BOWIE PUMPS Eco-Seal Series User manual

ES IOM Rev 1 - 5/13/2021 1

These are SAFETY ALERT SYMBOLS.

When you see these symbols, be alert to

the potenal for personal injury, death or

major property damage.

Warns of hazards that WILL

cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause

serious personal injury, death or

major property damage.

Warns on hazards that CAN

cause personal injury or property

damage.

NOTICE:

Indicates special instrucons which are very

important and must be followed.

NOTICE:

Bowie pumps MUST only be installed in

systems which have been designed by quali-

ed engineering personnel. The system

MUST conform to all applicable local and

naonal regulaons and safety standards.

This manual is intended to assist in the in-

stallaon and operaon of the Bowie Eco-

Seal™ Series pumps, and when possible kept

with the pump.

Pump service shall be performed by quali-

ed technicians ONLY. Service shall con-

form to all applicable local and naonal reg-

ulaons and safety standards.

Thoroughly review this manual, all instruc-

ons and hazard warnings BEFORE perform-

ing any work on the pump.

Manuals, parts lists, and

technical informaon availa-

ble at:

www.bowiepumps.com

TABLE OF CONTENTS

Secon Page

Pump Data

Installaon

Operaon

Preventave

Maintenance

Correcve

Maintenance

Troubleshoong

Contact

Informaon

2

3

5

8

10

12

13

Eco-Seal ™ SERIES

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

ES IOM Rev 1 - 5/13/2021 2

PUMP IDENTIFICATION

Pump serial number and model designaon will be sup-

plied with each pump. It is recommended that this data

be recorded and led for future reference. This data

should be supplied to a Bowie representave when re-

placement parts, repair work, or informaon pertaining

to the pump is required.

PUMP DATA

PUMP INFORMATION

Model No.: _____________________

Serial No.: _____________________

Date of Installaon: _____________

PUMP DESCRIPTION

Eco-Seal pumps are based on our industry leading Signature Series of pumps but with one major dierence: the pumps are

engineered with a high performance lip sealing system for enhanced leak protecon. The result: an aordable, long lasng,

low maintenance bushing-design pump which meets more stringent environmental and safety standards.

There are three lines of Eco-Seal Series pumps: 300 Eco-Seal – the standard pump; 300 Eco-Seal S – short drive neck for ac-

cess in ght spaces; 300 Eco-Seal ED – extended duty.

PUMP DIMENSIONS, EXPLODED VIEWS, AND OTHER TECHNICAL INFORMATION

All technical informaon, including pump dimensional diagrams, exploded views with part lisngs, and other technical informaon

are available at www.bowiepumps.com.

Noise levels for all pumps will not exceed 95dB at a distance of one

meter from the pump.

