Botron B8572 User manual

SPECFICITIONS

Accuracy range: +/-3 % per gegohm

Test voltage: 10,25,50,100,250 & 500volts

Electrodes: Two (2) 5lb weights

Power: Six (6)AA

Auto shut off: Conserve batteries

Lock test : As needed

Resistance range: 100G/100v , 100G/500v analog

20G/100v digital

Continuity test: .01meg-220G

Diode test: .01kohm-10000kohm Size:

Voltage: +/-1 V-500V

Test leads: 2-4’ long banana to banana

(red & black)

Millivolt test: +/- 1m-1999mV

Low battery: Symbol

Water& dust proof: IP54

Weight: 775gms with boot

Size: 11mm x 220mm x 45mm

Designed to: IEC1010-1

Case: Foam filled

Warranty: Three (3) years

ACCESSORIES:

B8563/20: 20’ lead for floor testing

B48775: Electrostatic field meter

B48775PVS: Complete periodic verification system for testing

ionization. Field meter, charger, plate & case.

Locking

Auto-shut off

Digital scale

Analog scale

Footwear: Incoming testing on sampling basis should be

performed for all static footwear products.

(TR 20.20 pgh. 5.3.3.4)

Floor: Per (TR 20.20 pgh. 5.34.13)

Testing and monitoring are required

for performance.

Seating: ESD STM 12.1 and (TR 20.20 pgh. 5.3.5.3)

recommend testing should be preformed. With a reading

of 1 x109 ohms.

Garments: A process of testing garments per ESD STM

2.1, point-to point and sleeve-to-sleeve resistance should

be done.

see (TR 20.20 pgh. 5.3.3.4)

MODEL # B8572

SERIAL # 1000-351/110111/1335

DATE 06-21-11

Must call to activate warranty

1-888-257-3680

Information sent by mail

M ohm

EXAMPLE:

Reading (115.)= 1.15 x 108

Reading (.096.)= 9.6 x 104

Reading ( .96)= .96 x 105

Reading ( 6.3)= 6.3 x 106

Reading (16.3)= 1.63 x 107

Reading (6.13 G)= 6.13 x 109

Reading (>20G)= 2 x 1010

Reading (100G)= 1 x 1011 analog

Backlight

Test button

Test voltage at probes

BOTRON CO INC.

325 W. Melinda Ln.

Phoenix AZ 85027

Ph 623-582-6700

Fax 623-582-6776

Caution, risk of shock.

Caution, refer to user guide.

Equipment protected throughout by

Double insulation case (Class II).

Equipment complies with current EU directives.

Equipment must not be connected to installations >500V.

Test voltage

Locking

Voltage Test

voltage

Locking

Continuity Test

Resistance in K ohms

Buzzer

DIGITAL/ ANALOG

AUDIT MEGOHM

METER B8572

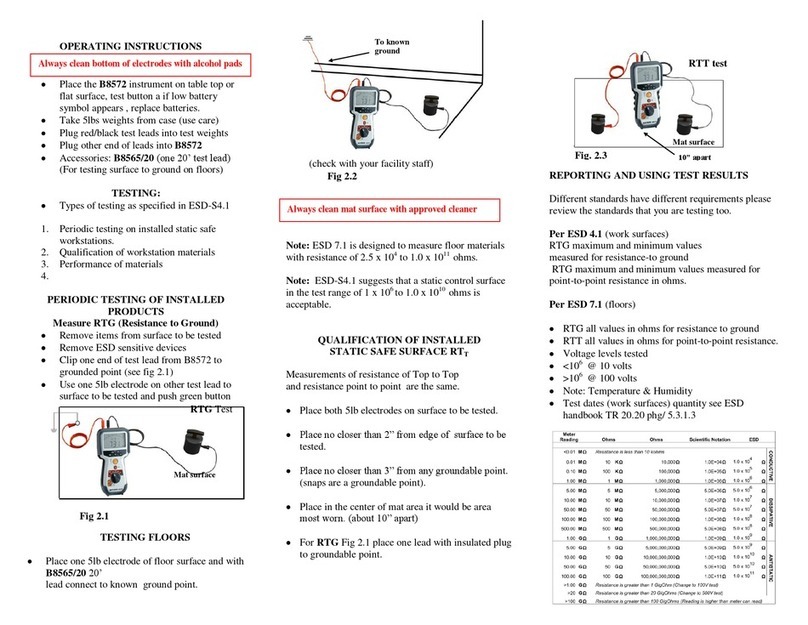

OPERATING INSTRUCTIONS

Place the B8572 instrument on table top or

flat surface, test button a if low battery

symbol appears , replace batteries.

