Botron OMNIGND B92700 User manual

Operation Manual

Description:

The Botron B92700 OMNIGND is a Multi-Ground Continuous

Monitoring Automation System.

Directory:

Overview Pg. 2

Features Pg. 3

Quick Setup Guide Pg. 3

Pg. 5

Display Screens Pg. 15

Functionality Pg. 18

Pg. 19

Relay Warnings Pg. 20

Pg. 20

Contact Information Pg. 21

Table of Contents

OMNIGND Operation Manual Page 1

OMNIGND Operation Manual Page 3Page 2 OMNIGND Operation Manual

Intuitive Tri-color LCD screen display

8 monitored ports for real-time measurement and recording events

2 Relays for TTL equipped devices

Network communication through built-in Ethernet connection

USB connection

Measures Ground resistance of 1 ohm—20M

VTR Technology (Variable Test Resistance Technology) for each port

Web Server TCP communication

Ports are transistor-transistor logic (TTL)

Ports accept Analog in Resistance and Digital IN and OUT

Aluminum Grounding Hub with 6 Banana Jacks and 5 Ring Terminals

Quick Setup Guide:

What’s in the box

1 x B92700 OMNIGND Unit

1 x Ethernet Cable

1 x USB Cable

1 x 12V DC Power Cable

1 x Ground Cord

1 x Mounting Bracket

Powering On

Install the power cable to the OMNIGND located on the top of the device.

Plug the power cable into desired outlet.

The OMNIGND will automatically power up and display the Serial

Number and Version.

Once booted, you will be presented with the Status Screen (Home).

You can then cycle through the screens by pressing the Select Button

on the top left corner of the device.

ºOn 1st Press: The TCP Information Screen

ºOn 2nd Press: The Fail Range Screen

ºOn 3rd Press: The System Information Screen

ºOn 4th Press: The Auto-Logging Screen

ºOn 5th Press: Returns to the Status Screen.

(For more information on what these screens mean, see page 15)

OMNIGND Features

OMNIGND Overview:

OMNIGND Operation Manual Page 5Page 4 OMNIGND Operation Manual

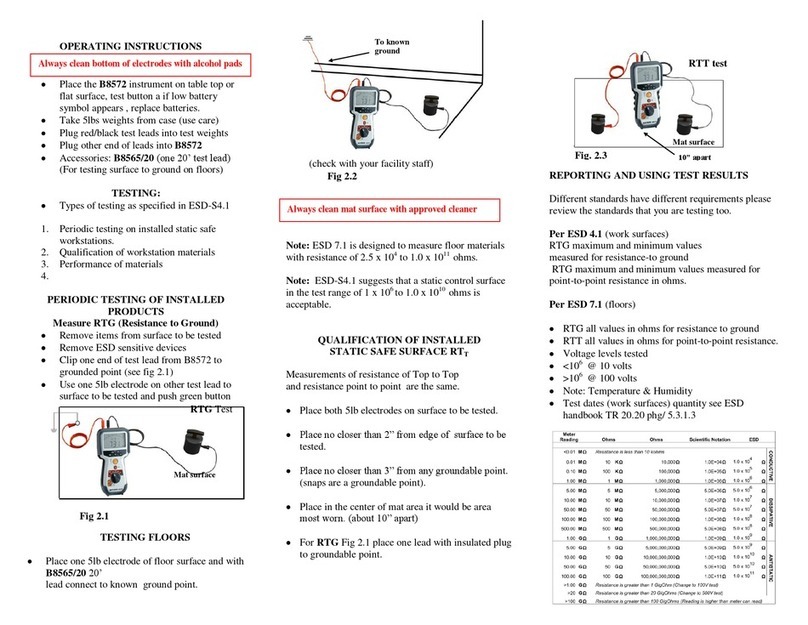

Grounding:

To ground the OMNIGND, connect a wire from a properly grounded source

(eg: the B92500 GroundHog from Botron) to either ring terminal or banana

jack of the Ground Hub located on the bottom of the OMNIGND. This will

ground the entire Ground Hub.