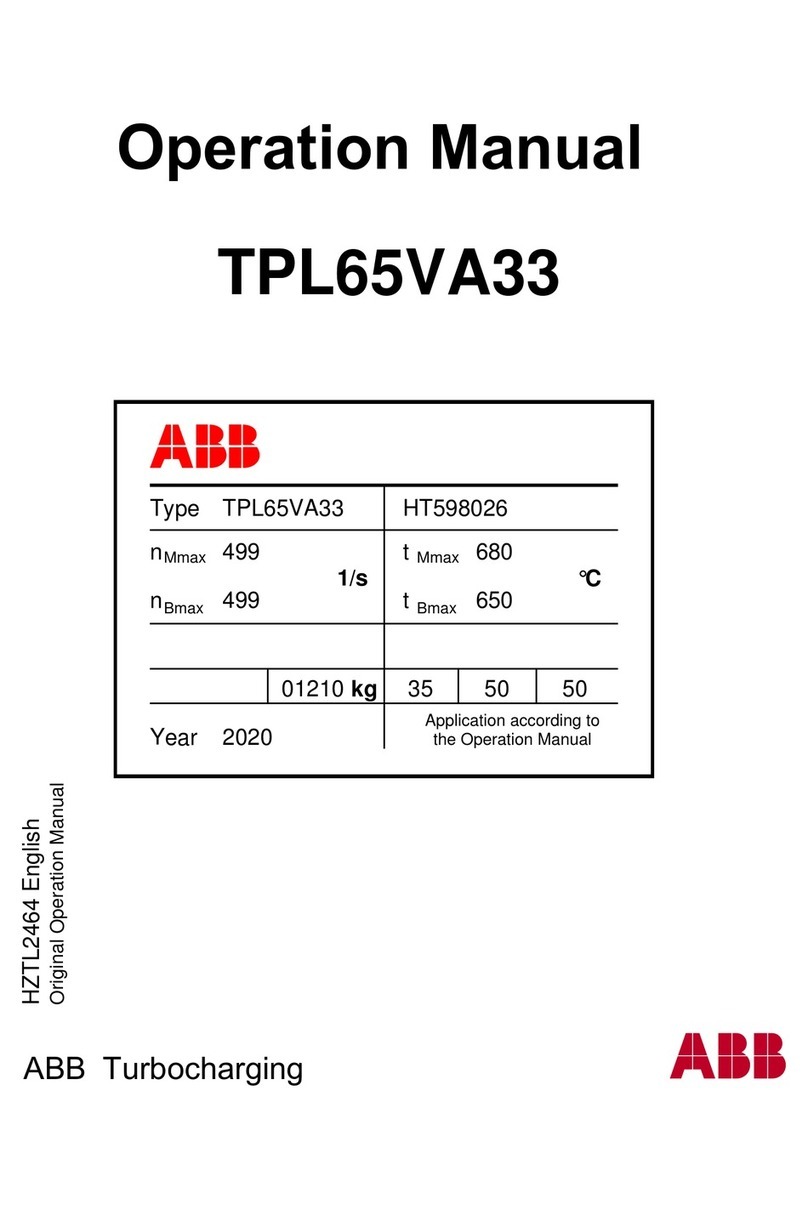

TECHNICAL DATA

* Pressures must be measured no farther than 6” from the discharge port.

Maximum operang limits are dependent on the materials of construcon and

applicaon design requirements.

Operang

Criteria

Buna-N

Rubber Gears

Progressive Helical Steel

Gears

Maximum

Operang

Temperature*

70°C 160°C

Maximum

Speed* 500 RPM 750 RPM

Maximum

Viscosity* 60000 SSU

Maximum

Dierenal

Pressure*

125 psi 150 psi

Maximum

Working

Pressure*

125 psi 150 psi

ES IOM Rev 1 - 5/13/2021 3

PRE-INSTALLATION CLEANING

Any large foreign maer that enters the pump WILL cause extensive damage. The supply tank and piping

MUST be cleaned and ushed before pump installaon and operaon.

LOCATION AND PIPING

1. Locate the pump as close to the source of supply as possible to maximize intake.

2. Piping MUST have proper support to prevent any load being placed on the pump.

3. Piping and ngs MUST be at least the same diameter as the pump port.

4. Minimize the number of intake line ngs and piping turns or bends to maximize performance.

5. Install a strainer or screen on the sucon line to prevent large foreign maer from entering the

pump. Place the strainer in an accessible locaon for frequent cleaning.

6. It is recommended to install a suitable device to prevent over-pressurizaon of the system.

Bowie Pumps of Canada Ltd. supplies a bi-direconal pressure relief plate (BP7000) for this

purpose.

7. Sucon and discharge lines and piping MUST be free of all leaks.

NOTICE:

Bowie pumps must be installed only in

systems design by qualied engineering

personnel. Bowie pumps should only be

installed in dues for which Bowie Pumps

of Canada Ltd. have specied the aributes

of the pump. System design must conform

to all applicable regulaons and codes and

provide warning of all system hazards.

NOTICE:

PTO and hydraulically driven units MUST

use speed control devices to limit the sha

from exceeding maximum RPM specica-

ons, regardless of unloading speeds. If

uid ow is less than expected, consult the

“General Pump Troubleshoong” secon.

