3

Installation S19-210BF

Bradley Corporation • 215-619BF Rev. S; ECM 10-05-031 8/27/10

Installation

Supplies Required:

• (3)3/8"flooranchorsandbolts

• Pipesealant

• Pipingto1/2"NPTwatersupplyinlet

• Pipingto1-1/4"NPTdrainoutlet

• Sign-mountinghardware

NOTE: Local codes may require the installation of

a backflow prevention valve to complete proper

installation. Compliance with local codes is the

responsibility of the installer. Valve must be tested

annually to verify that it is functioning properly.

Backflow prevention valves are not included with

the fixture and may be supplied by the contractor

or purchased from Bradley Corporation.

Step 1: Secure base to floor

1. Installthreesuitableanchors(suppliedby

installer)for3/8"boltsinthefloor.

2. Boltthebasetotheflooranchorsusing3/8"

bolts(suppliedbyinstaller).

Step 2: Assemble eyewash

1. Assembleeyewashcomponentsasshown

onpage4.

• Applypipesealant(suppliedbyinstaller)to

allmale-threadedpipejoints.

• Usetherubbergrippadprovidedora

strapwrencharoundpipeswhentightening

topreventmarring.Placethegrippadon

thepipe,thenputthewrenchoverthegrip

padandturnthepipewiththewrench.

• Usecautionwhenconnectingitems3,4.2

and5.Handtightplus1/8turnissufficient.

Step 3: Connect water supply

1. Connectthewatersupplypiping(supplied

byinstaller)tothe1/2"NPTinletonthe

eyewash.

2. Connectthedrainpiping(suppliedby

installer)tothe1-1/4"NPTdrainoutletonthe

eyewash.

3. Mountthesafetysigntothewallusingsign-

mountinghardware(suppliedbyinstaller).

4. Openthewatersupplylinesandtestfor

leaksandadequatewaterflow.

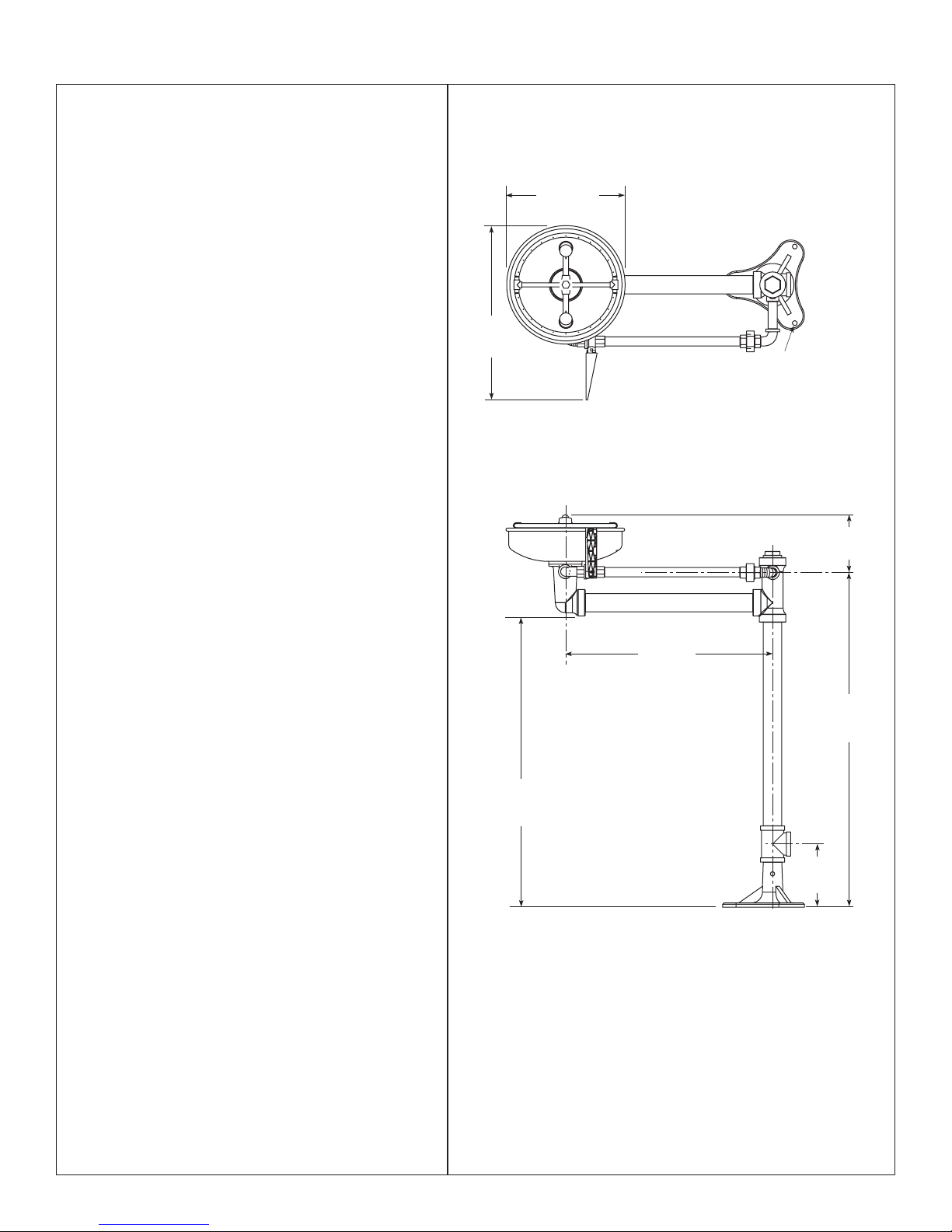

NOTE: All dimensions assume standard thread engagement.

Variations in manufacturing allow for +/- 1/8”

(3mm) per threaded joint. To find the tolerance of

a dimension, add the number of thread joints in

between a dimension and multiply it by 1/8” (3mm).

27"

(686mm)

Ø 10-3/4"

(273mm)

18-3/4"

(476mm)

15-3/4"

(400mm)

6"

(152mm)

31"

(787mm)

5-5/8" (143mm)

Ø9"(229mm)Flange

with(3)Ø3/8"(10mm)

HolesonØ8"(203mm)

Bolt Circle