When the OMNIGND has been properly grounded, the rest of the open

ports of the Ground Hub may be used for grounding other devices.

It is recommended that a ground wire is used to connect the grounding

block on the bottom of the OMNIGND to the far left monitoring port

(Port H) on the top of the OMNIGND. By factory default this Port H is

named OMNIGND.

continuously verify the built-in Ground Hub to insure that it is properly

grounded.

Connecting Devices:

To monitor equipment, connect a ground wire from one of the available

monitoring ports located on the top of the OMNIGND to a known point of

ground on the desired device. (The name and description for the port may be

Connecting the Relays (Optional):

When connecting a device to the relays, located on the left side of the

OMNIGND, ports TWO and THREE are used in general. Port ONE of the relay

is used for customized applications. (needs rewording to better understand)

Connect a wire from a power source to port TWO of the Relay and a wire from

port THREE of the Relay to the device.

For the Relay to OPEN for the device to work:

The Relay must be turned on for one or more Ports.

The Ports that are turned on for the Relay must be in PASS states.

*Note: Ports 1 & 2 are normally open. Ports 2 & 3 are normally closed.

Getting Online:

To connect the OMNIGND to your local area network (LAN), connect an

Ethernet cable from an active router, switch or terminal that provides network

access, to the Ethernet connector located on the top of the OMNIGND.

Mounting:

Once your OMNIGND is connected and your equipment setup is complete,

accessed and/or viewed.

Ready for Customization.

Configuring Your Settings Online:

Locating the OMNIGND in your network:

Finding the IP address on your OMNIGND

ºOn the OMNIGND press the Select Button until you reach the TCP

Information Screen (one press from the Status Screen).

ºLocate the IP Address on the screen. (ex.: IP: 192.168.1.217)

Open an internet browser on a PC/Mac, tablet or phone connected to the

same network as the OMNIGND.

ºType in the IP address (located in the steps above) of the OMNIGND

in your browser’s address bar.

◆OPTIONAL: Type in http://OMNIGND to an internet browser

connected to the same network as the OMNIGND.

Getting to know the OMNIManager interface:

The Menu on the left side of the page contains the following sections for

information and customization of the OMNIGND.

• Main Tab

º

on the Main page.

ºThe Main page displays the following:

ºThe name of the unit

ºThe unit description.

◆Individual port information

◆

◆Port Name (LCD Display Name)

◆Port Description (Descriptions)

◆Current Resistance Value

◆Port Status

Quick Setup Guide Continued: Quick Setup Guide Continued:

OMNIGND Operation Manual Page 7Page 6 OMNIGND Operation Manual

Configuring Your Settings Online Continued: Configuring Your Settings Online Continued:

Port Name Tab

The Port Name page is where you can change the name of the Unit and

its description, along with the name of each individual port and their

corresponding descriptions.

We recommend you change each ports display name to something easily

After changes are made, press the Save Button in order to update the

Unit with your new settings.

The maximum number of characters for the name and description of

the Unit and the names and descriptions of the ports are as follows:

ºUnit Name: 33 Characters Max

ºUnit Description: 33 Characters Max

ºPort Names: 8 Characters Max

ºPort Descriptions: 33 Characters Max

Fault Logs Tab

The Fault Log Tab is where you can access the recorded data of port events.

Press the Retrieve Log button to retrieve the Fault Log information for

the Unit.

ºOMNIManager will display up to 50 events at a time.

ºThe Start and End positions of the Fault Log can be changed to

retrieve any stored events in batches of 50 by either entering a

value or using the up/down arrows.

The web page will then display a table of recorded Fault Log information

stored on the Unit.

This information will include:

ºRow Number

ºLog Number (event number)

ºThe Port that recorded the event

ºThe Date in which the event took place

◆Format: MM/DD/YY

ºThe Time in which the event took place

◆Format: HH:MM:SS

ºThe Status of the event

◆Ex: High Fault, Low Fault, or PASS

º

ºThe Low Fault setting for the port

ºThe High Fault setting for the port

OMNIGND Operation Manual Page 9Page 8 OMNIGND Operation Manual

Configuring Your Settings Online Continued: Configuring Your Settings Online Continued:

Hardware Tab

This is one of the many VTR Technology customization pages featured in

OMNIManager. In this page, the controls for individual monitored ports may

be changed.

