MOP-TFT480272-43A-BLM-CTB 2

Contents

Revision History..............................................................................................................................................................................1

Contents .........................................................................................................................................................................................2

1 General Information ....................................................................................................................................................................3

2 Absolute Maximum Ratings.........................................................................................................................................................3

3 Electrical Characteristics..............................................................................................................................................................3

4 Backlight Characteristics..............................................................................................................................................................3

5 Touch Panel Characteristics .........................................................................................................................................................4

6 External Dimensions....................................................................................................................................................................5

7 Electro-Optical Characteristics ....................................................................................................................................................6

8 Interface Description ...................................................................................................................................................................7

8.1 LCM Interface Description ................................................................................................................................................7

8.2 CTB Interface Description .................................................................................................................................................7

9 AC Characteristics ........................................................................................................................................................................8

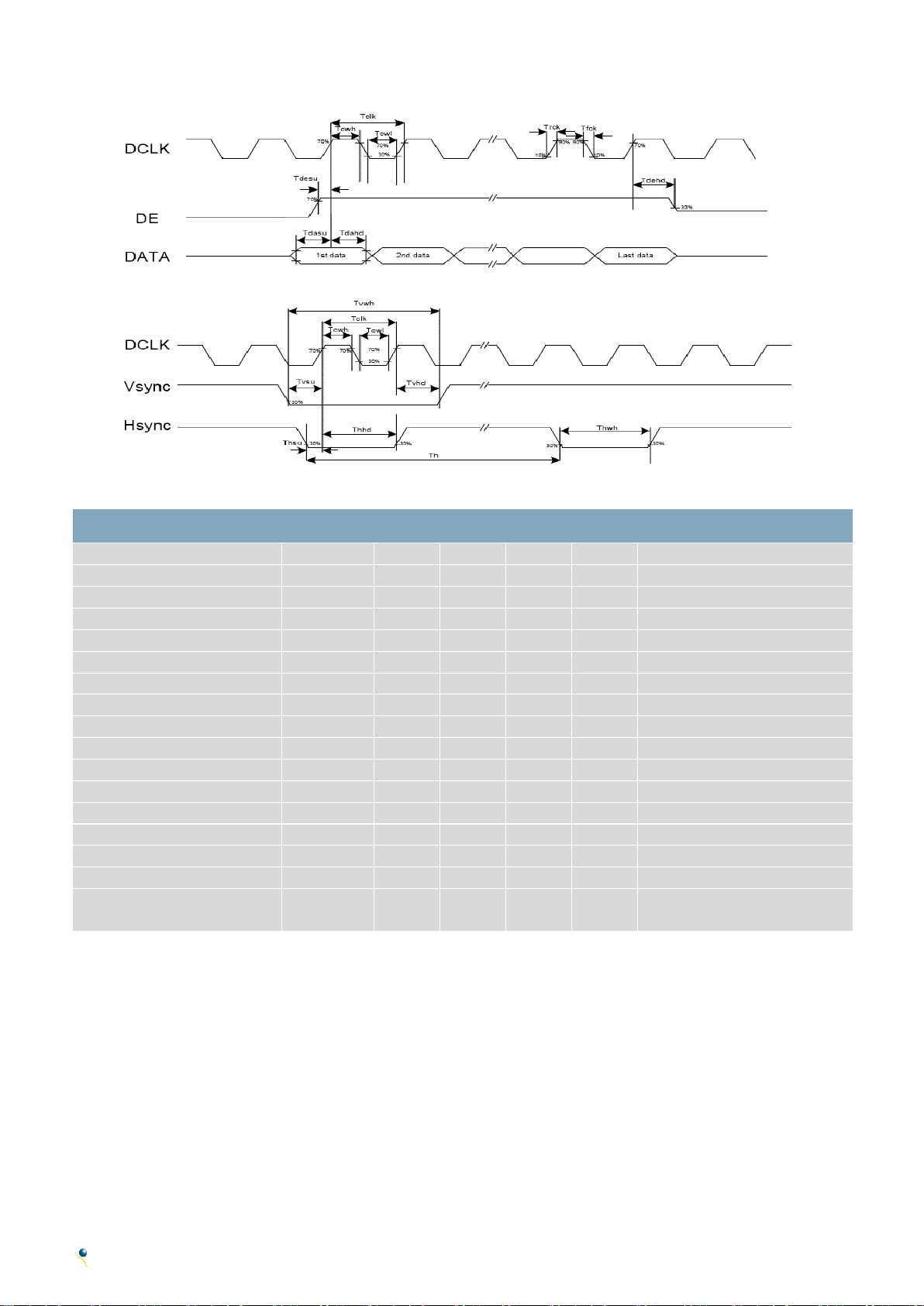

9.1 Pixel Timing.......................................................................................................................................................................8

