18

WELDING PRODUCTS TO HELP PROLONG, MAINTAIN

AND PRODUCE BETTER WELDS

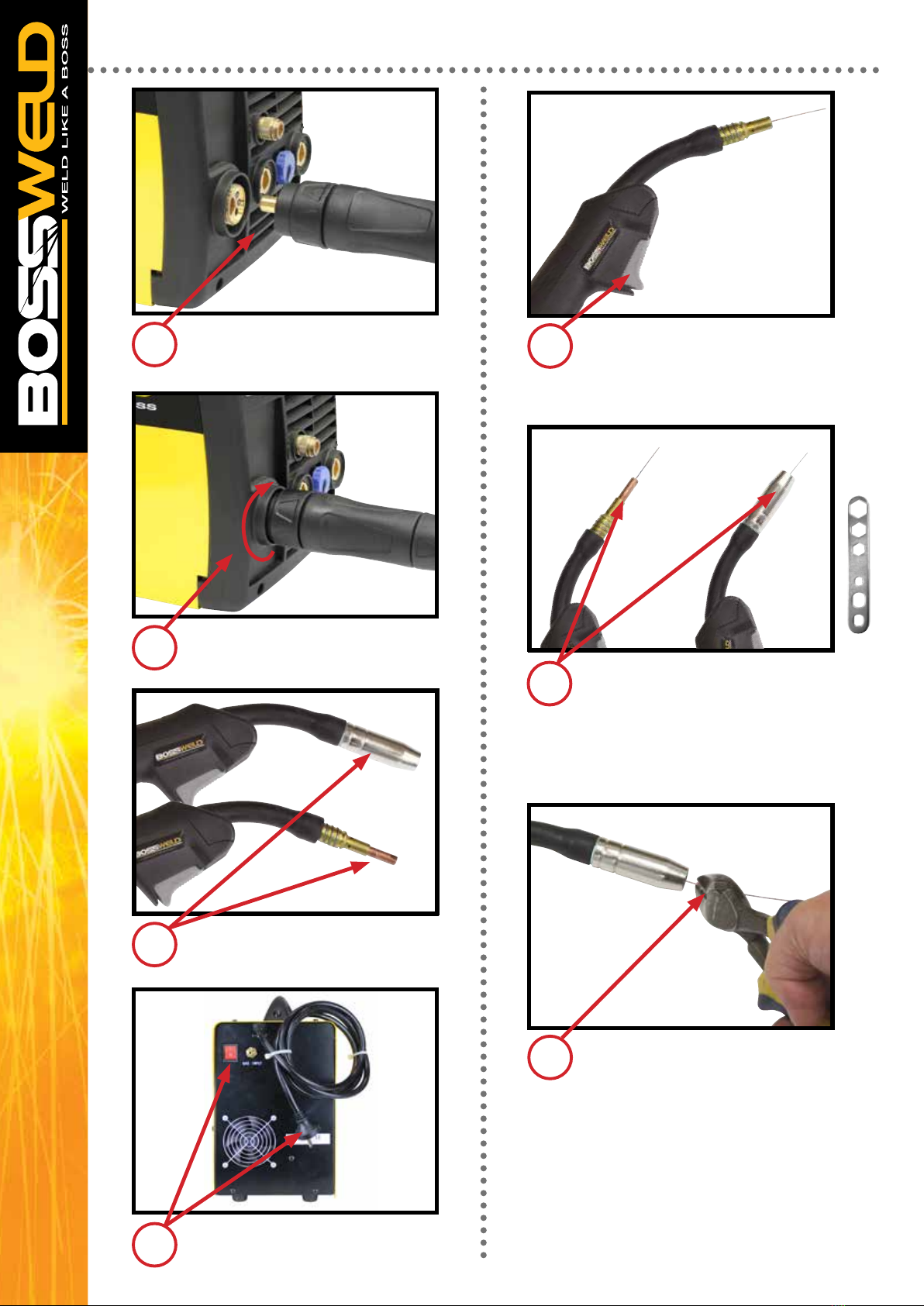

Bossweld Aerosol Anti Spatter Spray (Part No: 800041)

This silicon free spatter release coating is a colourless

lm which stops weld spatter from sticking to welding equipment,

work pieces & xtures. Easily removed before painting or nishing.