Take 5lbs weights from case (use care)

Plug red/black test leads into test weights

Plug other end of leads into B8572

Accessories: B8565/20 (one 20’ test lead)

(For testing surface to ground on floors)

TESTING:

Types of testing as specified in ESD-S4.1

1. Periodic testing on installed static safe

workstations.

2. Qualification of workstation materials

3. Performance of materials

4.

PERIODIC TESTING OF INSTALLED

PRODUCTS

Measure RTG (Resistance to Ground)

Remove items from surface to be tested

Remove ESD sensitive devices

Clip one end of test lead from B8572 to

grounded point (see fig 2.1)

Use one 5lb electrode on other test lead to

surface to be tested and push green button

TESTING FLOORS

Place one 5lb electrode of floor surface and with

B8565/20 20’

lead connect to known ground point.

(check with your facility staff)

.

Note: ESD 7.1 is designed to measure floor materials

with resistance of 2.5 x 104to 1.0 x 1011 ohms.

Note: ESD-S4.1 suggests that a static control surface

in the test range of 1 x 106 to 1.0 x 1010 ohms is

acceptable.

QUALIFICATION OF INSTALLED

STATIC SAFE SURFACE RTT

Measurements of resistance of Top to Top

and resistance point to point are the same.

Place both 5lb electrodes on surface to be tested.

Place no closer than 2” from edge of surface to be

tested.

Place no closer than 3” from any groundable point.

(snaps are a groundable point).

Place in the center of mat area it would be area

most worn. (about 10” apart)

For RTG Fig 2.1 place one lead with insulated plug

to groundable point.

REPORTING AND USING TEST RESULTS

Different standards have different requirements please

review the standards that you are testing too.

Per ESD 4.1 (work surfaces)

RTG maximum and minimum values

measured for resistance-to ground

RTG maximum and minimum values measured for

point-to-point resistance in ohms.

Per ESD 7.1 (floors)

RTG all values in ohms for resistance to ground

RTT all values in ohms for point-to-point resistance.

Voltage levels tested

<106 @ 10 volts

>106 @ 100 volts

Note: Temperature & Humidity

Test dates (work surfaces) quantity see ESD

handbook TR 20.20 phg/ 5.3.1.3

Fig 2.1

10” apart

Test leads

Fig 2.2

Fig. 2.3

To known

ground

RTG Test

Mat surface

Mat surface

RTT test

Always clean bottom of electrodes with alcohol pads

Always clean mat surface with approved cleaner

OPERATING INSTRUCTIONS

Place the B8572 instrument on table top or

flat surface, test button a if low battery

symbol appears , replace batteries.

Take 5lbs weights from case (use care)

Plug red/black test leads into test weights

Plug other end of leads into B8572

Accessories: B8565/20 (one 20’ test lead)

(For testing surface to ground on floors)

TESTING:

Types of testing as specified in ESD-S4.1

1. Periodic testing on installed static safe

workstations.

2. Qualification of workstation materials

3. Performance of materials

4.

PERIODIC TESTING OF INSTALLED

PRODUCTS

Measure RTG (Resistance to Ground)

Remove items from surface to be tested

Remove ESD sensitive devices

Clip one end of test lead from B8572 to

grounded point (see fig 2.1)

Use one 5lb electrode on other test lead to

surface to be tested and push green button

TESTING FLOORS

Place one 5lb electrode of floor surface and with

B8565/20 20’

lead connect to known ground point.

(check with your facility staff)

.

Note: ESD 7.1 is designed to measure floor materials

with resistance of 2.5 x 104to 1.0 x 1011 ohms.

Note: ESD-S4.1 suggests that a static control surface

in the test range of 1 x 106 to 1.0 x 1010 ohms is

acceptable.

QUALIFICATION OF INSTALLED

STATIC SAFE SURFACE RTT

Measurements of resistance of Top to Top

and resistance point to point are the same.

Place both 5lb electrodes on surface to be tested.

Place no closer than 2” from edge of surface to be

tested.

Place no closer than 3” from any groundable point.

(snaps are a groundable point).

Place in the center of mat area it would be area

most worn. (about 10” apart)

For RTG Fig 2.1 place one lead with insulated plug

to groundable point.

REPORTING AND USING TEST RESULTS

Different standards have different requirements please

review the standards that you are testing too.

Per ESD 4.1 (work surfaces)

RTG maximum and minimum values

measured for resistance-to ground

RTG maximum and minimum values measured for

point-to-point resistance in ohms.

