ME806-16 Series

Form #435 Rev D 5/8/19

!CAUTION!

The ME806 valve series is rated for a maximum pressure of 400 psi

and an operating temperature range of -40°F to 212°F (-40°C to

100°C). DO NOT exceed these parameters during valve operation or

use.

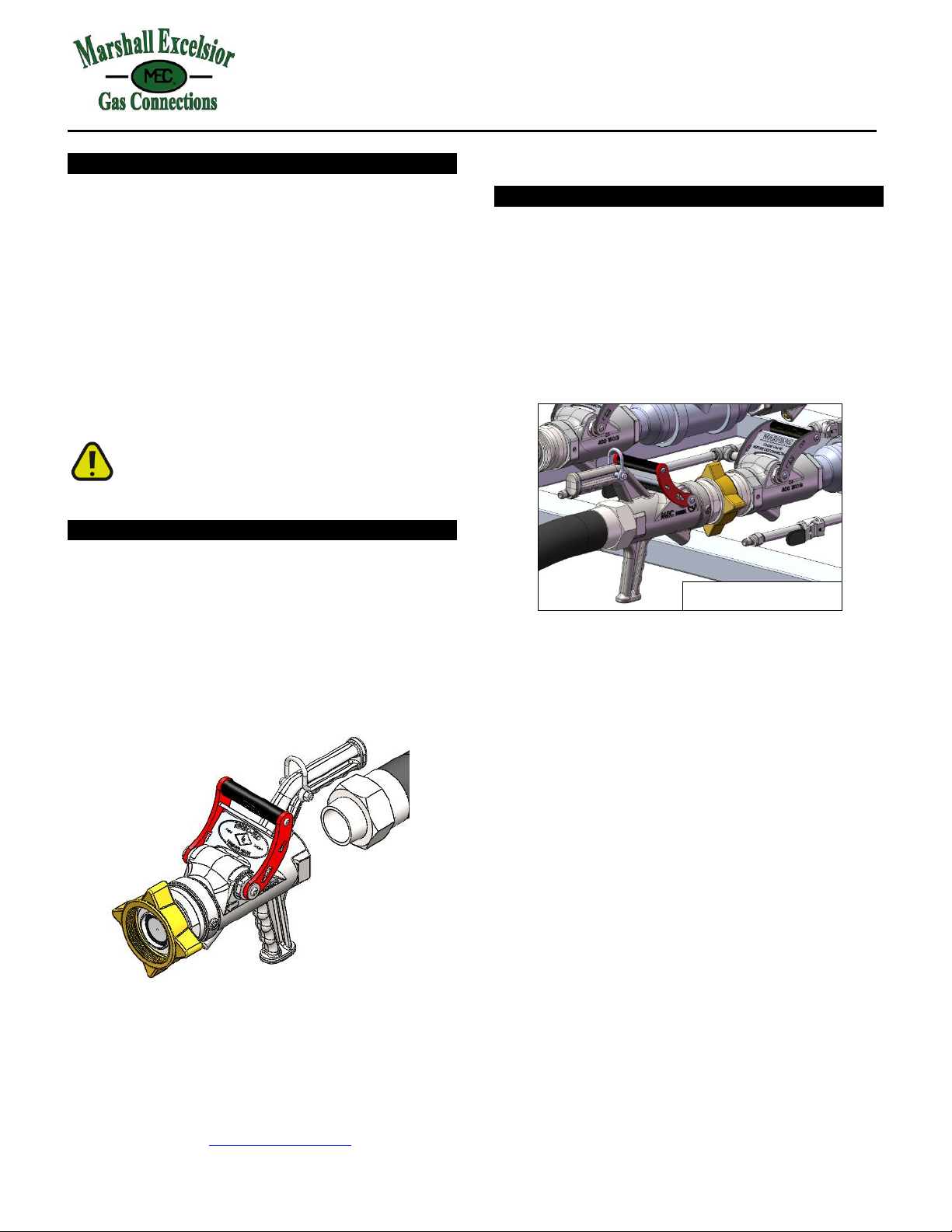

4. End Transfer –Turn off pump, then close the ME806 Transfer

valve by pushing the handle away from the ACME adapter until

the handle safety latch locks in the closed position. Close the

inlet Shut-Off valve or other connection next. Disconnect

Transfer valve.