Bossweld Tip Dip Gel (Part No: 800055)

Non toxic water based dipping gel for the prevention

of weld spatter adherence to MIG torch parts.

This silicon free compound is used to prolong

the life of nozzles & tips.

Bossweld 8 Ways MIG Welding Pliers (Part No: 800074)

Handy 8 function welders pliers. Functions include,

nozzle removal, tip removal, cleaning inside of nozzle

and wire cutting.

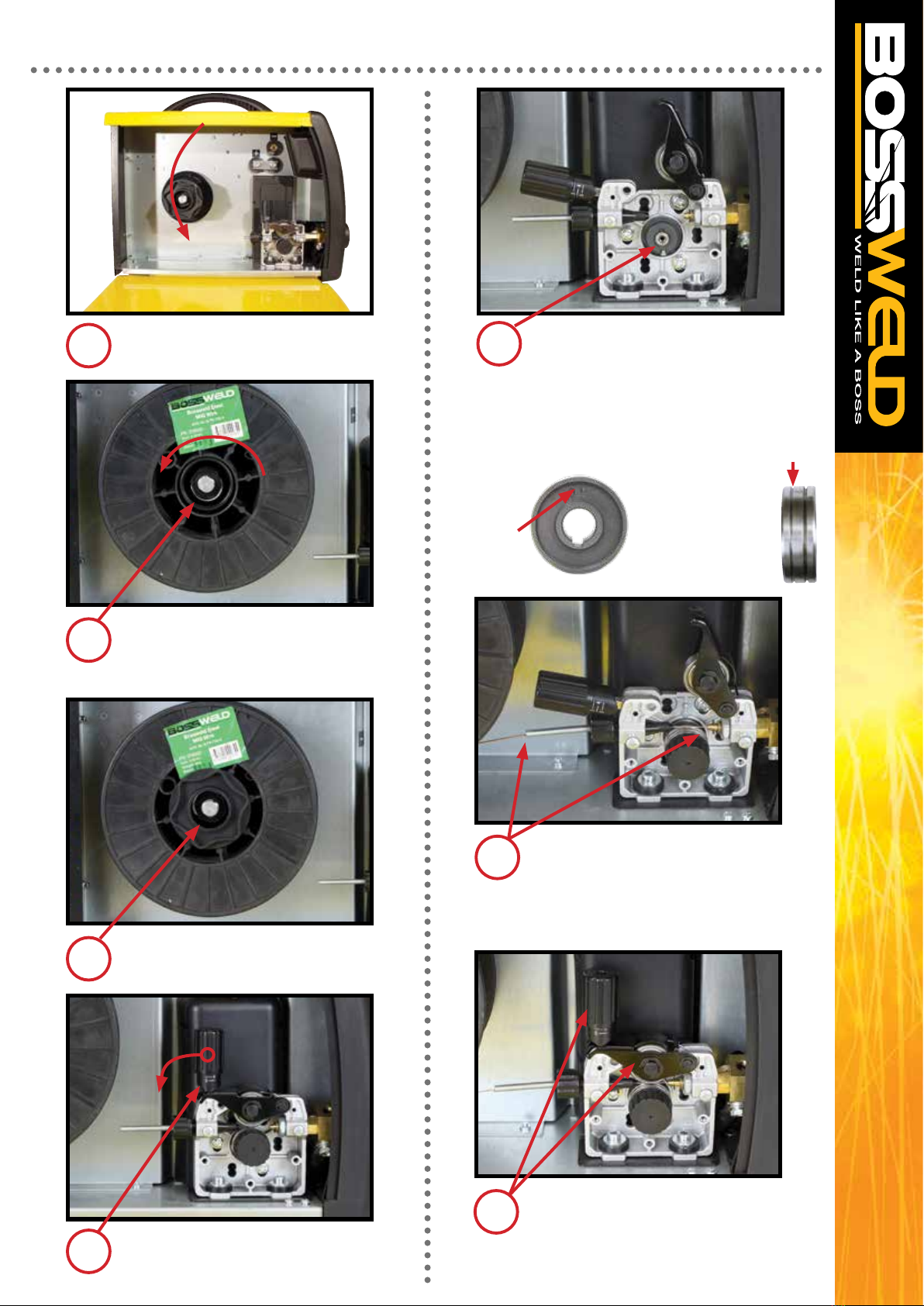

