14 15

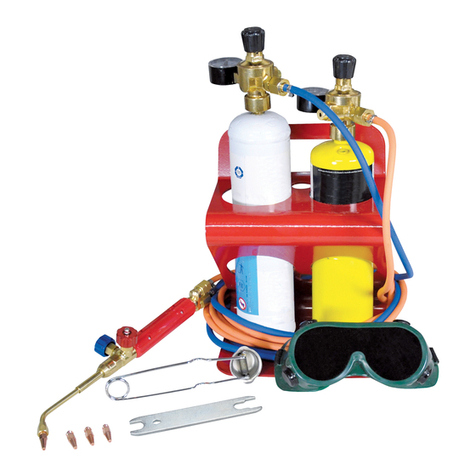

MANUAL METAL ARC PROCESS (MMA WELDING)

When an arc is struck between the metal rod (electrode) and the workpiece, both the rod and workpiece

surface melt to form a weld pool. Simultaneous melting of the ux coating on the rod will form gas and slag

which protects the weld pool from the surrounding atmosphere. The slag will solidify and cool and must be

chipped off the weld bead once the weld run is complete (or before the next weld pass is deposited).

The process allows only short lengths of weld to be produced before a new electrode needs to be inserted in

the holder. Weld penetration is low and the quality of the weld deposit is highly dependent on the

skill of the welder.

TYPES OF ELECTRODES

Arc stability, depth of penetration, metal deposition rate and positional capability are greatly inuenced by the

chemical composition of the ux coating on the electrode. There are many types of Electrodes, and these

are generally matched to the base metal. For example if welding Mild Steel then select a Mild Steel (General

Purpose Electrode). Electrodes are identied by a universal numbering system (AWS Type code).

Base Metal Electrode Type Type

Mild Steel Mild Steel General Purpose 6013

Stainless Steel Stainless Steel 316L 316L

Dissimilar Metals Dissimilar 680 312

Cast Iron Nickel Arc 98 Ni99

High Strength Steel Low Hydrogen TC16

ELECTRODE SIZE SELECTION

Electrode size selection will be determined by the

thickness of the section being welded. A thicker

section will need a larger diameter electrode. The

table below shows the maximum size of electrodes

for average thicknesses of section (based on

General Purpose 6013 Electrode).

WELDING CURRENT

Welding current level is determined by the size

of electrode - the normal operating range and

current are recommended by manufacturers. Typical

operating ranges for a selection of electrode sizes

are illustrated in the table. As a rule of thumb when

selecting a suitable current level, an electrode will

require about 40 Amps per millimetre (diameter).

Therefore, the preferred current level for a 4mm

diameter electrode would be 160 Amps, but the

acceptable operating range is 140 to 180 Amps.

It is important to match the machine to the job

Amperage Selection Guide

Rod Size/ Gauge Welding Current

1.6mm 40-50 Amps

2.0mm 50-75 Amps

2.5mm 75-105 Amps

3.2mm 105-140 Amps

4.0mm 140-160 Amps

Average Metal Thickness Electrode Size

1.0 - 2.0mm 2.0mm

2.0 - 5.0mm 2.6mm

5.0 - 8mm 3.2mm

8.0mm + 4.0mm

FLUX COATING

ROD

ARC

CONTACT TIP

DROPLETS

SHIELDING GAS

ARC

MOLTEN WELD METAL

SHROUD

WORK PIECE WORK PIECE

WORK PIECE WORK PIECEWORK PIECE WORK PIECE

WORK PIECE WORK PIECE

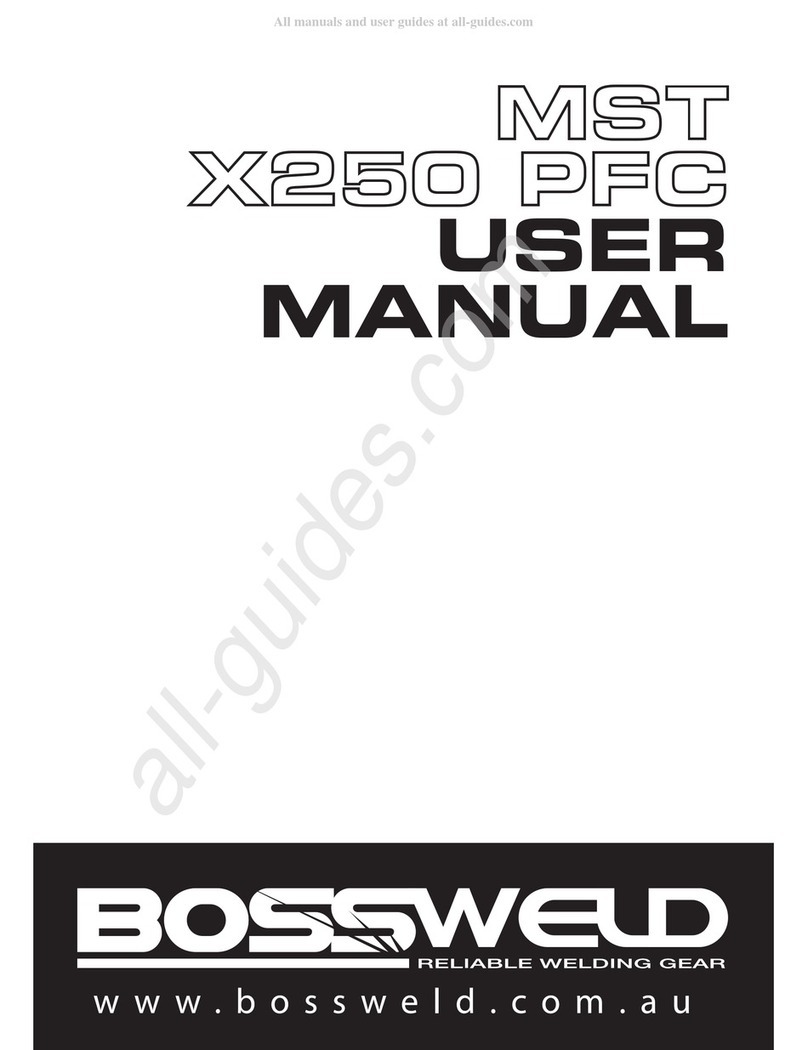

STRAIGHT GROUND

CORRECT PREPERATION - STABLE ARC INCORRECT PREPERATION - STABLE ARC

RADIAL GROUND

ARC WANDER

TUNGSTEN ELECTRODE

GAS LENS

STABLE ARC

FLAT TIP POINTED TIP

GRINDING WHEELGRINDING WHEEL

FILLER WIRE

Note: Do not use wheel for other jobs or tugsten can become contaminated and cause lower weld quality

Electrodes are often packed in sealed packaging to keep

moisture out. However, if a pack has been opened or

damaged, it is essential that the electrodes are redried

according to the manufacturer’s instructions.

ARC FORCE

Also called Dig and Arc Control. Gives a power source

variable additional amperage during low voltage

(short arc length) conditions while welding. Helps avoid

“sticking” stick electrodes when a short arc length is used.

POWER SOURCE

Electrodes can be operated with AC and DC power supplies.

Not all DC electrodes can be operated on AC power sources;

however AC electrodes may be used on either AC or DC