Bradford EcoPower 400 User manual

EcoPower®Hybrid Ventilator

Installation Manual

PRINT IN COLOUR

2

1. SYSTEM PRE-REQUISITES –Check Before Commencing

Before attempting to start the installation, please ensure that the following allowable roof pitch and

make-up air requirements can be met.

Product

Make-Up Air* per ventilator - 100%

open, evenly distributed open area

Allowable Roof Pitch

EcoPower 400

≥0.3m²

0°- 45°

EcoPower 600

≥0.5m²

0°- 45°

EcoPower 900

≥0.9m²

0°- 22.5°

* performance values based on 5Pa pressure loss across the make-up air opening.

Additional make-up air can be provided as per the AS1668.2.

DO NOT PROCEED TO INSTALL THIS PRODUCT IF THE ABOVE REQUIREMENTS ARE

UNABLE TO BE MET

2. PACKING LIST –Check Before Commencing

Included Parts

Additional Materials Required - Not Supplied

a. FASTENERS (Quantity and Type)

Product

Head to Varipitch

Varipitch to Flashing

Flashing to Roof

EP400

6

6

12

EP600

9

9

16

EP900

12

12

26

Fasteners

Use 10G X 16MM Galvanised Self Drilling TEK Screws with Neo or

5/32" (4.0mm) Rivets Aluminium/Steel Sealed

b. SUPPLEMENTARY FLASHING (if required) to provide a minimum of 1 dry pan on each side of

the ventilator throat –refer to section 5 for details.

c. SPARKGUARD (if required) for BAL rated applications or to provide protection against the

entry of vermin.

Ventilator Head

Varipitch

Flashing

3

IMPORTANT Note Regarding Lifting This Product

Lift the product in its original packaging using a crane or similar equipment to roof mounting location –prior

to handling the product.

Caution:

The ventilator top surface/dome can be easily scratched or deformed when placed upside down so always

place it on a soft/smooth surface such as cardboard or a soft-foam mat.

4

SAFETY AND WARNINGS

a. Please read this manual carefully before installing this product and keep it for future reference or

provide it to the building owner/maintenance manager.

b. The installation of this product involves working at heights on a sloping surface and may be dangerous

which includes the potential of death, personal injury, or property damage. Please be aware of the

following before installing this product.

c. Follow the state or territory regulator OH&S guidelines for working at height (e.g. Roof work), electrical,

working in elevated temperatures (e.g. roof space in summer). For more information on your state’s

OH&S guidelines for working at heights, please refer to: https://www.safeworkaustralia.gov.au/heights

d. This product must be installed by a qualified installer and all electrical wiring must be undertaken by a

qualified electrician.

e. This hybrid ventilator uses 220V-240V AC power for the electrically powered components and electrical

connections must only be undertaken by a qualified electrician.

f. This hybrid ventilator is supplied with either a Smart Controller or Interface Box - these devices must not

be tampered with and the hybrid ventilator must not be operated without either of these devices.

g. Do not attempt to power up the product when the product is not suitably roof mounted as the turbine

will rotate without warning and may create a hazard.

h. Due to the size and weight of the turbine, it is recommended that it is always lifted by 2 people or a

crane. Refer to the lifting instructions.

i. Damaged parts must be replaced with a genuine replacement part from Bradford Ventilation.

5

3. VENTILATOR POSITIONING & PROVISION FOR MAKE-UP AIR

Bradford Ventilation recommends that ventilators are positioned 4m to 6m away from each other in all

directions for effective and efficient performance. Ensure that the ventilators are not sheltered from the wind

by surrounding objects, the angle created by the roof ridge or from each other.

Make-up air is required for this hybrid ventilator to replenish the exhausted air. As a general guide, the

largest make-up air entry should be positioned on the opposite side of the building to the largest ventilator

demand. The make-up air location should be positioned at optimum height to provide efficient sweeping of

the area.

The illustrations below provide a number of generic ventilator and make-up air layouts but it should be

noted that a whole-of-building assessment, as per AS1668.2, should be conducted by a suitably qualified

person prior to deciding upon site-specific ventilator and make-up air placement.