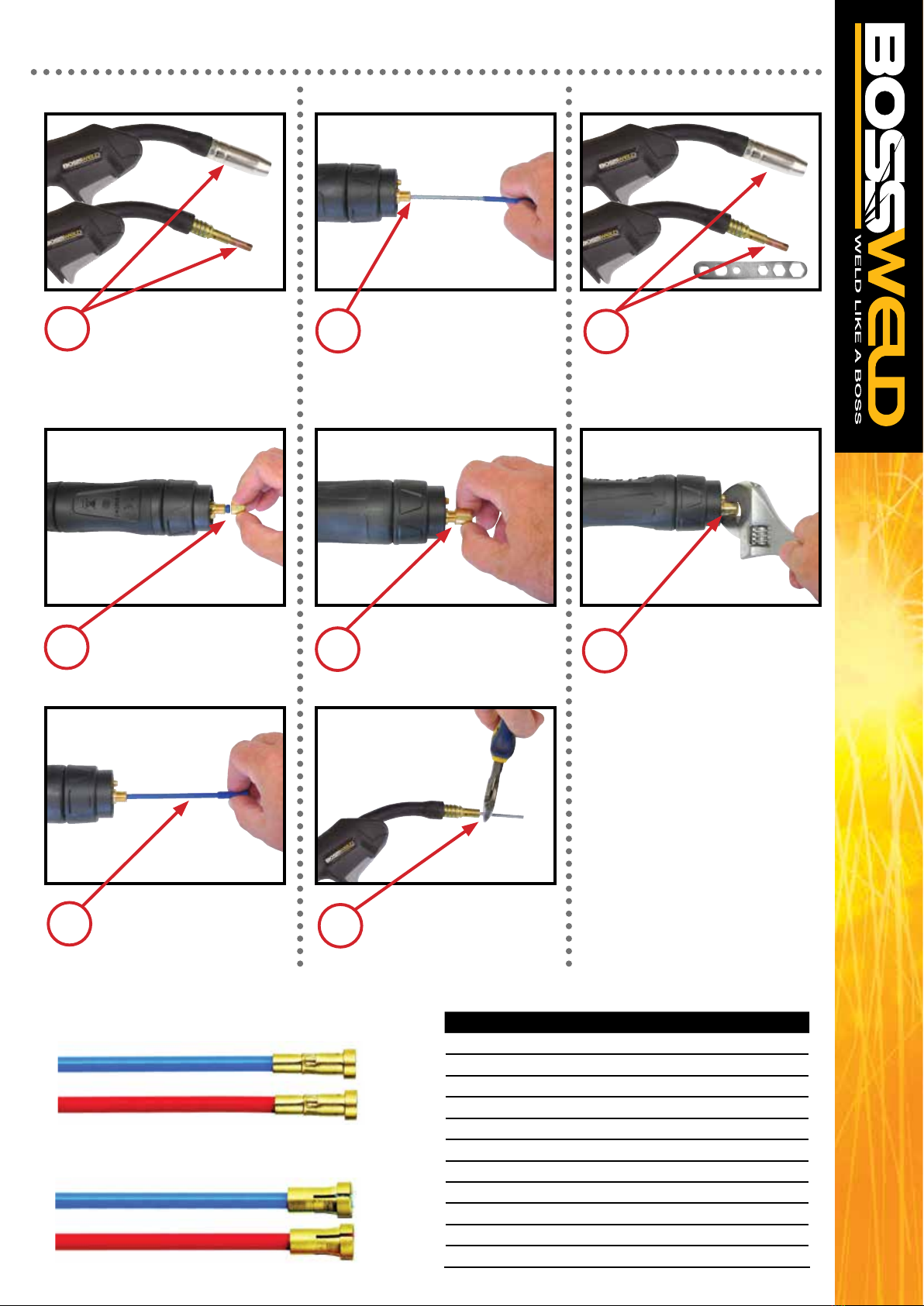

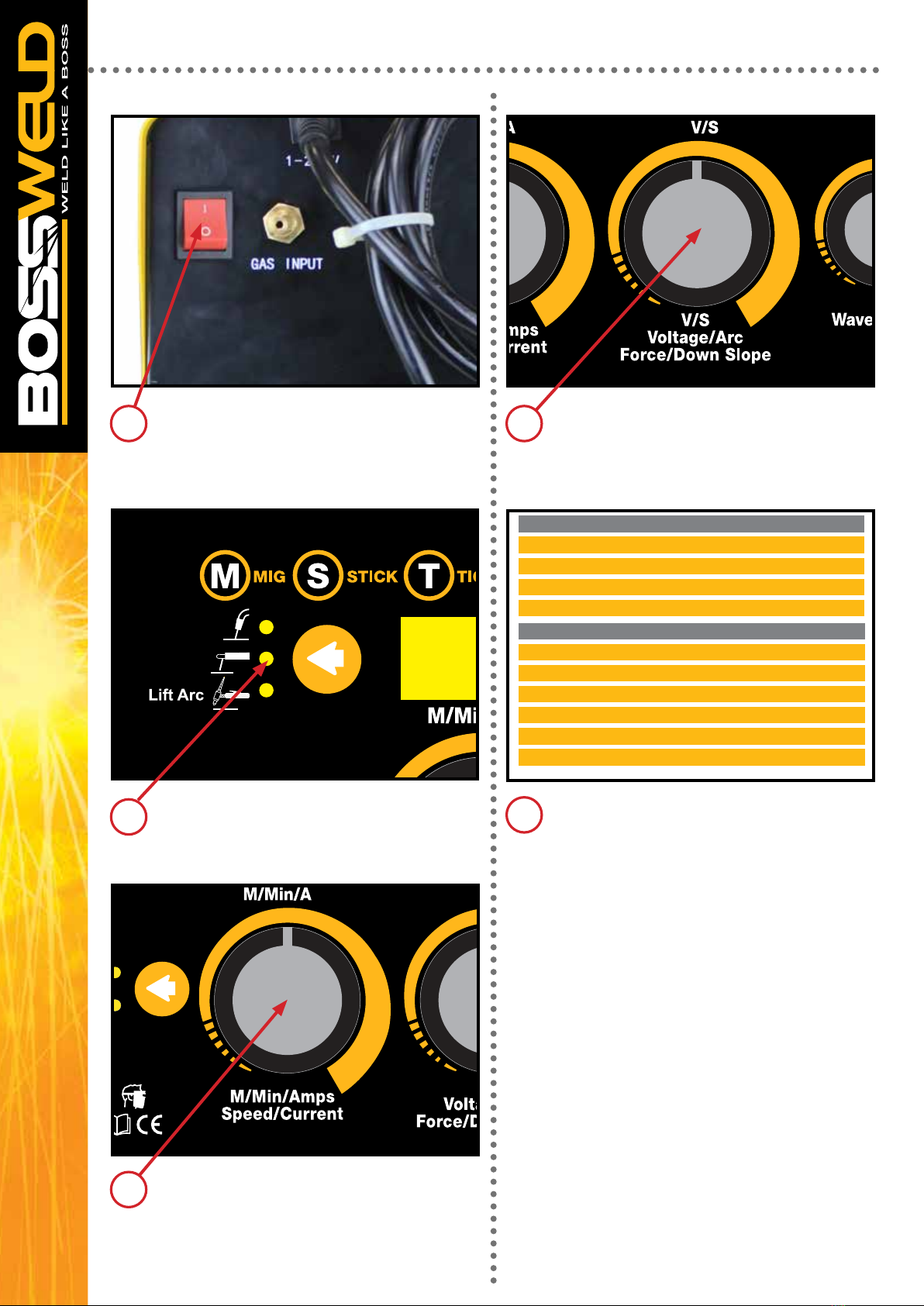

Proper MIG Torch inspection

Prior to welding, ensure all connections are tight and that consumables and equipment are in good condition

and free from damage. Start with the front of the gun and work your way back to the feeder. A tight neck

connection is essential to carry the electrical current from the welding cable to the front-end consumables.

Also, be sure to visually inspect the handle and trigger to check there are no missing screws or damage.

The cable should be free of cuts, kinks and damage along the outer cover. Cuts in the cable can expose the

internal copper wiring and create a potential safety hazard to the welding operator. In addition, these issues

can lead to electrical resistance that causes heat buildup — and ultimately cable failure.