9.2 Data Timing.......................................................................................................................................................................9

9.3 Touch Panel Timing...........................................................................................................................................................9

10 Power Sequence ......................................................................................................................................................................10

10.1 Power Up Sequence .....................................................................................................................................................10

10.2 Power Down Sequence.................................................................................................................................................10

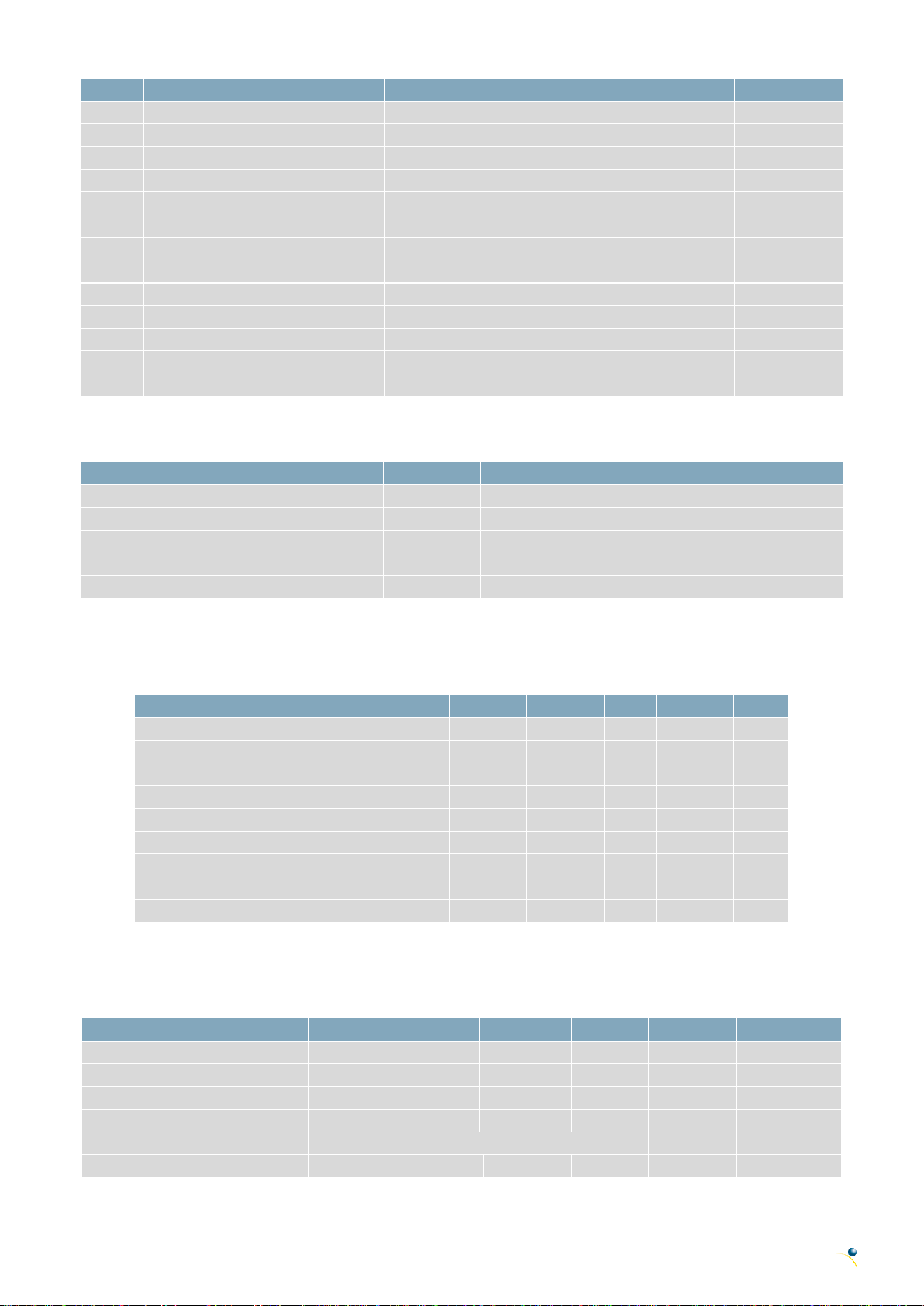

11 Inspection Criterion .................................................................................................................................................................11

11.1 Description ...................................................................................................................................................................11

11.2 Sample plan ..................................................................................................................................................................11

11.3 Inspection condition.....................................................................................................................................................11

11.4 Definition of inspection zone in LCD.............................................................................................................................11

11.5 Function Defect ............................................................................................................................................................11

