Bowers M1 User manual

+44 (0) 1276 469 866

Bowers Group Fax +44 (0) 1276 401 498

Unit 3, Albany Court, Web : www.bowersgroup.co.uk

Albany Park, Camberley, Email : sales@bowersgroup.co.uk

Surrey, GU16 7QR

M

M1

1

/

/

M

M3

3

D

Di

is

sp

pl

la

ay

y

u

un

ni

it

ts

s

f

fo

or

r

1

1

o

or

r

2

2

a

ai

ir

r

g

ga

au

ug

ge

es

s

USER’S MANUAL

Firmware 2.1

M1 –M3 Display Units

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS __________________________________________ 2

1. FOREWORDS _________________________________________________ 4

2. INTRODUCTION _______________________________________________ 6

2.1. PRODUCT PRESENTATION ........................................................................6

2.2. VERSIONS ....................................................................................................6

2.3. CHARACTERISTICS.....................................................................................7

2.3.1. MAIN TECHNICAL CHARACTERISTICS...............................................7

2.3.2. DIMENSION AND INSTALLATION ........................................................7

2.3.3. CONTENTS OF THE PACKAGING .....................................................10

2.3.4. ACCESSORIES....................................................................................11

2.3.5. OPTIONS / CABLES ............................................................................12

2.3.6. CONNECTORS....................................................................................15

2.3.7. STANDARD CABLING –RESTRICTOR CHOICE...............................15

2.3.8. CABLING WITH BY-PASS NOZZLE (INTEGRATED RESTRICTOR).18

2.3.9. THE RS232 COMMUNICATION PORT................................................19

2.3.10. MINI-USB CONNECTOR....................................................................20

2.3.11. THE 24VDC CONNECTOR................................................................20

2.3.12. THE USB STICK CONNECTOR ........................................................20

2.3.12. THE FOOTSWITCH CONNECTOR...................................................20

3. AIR PREPARATION UNIT –AIR PIPES ____________________________ 22

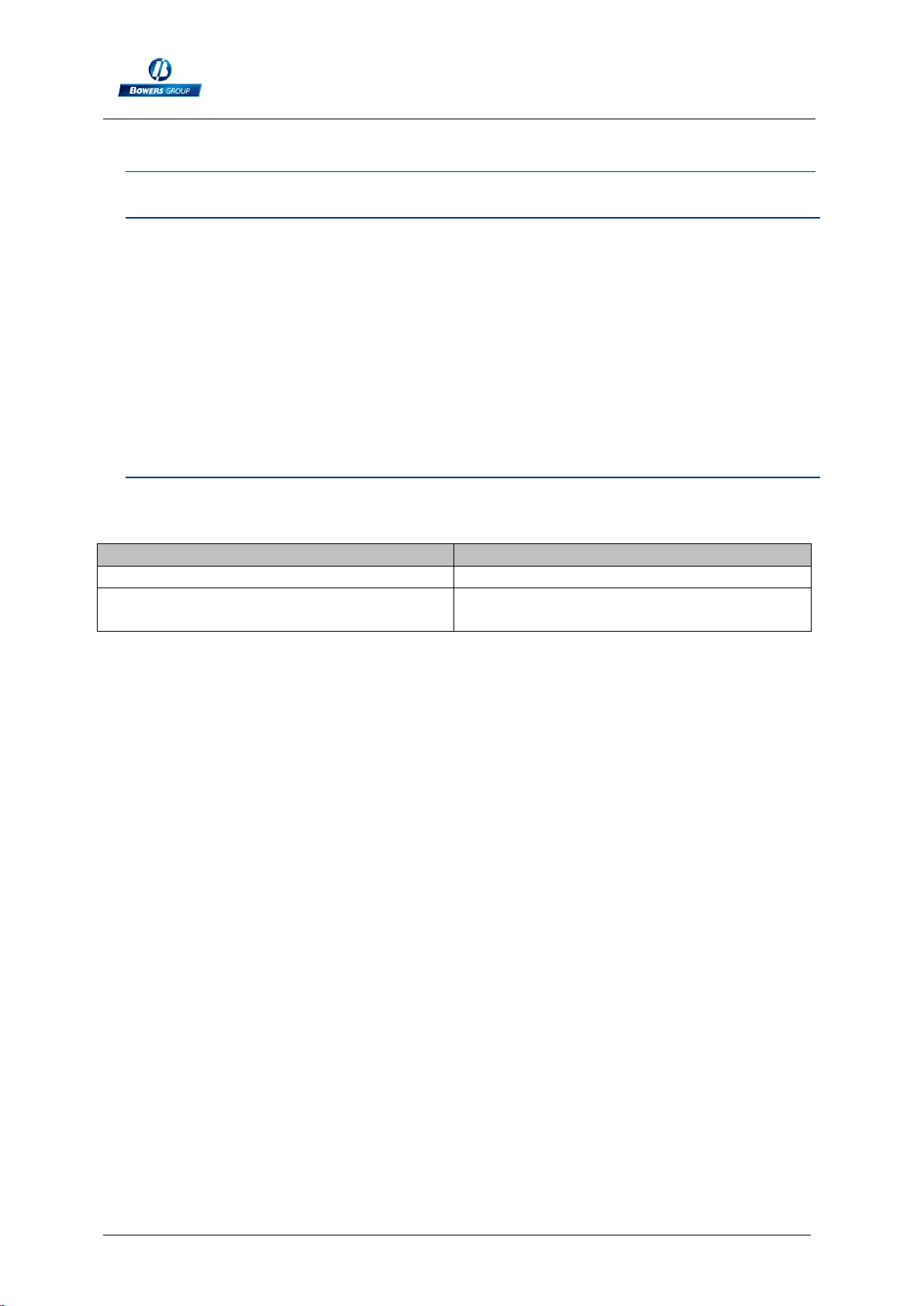

3.1. AIR PREPARATION UNIT...........................................................................22

3.2. AIR PIPES ...................................................................................................22

4. QUICK START ________________________________________________ 24

5. GRAPHICAL INTERFACE _______________________________________ 25

5.1. 2 MAIN PARTS............................................................................................25

5.2. GENERAL....................................................................................................26

5.3. CONFIGURATION WINDOWS ...................................................................28

5.4. VIRTUAL KEYBOARD.................................................................................29

6. CONFIGURATION OF THE DEVICE FOR MEASUREMENT ____________ 30

6.1. DEFINITION.................................................................................................31

6.1.1. PART 1.................................................................................................32

6.1.2. PART 2.................................................................................................35

6.1.3. PART 3 - CLASS..................................................................................36

6.1.4. PART 3 CONTROL LIMIT ....................................................................38

6.2. DISPLAY......................................................................................................39

6.3. SETUP.........................................................................................................41

6.3.1. CALIBRATION OF THE AIR GAUGE...................................................42

6.3.1.1. CALIBRATION IN 2 POINTS.............................................................42

6.3.1.2. CALIBRATION IN 3 POINTS.............................................................45

6.3.2. M-BUS MODULES ...............................................................................46

6.4. CONFIGURATION.......................................................................................52

6.5. LOCK...........................................................................................................55