IMPORTANT: If insufficient external make-up air is provided, the ventilators will draw make-up air from each

other –this will both diminish the effectiveness of the system and increase the risk of the system drawing

external water into the building during periods of rain.

Ventilator

Make-Up Area

Ridge Line

Ridge Line

Ridge Line

Ridge Line

6

4. VENTILATOR INSTALLATION –Ridge Installation

NOTE: Cyclonic application variations to these instructions are set out in Section 6.

a. Set Position: Place the base flashing under the ridge cap in the required position and adjust position to

avoid structural roof members below the roof sheet.

Important Note Regarding Roof Structural Support:

EP400 & EP600 –If the purlin spacing is larger than 600mm, trimmers are required. Install the

trimmers between the purlin on the either side of the opening. Do not cover the openings.

EP900 –If the purlin spacing is larger than 1000mm, trimmers are required. Install the trimmers

between the purlin on the either side of the opening. Do not cover the opening.

b. Mark Hole Position: Ensure the flashing covers the corrugation or ribs equally on each side of

the flashing, then mark a circle on the roof using the hole in the flashing as a template.

c. Cut Hole: Carefully cut the hole, remembering that there may be insulation and other roof

members under the roof sheet. Once the hole has been cut, fold up the edge of the

corrugations or pans.

7

d. Secure Flashing: Attach the flashing to the roof (refer to the table below for the required

number of fasteners). If trimmers are used ensure the flashing is secured to the trimmers. Seal

all fasteners with suitable sealant to ensure they are weatherproof.

e. Assemble the Varipitch: When a Varipitch throat is being used, place the Varipitch on the

flashing and rotate the top and bottom halves until the top of the Varipitch is level (horizontal) -

it is recommended that an electronic or spirit level is used to ensure that the top edge of the

throat is horizontal in all directions.

Secure the Varipitch angle: With the varipitch upper throat positioned horizontally, lock it into

position using the supplied varipitch clip. Use either self-tapping screws or blind rivets to

secure the clip between the two halves of the varipitch.

Model

Fasteners to secure

Flashing to Roof

EP400

12 (4 near throat)

EP600

16 (4 near throat)

EP900

26 (4 near throat)

Use 10G X 16MM Galvanised Self Drilling TEK Screws

with Neo or 5/32" (4.0mm) Rivets Aluminium/Steel

Sealed

8

f. Weather Sealing: Seal the Varipitch seam on the inside with a bead of weather-resistant

suitable sealant.

NOTE: DO NOT apply sealant to the joint between the flashing and Varipitch. This is a natural

gutter to release any trapped condensation.

g. Secure Varipitch to Flashing: Secure the varipitch to the flashing using the recommended

number of screws shown in the table below –DO NOT seal this connection.

Model

Fasteners to secure

Varipitch to Flashing

EP400

6

EP600

9

EP900

12

Use 10G X 16MM Galvanised Self Drilling TEK Screws with

Neo or 5/32" (4.0mm) Rivets Aluminium/Steel Sealed

9

h. Assemble Turbine: Assemble the turbine head to the Varipitch. Re-check if the assembly is

level (horizontal) and adjust the turbine by tilting the throat slightly if required. Ensure the

knurling (the tapered section of the Varipitch) is fully inside the ventilator throat and secure the

ventilator throat by fastening it to the top of the Varipitch with the number of fasteners shown in

the table below.

i. Sealing is crucial for this product to ensure no leaking occur during its lifespan. Ensure the

following areas are sealed;

Go to Section 6 for Additional Requirements for Cyclonic Wind Regions

Model

Fasteners to secure

Turbine to Varipitch

EP400

6

EP600

9

EP900

12

Use 10G X 16MM Galvanised Self Drilling TEK Screws with

Neo or 5/32" (4.0mm) Rivets Aluminium/Steel Sealed

Location Area

Sealing Requirement

All Fasteners

Seal

Flashing perimeter to roof

Seal

Varipitch Seam (inside throat)

Seal

Varipitch to Flashing

Do Not Seal

10

5. VENTILATOR INSTALLATION –Away from Ridge Line - Back-Flashing Required

NOTE: Cyclonic application variations to these instructions are set out in Section 6.

a. Hole Layout: It is recommended that 1 dry pan is flashed on each side of the ventilator throat

cut-out. If the ventilator diameter is greater than 1 pan width and less than 2 pans width –cut a

square hole for 2 pans.