INSTALLATION

Operaon without guards in

place can cause serious per-

sonal injury, property damage,

or death.

TRUCK MOUNTING

Bowie pumps are designed to be installed in a horizontal posion with base plates mounted and parallel

to ground on a at surface. The pump should be installed with access to both the drain plugs and mul-

ple grease ngs on the pump. The pump may be bolted to the truck frame or on a saddle hung below

the frame, however it MUST be grouted and bolted, ensuring rm xing and a reducon in noise and

vibraon.

ES IOM Rev 1 - 5/13/2021 4

HYDRAULIC DRIVE

Bowie pumps may be hydraulically driven. The hydraulic motor should be well supported with the drive

sha in-line with the pump sha in all respects. A sleeve joint is recommended to compensate for any

play caused by road condions. Bowie Pumps of Canada provides a Hydraulic Mount Adapter for this

purpose. Please contact your nearest Bowie agent for more informaon.

General guidelines for proper pump drive:

1. The sha of the hydraulic motor should be aligned with the Bowie pump drive sha. The two

shas should be parallel and concentric.

2. Alignment of the hydraulic motor sha and the Bowie pump drive sha can be measured using a

straight edge and feeler gauges, or a taper gauge or caliper.

3. Axial misalignment (in which the shas are parallel but are not concentric) is measured at the

coupling. The maximum allowable axial misalignment is 0.005”.

4. Angular misalignment (in which the shas are concentric but are not parallel) is measured at the

coupling. The maximum allowable angular misalignment is 20°.

Failure to follow these guidelines may result in excessive wear on the internal components of the pump.

This will result in improper performance and may result in premature pump failure. Failure to follow

these guidelines may also result in uneven turning of the gears, in turn causing a surging vibraon to the

uid system.

POWER TAKE OFF (PTO) DRIVE

Bowie pumps may be driven by a PTO drive. A direct drive sha with a universal joint on each end of the

sha is used to connect the pump to the drive. A sleeve joint can be used to compensate for any play

caused by road condions.

General guidelines for proper pump drive:

1. The angle of drive sha between pump and PTO must be NO LESS than 3° and NO GREATER than

20° to ensure proper performance and protect from premature pump failure.

2. Use the least number of jackshas as is praccal.

3. Use an even number of universal joints (U-joints).

4. The yokes of the universals at both ends of the jacksha must be in phase and parallel.

5. The angle between the jacksha and the pump sha must be NO LESS than 3° and NO GREATER

that 20° (refer to guideline 1).

6. The PTO sha must be balanced and maintained to manufacturers specicaons.

7. The PTO sha RPM must not exceed the recommended pump RPM for operaon.

Failure to follow these guidelines may result in excessive wear on the U-joints, bearing, seals and internal

components of the pump. This will result in improper performance and may result in premature pump

failure. Failure to follow these guidelines may also result in uneven turning of the gears, in turn causing a

surging vibraon to the uid system.

NOTICE:

Drive shaft angular and axial alignment can

be determined using a straight edge and

feeler gauges.

INSTALLATION

Operaon without guards in

place can cause serious per-

sonal injury, property damage,

or death.

ES IOM Rev 1 - 5/13/2021 5

PRE-START UP CHECK LIST

1. Check alignment and connecons of all piping/tubing to the pump. Pipes must be supported

to prevent drop down or pressurized recoil when the pump anges or unions are disconnected.

2. Inspect complete piping/tubing system ensuring that no external piping loads are being placed

on the pump.

3. Secure appropriate hose connecons.

4. Check all nuts and bolts, anges, and base mounng xtures for ghtness.

NOTICE:

If dicules or issues are experienced dur-

ing start up, please consult the “General

Pump Troubleshoong” secon.

NOTICE:

“Dry running” the pump WILL result in gear

and pump damage.

START UP PROCEDURES

1. Ensure appropriate valves are open in the inlet and discharge lines.

2. Start the pump. Priming should occur within one minute.

3. Inspect all associated piping, ngs and system equipment for issues such as leaks, noise, vibraon

and overheang.