6.6. MEASURE...................................................................................................57

7. MEASURING SCREEN _________________________________________ 58

7.1. LATERAL BUTTON FUNCTIONS ...............................................................58

7.2. CHOICE OF THE NEEDLE INDICATOR STYLE ........................................61

M1 –M3 Display units

Page 3

7.3. TEMPORARY DYNAMIC MODE.................................................................62

7.4. DISPLAY MODE WITHOUT TOLERANCE .................................................63

8. USB COMMUNICATION_________________________________________ 64

9. RS232 COMMUNICATION_______________________________________ 66

9.1. COMMANDS..............................................................................................66

9.1.1. GENERAL...........................................................................................66

9.1.2. COMMAND LIST ................................................................................67

9.1.2.1. WINDOW PART..............................................................................67

9.1.2.1. WINDOW DISPLAY.........................................................................68

9.1.2.2. WINDOW CONFIGURATION..........................................................68

9.1.2.3. WINDOW « LOCK »........................................................................69

9.1.2.4. MEASURING SCREEN...................................................................70

10. DATA EXPORT ON USB KEYS ___________________________________ 71

10.1. STANDARD MODE : .................................................................................71

10.2. ADVANCED MODE : .................................................................................72

11. CONFIGURATION OF THE UNIT WITH QR CODES __________________ 73

11.1. CALIBRATION COMMANDS:....................................................................73

11.2. ADVANCED CONFIGURATION................................................................74

11.3. EXAMPLE OF QR CODE CONFIGURATION ...........................................74

12. MODBUS RTU Protocol _________________________________________ 76

13. OPTIONAL I/O MODULE ________________________________________ 79

13.1. MB-IO MODULE ........................................................................................79

13.2. MB-RL MODULE .......................................................................................82

13.3. MB-TP MODULE –FOR TEMPERATURE COMPENSATION..................86

14. FACTORY RESET _____________________________________________ 90

15. FIRMWARE UPDATE___________________________________________ 91

M1 –M3 Display Units

Page 4

1. FOREWORDS

ONE YEAR LIMITED GUARANTEE FOR MULTIVISION

MANUFACTURER'S RESPONSIBILITY

SPARE PARTS AND LABOUR.

The manufacturer commits himself to pay for repair or replacement costs (labour

costs included) during a period of one year as from the date the guarantee came into

force. The spare parts can be new or renovated and are guaranteed until the end of

the initial guarantee period.

FIRST END-USER COVERAGE.

This guarantee applies only to the first end-user of the product and is not assignable

to any other subsequent purchaser or user.

RESTRICTIONS.

Any accessory or expansion item not included in the original factory packaging is not

guaranteed.

The present guarantee does not cover: installation or repair costs, damages resulting

from circumstances beyond the manufacturer's control like damages following acts of

God, misuse, or careless mistake from the user, damages during the transport or due

to a wrong installation, use or application, such as any material damage caused by

the use of non-supplied products, components or accessories. It also does not cover

products modified without any written approval from the manufacturer, including

electrical or mechanical modification, removal of serial numbers or of the

manufacturer's trademarks or of any other identification.

THE SOLE RECOURSE UNDER THIS GUARANTEE SHALL BE THE REPAIR OR

THE REPLACEMENT OF DEFECTIVE PARTS AS INDICATED ABOVE. UNDER

NO CIRCUMSTANCES THE MANUFACTURER CAN BE HELD LIABLE FOR

INDIRECT OR SPECIAL DAMAGES OR FOR DAMAGES RESULTING FROM THE

USE OF THE PRODUCT, INCLUDING ANY LOSS OF DATA, BUSINESS OR

PROFIT, AND WHETHER THESE DAMAGES CAN BE FORESEEN OR NOT AND

WHETER THEY ARE BASED ON A GUARANTEE VIOLATION OR NOT.