If a Port is unchecked, then the port and its controls are considered to be

turned off. This port will not be active for monitoring.

Once the port is turned on, you may now activate any of the following

controls for each individual port.

ºTurn Log Events to Memory - On/Off

◆This must be turned on for the Unit to store any information

when a Port switches to a FAIL state and/or a FAIL state to a

PASS.

ºTurn the Port - On/Off (active/inactive)

ºTurn Relay A - On/Off

ºTurn Relay B - On/Off

ºTurn Buzzer - On/Off

ºTurn Auto Alert Send on Fault - On/Off

◆If turned on, an email will be sent to the selected recipient with

information regarding the event at the time of the fault.

The recipient may be changed under the Auto Alert page.

ºTurn Auto Alert Send on Fault to Pass - On/Off

◆If turned on, an email will be sent to the selected recipient with

information regarding the event at the time of the fault to pass.

The recipient may be changed under the Auto Alert page.

ºPress the Save Button to save the changed settings to the Unit.

Delay Tab

The Delay page is where you can customize the delay settings for the TTL

relays.

The delays for the following may be changed:

ºRelay A Delay before turned On

◆The amount of seconds to wait before the Relay turns on after

all Ports that are turned on are in PASS states.

ºRelay A Delay before turned Off

◆The amount of seconds to wait before the Relay turns off after

all one or more Ports that are turned on are in a FAIL state.

ºRelay B Delay before turned On

◆The amount of seconds to wait before the Relay turns on after

all Ports that are turned on are in PASS states.

ºRelay B Delay before turned Off

◆The amount of seconds to wait before the Relay turns off after

one or more Ports that are turned on are in a FAIL state.

ºAlarm Delay before turned On

◆The Alarm Delay is the amount of seconds that pass before the

buzzer goes off after a Port goes into a FAIL state.

To update the Unit with the new changes press the Save button.

OMNIGND Operation Manual Page 11Page 10 OMNIGND Operation Manual

Configuring Your Settings Online Continued: Configuring Your Settings Online Continued:

Range Tab

This is one of the many VTR Technology customization pages featured

in OMNIManager. In this page, the range value settings may be changed

anywhere from 0 to 20M.

Use the Range page to change the Low and High fault resistance values

of each individual Port.

ºEnter a number or use the arrows next to the input box to increase

or decrease the fault range.

To turn off the Low or High fault range of a Port, enter the ohm value

of zero (0) in the corresponding input box for the High or Low section.

To update the Unit with the new changes press the Save button.

Auto Alert Tab

The Auto Alert Tab is where you can enter email recipients information for

event alerts.

Under the Auto Alert Page the following settings may be changed:

ºSMTP Server

◆The SMTP Server name may be 32 characters or less.

◆Only letters from the English alphabet, numbers 0-9, and the

*Note: Only SMTP servers that do not require SSL may be used.

ºUser Name

◆The User Name is the email address used to send the emails

from. The User Name may be 32 characters or less.

◆Only letters from the English alphabet, numbers 0-9, and the

ºPassword

◆The Password may be 20 characters or less.

◆Only letters from the English alphabet and numbers 0-9

ºRecipient (To whom the email is to be sent to)

◆The Recipient name may be 32 characters or less. Commonly

known as an email address.

◆Only letters from the English alphabet, numbers 0-9, and the

ºPort

◆Use the Port that is in connection with the SMTP server that

will be used.

ºSend Alert On Power Failure

◆

an email alert to the chosen Recipient when the Unit is powered

back up.

ºMessage

◆Changes the message that is sent with the alert.

ºTo update the Unit with the new changes press the Test/Save

button.

