boviet SOLAR GAMMA Series Manual

02

02

02

02

03

04

04

04

05

06

07

08

12

13

14

17

17

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

01

MANUAL OVERVIEW

1.1 DISCLAIMER OF LIABILITY

1.2 DECLARATION

UNPACKING AND STORAGE INFORMATION

SAFETY PRECAUTIONS INFORMATION

ENVIRONMENTAL CONDITIONS INFORMATION

4.1 ENVIRONMENTAL CONDITIONS

4.2 INSTALLATION SITE

MOUNTING OVERVIEW

5.1 MOUNTING

5.2 MOUNTING WITH BOLTS

5.3 MOUNTING WITH CLAMPS

5.4 GROUNDING

ELECTRICAL CONFIGURATION INFORMATION

WIRING AND NOTES INFORMATION

MAINTENANCE INFORMATION

WARNING

1.1 DISCLAIMER OF LIABILITY

The installation, handling and use of modules are beyond Boviet’s control, and Boviet Solar does

not assume responsibility for loss, damage, injury, or expense resulting from the improper installation,

handling, use, or maintenance of the module.

Boviet Solar assumes no responsibility for any infringement of patents or other rights of the third parties that may

result from use of the module. No license is granted by implication or under any patents or patent rights.

Boviet Solar reserves the right to update this manual, module specications and/or relevant information

without prior notice.

1.2 DECLARATION

The re rating of the module is valid only when mounted in the manner specied in the mechanical

mounting instructions.

The module is considered in compliance with UL 1703/61730 or IEC 61215/61730 only when mounted in the manner

specied in the mechanical mounting instructions below.

A module with exposed conductive parts is considered to be in compliance with UL 1703/61730 or IEC 61215/61730

only when it is electrically in accordance with the instructions presented below and the National Electrical Code.

Any module without a frame (laminator) should not be considered to comply with the requirements of UL 1703

or IEC 61215/61730 unless the module is mounted with hardware that has been tested and evaluated with the

module under this standard or by a eld engineer certifying that the installed module complies with the requirements

of UL 1703/61730 or IEC 61215/61730.

2 |UNPACKING AND STORAGE INFORMATION

At the time of receipt, verify that the product delivered is the same product ordered. The product name, sub name,

and serial number of each module are clearly marked on the outside of each packing box.

Store packing boxes in a dry and ventilated room.

1 |MANUAL OVERVIEW

This manual offers general information regarding installation and maintenance of photovoltaic

modules manufactured by Boviet Solar, which thereafter will be referred to as “modules.”

These manual instructions should be read and understood before installation, handling, or

maintenance. To ensure the correct and safe use of the photovoltaic modules, the installer

should be familiar with the mechanical and electrical requirements for photovoltaic systems.

1.

2.

02

Leave the product in its original packing box until it is ready for installation.

If pallets are stored outside temporarily, a protective covering over the pallet should be placed to protect products

from direct weathering. Pallets should not be stacked more than one pallet high.

At the installation site, keep modules and electrical contacts clean and dry before installation.

Do not stack more than the maximum amount of allowable pallets on top of each other. Do not exceed two layers

of pallets high.

Do not place modules directly on top of each other.

Do not place excessive loads on the module or twist the module frame.

Do not stand, step, walk and/or jump on the module.

Do not carry a module by its wires or junction box but by its frame with both hands by two or more persons.

Do not mark the module with a sharp instrument.

3 |SAFETY INFORMATION

The instructions in this safety manual are intended to prevent danger, damage, and failure.

DO NOT touch electrically active parts of the panel, such as the output wiring, without the adequate safety protection.

Bare contact may cause an arc or shock that can lead to injury or even death. Do not use a module that is broken, torn,

or damaged. Non-conformity may cause damage, failure, and/or serious bodily injury.

1. Before installing a system, contact the appropriate authorities for site installation, inspection permission/s

and requirement/s.

2. Operators shall foresee the risk of injury during the processes of installation, troubleshooting and maintenance

of the modules. Therefore, only authorized, and trained personnel should have access to, and perform work

on the modules or system.

3. Ensure that modules meet the technical requirements of the system as a whole.

4. When connecting the modules, remove all metallic jewelry, use properly insulated tools, and wear appropriate

personal protective equipment to reduce the risk of electrical injury.

5. Do not disassemble the modules or remove any part of the module.

6. Do not stand, step on, damage, or scratch surfaces of the module.

03

3.