!WARNING!

NEVER disconnect the ME806 Transfer with the valve open. Ensure

the safety latch is in the locked position (both sides of the latch

engaged in notches on body) before disconnecting valve.

*Note: this valve system is designed for minimum product loss at

disconnect. To achieve the intended low emission feature of this

transfer system, you may need to adjust your standard operating

procedure for the filling process. When using the ME868 TURBO-FLO

ACME Adapter in conjunction with ME806 Transfer valve, do not vent

the product trapped between the container service valve and the

adapter.

!WARNING!

To avoid risk of serious injury or death, never attempt to open the

ME806 Transfer Valve when it is under pressure and not properly

connected to the system with an appropriate transfer hose.

Never attempt to remove, replace or service the ball bearings in

the bearing race.

Ensure hydrostatic relief valve is aimed away from people at all

times.

Remove valve from service immediately if any ball bearings come

out of bearing race.

Remove valve from service immediately if the safety latch does not

function properly.

Remove valve from service immediately if valve seals or joints leak.

ACME Nut Service and Replacement Instructions

!WARNING!

Failure to follow the adapter service and replacement instructions

could cause risk of serious injury or death. Adapter Nut replacement

must be performed by qualified service personnel.

1. Release all system pressure before attempting to service the nut.

2. Remove the (2) Set Screws [2] from Body [1] that retain the

Adapter Nut [3] and discard.

3. Remove the Adapter Nut [3] from the Body [1] casting using the

appropriate wrench on the wrench flats provided.

4. Remove Seal [4] from the Body [1] and discard.

5. Clean all threads and sealing surfaces and install new Seal [4] into

Body [1] casting.

6. Apply Loctite #242 (blue) or equivalent thread locker to new

Adapter Nut [3] and torque to 160 to 180 Ft-lbs (217-244 Nm).

*Note: If using an ACME Cap to install, leave Cap in place until after

set screws are installed in step 7.

7. Install new Set Screws [2] and torque to 80 in-lbs (9 Nm)

*Note: Use only the (2) Set Screws [2] provided with service kit.

8. Connect a pressure source of a least 150 psi (1034 kPa) and check

for leaks (as evidenced by bubbles) at all joints and sealing

surfaces by applying a suitable leak detector solution to all joints.

Component List

1. Valve Body

2. Set Screw, Qty: 2

3. Adapter Nut

ME806 Brass

ME806S Steel

4. Adapter O-Ring

Preventative Maintenance and Safety Checks

The ME806 Transfer Valve is designed to provide a long and trouble

free service life when properly installed and maintained. Like all

mechanical devices, however, it is subject to wear and requires

preventative maintenance to maintain safe and efficient operation.

The valve contains a date of manufacture code, see above.

Perform the inspections and service as follows:

Before each use:

1. Inspect the safety latch to ensure that it is in the locked position

(both sides of the latch engaged in notches on body) prior to and

after each use. If it is not fully latched, move the handle grip

away from the ACME nut until latch is fully engaged.

2. Inspect ACME nut for worn threads. Replace nut assembly if

required. See “Periodic Checks” for important safety

instructions regarding the ACME adapter.

Periodic Checks

The following checks should be performed weekly on valves exposed to

severe service conditions such as frequent use (over 100 connections

per week) or when exposed to contaminants, corrosive agents or

extreme weather conditions. The checks should be performed at least

monthly on all other valves.

1. Adapter Nut Assembly –Inspect the hardened steel bearing races

for wear by checking the gap between the ACME nut race and the

nut adapter race. A gap greater than 0.135” (3.4mm, 2 stacked US

quarters) indicates excessive wear and MUST be removed from

service immediately, see Service and Replacement

2. Handle assembly –Inspect the valve handle, latch and springs for

proper operation. If service is required. Have handle assembly

replaced by qualified service personnel using the service

instructions provided with the replacement parts. Remove valve

from service immediately if the safety latch does not function

properly.

3. Seals –Inspect the valve seals for leaks (as evidenced by bubbles)

at all joints and sealing surfaces by apply Marshall Excelsior ”Leak

Detector” solution to all joints. If service is required, have leak

repaired by qualified service personnel using the service

instructions provided with the replacement parts. Remove valve

from service immediately if valve seals or joints leak.