Note :

EP400 & EP600 –If purlin spacing larger than 600mm, trimmers may be required. Install the

trimmers between the purlin on the either side of the opening. Do not cover the openings.

EP900 –If purlin spacing larger than 1000mm, trimmers may be required. Install the trimmers

between the purlin on the either side of the opening. Do not cover the opening.

2 Pans width for

Ventilator Throat

Fold up on

both ends

Throat

Provide 1 dry pan each

side of the metal roof

cut-out

11

b. Back-Flashing Assembly: Ensure that the width of the back-flashing tray is sufficient to cover at

least 1 dry pan on each side of the cut-out in the metal roof. Position the flashing in the middle

of the tray with 1 dry pan on each side of the flashing cut-out. Mark a circle using the hole in

the flashing as a template and cut the hole in the back-flashing tray.

Secure the ventilator’s flashing to the back-flashing tray using the recommended number of

fasteners shown in the table below:

Note: Always provide 1 dry pan on each side of the ventilator throat to avoid water or rain

ingress.

Model

Fasteners to secure

Flashing to Roof

EP400

12 (4 near throat)

EP600

16 (4 near throat)

EP900

26 (4 near throat)

Use 10G X 16MM Galvanised Self Drilling TEK Screws

with Neo or 5/32" (4.0mm) Rivets Aluminium/Steel

Sealed

Provide 1 dry pan each

side of the metal roof

cut-out

12

c. Assemble Back-Flashing: Secure the back-flashing tray to the roof using a minimum of one

10G X 16MM Galvanised Self Drilling TEK Screws with Neo or 5/32" (4.0mm) Rivets

Aluminium/Steel Sealed every 150mm.If trimmers are used ensure the flashing is secured to

the trimmers. Seal all fasteners with suitable sealant to ensure they are weatherproof.

d. Assemble the Varipitch: When a Varipitch throat is being used, place the Varipitch on the

flashing and rotate the top and bottom halves until the top of the Varipitch is level (horizontal) -

it is recommended that an electronic or spirit level is used to ensure that the top edge of the

throat is horizontal in all directions.

e. Secure the Varipitch angle: With the varipitch upper throat positioned horizontally, lock it into

position using the supplied varipitch clip. Use either self-tapping screws or blind rivets to

secure the clip between the two halves of the varipitch.

13

f. Weather Sealing: Seal the Varipitch seam on the inside with a bead of weather-resistant

suitable sealant.

NOTE: DO NOT apply sealant to the joint between the flashing and Varipitch. This is a natural

gutter to release any trapped condensation.

j. Secure Varipitch to Flashing: Secure the varipitch to the flashing using the recommended

number of screws shown in the table below –DO NOT seal this connection.

Model

Fasteners to secure

Varipitch to Flashing

EP400

6

EP600

9

EP900

12

Use 10G X 16MM Galvanised Self Drilling TEK Screws with

Neo or 5/32" (4.0mm) Rivets Aluminium/Steel Sealed

14

g. Assemble Turbine: Assemble the turbine head to the Varipitch. Re-check if the assembly is

level (horizontal) and adjust the turbine by tilting the throat slightly if required. Ensure the

knurling (the tapered section of the Varipitch) is fully inside the ventilator throat and secure the

ventilator throat by fastening it to the top of the Varipitch with the recommended number of

fasteners shown in the table below.

h. Sealing is crucial for this product to ensure no leaking occur during its lifespan. Ensure the

following areas are sealed ;

Go to Section 6 for Additional Requirements for Cyclonic Wind Regions

Model

Fasteners to secure

Turbine to Varipitch

EP400

6

EP600

9

EP900

12

Use 10G X 16MM Galvanised Self Drilling TEK Screws with

Neo or 5/32" (4.0mm) Rivets Aluminium/Steel Sealed

Location Area

Sealing Requirement

Fasteners

Seal

Flashing

Seal

Varipitch Seam

Seal

Varipitch to Flashing

Do Not Seal

End of the ribs

Seal

Tray

Sealed and fixed to the roofing

Tray Notches

Folded down into pans –do not seal

Varipitch to Flashing –DO NOT SEAL

Fold down the tray notches –DO NOT

SEAL

15

6. CYCLONE REGION INSTALLATION –Additional Requirements for Cyclonic Wind Regions

The specific installation instruction variations in this section must be applied to installations in

cyclonic regions or where the use of a cyclonic restraint has been designated –replace guidance

in Section 6 & 7 with specific information in this Section.