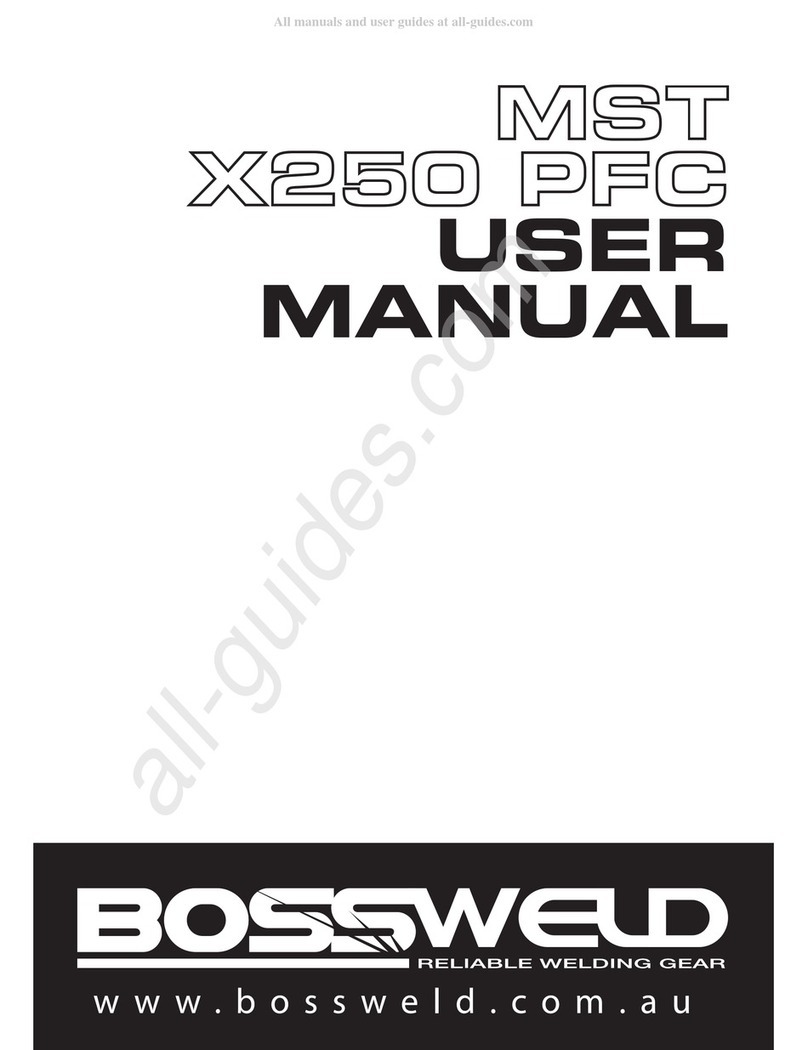

Consumables

MIG gun front-end consumables are exposed to heat and spatter and therefore often require frequent

replacement. However, performing some simple maintenance can help extend consumable life and improve

gun performance and weld quality. The gas diffuser provides gas ow to the weld pool and also connects to

the neck and carries the electrical current to the contact tip. Make sure all connections are tight, and check

the diffuser’s O-rings for cracks, cuts or damage. The nozzle’s main role is to focus the shielding gas around

the weld pool. Watch for spatter buildup in the nozzle, which can obstruct gas ow and lead to problems

due to inadequate shielding coverage. Use MIG pliers to clean spatter from the nozzle. The contact tip is

the last point of contact between the welding equipment and the welding wire. Keyholing of the contact tip

is a concern to watch for with this consumable. This occurs when the wire passing through the tip wears an

oblong-shaped slot into the diameter of the tip. Keyholing can put the wire out of center and cause problems

such as an erratic arc. If you are experiencing wire feeding issues, try changing the contact tip or switching to

a larger-size contact tip. Tips that look worn should be replaced.