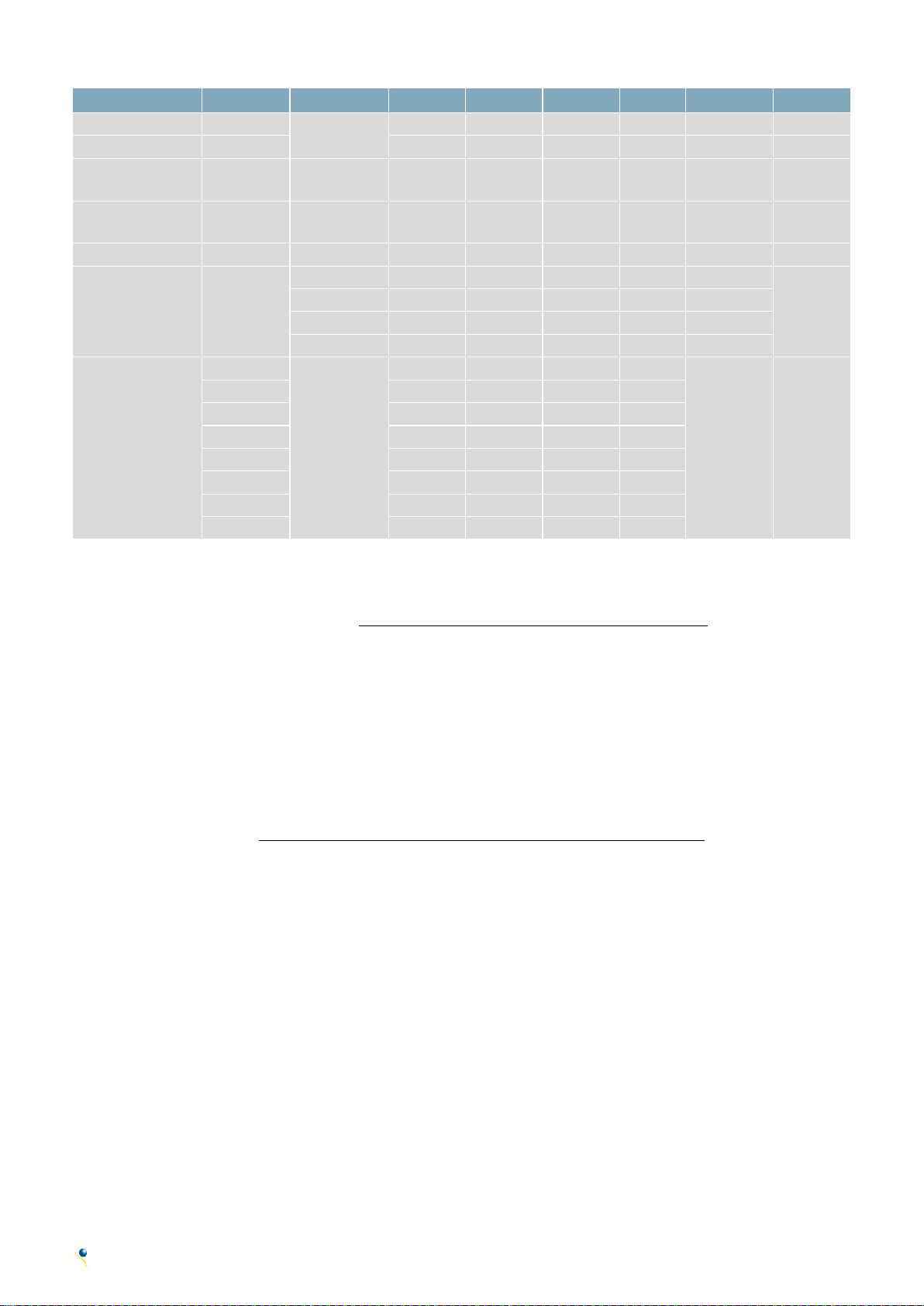

11.6 LCD pixel defect ............................................................................................................................................................12

11.7 Dot and line defect .......................................................................................................................................................12

12 Handling Precautions...............................................................................................................................................................13

12.1

Mounting method

.....................................................................................................................................................13

12.2

LCD Handling and Cleaning Precaution

..................................................................................................................13

12.3 Static Charge Precaution ..............................................................................................................................................13

12.4 Packing

........................................................................................................................................................................13

12.5 Precautions during Operation

.................................................................................................................................13

12.6 Storage Recommendations

.....................................................................................................................................14

12.7 Safety Precautions

....................................................................................................................................................14

13 Ordering ..................................................................................................................................................................................15

13.1 Part Numbering Scheme...............................................................................................................................................15

13.2 Options .........................................................................................................................................................................15

14 Contact ....................................................................................................................................................................................15