Fastener Selection

a. Fix Flashing to roof with 14G Class 3 or 4 Tek screws. Locate 4 close to Varipitch and 26

around the 4 sides of the flashing.

b. Fix Varipitch to Flashing with 12 x 6-4 AS blind rivets. Seal with suitable sealant if unsealed

rivets are used.

c. Fix Throat to Varipitch with 12 x 6-4 AS blind rivets. Seal with suitable sealant if unsealed rivets

are used.

16

Cyclone Strap Assembly

Note: Safety mesh shall not be removed. The safety mesh has been removed in the above

figure to show internal installation of the cyclone strap only.

d. Attach the 30x0.8x950mm long Cyclone Straps to the inside top edge of the Varipitch, down to

the underside of a roof purlin as shown above.

e. Fix both cyclone fixing straps to the inside of the varipitch with at least 4 x 6-4 AS rivets. Two

rivets must be located above the varipitch seam with one through the throat, varipitch and

strap.

f. Fix the lower end of the strap to the purlin with M8 hex head screws (minimum class 4.6) and

two M8 nuts per screw.

17

Cyclone Strap Assembly - Cross Section View 1

Cyclone Strap

4 x 6-4 AS Rivets

Purlin

2 x M8 Nuts

M8 x 25 Hex Head

Screw

18

Cyclone Strap Assembly - Cross Section View 2

Cyclone

Strap

Varipitch

Ventilator

Throat

19

7. MAINTENANCE

Regular maintenance of this product is essential to ensure its safe and long-term operation. It is the

responsibility of the building owner or manager to outline the maintenance program throughout the

products lifespan. The following components should be inspected on a regular basis:

WARNING: Prior to inspecting the ventilator ensure that the power is turned off and that the ventilator head

is held in a static position by another person using a gloved hand on the top surface of the turbine (away

from the turbine blades) –this should not be undertaken on a windy day when the turbine head cannot be

safely slowed

•Rotating/turbine head –check for excessive movement/contact between components, unusual noise

during rotation, listen for noises and assess visual wear & tear.

•Fasteners –check all are in situ and well sealed.

•Flashing Connections –check joints that are meant to be sealed remain sealed and that those that

are meant to be unsealed are clear of obstruction.

•Sparkguard (if provided) –ensure this is clear of debris.

•Cyclone Strap (if provided) –check fastener tension.

•Electrical component and connections –check connections for wear or exposure damage.

8. TROUBLESHOOTING GUIDE

No

Failure Mode / Potential Cause(s)

Image / Description

1

Water or rain leakage.

Varipitch connection not sealed.

The photo in the sidebar shows the possible outcome if

the varipitch connection has been slightly separated

during angle adjustment or has not been sealed with

silicon.

ACTION: Seal varipitch connection.

2

Water or rain leakage.

Ventilator throat gutter blocked.

Placing silicon around the bottom of the vent throat

where it contacts the flashing blocks the vent gutter at

the base of the throat, preventing the release of internal

condensation and mist from the inside of the throat.

ACTION: Remove blockage

20

3

Water or rain leakage.

Insufficient turndowns along the front edge of the back-

flashing due to low roof pitch and driving rain.

ACTION: Extend and seal flashing.

4

Water or rain leakage.

No back-flashing provided.

ACTION: Extend back-flashing to under sheet above or

roof ridge.

5

Water or rain leakage.

Ventilator throat shortened or not used which allows rain

‘bounce’ to drive water off roof into ventilator.

ACTION: Install recommended ventilator throat.

6

CAUTION: Reliance upon flexible sealants.

Through expansion and contraction of building components over time, silicon may develop cavities

or cracks which then permit water ingress. It is always recommended that mechanically overlapped

seals are created with metal components to provide water protection and that flexible sealants are

used to provide secondary protection. While it is recommended that silicon be applied over roofing

screws - it is more reliable to use high quality blind rivets or roofing screws with integrated washers.