THE PRESENT GUARANTEE REPLACES ANY OTHER EXPRESSED OR IMPLIED

GUARANTEE INCLUDING BUT NOT LIMITED TO ANY GUARANTEE OF

MARKETING OR ADEQUACY FOR A PARTICULAR USE; AND ALL THESE

GUARANTEES ARE EXPRESSLY EXCLUDED AND CANCELLED.

WARNING

The information contained in this booklet can be changed without notice.

M1 –M3 Display units

Page 5

The manufacturer makes no warranty whatsoever with respect to the warranties of

commercial quality of this product or its suitability to a particular use.

The manufacturer is not responsible for mistakes that could be found in this

handbook and also for direct or indirect damage resulting from the equipment, its

performances and the use of this product.

It is the responsibility of the user to verify the calibration of the display before

measuring and it is advised to check periodically the calibration and

measurement performance.

CLEANING

Use a soft cotton cloth slightly soaked with an ethyl alcohol based product.

DO NOT USE the following products: acetone, benzene, toluene and halogens

hydrocarbons.

M1 –M3 Display Units

Page 6

2. INTRODUCTION

2.1. PRODUCT PRESENTATION

The M1 and M3 display units allow making dimensional control using 1 or 2 air

gauges. Depending on the version it is possible to make simple measurement (with

one air gauge), or display 2 characteristics on the screen and can make static

measurement or dynamic (Max, Min, Max-Min…)

The M1-M3 can be connected to a PC thanks to its RS232 or USB connection.

A footswitch can be connected in order to transfer measurements.

The M1 / M3 displays for air gauges requires a minimum of 2 masters for calibration.

2.2. VERSIONS

REF

Description

55-AIR 1 (M1)

Display unit M1 for 1 air gauge

55-AIR 2 (M3)

Display unit M3 for 2 air gauges or 1 air

gauge with 2 measuring levels

M1 –M3 Display units

Page 7

2.3. CHARACTERISTICS

2.3.1. Main technical characteristics

TFT colour touch screen display 4,3’’, resolution 480x272.

Static or dynamic measurements (Max, Min, Max-Min, Average, Median)

Analogue or digital display

1 or 2 measurement configurations (2 characteristics)

Possibility to select automatically the characteristic by using the air gauge or by

touching the screen.

Relative or absolute display

Display resolution (up to 0.1µm)

Metric (mm or µm) or Imperial (Inches) measurement

RS232 port for communication with a PC

USB port for communication and/or power supply

USB Stick for data saving on a CSV file

Optional connection of M-Bus modules

Measurement transfer by pressing a key, footswitch input or retro-command on

the RS232 port.

Operating temperature : +15°C to +30°C

Power supply from 85 to 265 VAC by using the supplied main transformer (or by

connecting it directly on your PC USB port, or through the 24 VDC screw

terminal.

Relative humidity : maximum 80%

Dimensions : width 130 mm, height 111 mm, depth 105 mm

Mass : 600 grams (700g with the power supply)

2.3.2. Dimension and installation

M1 –M3 Display Units

Page 8

The M3 is fitted with 4 thread M5 allowing to attach it. To access to these threads, it

is necessary to remove the 4 antiskid plastic parts.

It is also possible to panel mount the display, using bracket (see page 12)

Be careful not to use longer screw than M4*16.

Pneumatic connections (see also chap.4) :

Remove the

antiskid parts

to attach it on

the table

M1 –M3 Display units

Page 9

M1 –M3 Display Units

Page 10

2.3.3. Contents of the packaging

The M1/3 package includes :

- 1 M1/3 display mounted on an orientable stand

- 1 USB cable, (length =1.8m) for power supply and/or data transfer

- 1 USB main adaptor for the display power supply. The M3 can also be powered by

a computer when connected to it with the USB.

- 1 Mini-CD containing the user manual.

