal

responsibility for it or for any damage which may result from reliance on

or use of it or from any negligence of BOSSWELD or other person(s) with

respect to it.

19

Bossweld Goat Skin Tig Glove

White goat skin TIG glove, reinforced tipping on back

of 2nd and 3rd ngers, yellow cow split cuff,

Kevlar stitching, unlined, (32cm for size M).

Features

Reinforced tipping on the back of the 2nd and 3rd ngers

Yellow cow split cuff

Kevlar stitching

Goat skin gloves

Silver Brazing Flux

Fine paste with excellent suspension & easy to spread.

For low temperature silver brazing, provides quality

joints in station less, copper, brass & bronzes

Bossweld Silver Brazing Alloys

CAWS A5.8-B CuP5

A ller for brazing copper. Wide molting range for lling

loose connections and to build up around nished joints.

When heated above liquidus temperature will ow into

tight connections. Extensively used on hot water tanks,

copper tubing, plumbing or where a strong, ductile joint is

required. Not recommended for brazing steel or other

ferrous metals.

CODE DESCRIPTION

700015M Bossweld “GoaTig” Tig Welding Glove - Medium

CODE DESCRIPTION

FLUX602250 Silver Brazing Flux x 250g Jar

CODE DESCRIPTION

300201 2.4mm 2% Silver Brazing 1Kg

300202 2.4mm 5% Silver Brazing 1Kg

300203 3.2mm 5% Silver Brazing 1Kg

300204 1.6mm 15% Silver Brazing 1Kg

300206H 2.4mm 15% Silver Brazing 6 stk

300206 2.4mm 15% Silver Brazing 1Kg

OTHER PRODUCTS IN OUR RANGE

• ELECTRODES

• TIG RODS

• WELDING HELMETS

• WELDING MACHINES

• TORCH SPARE PARTS

• WELDING ACCESSORIES

• MIG WIRE

• GAS EQUIPMENT

• WELDING SAFETY

• MIG TORCHES

• TIG TORCHES

• WELDING CABLE

Table of contents

Other BossWeld Welding System manuals

BossWeld

BossWeld M100 User manual

BossWeld

BossWeld POWERPULSE 250 User manual

BossWeld

BossWeld 200X User manual

BossWeld

BossWeld MST X250 PFC User manual

BossWeld

BossWeld X Series User manual

BossWeld

BossWeld P40 User manual

BossWeld

BossWeld TS200 User manual

BossWeld

BossWeld MST X250 PFC User manual

BossWeld

BossWeld S140 User manual

BossWeld

BossWeld Buddy MIG 150 User manual

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric AC-235 Guide

Linde

Linde BOC Raptor CUT 30C operating manual

MK Welding

MK Welding PC 40 PFC user manual

Lincoln Electric

Lincoln Electric RANGER 300 D Operator's manual

Lincoln Electric

Lincoln Electric Power MIG 350MP Operator's manual

Miller

Miller Spectrum 700i owner's manual