Disclaimer. All statements of technical information are believed to be true and are based upon tests we

believe to be reliable. The proper use and application for this product must be the responsibility of the user.

The statements herein shall have no force or effect.

Botron Company Inc. | 21601 N 21st Ave Phoenix AZ 85027 | Ph# 623-582-6700 | Fax# 623-582-6776

2 of 2

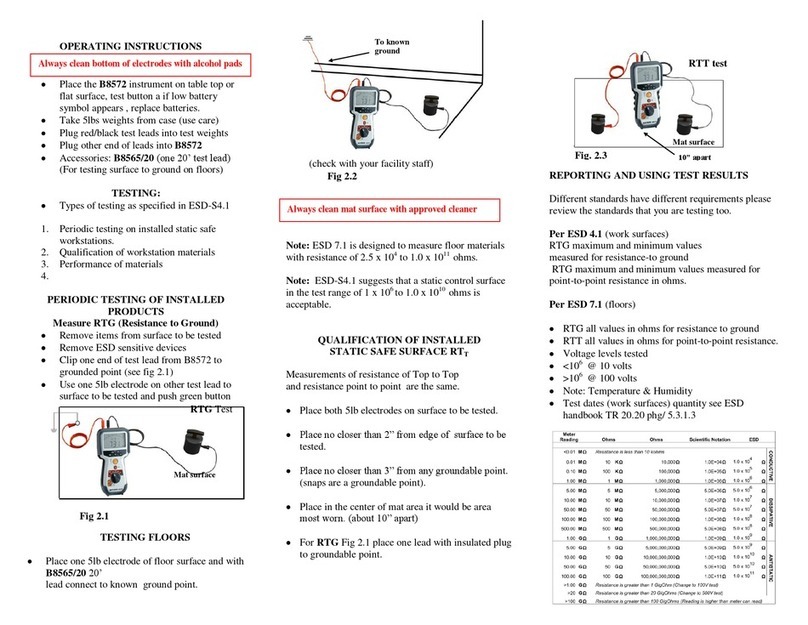

APPLICATIONS

To be used in work environments in accordance with S20.20

standard for monitoring resistance from worker to ground. It is

recommended to use constant monitoring in work environ-

ments handling components that are more susceptible to ESD

damage.

INSTALLATION

1. Mount monitor under bench area. ** If installed this way, use

standard grounding methods

2. Plug in power supply to 115v grounded outlet & unit

3. Plug grounding wire into back of unit.

4. Plug wrist strap into monitor B9201

5. Turn switch on.

6. LED will light green if good. Time to time some people have

higher and lower resistance. You can adjust this unit by

turning the adjustment screw. If the body resistance is low

turn adjustment screw to left to increase the resistivity.

When the lamp is green it is in the correct position. If the body

resistance is high, turn adjustment screw right to

decrease resistivity. When green light comes on, that is the

correct position

7. Alarm will sound and light will go red if strap is bad. It will

also go into alarm if the ground is lost. You may turn o

alarm with on/o switch in front of unit when not in use.

8. * Alternate mounting, use snap ground on monitor, to snap

on mat. (must have 3/8”F-snap on mat)

CALIBRATION

All Botron continuous monitors part numbers above do not

need to be calibrated. They are a Go/No-go solid state, imped-

ance based, monitors with no adjustability and does not need

to be calibrated. It is always important to make sure that all

units have a proper ground. An improper ground or poor

connection will sound the alarm.