Per ESD 7.1 (floors)

RTG all values in ohms for resistance to ground

RTT all values in ohms for point-to-point resistance.

Voltage levels tested

<106 @ 10 volts

>106 @ 100 volts

Note: Temperature & Humidity

Test dates (work surfaces) quantity see ESD

handbook TR 20.20 phg/ 5.3.1.3

Fig 2.1

10” apart

Test leads

Fig 2.2

Fig. 2.3

To known

ground

RTG Test

Mat surface

Mat surface

RTT test

Always clean bottom of electrodes with alcohol pads

Always clean mat surface with approved cleaner

OPERATING INSTRUCTIONS

Place the B8572 instrument on table top or

flat surface, test button a if low battery

symbol appears , replace batteries.

Take 5lbs weights from case (use care)

Plug red/black test leads into test weights

Plug other end of leads into B8572

Accessories: B8565/20 (one 20’ test lead)

(For testing surface to ground on floors)

TESTING:

Types of testing as specified in ESD-S4.1

1. Periodic testing on installed static safe

workstations.

2. Qualification of workstation materials

3. Performance of materials

4.

PERIODIC TESTING OF INSTALLED

PRODUCTS

Measure RTG (Resistance to Ground)

Remove items from surface to be tested

Remove ESD sensitive devices

Clip one end of test lead from B8572 to

grounded point (see fig 2.1)

Use one 5lb electrode on other test lead to

surface to be tested and push green button

TESTING FLOORS

Place one 5lb electrode of floor surface and with

B8565/20 20’

lead connect to known ground point.

(check with your facility staff)

.

Note: ESD 7.1 is designed to measure floor materials

with resistance of 2.5 x 104to 1.0 x 1011 ohms.

Note: ESD-S4.1 suggests that a static control surface

in the test range of 1 x 106 to 1.0 x 1010 ohms is

acceptable.

QUALIFICATION OF INSTALLED

STATIC SAFE SURFACE RTT

Measurements of resistance of Top to Top

and resistance point to point are the same.

Place both 5lb electrodes on surface to be tested.

Place no closer than 2” from edge of surface to be

tested.

Place no closer than 3” from any groundable point.

(snaps are a groundable point).

Place in the center of mat area it would be area

most worn. (about 10” apart)

For RTG Fig 2.1 place one lead with insulated plug

to groundable point.

REPORTING AND USING TEST RESULTS

Different standards have different requirements please

review the standards that you are testing too.

Per ESD 4.1 (work surfaces)

RTG maximum and minimum values

measured for resistance-to ground

RTG maximum and minimum values measured for

point-to-point resistance in ohms.

Per ESD 7.1 (floors)

RTG all values in ohms for resistance to ground

RTT all values in ohms for point-to-point resistance.

Voltage levels tested

<106 @ 10 volts

>106 @ 100 volts

Note: Temperature & Humidity

Test dates (work surfaces) quantity see ESD

handbook TR 20.20 phg/ 5.3.1.3

Fig 2.1

10” apart

Test leads

Fig 2.2

Fig. 2.3

To known

ground

RTG Test

Mat surface

Mat surface

RTT test

Always clean bottom of electrodes with alcohol pads

Always clean mat surface with approved cleaner

SPECFICITIONS

Accuracy range: +/-3 % per gegohm

Test voltage: 10,25,50,100,250 & 500volts

Electrodes: Two (2) 5lb weights

Power: Six (6)AA

Auto shut off: Conserve batteries

Lock test : As needed

Resistance range: 100G/100v , 100G/500v analog

20G/100v digital

Continuity test: .01meg-220G

Diode test: .01kohm-10000kohm Size:

Voltage: +/-1 V-500V

Test leads: 2-4’ long banana to banana

(red & black)

Millivolt test: +/- 1m-1999mV

Low battery: Symbol

Water& dust proof: IP54

Weight: 775gms with boot

Size: 11mm x 220mm x 45mm

Designed to: IEC1010-1

Case: Foam filled

Warranty: Three (3) years

ACCESSORIES:

B8563/20: 20’ lead for floor testing

B48775: Electrostatic field meter

B48775PVS: Complete periodic verification system for testing

ionization. Field meter, charger, plate & case.

Locking

Auto-shut off

Digital scale

Analog scale

Footwear: Incoming testing on sampling basis should be

performed for all static footwear products.

(TR 20.20 pgh. 5.3.3.4)

Floor: Per (TR 20.20 pgh. 5.34.13)

Testing and monitoring are required

for performance.

Seating: ESD STM 12.1 and (TR 20.20 pgh. 5.3.5.3)

recommend testing should be preformed. With a reading

of 1 x109 ohms.