Configuring Your Settings Online Continued: Configuring Your Settings Online Continued:

OMNIGND Operation Manual Page 13Page 12 OMNIGND Operation Manual

The Email Alert to the recipient when a Port goes into a FAIL state will

contain:

Unit Name

Unit Description

Port Name

Port Description

Event value at time of fail

Low Fault

High Fault

Network Tab

The Network Page displays the network information for the OMNIGND Unit:

The MAC Address and Host name are non-changeable

ºThe MAC Address is a way of identifying the Unit.

ºThe Host Name may be used in an internet browser connected to

the same network as the OMNIGND unit to get the TCP settings.

Enable DHCP

ºBy enabling DHCP, the user may change the IP Address, Gateway,

Subnet Mask, Primary DNS, and Secondary DNS.

ºThe IP Address, Gateway, Subnet Mask, Primary DNS, and Secondary

DNS must be in the format: XXX.XXX.XXX.XXX

◆Note: If one or more of the four sections of numbers is in a

◆Note: If one or more of the four sections of numbers is in a

To save and chances to the Network Interface, press the Restart

Interface button. The Unit will then refresh its LCD screen, returning

to the Status Screen.

Configuring Your Settings Online Continued: Display Screens:

OMNIGND Operation Manual Page 15Page 14 OMNIGND Operation Manual

Factory Default Tab

The Factory Default page may be used to reset the unit back to factory

default values for the following:

ºTable of Content

ºHardware Setting

ºFault Range Setting

ºFault Log Reset

ºAlert Setting

ºPort Name

ºNetwork Setting

Choose one of the available selections to be reset to its factory default

values by the corresponding box next to it.

After you have made your selections; press the Update button to begin

the reset process.

º(Please note that any values reset on a given tab will affect

corresponding values across the OMNIManager.)

Resetting Table of Contents is a full factory refresh.

When the reset command is sent, the Unit will power off, and reboot

with factory default settings.

º(Please note the OMNINGND will disconnect with the TCP website

as it powers down. When the Unit reboots, the TCP website will

need to be refreshed to establish a connection with the Unit again.

Understanding Screen Modes

The Tri-color LCD screen gives color coded back lighting indicating the status

of the OMNIGND.

• Blue: Passive Mode (not recording data)

• Green: Logging Mode

• Red: Ground Failure

The Status Screen displays 3 columns; Port Name, Resistance Value and

Current State.

Column One:

ºOMNIGND

monitors.

ºBy default the ports are named:

1. Port A

2. Port B

3. Port C

4. Port D

5. Port E

6. Port F

7. Port G

8. OMNIGND

◆The name of these ports can be changed by USB or Web Server.

(See Page 6.)

Column Two:

º

of each port.

◆OFF

monitoring.

ºNo numerical indicator represents Ohms

◆Example: 200 is the equivalent of 200 Ohms.

ºk represents kilohms

◆Example: 200k is the equivalent of 200,000 Ohms.

◆Example: 1.5k is the equivalent of 1,500 Ohms.

ºM represents Megohms

◆Example: 3M is the equivalent of 3,000,000 Ohms.

◆Example: 2.5M is the equivalent of 2,500,000 Ohms.

º> (greater than sign)

◆Example: >20.0M means the resistance value of the Port is

greater than 20,000,000 Ohms limit.

OMNIGND Operation Manual Page 17Page 16 OMNIGND Operation Manual

Display Screens Continued: Display Screens Continued:

Column Three:

ºThe third column lists the current state that each Port is in:

◆A PASS state means the current resistance value is in between

the Low and High resistance values for that Port.

◆A FAIL state means the current resistance value is outside

either the set Low or High resistance values for the Port.

◆If the Port is turned off, column three will not display anything.

TCP Information Screen

The Network Information Screen displays the Unit’s:

1. IP address

2. Gateway (GWY)

3. Subnet Mask (Mask)

4. DHCP (ON or OFF)

5. MAC address

6. NetBIOS

VTR Screen

Column One

ºLists the name of each Port, A through H.