M1 –M3 Display units

Page 11

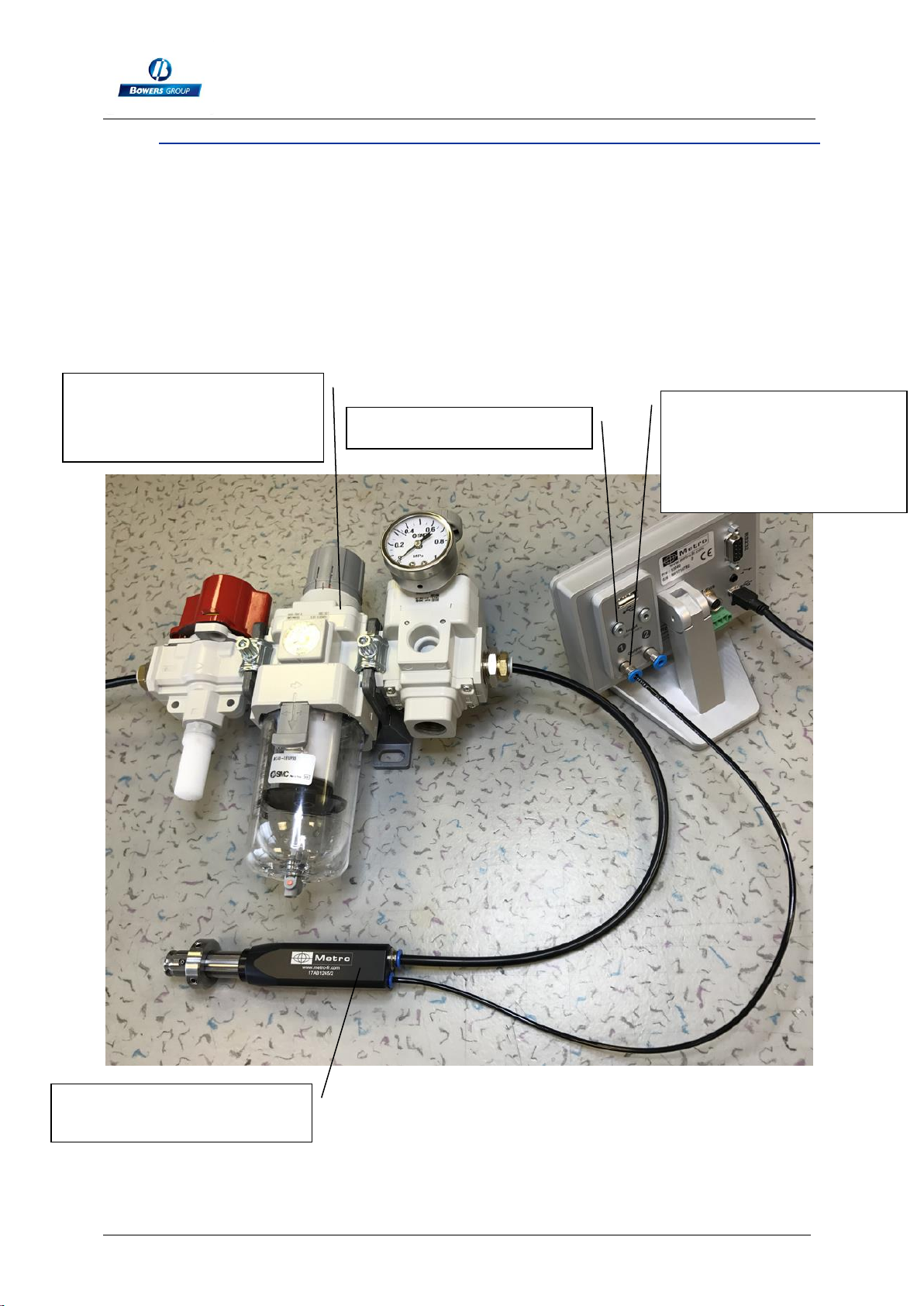

2.3.4. Accessories

Reference

Description

Picture

55-MBV001

Air preparation unit :

It is mandatory to use a

precision regulation system,

otherwise the measurements

will not be stable.

We can supply the adapted

air preparation unit from SMC,

including stop valve, filter and

regulator + precision

regulator.

The precision regulator must

be adjusted at 3 BARS

(0.3MPa)

N/A

For M3 displays.

It allows to divide the 8mm

tube at the output of the air

preparation unit into 2 tubes

of 6 mm adapted for the

connection on the M3 input.

N/A

Soft polyurethane tubes

6*4mm :

The M1 / M3 are fitted with 2

connectors for air tube with

6mm external diameter and

4mm internal diameter.

We advise to use soft

polyurethane tubes from

SMC, because their flexibility

prevent the display to knock

over due to the pressure of

the tubes on the table.

N/A

Soft polyurethane tubes

8*5mm :

The air preparation unit is

fitted with a connection for

8mm tubes (external

diameter)

M1 –M3 Display Units

Page 12

2.3.5. Options / cables

Reference

Description

Picture

30-904-

4102

Footswitch :

This footswitch with a robust construction can be

configured in different ways: preset, measurement

transmission, start dynamic measurement etc...

N/A

Accessory for panel mounting.

To be installed instead of the stand.

30-804-

2130

This M-Bus module is fitted with 8 input/outputs

isolated with optocouplers allowing to get additional

functionalities, for example: output for Go/noGo, input

for preset or start dynamic measurement... The M-Bus

modules are mounted on an aluminum profile allowing

to mount them on a standard DIN rail.

Up to 4 modules can be mounted

N/A

The optional MB-RL module is

Fitted with 2 independent relays min and max, free of

potential that indicate the position of the measure

according to the part tolerances. The module is also

fitted with 6 inputs allowing

remote control display.

This MB-RL module is wired exactly like the #24136

optional board for Monocote displays. It allows then to

replace a Monocote by a M3 without changing the

machine wiring.

M1 –M3 Display units

Page 13

N/A

M-Bus cable for M3 :

This cable allows to connect the compatible M-Bus

modules on a M3 display unit. Length 1.5m

30-926-

5608

RS232 cable

This cable allows to connect a M1//M3 display to a

computer or a PLC.

30-926-

5521

This cable allows to connect a M1 /M3 display to a

Multiplexer Mux

M1 –M3 Display Units

Page 14

20-USB

RS232/USB cable converter :

This cable allows a M1/M3 display to

communicate with a computer. It creates a

virtual COM port on the computer. It is

delivered with a driver on a CD.