4. Check ow rate to ensure the pump is operang within expected limits.

5. If equipped, check the relief valve pressure seng by momentarily closing a valve in the discharge

line and reading the pressure gauge. This pressure must be a minimum of 20-30 psi (1.4-2.1 Bar)

higher than the maximum system operang pressure or pressure relief plate seng, and must not

exceed 150 psi. DO NOT operate the pump against a closed discharge valve for more than 15

seconds. If adjustments need to be made, refer to the “Relief Valve Seng and Adjustment” sec-

on of this manual.

NOTICE:

The range of temperatures that pump sur-

faces will develop is dependent upon fac-

tors such as product temperature and am-

bient temperature of operaon. There

may be instances where the external pump

surface can exceed 50°C. In these situa-

ons, proper warnings/guards MUST be

used.

PUMP OPERATION

Pumps operang against a

closed valve can cause system

failure resulng in personal

injury and property damage

Pumping hazardous or toxic

uids can cause personal injury

and property damage.

NOTICE:

High Viscosity uids and / or low uid lev-

els will lead to high sucon at start up.

This will cause a “dry run” situaon. The

pump must be adequately primed by add-

ing uid to the inner pump area through

drain plug openings in the back plate.

Disconnecng uid or pressure

containment components dur-

ing pump operaon can cause

serious personal injury, death

or major property damage.

ES IOM Rev 1 - 5/13/2021 6

NOTICE:

Only lubricang, non-corrosive uids may

be le in the pump for an extended period

of me. Any other uids must be ushed

from the pump immediately.

NOTICE:

Aer ushing the pump some residual uid

will remain in the pump and piping.

FLUSHING THE PUMP

1. Evacuate as much exisng uid as possible from the pump.

2. Run cleaning uid through the pump intake. The cleaning uid should be compable with the

pump O-rings and gear material. In situaons with “scky” uids that solidify within the pump (i.e.

waxes, adhesives etc.) use a uid that prevents solidicaon of the uid to facilitate ushing.

NOTICE:

Properly dispose of all waste uids in ac-

cordance with appropriate codes and regu-

laons.

PUMP OPERATION

Disconnecng uid or pressure

containment components dur-

ing pump operaon can cause

serious personal injury, death

or major property damage.

Pumps operang against a

closed valve can cause system

failure resulng in personal

injury and property damage

Pumping hazardous or toxic

uids can cause personal injury

and property damage.

NOTICE:

Threaded drain plug holes on the back

plate can be used to ush the pump.

ES IOM Rev 1 - 5/13/2021 7

NOTICE:

Both Pressure Relief locking caps come

with a control marker lisng the exisng

pressure seng. Removal of the control

marker will void all warranty of BPOC

products.

BI-DIRECTIONAL PRESSURE RELIEF PLATE SETTING

The Bi-Direconal Pressure Relief Plate pressure seng should be set a minimum of 20-30 psi higher than

the operang pressure. When adjusng the pressure seng, the correct locking cap must be adjusted for

the correct direcon of ow at operang rotaonal speed of the pump’s drive sha. Pressure may be ad-

justed within a range of approximately 20 psi per spring. Addional springs are available for higher psi

changes. Contact your BPOC repair or warranty agent for more informaon.

Adjusng the PRESSURE SETTING:

1. To INCREASE the pressure seng, remove the correct locking cap (see selecng the correct locking

cap). Loosen the locking nut, and then rotate the seng screw clockwise. Record the dierence

between original and new sengs. Tighten the locking nut, and replace the locking cap.

2. To DECREASE the pressure seng, remove the correct locking cap (see selecng the correct lock-

ing cap). Loosen the locking nut, and then rotate the seng screw counterclockwise. Record the

dierence between original and new sengs. Tighten the locking nut, and replace the locking cap.

Selecng the CORRECT LOCKING CAP viewing the front plate of the pump:

To adjust ow pressure for CLOCKWISE sha rotaon:

a) The drive sha below the idler sha. Adjustments must be made to the RIGHT side spring.

b) The drive sha above the idler sha. Adjustments must be made to the LEFT side spring.