4.

5.

6.

7.

8.

9.

10.

11.

7. Do not install or handle wet modules.

8. Do not touch the exposed cables or connectors.

9. Do not articially concentrate sunlight on the solar modules.

4 |ENVIRONMENTAL CONDITIONS INFORMATION

4.1. ENVIRONMENTAL CONDITIONS

Only Install the PV modules within the following conditions:

1. Ambient temperature: -40°C to 40°C

2. Operating temperature: -40°C to 85°C

3. Storage temperature: -30°C to 50°C

4. Humidity: <85RH%

5. Keep modules away from inflammable gas, hazardous chemicals, or re sources.

4.2. SITE INSTALLATION

1. To ensure the modules receive the most sunlight exposure, position the modules in a manner to minimize

the chances of shading throughout the day by trees, buildings, or any other surrendering objects.

2. Solar modules should normally be mounted facing the equator at an angle to the horizontal plane equivalent

to the latitude of the installation for optimum energy generation. The module tilt angle is measured between

the solar modules and the horizontal (Figure 1). Any slope less than 5in/ft(127mm/305mm) is required

to maintain a re class rating. The PV module generates maximum output power when it faces the sun directly.

3. Do not install modules in the location where they will be immersed in water or continually exposed to water

from a sprinkler, hose, or fountain.

4. Please leave a safe working area between the edge of the roof and the external edge of the solar array when

installing modules on a roof.

5. Avoid a mounting method that will block the drainage holes in the module frame.

04

5 |MOUNTING OVERVIEW

Figure 2: PV Module I Mechanical Drawing

When the climate of the project site is normal,

we recommend using 4-hole mounting (M8 nut).

The yellow 4-hole mounting (M8 nut), or blue

4-hole mounting (M8 nut) can be used.

When the climate of the project site reaches

severe conditions (2400Pa wind load and 5400Pa

snow load), the blue or yellow 4-hole mounting

(M8 nut) needs to be used, in addition to the

middle red auxiliary mounting hole (M6 nut).

5.1 MOUNTING

Solar PV modules usually can usually be mounted by using

the following methods: bolts or clamps.

PV modules can be mounted to a substructure with either

corrosion-proof M8 (bolts placed through the mounting

holes on the module frame) or with specially designed

module clamps.

Note: All installation methods herein are only for

reference. Boviet Solar will not provide related BOS

components. The system installer or trained professional

personnel must be responsible for the PV system’s design,

installation, mechanical load calculation and security

of the system.

Regardless of the method, the nal installation of the

modules should ensure that:

A clearance of at least 115mm (4.5in) is required provided

between the module frame and the surface of the wall

or roof. The minimum distance between two modules is

10mm(0.4in).

The mounting method should not block the drainage holes.

Panels are not subjected to wind or snow loads exceeding

the maximum permissible loads and are not subject

to excessive forces due to the thermal expansion

of the support structures.

Note: The drainage holes cannot be blocked in any

situation during installation or use.

Figure 1. PV Module Tilt Angle

05

Figure 3: PV Module I Mechanical Drawing

No PV Module:

# of Cell & Cell Type PV Module: Name PV Module: Size

(Length*Width*Thickness)

PV Module: Installation

Hole Spacing

1 182-Half-cut module BVM7612M-XXX-H-HC (144 cells) 2296*1134*35mm A:1300 B:1600

2 166-Half-cut module BVM6612M-XXXS-H-HC (144 cells) 2135*1046*35mm A:1080 B:1360

3 166-Half-cut module BVM6610M-XXXS-H-HC (120 cells) 1794*1046*35mm A:1080 B:1260

4 158-Half-cut module BVM6612M-XXXL-H-HC (144 cells) 2052*1002/1004*35mm A:1080 B:1360

5 158-Half-cut module BVM6610M-XXXL-H-HC (120 cells) 1727*1002/1004*35mm A:960 B:1200

6 158-full cell module BVM6612M-XXXL-H-BF-DG (144 cells)

BVM6612M-XXXL-H-BF (144 cells) 2015*1002/1004*35mm A:900 B:1300

7 158-full cell module BVM6610M-XXXL-H-BF-DG (120 cells)

BVM6610M-XXXL-H-BF (120 cells) 1693*1002/1004*35mm A:960 B:1200

8 156-Half-cut module BVM6612M-XXX-H-HC-BF-DG (144 cells)