55-DP1

Ticket printer

Allows to print the displayed value of the

M1/M3

55-

HD3430-

BKK1B

QR code reader

2 main functions :

- Allow to send a configuration on the display

(part definition, tolerance, display type,

calibration of the air gauge, etc…)

- Send a Manufacturing order number. The

export file will take the name of the number

entered.

M1 –M3 Display units

Page 15

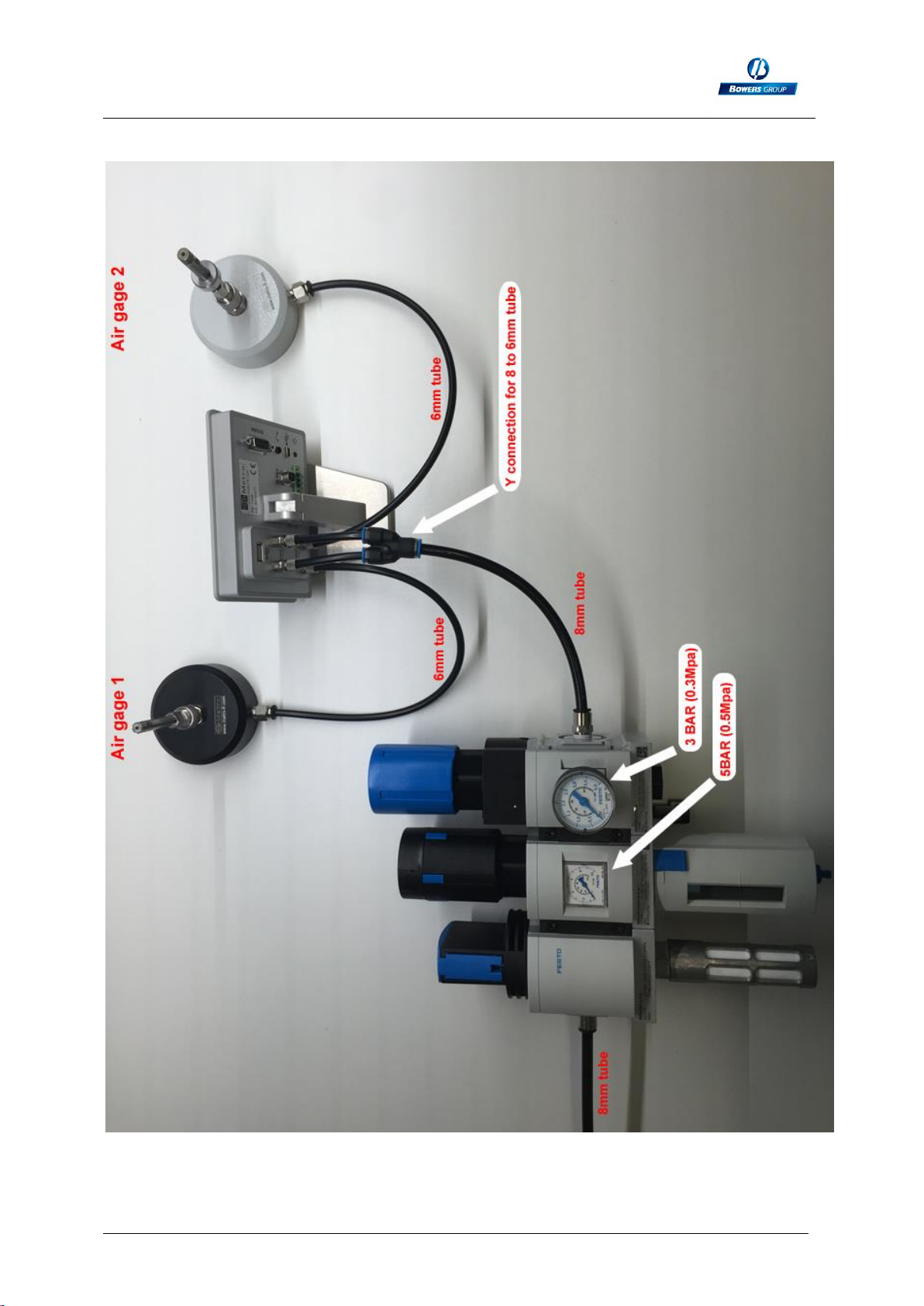

2.3.6. Connectors

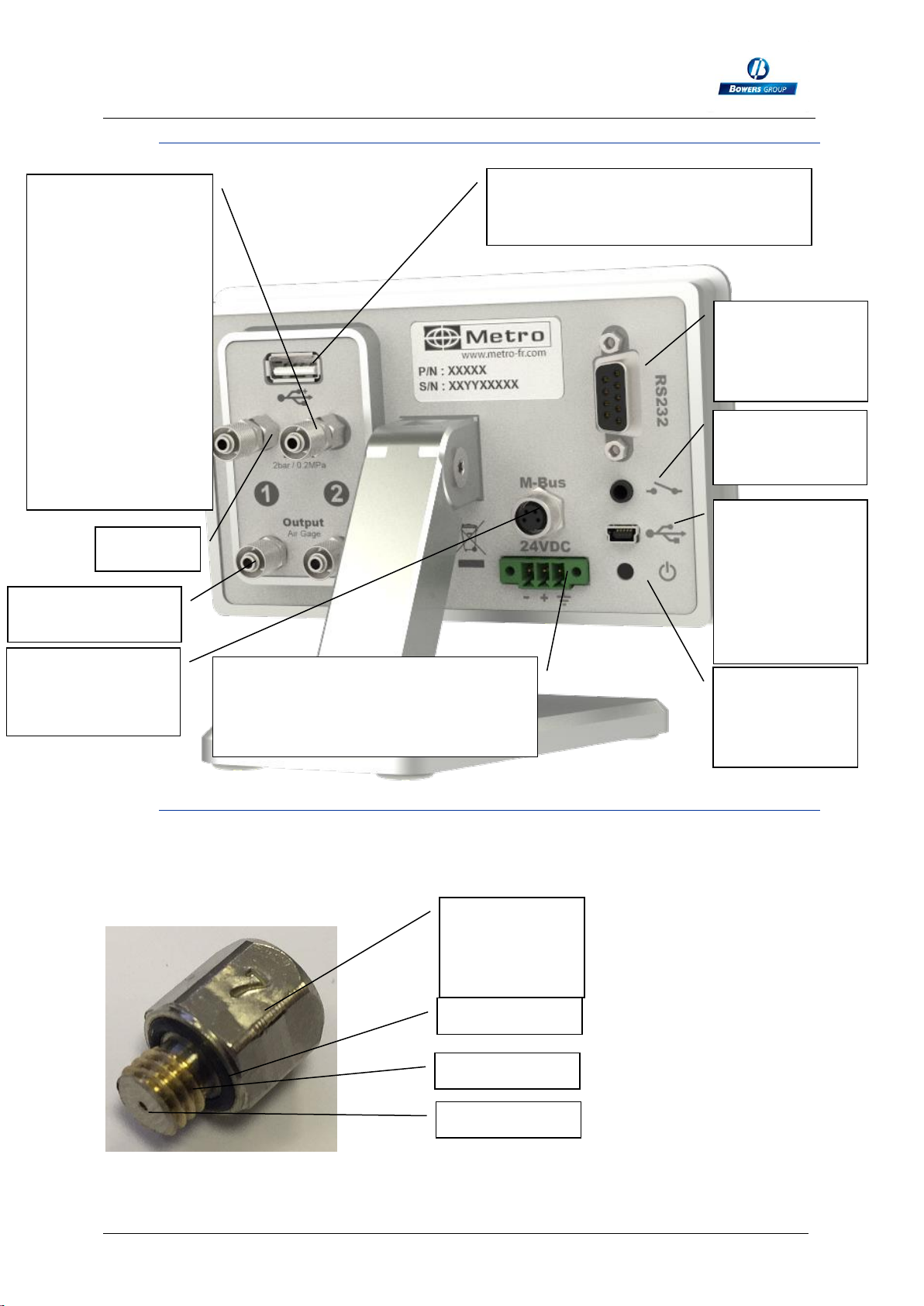

2.3.7. Standard cabling –restrictor choice

The M1 or M3 are delivered with 1 or 2 restrictors of 0.5mm on the air input + 1 or 2

0.7mm restrictors as spare parts. The value of the restrictor is indicated as below:

7 =0.7mm

5=0.5mm

On/Off switch

(press 2s. for

shutting down)

2 inputs for AIR at

3BAR (0.2Mpa) (air

filtered at 5µm and

regulated at

0.1BAR /

0.01MPA). NEVER

EXCEED

4BAR/0.4MPA. It is

very recommended

to use Air

preparation set

from Bowers ref

55-MBV001. See

details on the chap.

3.3.4

RS232

connector for

connection to a

PC

Multi-function

foot switch

connector

Mini-USB

connector for

power supply

and

measurement

transfer to a

PC

To connect m-bus

modules

(optional)

24 VDC power supply. If you

choose this connector to power the

display, the ON-OFF switch will be

deactivated.

Output to the Air

gauge

USB Stick connector for data saving

on a CSV file.

