MyBot Base Kit Assembly Instructions v1.4a Page 7 of 18

(For kits supplied with black wheels)

MyBot Base Kit | Assembly Guide

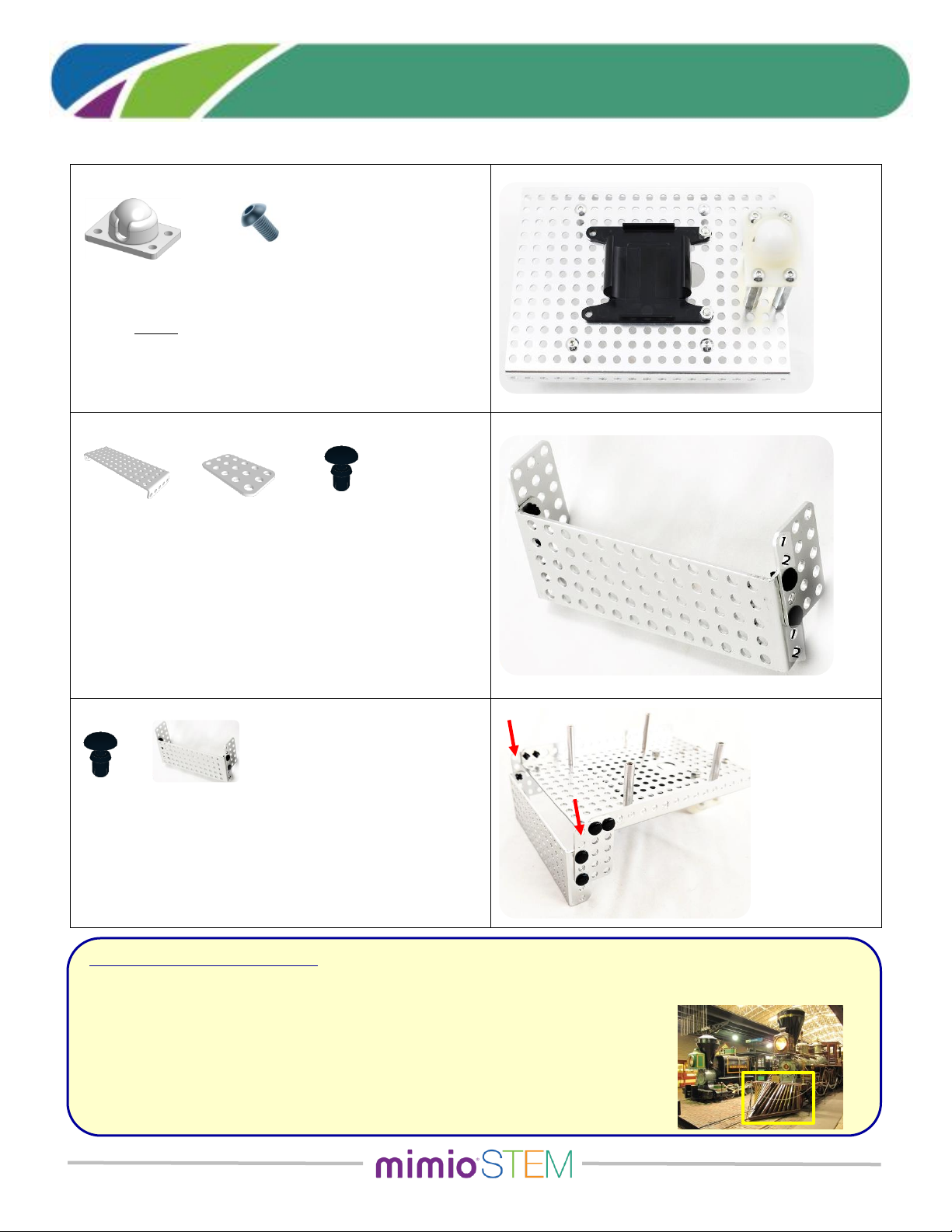

STEP 7 –Assembling the Touch Sensor “Plunger” – Part 1:

The Plunger extends the reach of the touch sensor in front of

the robot. An exploded image is shown here. These

instructions will build the plunger in steps.