7

Failure to Use Ventilator Throat.

It is crucial that the ventilators are installed with a varipitch to ensure the turbine has adequate

clearance from the flashing. Failure to comply with this recommendation could lead to rain ingress

through the vanes resulting in leakage.

8

Creation of Negative Pressure in a Building Leading to Back-drafting.

The demand for make-up air by the ventilators leads to the creation of sufficient negative pressure in

the building that vents of a lower height (downslope from ridge) can be forced to rotate in the

opposite direction to, in effect, supply air to equalise pressure. This can lead to rain being

inadvertently draw into the building when the phenomenon occurs during wet weather.

The characteristics of this phenomenon occur when:

a. The building is very air-tight and make-up air is not balanced.

This manual suits for next models

5

Table of contents

Other Bradford Fan manuals

Popular Fan manuals by other brands

System air

System air Combi Unit Genius Installation, operation and maintenance instructions

System air

System air VM User and maintenance instructions

Ebmpapst

Ebmpapst G3G133-RF15-03 operating instructions

Ebmpapst

Ebmpapst G1G085-AB05-01 operating instructions

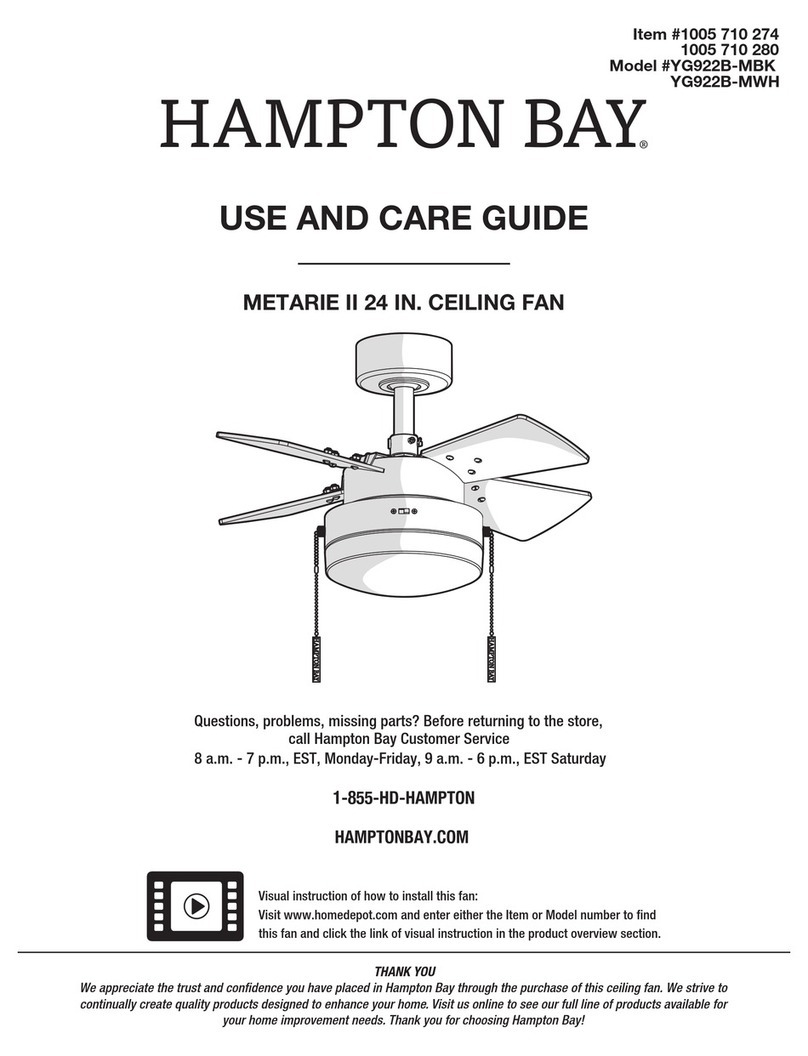

HAMPTON BAY

HAMPTON BAY METARIE II YG922B-MBK Use and care guide

Ebmpapst

Ebmpapst A4E450-AN05-01 operating instructions