Value of the

restrictor

7=0.7mm

O ring

M5 thread

Restrictor

Restrictor

M1 –M3 Display Units

Page 16

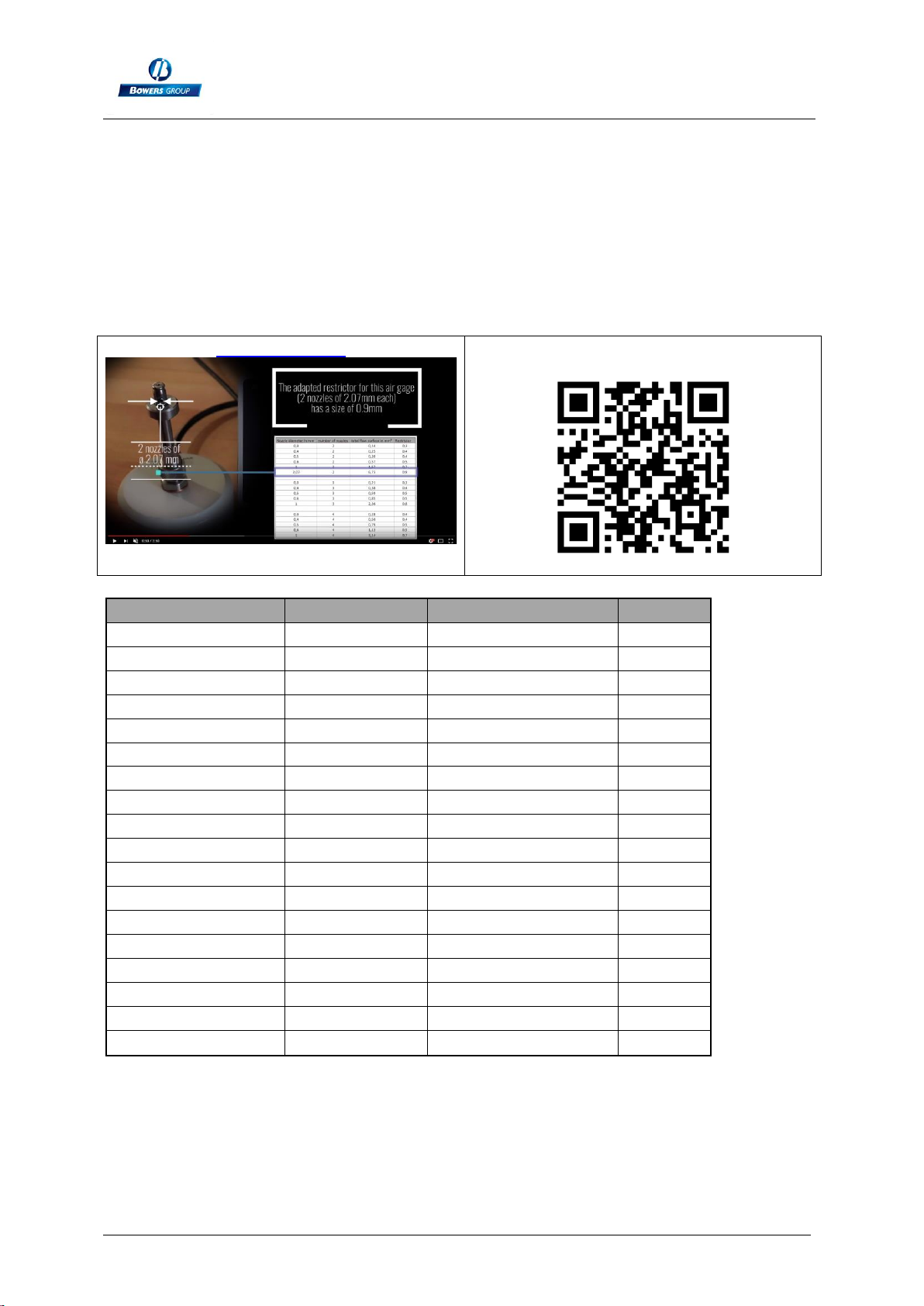

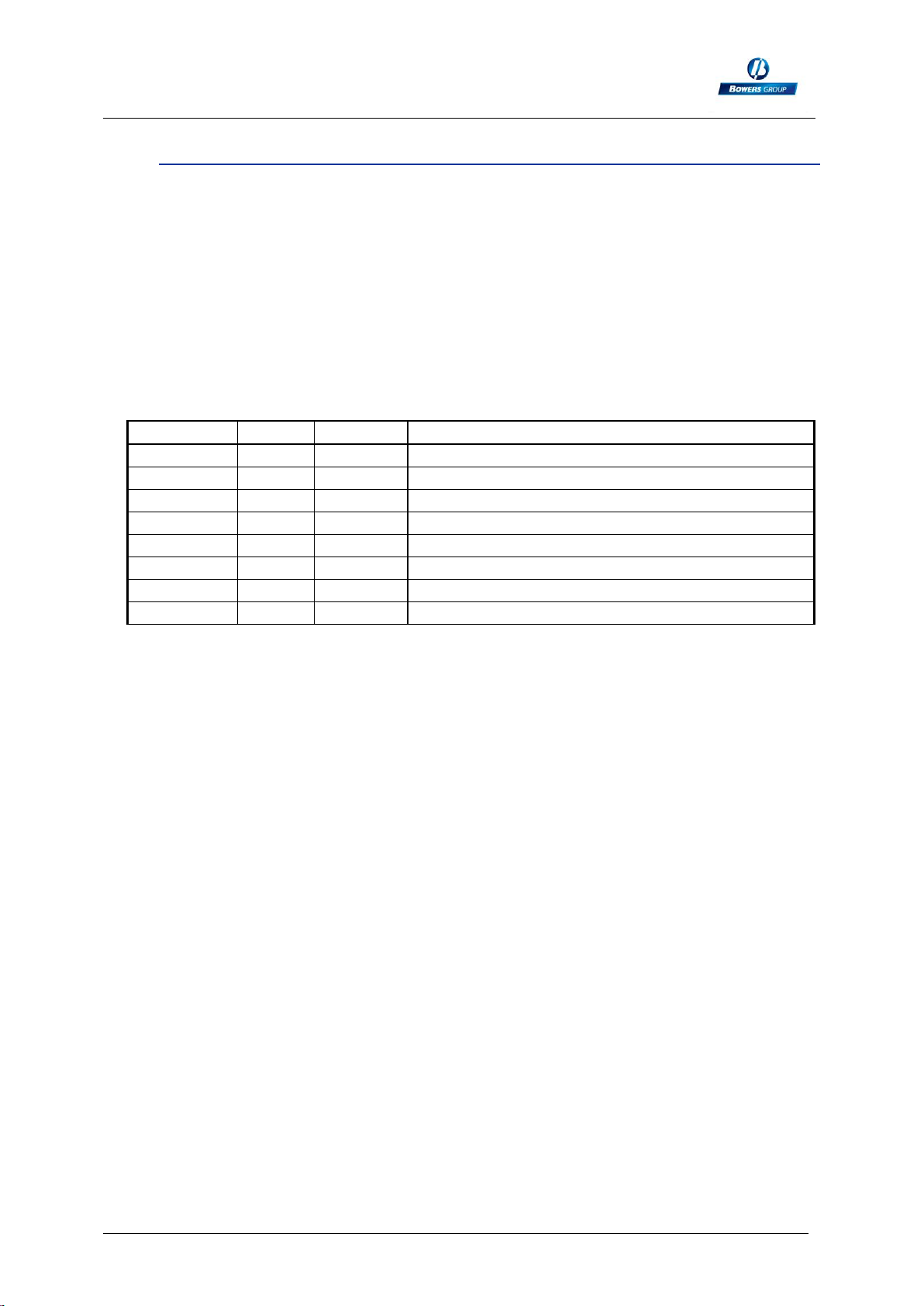

The following table shows some frequent cases to define which restrictor will be the

most applicable to your application.

If you order a turnkey solution at Bowers, we will deliver the display with the

applicable restrictor. But if you want to use the M1 / M3 display together with your

existing air gauge. Alternative restrictor may be required.

It is advised to contact Bowers for advices or confirmation around this subject.

Check this video for understanding the influence of the restrictor on the

linearity :

link to the video

Or scan the QR code :

Nozzle diameter in mm

number of nozzles

total flow surface in mm²

Restrictor

0,3

2

0,14

0,3

0,4

2

0,25

0,4

0,5

2

0,39

0,4

0,6

2

0,57

0,5

1

2

1,57

0,7

2,07

2

6,73

0,9

0,3

3

0,21

0,3

0,4

3

0,38

0,4

0,5

3

0,59

0,5

0,6

3

0,85

0,5

1

3

2,36

0,7

0,3

4

0,28

0,4

0,4

4

0,50

0,4

0,5

4

0,79

0,5

0,6

4

1,13

0,5

1

4

3,14

0,7

M1 –M3 Display units

Page 17

Example :

2.3.8.

PLEASE CONTACT BOWERS FOR FURTHER ADVICE

M1 –M3 Display Units

Page 18

Cabling with by-pass nozzle (integrated restrictor)

Some air gauges are delivered with a by-pass nozzle (or integrated restrictor). It

means that the restrictor is integrated inside the air gauge itself, and there is no need

to install it on the display. NO RESTRICTOR ON THE DISPLAY.

This configuration allows to have a faster the reaction time and makes the installation

easier by removing the need to choose the adapted restrictor.

If you order a turn key solution at Bowers, it will generally be delivered according to

this principle.

Air gauge with by-pass

nozzle (integrated restrictor)

Regulation unit

ref 55-MBV001 (delivers

3BAR/0.3MPa pressure)

Stopper ref CMP-PNE-018

Standard push-in

connector, M5 thread.

Generally, for tube

external diam 3mm (ref

CMP-PNE-014)

Please discuss with Bowers for applications

M1 –M3 Display units

Page 19

2.3.9. THE RS232 COMMUNICATION PORT