BVM6612M-XXX-H-HC-BF (144 cells) 2028*992*35mm A:1080 B:1360

9 156-Half-cut module BVM6610M-XXX-H-HC-BF-DG (120 cells)

BVM6610M-XXX-H-HC-BF (120 cells) 1706*992*35mm A:960 B:1200

10 156-full cell module BVM6612M-XXX-H-BF-DG (144 cells)

BVM6612M-XXX-H-BF (144 cells) 1991*992*35mm A:900 B:1300

11 156-full cell module BVM6610M-XXX-H-BF-DG (120 cells)

BVM6610M-XXX-H-BF (120 cells) 1673*992*35mm A:900 B:1300

Table 1: PV Module I Installation Hole Spacing

06

Figure 4: PV Module I Mounting Information, Installed with screw fitting method

When the climate of the project site is normal, we recommend using 4-hole mounting (M8 nut). The yellow 4-hole

mounting (M8 nut), or blue 4-hole mounting (M8 nut) can be used.

When the climate of the project site reaches severe conditions (2400Pa wind load and 5400Pa snow load), the blue or

yellow 4-hole mounting (M8 nut) need to be used, in addition to the middle red auxiliary mounting hole (M6 nut).

In any case clamps should not contact the glass or deform the assembly frame.

The surface of the clamps touching the frame should be flat and smooth; otherwise, the frame and components may be

damaged. For better performance be sure to avoid shading from module clamps.

The drainage holes are not blocked by clamps.

The module frame is not modied under any circumstances as this will not void the warranty.

5.2 MOUNTING WITH BOLTS

There are four 4 (9*14mm) and six (7*10mm size) mounting holes at each panel to mount the modules on a supporting

structure. The module frame must be installed on the mounting rail using M8 corrosion-proof screws together with

spring washers and flat washers in four (4) symmetrical locations on the module.

The applied torque should be approximately 17-23 N*m. The applied torque value should be big enough to x the

modules securely. For special support systems or special installation requirements, please conrm torque value with the

specic support supplier. Please nd detailed mounting information in Figure 4.

When using six (6) mounting holes, the middle two (2) mounting holes are the auxiliary mounting holes which use M6

bolts. The applied torque should be approximately 7-11 N*m for these bolts. PV module mounting information when

installed with screw tting method as shown in Figure 4.

07

5.3 MOUNTING WITH CLAMPS

Mounting with clamps at the long side of frames

The module frame is not to be modied under any circumstance. When choosing this type of clamp mounting method,

please be sure to use at least four (4) clamps on each module, two (2) clamps should be attached on the long sides

of the module.

Depending on the local wind and snow loads, if excessive pressure load is expected, additional clamps may be required

to ensure that the module can bear the loads. The applied torque should be 18-24 N*m.

No PV Module:

# of Cell & Cell Type PV Module: Name PV Module: Size

(Length*Width*Thickness)

PV Module:

Installation Hole

Spacing

1 182-Half-cut module BVM7612M-XXX-H-HC

(144 cells) 2296*1134*35mm J:350

K:500

2 166-Half-cut module BVM6612M-XXXS-H-HC

(144 cells) 2135*1046*35mm J:385

K:530

3 166-Half-cut module BVM6610M-XXXS-H-HC

(120 cells) 1794*1046*35mm J:270

K:355

4 158-Half-cut module BVM6610M-XXXL-H-HC

(144 cells) 2052*1002/1004*35mm J:350

K:490

5 158-Half-cut module BVM6610M-XXXL-H-HC

(120 cells) 1727*1002/1004*35mm J:265

K:380

6 158-full cell module BVM6612M-XXXL-H

(144 cells) 2015*1002/1004*35mm J:360

K:560

7 158-full cell module BVM6610M-XXXL-H

(120 cells) 1693*1002/1004*35mm J:250

K:365

Table 2: Fixture Range

08

Figure 5: PV Module I J and K represent the range of the fixture, A and B represent the module size.

Figure 6: PV Module I PV module installed at long side with clamp fitting method

09

Mounting with clamps at short side of frames

Given that some projects need to install the clamps on the short side of the frame, please nd detailed mounting

information as shown in Figure 7. The mounting placement distance should be further than J, but less than

K as shown below.

Boviet Solar suggests that the clamp width should not be less than 35mm, the thickness should not be less than 3mm,

and that the screw should be an M8 model. It is recommended that the tightening torque of the clamp screw nut be

within 18-24 N*m.