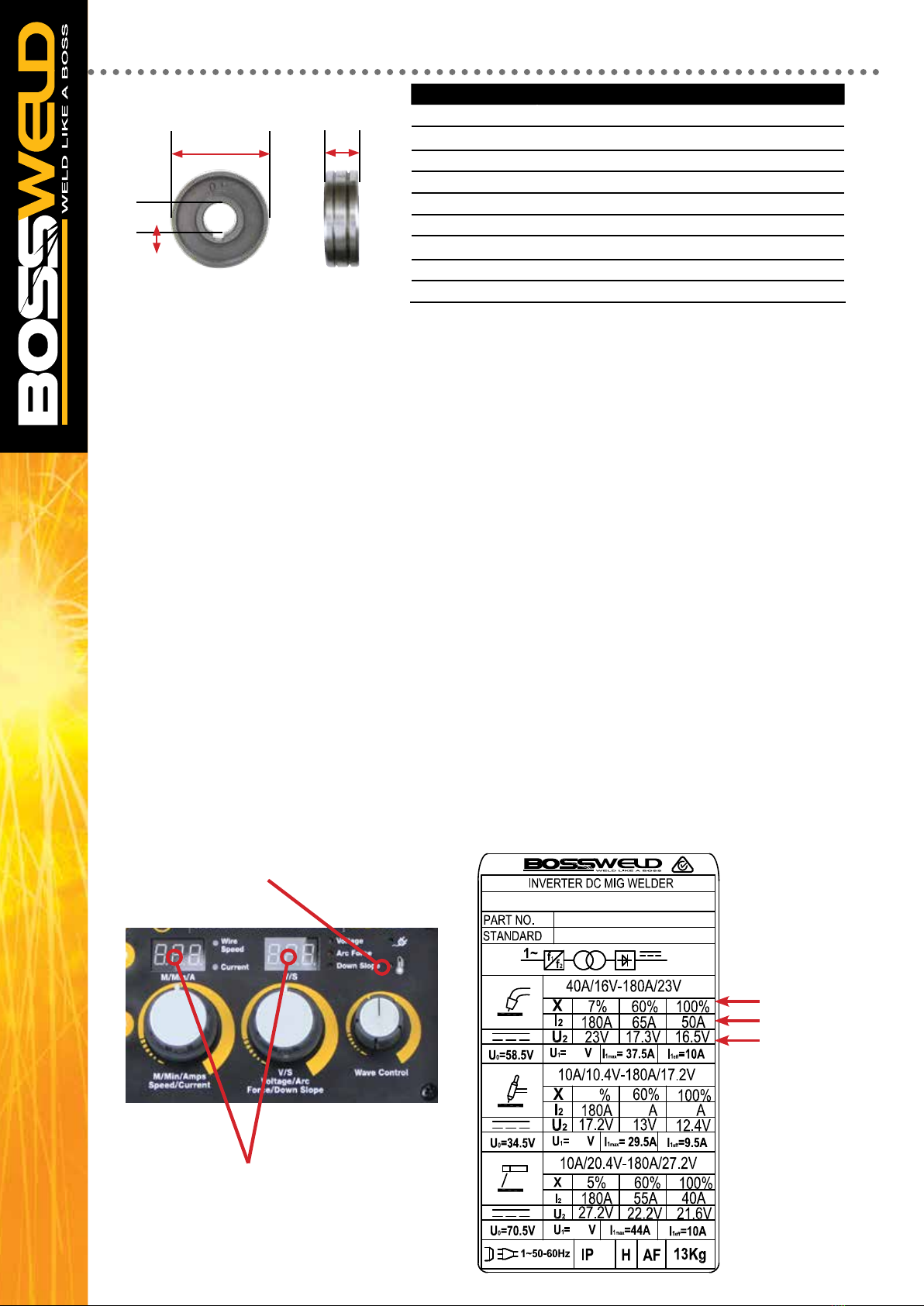

Final thoughts

Taking the time for preventative maintenance can pay off in less downtime in the long run. Along with that,

always remember to properly store your MIG gun consumables to help you achieve the best results and

extend the life of your equipment. When not in use, the MIG gun should be stored in a coiled position, either

hanging or lying at, such as on a shelf. Do not leave MIG gun on the oor of the shop, where there is a

chance the cable could be run over, kinked or damaged.