7. Begin by threading the Set Screw into the Axle Hub.

Since the set screw is so small, it helps to put the set

screw onto your allen wrench, then line it up with the

hole on the side of the hub and screw it in about half-

way. Confirm that the shaft slides easily through the

center hole of the hub.

a. Next, place the Axle Hub on a flat surface with the

‘dimple’ facing up (as shown in the parts drawing

above).

b. Insert the axle into the center hole of the hub so

that it is standing straight up with the flat of the

shaft facing the set screw.

c. Without lifting or tilting, tighten the set screw to

securely hold the shaft in the axle hub.

d. Inspect the flat end of the Axle Hub. The shaft

should be flush with the surface

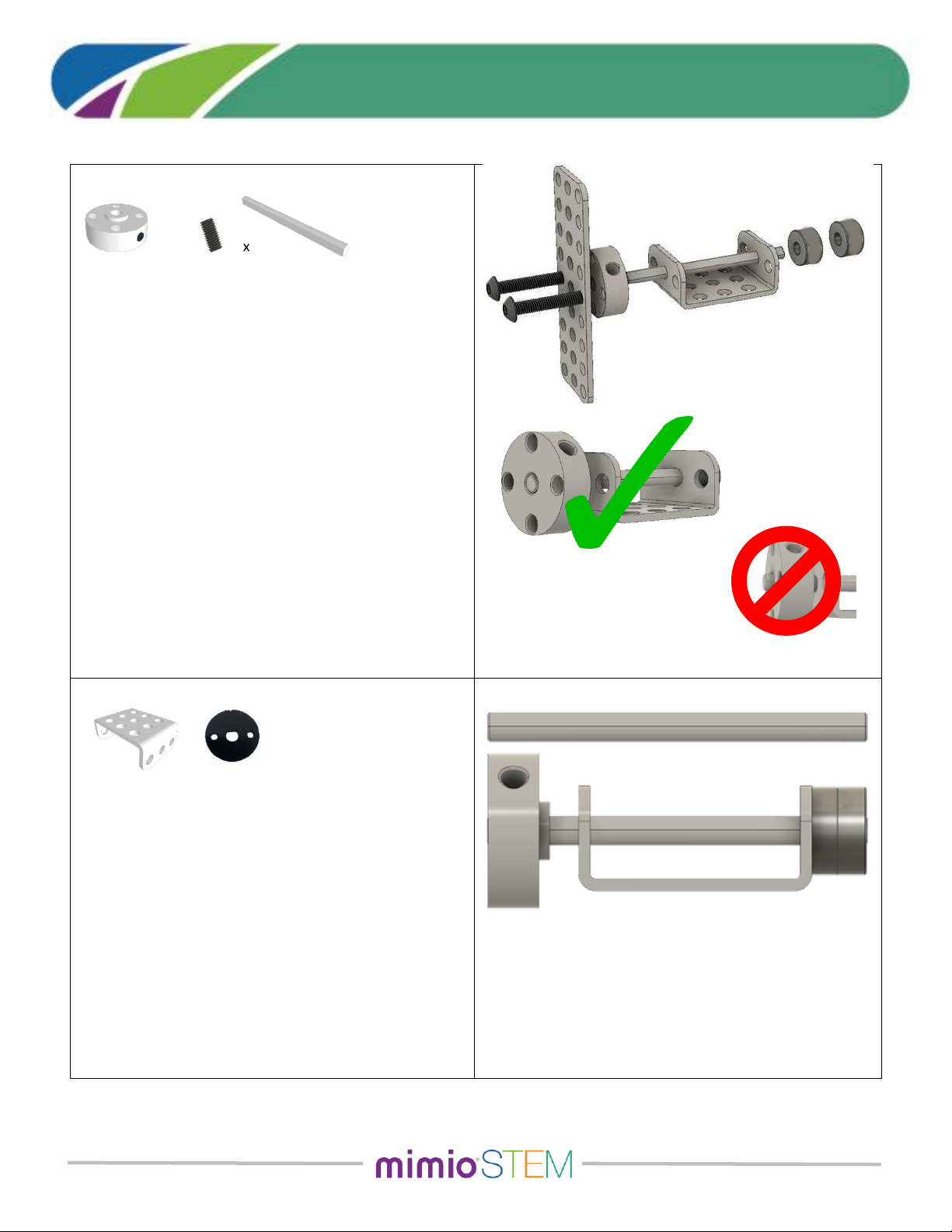

STEP 8 –Assembling the Touch Sensor “Plunger” – Part 2:

When complete, the length of this plunger will be the same as

the length of the shaft by itself.

8. With the Axle Hub still on the table, slide the 3x3

Flanged Plate onto the shaft using the center holes on

the two flanges.

a. Align one of the Axle Collars with the D-shape of the

shaft and push the Collar onto the shaft. You may

find that using a small hammer to tap the collar

down will help. (Alternately, using a quarter-sized

coin between the collar and your hand will help you

apply more force to the collar.) Push the Collar so it

is flush with the end of the shaft.

b. Using the same procedure, press the second Collar

onto the end of the shaft and press it down so it is

flush with the end of the shaft.