Figure 7: PV Module I Short Side Mounting

10

11

Figure 8: PV Module I PV module installed at short side with clamp fitting method

No PV: Cell PV Module: Type PV Module: Width (mm) Fixture Range: mm

1 182 ALL 1134 J:80

K:280

2 166 ALL 1046 J:60

K:260

3 158 ALL 1002/1004 J:50

K:250

Table 3: Short side Mounting

12

5.2 GROUNDING

1. All module frames and mounting racks must be properly grounded in accordance with the National Electrical Code

and any local jurisdictions.

2. The modules are required to be grounded, and the module installation needs to comply with all local electrical codes

and regulations. Additionally, the grounding connection should be made by a qualied electrician.

3. Proper grounding is achieved by bounding the module frame and all metallic structural components together using

a suitable grounding conductor. The grounding conductor or strap may be copper, copper alloy, or another material

acceptable for use as an electrical conductor per respective National Electrical Codes. The grounding conductor

must make a connection to earth using a suitable earth ground electrode.

4. Where common grounding hardware (nuts, bolts, star washers, split-ring lock washers, flat washers, etc.) is used

to attach a grounding/bonding system, the attachment must be made in conformance with the manufacturer’s

instructions of grounding devices used in the system.

5. Common hardware items such as nuts, bolts, star washers, lock washers and the like have not been evaluated

for electrical conductivity or for use as grounding devices and should be used only for maintaining mechanical

connections and holding electrical grounding devices in the proper position for electrical conductivity. Such devices,

when supplied with the module and evaluated through the requirements in IEC and UL standard, may be used for

grounding connections in accordance with the instructions provided with the module.

6. Boviet Solar recommends the method below:

a. A grounding kit with M4 size SS cap bolt, M4 size SS flat washer, M4 size SS cup washer, and M4 size

SS nut (with teeth) is to be attach a copper grounding wire to a grounding hole pre-drilled on the frame.

b. Attach the wire between the flat washer and the cup washer. Ensure the cup washer is between the frame

and the wire with concave side up to prevent corrosion due to dissimilar metal. Tighten the bolt securely

using the SS nut with teeth (a wrench may be used in this application.) The tighten torque should be 2-3N*m.

7. Alternate grounding options built into the racking system are acceptable as long as they have been UL approved.

13

Figure 9: PV Module I Schematic drawing for the PV module grounding

06 |ELECTRICAL CONFIGURATION

PV systems operates automatically and require day-to-day supervision. The solar array generates DC electricity

whenever light falls on it. Similarly, the inverter automatically turns ON as soon as there is sufcient solar energy

from the array to efciently convert it into grid quality AC Power.

Boviet Solar produces following models, XXX presents the power range.

Table 4: PV Module Model

No PV Module: Type PV Module: Model

1 Bifacial Double Glass module BVM7612M-XXX-H-HC-BF-DG

2 Bifacial Transparent module BVM7612M-XXX-H-HC-BF

3 Monofacial module BVM7612M-XXX-H-HC

4 Monofacial module BVM7610M-XXX-H-HC

5 Bifacial Double Glass module BVM6612M XXXS-H-HC-BF-DG

6 Bifacial Double Glass module BVM6612M XXXS-H-HC-BF

7 Monofacial module BVM6612M XXXS-H-HC

8 Bifacial Transparent module BVM6610M-XXXS-H-HC-BF

9 Monofacial module BVM6610M-XXXS-H-HC

14

Table 5: Electrical Data

The electrical characteristics are within ±10 percent of the indicated values of Isc, Voc and Pmax under Standard Test

Conditions (STC) (irradiance of 100mW/cm², AM 1.5 spectrum, and a cell temperature of 25°C (77°F)).

Under normal conditions, a photovoltaic module is likely to experience conditions that produce more current and/or

voltage than reported at standard test conditions. The requirements of the National Electrical Code (NEC) in Article 690

shall be followed to address these increased outputs. In installations not under the requirements of the NEC, the values

of Isc and Voc marked on this module should be multiplied by a factor of 1.25 when determining component voltage

ratings, conductor ampacities, overcurrent device ratings, and size of controls connected to the PV output.

No Technical Highlight Information

1 System voltage (V) DC1000V/1500V

2 Power Tolerance 0~+5W

3 Insurance Current (A) 15/20

4 Insulation resistance ≥ 40MΩ, m2

5 Application Class Class A

07 |WIRING AND NOTES

All wiring should be performed by qualied installers according to the local codes and regulations.