The M3 is fitted with a RS232 port. It allows linking the M1/M3 to PC or an external

system. The port configuration is as following

9600 bauds, 8 bits, 1 stop bit, no parity

CONNECTOR PINOUT

It is fitted with a SUBD 9 pins female connector.

Pin

Signal

Direction

Description

1

Not used

2

RX

Input

Reception of data

3

TX

Output

Transfer of data

4

IN1

Input

Do not use. Only for firmware update

5

Gnd

-

Ground

6

Not used

7

IN2

Input

Do not use. Only for firmware update

8 &9

Not used

M1 –M3 Display Units

Page 20

2.3.10. MINI-USB connector

The mini-USB connector has 2 functions

1. Power supply through a wall mounted transformer. This transformer supplies a

regulated 5V/1A DC voltage.

2. Measurement transmission. If you connect your M3 to a PC, the PC will detect

and install automatically the M3 as a standard USB keyboard with the standard

drivers of your operating system (Windows, Mac OS etc..). When you send the

measurement, the value will be written on your PC screen where your cursor

is, in the same way as it would have been typed with a keyboard.

Message that appears when the M1/M3 has been correctly installed:

2.3.11. The 24VDC connector

It is advised to use this power supply when the M3 is panel mounted.

Using this power supply instead of the mini-USB will deactivate the ON-OFF switch.

Therefore, when the M3 is powered, it will start automatically.

2.3.12. The USB stick connector

It is possible to save measurements on a CSV file.

In this case the display must be set the following way:

ConfigurationTransferUSB key

Then once the user either press on the « PRINT » button of the measuring screen or

on the footswitch, one line will be added on the CSV file. (a « output.csv » file is

created when the operator transfers the data for the first time). When the USB stick

has been correctly detected, a USB logo will appear on top bar. If the USB stick is not

connected when the operator transfers the measurement, an error message will pop

up. USB sticks with partitions are not supported.

2.3.12. The footswitch connector

This manual suits for next models

1

Table of contents