Garments: A process of testing garments per ESD STM

2.1, point-to point and sleeve-to-sleeve resistance should

be done.

see (TR 20.20 pgh. 5.3.3.4)

MODEL # B8572

SERIAL # 1000-351/110111/1335

DATE 06-21-11

Must call to activate warranty

1-888-257-3680

Information sent by mail

M ohm

EXAMPLE:

Reading (115.)= 1.15 x 108

Reading (.096.)= 9.6 x 104

Reading ( .96)= .96 x 105

Reading ( 6.3)= 6.3 x 106

Reading (16.3)= 1.63 x 107

Reading (6.13 G)= 6.13 x 109

Reading (>20G)= 2 x 1010

Reading (100G)= 1 x 1011 analog

Backlight

Test button

Test voltage at probes

BOTRON CO INC.

325 W. Melinda Ln.

Phoenix AZ 85027

Ph 623-582-6700

Fax 623-582-6776

sales@botron.com / www.botron.com

Caution, risk of shock.

Caution, refer to user guide.

Equipment protected throughout by

Double insulation case (Class II).

Equipment complies with current EU directives.

Equipment must not be connected to installations >500V.

Test voltage

Locking

Voltage Test

voltage

Locking

Continuity Test

Resistance in K ohms

Buzzer

DIGITAL/ ANALOG

AUDIT MEGOHM

METER B8572

SPECFICITIONS

Accuracy range: +/-3 % per gegohm

Test voltage: 10,25,50,100,250 & 500volts

Electrodes: Two (2) 5lb weights

Power: Six (6)AA

Auto shut off: Conserve batteries

Lock test : As needed

Resistance range: 100G/100v , 100G/500v analog

20G/100v digital

Continuity test: .01meg-220G

Diode test: .01kohm-10000kohm Size:

Voltage: +/-1 V-500V

Test leads: 2-4’ long banana to banana

(red & black)

Millivolt test: +/- 1m-1999mV

Low battery: Symbol

Water& dust proof: IP54

Weight: 775gms with boot

Size: 11mm x 220mm x 45mm

Designed to: IEC1010-1

Case: Foam filled

Warranty: Three (3) years

ACCESSORIES:

B8563/20: 20’ lead for floor testing

B48775: Electrostatic field meter

B48775PVS: Complete periodic verification system for testing

ionization. Field meter, charger, plate & case.

Locking

Auto-shut off

Digital scale

Analog scale

Footwear: Incoming testing on sampling basis should be

performed for all static footwear products.

(TR 20.20 pgh. 5.3.3.4)

Floor: Per (TR 20.20 pgh. 5.34.13)

Testing and monitoring are required

for performance.

Seating: ESD STM 12.1 and (TR 20.20 pgh. 5.3.5.3)

recommend testing should be preformed. With a reading

of 1 x109 ohms.

Garments: A process of testing garments per ESD STM

2.1, point-to point and sleeve-to-sleeve resistance should

be done.

see (TR 20.20 pgh. 5.3.3.4)

MODEL # B8572

SERIAL # 1000-351/110111/1335

DATE 06-21-11

Must call to activate warranty

1-888-257-3680

Information sent by mail

M ohm

EXAMPLE:

Reading (115.)= 1.15 x 108

Reading (.096.)= 9.6 x 104

Reading ( .96)= .96 x 105

Reading ( 6.3)= 6.3 x 106

Reading (16.3)= 1.63 x 107

Reading (6.13 G)= 6.13 x 109

Reading (>20G)= 2 x 1010

Reading (100G)= 1 x 1011 analog

Backlight

Test button

Test voltage at probes

BOTRON CO INC.

325 W. Melinda Ln.

Phoenix AZ 85027

Ph 623-582-6700

Fax 623-582-6776

sales@botron.com / www.botron.com

Caution, risk of shock.

Caution, refer to user guide.

Equipment protected throughout by

Double insulation case (Class II).

Equipment complies with current EU directives.

Equipment must not be connected to installations >500V.

Test voltage

Locking

Voltage Test

voltage

Locking

Continuity Test

Resistance in K ohms

Buzzer

DIGITAL/ ANALOG

AUDIT MEGOHM

METER B8572

Other manuals for B8572

1

Table of contents

Other Botron Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Forward

Forward STM-6600 user manual

Klein Tools

Klein Tools CL110 instruction manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS HT625B01 Installation and operating manual

Elcometer

Elcometer 124 operating instructions

HEIDENHAIN

HEIDENHAIN ND 1200R Radial operating instructions

ATAGO

ATAGO PAL-41S instruction manual