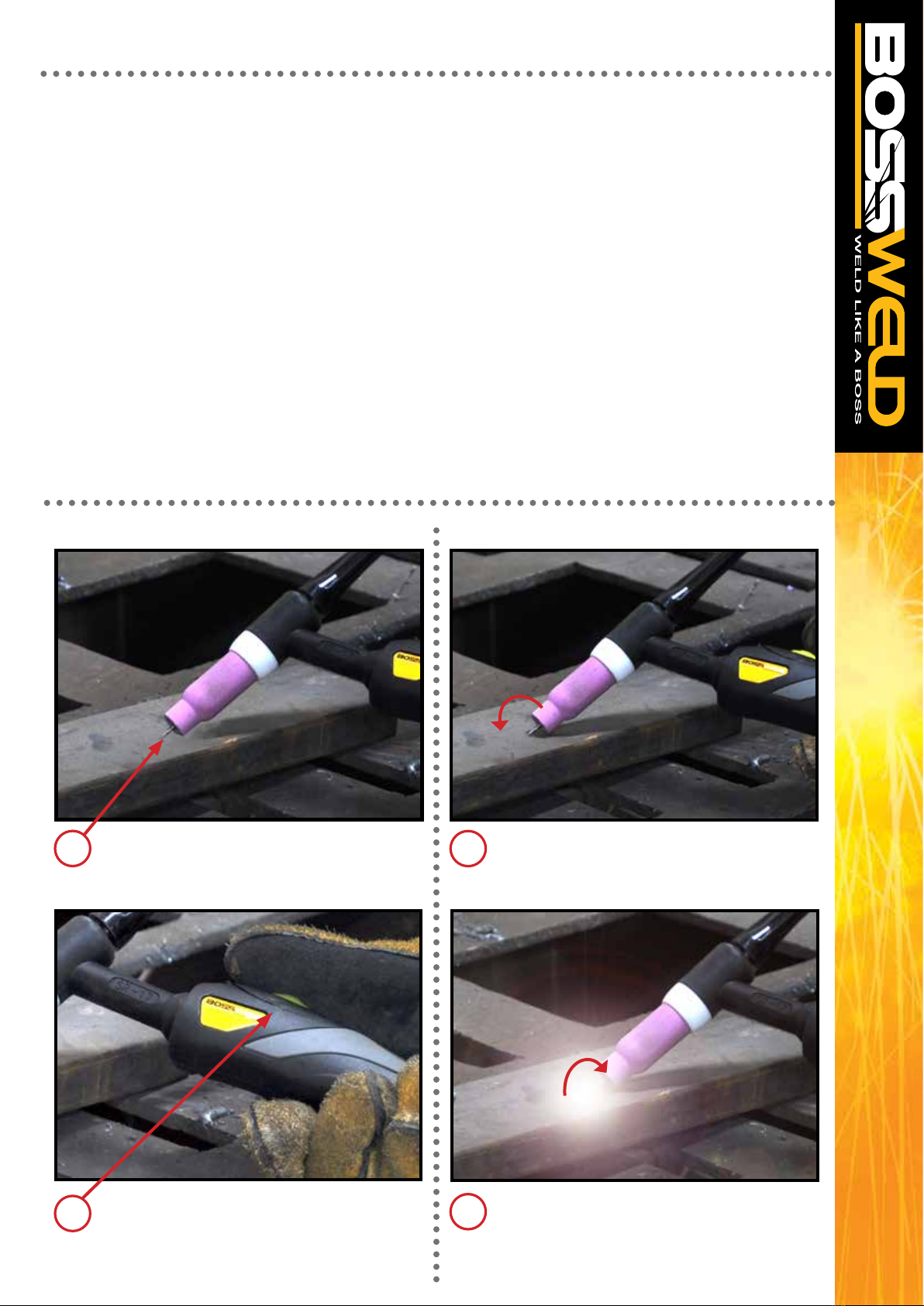

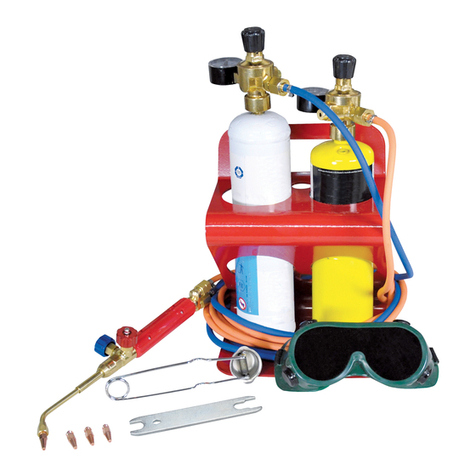

Spatter removal from inside and outside the nozzle using MIG pliers

Build up of spatter can

cause damage to

nozzle and tip

Keyholing of the

contact tip