1. Before connecting modules, always ensure that the contacts are corrosion free, clean, and dry.

2. Before connecting modules, verify that the proper electrical values are measured.

3. To minimize the risk of indirect lighting strike and avoid forming closed loops, review that wiring has been properly

done before starting. If the measured data of open circuit voltage and short-circuit current differ from the

specications, please check the wiring before proceeding.

4. Products can be irreparably damaged if an array string is connected in reverse polarity to another. Always verify the

voltage and polarity of each individual string before making a parallel connection. If strings are connected in reverse

polarity and a difference of more than 2V between 10 strings are measured, please check the string wiring

before making the parallel connection.

No Manufacturer

The Model of

the Connector

Manufacturer

Allowable Mating

Connector

Manufacturer

Website

1Zhe Jiang Jiaming

Tianheyuan PV-JM608 PV-JM608 http://www.jmthy.com

2Zhe Jiang Jiaming

Tianheyuan PV-JM601 PV-JM601 and PV-JM601A http://www.jmthy.com

3Zhe Jiang Jiaming

Tianheyuan PV-JM601A PV-JM601 and PV-JM601A http://www.jmthy.com

4 Multi-Contact USA PV-KST4/6II-UR (male)

PV-KBT4/6II-UR (female)

PV-KST4/6II-UR (male)

PV-KBT4/6II-UR (female)

http://ec.staubli.com/

downloads/

5 Multi-Contact USA PV-KST4-EV02/6II-UR (male)

PV-KBT4-EV02/6II-UR (female)

PV-KST4-EV02/6II-UR (male)

PV-KBT4-EV02/6II-UR (female)

http://ec.staubli.com/

downloads/

6Amphenol Industrial

Operations UTXCFA4AI UTXCFA4AI http://www.amphenol

-Solar.com

7Amphenol Industrial

Operations Helios H4 Assembled Helios H4 Assembled http://www.amphenol

-Solar.com

8Amphenol Industrial

Operations Helios HH4 Assembled Helios HH4 Assembled http://www.amphenol

-Solar.com

9 Zhe Jiang Renhe 05-6-2q 05-6-2q http://www.renhesolar

.com/cn/index.php

Table 6: PV Module I Connector Information

5. The maximum voltage of the system should be less than the maximum certied voltage and less than the maximum

input voltage of the inverter and of the other electrical devices installed in the system. To ensure this, the open circuit

voltage of the array needs to be calculated at the lowest ambient temperature for the location.

6. Before connecting the components, check the appearance of the material to verify that there is no problem.

The connector itself cannot be damaged, have fractures, or have other issues that cause an electrical hazard.

7. Please see the table below for which indicates the connectors to use on the module and the allowable

mating connector.

15

Table 7: PV Module I Connector Images

No Connector Model Connector Picture Website

1 PV-JM608 http://www.jmthy.com

2 PV-JM601 http://www.jmthy.com

3 PV-JM601A http://www.jmthy.com

4PV-KSTA/611 -UR (Male)

PV-KBTA/611-UR (Female)

http://www.staubli.com/

en/connectors/

5PV-KSTA-EV02/611-UR (Made)

PV-KBT4-EV02/611-UR (Female)

http://www.staubli.com/

en/connectors/

6 05-6-2q http://www.renhesolar.

com/cn/index.php

16

08 |MAINTENANCE INFORMATION

A well-designed system needs minimal maintenance.

Maintenance should be carried out at least once a year by well-trained personnel.

Check that the mounting hardware is properly tightened. Check if cables, nuts, and bolts are secure and not loose.

Tighten any loose components if necessary.

Check ground resistance performance and water resistance of connecting cables, grounding cables, connectors, and

any other connections.

Verify that the electrical and mechanical connections are free from corrosion.

Do not touch the live part of the wire, cable, or connector directly, but only with safety equipment (insulating tools and

electrical protection) when necessary.

Use an opaque cloth or other opaque materials to cover the front side of the modules during the maintenance. When

exposed to sunlight the module may produce high voltage which can cause injury and even death.

In the event that modules need to be cleaned, clean modules with a soft cloth together with a mild detergent and clean

water. To avoid severe thermal shocks, which might damage the module, use water at a similar temperature to the

modules being cleaned.