To adjust ow pressure for COUNTERCLOCKWISE sha rotaon:

a) The drive sha below the idler sha. Adjustments must be made to the LEFT side spring.

b) The drive sha above the idler sha. Adjustments must be made to the RIGHT side spring.

NOTICE:

Adjustment of pressure sengs by any

party other than a specied BPOC repair or

warranty agent will void all warranty of

BPOC products.

NOTICE:

Any internal pump relief valve is designed to protect the pump from excessive pressure and

must NOT be used as a system pressure control valve. See your local Bowie dealer for a list

of Bowie manufactured system pressure control valves.

BI-DIRECTIONAL PRESSURE RELIEF PLATE

An available bi-direconal pressure relief plate is manufactured and can be supplied by Bowie Pumps of

Canada Ltd. This will set a dierent maximum pressure for each direcon of uid ow. Inial pressure is

set at the factory to the customer’s specicaons, based on the specic operaonal rotaonal speed of the

pump’s drive sha.

BI-DIRECTIONAL PRESSURE RELIEF PLATE OPERATION

Pressure Relief locking caps are

exposed to and retain some

pumped uids

ES IOM Rev 1 - 5/13/2021 8

NOTICE:

Some volume of bearing grease MAY ac-

cess the main chamber and contact the

pumping liquid. Any compability issues

between grease and liquid should be in-

vesgated prior to use of pump.

NOTICE:

To avoid possible injury or entanglement

with moving parts, do not lubricate pump

bearings, couplings or any other parts

while the pump is running.

NOTICE:

Any maintenance should follow the appro-

priate procedures and warnings presented

in this manual.

LUBRICATION

Bowie’s Eco-Seal™ pumps are designed with a system of high-performance elastomeric seals and a combi-

naon of cross-hatched Aluminum-Bronze bushings. These pumps contain ve (5) easily accessible grease

ngs which allow grease to lubricate the brass bushings. The pumps come fully lubricated with Metalon®

Hi-Tech EP 1.5 grease and are ready for use. This grease’s penetraon rang bridges the NLGI #1 and #2

grades. Once your pump is in operaon, it is absolutely crical that a regular lubricaon program be fol-

lowed to allow the pump to operate as designed and to prevent premature failure.

We recommend the following lubricaon ‘Best Pracces’:

• Lubricant: Select grease with the following properes: water resistance, rust and corrosion protec-

on, extreme pressure protecon and lm strength and stability through temperatures ranging

from -40°C/F to 300°C/570°F.

• Quanty and Time for Normal Operang Condions: Bowie recommends 2-4 ounces of grease

applied approximately every four (4) operang hours in the front drive neck of the pump. For all

other grease ng locaons, we recommend 1-2 ounces of grease applied every four (4) operang

hours. The actual amount of grease to be applied can be idened as the point when high re-

sistance to further greasing has been achieved. For operang condions above those specied

refer to the above noce.

Normal operang condions for greasing pracces are:

• Operang Temperature ≤ 90° C (Progressive Helical Steel Gears) or ≤ 50° C (Buna-N rubber Gears)

• Rotaon Speed ≤ 500 RPM

• Discharge Pressure ≤ 70 PSI

NOTICE:

Strainers must be cleaned regularly to

avoid pump starvaon. Schedule is de-

pendent upon the applicaon and

condions.

PREVENTATIVE MAINTENANCE

NOTICE:

For operang condions ABOVE NORMAL, Bowie recommends 2-4 ounces of grease ap-

plied approximately every two (2) operang hours in the front drive neck of the pump. For

all other grease ng locaons, we recommend 1-2 ounces of grease applied every two (2)

operang hours. The actual amount of grease to be applied can be idened as the point

when high resistance to further greasing has been achieved.

Failure to set vehicle emergency

brake and chock wheels before

performing service can cause

severe personal injury or prop-

erty damage.