Column Two

ºLists the LOW Fail Range

OFF

Column Three

ºLists the High Fail Range

System Information Screen

The System information Screen displays the Unit’s:

1. Serial Number (SN)

2. Firmware (FW)

3. Fault Count

ºThe Fault Count is the cumulative number of recorded faults.

◆The Fault Count will also increase if the Unit is powered off

4. Date (MM/DD/YY)

5. Time (HH:MM:SS)

Auto-Logging Screen

The Auto-Logging Screen is used to turn Auto-Logging on and off.

ºAuto-Logging means the unit will record all monitored ground

events.

Changing Auto-Logging ON and OFF:

ºHold the Select Button (located on the top of the unit) until loading

is completed.

ºIf Auto-Logging is turned on, the background color of the screen will

change from blue to green.

ºIf Auto-Logging is turned off, the background color of the screen

will change from green to blue.

OMNIGND Operation Manual Page 19Page 18 OMNIGND Operation Manual

Functionality: Technical Specifications:

Buzzer Alert

An audible alert that sounds on ground failure.

The Buzzer alert for each individual port may be changed using the

OMNIManager.

In order for the Buzzer to sound:

ºThe OMNIGND must be in logging mode.

ºThe Port must be turned on.

ºThe Buzzer feature must be selected.

The Buzzer will continue to sound unless the failing Port or Buzzer is

turned off from the OMNIManager.

Relay

The OMNIGND comes with two relay connections. Each port can be assigned

to one of the two relays. The relays can be connected to compatible TLL

devices, lights, alarms, doors, etc.

The Relay Functions for each individual port may be set using the

OMNIManager.

When all of the active Ports with the Relay setting turned on are in

PASS states; the switch will remain open, passing current to the device

connected to the Relay.

When one or more of the active Ports with the Relay setting turned

on are in FAIL states; the switch will be closed, not allowing passing

current to the device connected to the Relay. (See Relay warnings and

Select Button

The Select Button is used to toggle between Display screens and to enter

into Logging Mode when the Auto-Logging Screen is displayed.

Ground Hub

When one of the banana jacks of the Ground Hub is connected to ground,

the entire Ground Hub

banana jacks and ring terminals may then be used to ground workstations,

carts, ionization, benches, matting, and much more.

Size and weight

º

º13.97cm x 10.16cm x 3.51 (w/Stand 5.69cm)

º.7 lbs. (11.4oz.)

Display

ºTricolored LCD Screen (Red, Green, Blue)

Connections and Expansion

º(2) Relay Ports

º(8) Data Ports

ºAluminum Grounding Hub

Electrical

º12V Power Jack DC/100mA

ºRJ11 Serial Connector to PC

Audio

ºBuilt-in audible failure alarm

Internet Connection

ºRJ45 Ethernet Connector

Logo

º5 Blue LEDs located behind OMNIGND logo

OMNIGND Operation Manual Page 21Page 20 OMNIGND Operation Manual

Relay Information: Botron Contact Information:

Relay Warnings

The relay only acts as an off or on switch.

The relays do not provide any power or current.

The relays should not be used for voltage over 30volts.

The relay should not be used for current over 1 ampere.

The relay can be use on access control or signaling of devices that

operator on voltage less or equal to 30Volts at 1amp max.

Recommend wire gauge to be use with relay system 12gauge for wires

length under 13ft.

Recommend wire gauge to be use with relay system 10gauge for wires

length under 22ft.

Do not connect wire length over 22ft with relay system.

Do not connect voltage over 30volts and over 1amp to relay.

Do not connect AC line power to relay.

Relay Specifications

Nominal switching capacity : 1A 30V DC

Max switching power: 30W

Max switching volt: 30V DC

Max switching current: 1A

Recommended wire gauge: 0-13ft 12-ga; 13-22ft 10-ga

Recommended max wire length from load/source to relay: 22ft

Recommended operating temperature: 15°C to 35°C; 59°F to 95°F

Recommended operating humidity 25% to 85%

Botron Company Inc.

21601 N. 21st Avenue

Phoenix, AZ 85027

(623)582-6700

Table of contents

Other Botron Measuring Instrument manuals