09 |WARNING INFORMATION

Contact your installer immediately if you suspect your system is not working properly. For any warranty related concerns

contact our Boviet Solar after sales service team at bovietsolar.com/company/contact-us or your sales contact.

WARNING: The PV system must be shut down rst if it needs any electrical maintenance. Improper maintenance may

cause burns and/or electrical shock, which can both be lethal.

CONTACT

Website: bovietsolar.com

17

Disclaimer: The information included in this document is subject to change without any notice and is provided for informational purposes only. No

contractual rights are established or should be inferred because of user’s reliance on the information contained in this PV module installation manual

Please contact with Boviet Solar’s local ofces for more up-to-date product information.

Table of contents

Other boviet SOLAR Solar Panel manuals

Popular Solar Panel manuals by other brands

Carbest

Carbest POWER SOLAR PANEL 135 User instruction

Linyang Photovoltaic

Linyang Photovoltaic BP60T installation manual

Solar Frontier

Solar Frontier SF140-S Data sheet and installation and maintenance manual

MobiSolar

MobiSolar 60W-ETFE-B user guide

Nature Power

Nature Power 42022 user manual

SolarWorld

SolarWorld Sunmodule SW *** poly User instructions

Vaillant

Vaillant auroTHERM VTK 570/2 installation manual

Tycon Power Systems

Tycon Power Systems RPDC-12 Series quick start guide

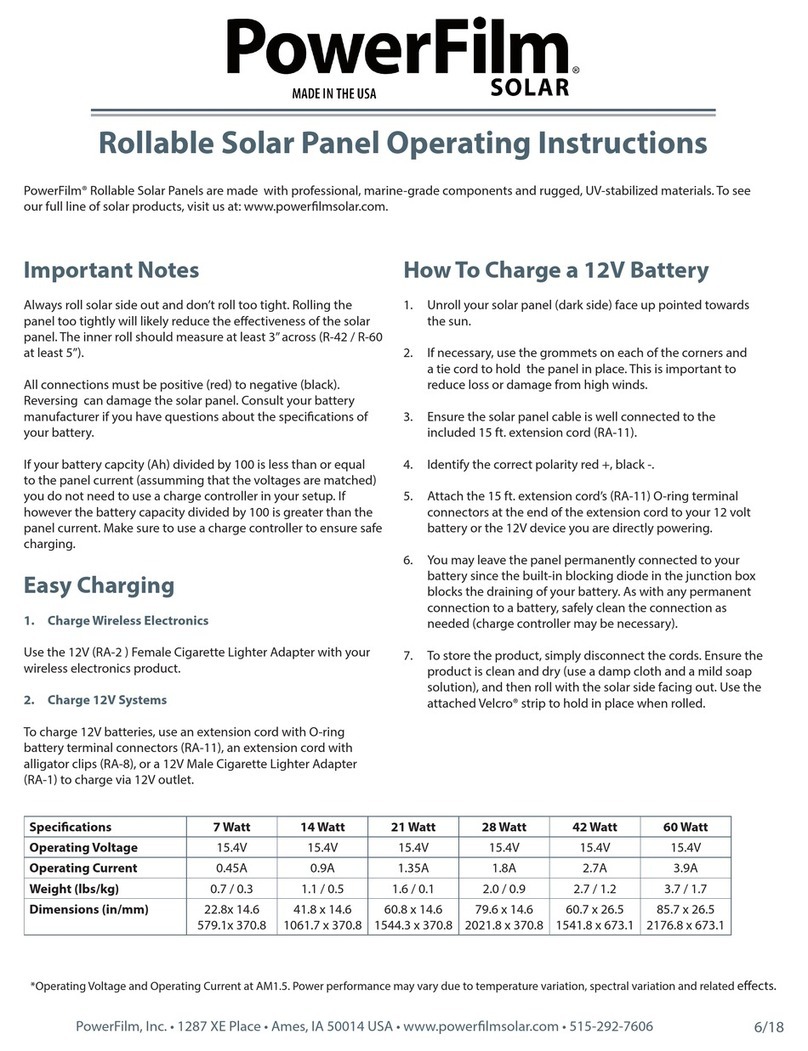

PowerFilm

PowerFilm R-14 operating instructions

LG

LG LGxxxN1CW-A3 Series installation instructions

Viessman

Viessman VITOSOL 100-F installation instructions

Energie

Energie Solar Block 4 Installation and use manual