Failure to disconnect and lock-

out electrical power or engine

drive prior to performing ser-

vice can cause personal injury

or property damage.

Failure to relieve system pres-

sure prior to performing ser-

vice can cause personal injury

and property damage

If pumping hazardous or toxic

uids, pump must be ushed

before service.

ES IOM Rev 1 - 5/13/2021 9

NOTICE:

Check and inspect all components thor-

oughly for damage/wear and replace as

necessary.

STORAGE

Short Term Storage (6 months or less)

For storage less than 6 months the following steps are strongly advised:

1. Store pumps indoors. If this is not possible, then provide adequate protecve covering. DO NOT

allow moisture to collect around the pump.

2. Remove the drain plugs, if ed. Remove any ed inspecon plates to ensure that the pump

housing is dry.

3. See Manufacturer’s Instrucons for motor/gearbox/drive instrucons for storage procedures.

Long Term Storage (6 months or more)

For storage longer than 6 months in addion to following the short term storage steps, the following pro-

cedures should be carried out every 2-3 weeks.

1. Rotate the pump several full revoluons to avoid the gears seng in the housing.

2. If corrosion is present, apply light oil to all rotang parts and repeat step 1.

PREVENTATIVE MAINTENANCE

Failure to set vehicle emergency

brake and chock wheels before

performing service can cause

severe personal injury or prop-

erty damage.

Failure to disconnect and lock-

out electrical power or engine

drive prior to performing ser-

vice can cause personal injury

or property damage.

Failure to relieve system pres-

sure prior to performing ser-

vice can cause personal injury

and property damage

If pumping hazardous or toxic

uids, pump must be ushed

before service.

ES IOM Rev 1 - 5/13/2021 10

NOTICE:

Follow all hazard warnings and instrucons

shown in the “Maintenance” secon of

this manual. Pump should be dissembled

using a Bowie Eco-Seal™

Series Tool Kit, or at a registered Bowie

Repair Depot, listed at

www.bowiepumps.com.

NOTICE:

Check and inspect all components thor-

oughly for damage/wear and replace as

necessary.

CORRECTIVE MAINTENANCE

Failure to set vehicle emergency

brake and chock wheels before

performing service can cause

severe personal injury or prop-

erty damage.

Failure to disconnect and lock-

out electrical power or engine

drive prior to performing ser-

vice can cause personal injury

or property damage.

Failure to relieve system pres-

sure prior to performing ser-

vice can cause personal injury

and property damage

If pumping hazardous or toxic

uids, pump must be ushed

before service.

PUMP DISASSEMBLY

1. Remove the two drain plugs (3318) from back plate.

2. Remove the three end plugs (4308BF) from the front and back plates.

3. Remove secure wire from packing nut and packing nut itself (4301).

4. Remove the quick change sleeve (ECOEDSL) and quick change containment seal (3325V) from the

Drive sha.

5. Remove all bolts on the back plate and remove the back plate (3307ECO). Remove any wear plates

(3307HWP) (if applicable) and aached gaskets (3306).

6. Remove the pressure relief plate if equipped.

7. Remove the two lip seals (3325) from seal pockets in the back plate.

8. Remove the idler (●304ED) and drive sha (●305ED) assemblies from housing.

9. Remove all bolts on the front plate and remove the front plate (4302ECO). Remove any wear

plates (3307HWP) (if applicable) and aached gaskets (3306).

10. Remove one lip seal (3325) and the seal cartridge (ECOEDSH) with three seals from seal pockets in

the front plate.

11. Clean and examine dismantled components.

ES IOM Rev 1 - 5/13/2021 11

NOTICE:

Check and inspect all components thor-

oughly for damage/wear and replace as

necessary.

PUMP ASSEMBLY

1. Install one housing gasket (3306) on the front side of the casing (inserted centering pins will ease

the process). For oponal hardened wear plate, install one hardened wear plate (3307HWP) on

the housing gasket. Install one housing gasket shim on hardened wear plate.

2. Gently insert the drive (●305ED) and idler (●304ED) sha subassemblies into the casing with the

long end of the sha entering the aached wear plate.

3. Lube housing, drive gear with sha (●305ED) and idler gear with sha (●304ED) with a thin coat

of light oil or grease.

4. Install one lip seal on the idle sha, against the face of the gear. Ensure the lips are oriented to-

wards the casing.

5. Pre-install three lip seals into the seal cartridge (ECOEDSH), with lips oriented in the same direcon.

Ensure O-Rings are inserted into the external grooves.

6. Install the seal cartridge onto the front of the drive sha, with the lips of the seals oriented to-

wards the casing.

7. Three bushings (●309) have to be installed by pressing in to the front plate and two in to the back

plate. Make sure two dowel (locator) pins #3315H are installed in corresponding holes in plates.

8. Mount front plate (4302ECO) on to the casing with four bolts ghtening them in a cross paern.

9. Install a number of housing gaskets (3306) 5 for steel gears and 8 for rubber gears onto the back

side of the housing (inserted centering pins will ease the process). For oponal hardened wear

plate, install one hardened wear plate (3307HWP) and install one addional housing gasket on to

hardened wear plate.

10. Apply light oil on two seals and around the seal pockets in the back plate. Insert one lip seal (3325)

on to each of the two shas ends. Keep lips orientaon toward the casing.

11. Mount back plate with four bolts ghtening in a cross paern.

12. Turn drive sha to ensure proper meshing of gears and acceptable clearances between the gears

and plates. Adding or removing housing gaskets will adjust clearances.

13. Install bronze end plugs (4308BF) on to either end of the idler sha and onto the rear drive sha.

14. Install the ve grease ngs (3316).

15. Apply An-seize Lubricant “550” (petrochemical grease) on the threaded part of drive sha front

plate.

16. Install the quick change sleeve (ECOEDSL), quick change containment seal (3325V) and bronze

bushing (4309B) onto the Drive sha.

17. Install and secure the seal nut (4301) with wire.

18. Finish installing the remainder of the bolts for the back plate and ghten in a cross paern.

19. Finish installing the remainder of the bolts for the front plate and ghten in a cross paern.

CORRECTIVE MAINTENANCE

Failure to set vehicle emergency

brake and chock wheels before

performing service can cause

severe personal injury or prop-

erty damage.

Failure to disconnect and lock-

out electrical power or engine

drive prior to performing ser-

vice can cause personal injury

or property damage.

Failure to relieve system pres-

sure prior to performing ser-

vice can cause personal injury

and property damage

If pumping hazardous or toxic

uids, pump must be ushed

before service.

NOTICE:

Follow all hazard warnings and instrucons

shown in the “Maintenance” secon of this

manual. Pump should be dissembled using

a Bowie Signature™ Series Tool Kit, or at a

registered Bowie Repair Depot, listed at

www.bowiepumps.com.

ES IOM Rev 1 - 5/13/2021 12

NOTICE:

Any maintenance should follow the appro-

priate procedures and warnings presented

in this manual

Bowie Pumps of Canada Ltd.

manuals and parts lists may

be obtained from

www.bowiepumps.com.

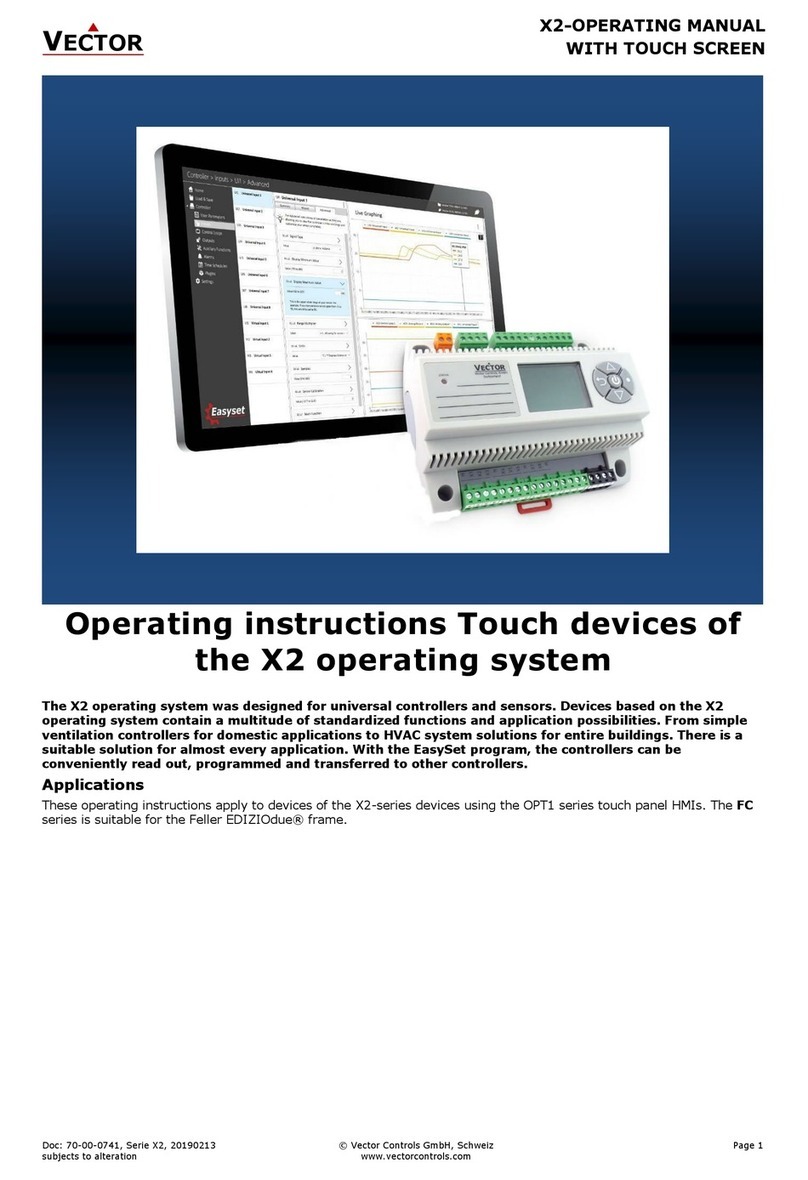

TROUBLESHOOTING

Reduced Fluid Flow

Noise

Damaged Gears

Damaged Shaft

Probable Causes

Pump speed too low for viscosity.

Leaks pump and / or connecting components

Restriction or blockage in the suction line

Restriction or blockage in the discharge line.

Damaged or worn parts.

Pressure Relief Plate is set too low or attached incorrectly (if installed).

Pump speed is too fast for viscosity or volatility of the liquid.

Pump not securely mounted.

Loose/undersized piping and fittings.

Pump is too far from fluid source.

Improper drive or hydraulic connection.

Dry running the pump.

Excessive heat in the pump.

Excessive discharge pressure.

Cavitation.

Normal end of gear life.

Abrasive wear from fluid in pump.

Relief valve malfunctioning or blocked.

Chemical attack, causing rubber gears to swell.

Foreign objects entering the pump.

Excessively worn pump center case or end plates.

Settled or solidified material in the pump at start up.

ES IOM Rev 1 - 5/13/2021 13

CONTACT INFORMATION

Bowie Pumps of Canada Ltd.

9333 41 Ave, T6E 6R5, Edmonton AB

Tel: 1.877.862.6943

Email: [email protected]

This manual suits for next models

1

Table of contents

Popular Industrial Equipment manuals by other brands

GSi

GSi PNEG-1829 owner's manual

Mec

Mec TURBO-FLO LE ME806 Series Installation and operating instructions

Virutex

Virutex PR25VJ operating instructions

SKIOLD

SKIOLD UNI-MIX 1000 GM: 590061 instruction manual

CARLO GAVAZZI

CARLO GAVAZZI SH2RODC224 instruction manual

ProMinent

ProMinent Ultromat ULFa Series Assembly and operating instructions