Brain Bee B-TP 1000 User manual

GB

B-TP 1000

TPMS SCANTOOL

Quick Guide

ENGLISH Ver. 1.3

B-TP 1000

ENGLISH 2

CONTENTS

CONTENTS ................................................................................................................................................................................ 2

GENERAL NOTES .................................................................................................................................................................... 3

MANUFACTURER IDENTIFICATION .................................................................................................................................. 3

TECHNICAL SERVICE CENTRES........................................................................................................................................... 3

DISPOSAL .................................................................................................................................................................................. 3

SYMBOLS ................................................................................................................................................................................... 3

SAFETY INSTRUCTIONS ........................................................................................................................................................ 3

GENERAL TECHNICAL FEATURES ...................................................................................................................................... 5

MARKING .................................................................................................................................................................................. 5

DECLARATION OF CONFORMITY ..................................................................................................................................... 5

EQUIPMENT DESCRIPTION ................................................................................................................................................. 5

ACCESSORIES COMING WITH THE EQUIPMENT ......................................................................................................... 6

DATABASE ................................................................................................................................................................................. 7

DESCRIPTION OF KEYPAD AND CONTROLS ................................................................................................................. 7

MENU STRUCTURE................................................................................................................................................................. 8

MAIN MENU AND STATUS BAR ........................................................................................................................................ 9

CORRECT POSITIONING OF THE EQUIPMENT ON THE SENSOR FOR PROGRAMMING PURPOSES ........ 11

SENSORS READING ............................................................................................................................................................. 11

SENSORS REPLACEMENT ................................................................................................................................................... 12

COPY SENSOR ID ............................................................................................................................................................ 13

CREATE SENSOR ID ........................................................................................................................................................ 14

ENTER SENSOR ID .......................................................................................................................................................... 15

CLONE ALL VEHICLE SENSORS ........................................................................................................................................ 15

CLONE SAVED VEHICLE ...................................................................................................................................................... 15

TECHNICAL INFORMATION .............................................................................................................................................. 16

SENSORS LEARNING PROCEDURES ............................................................................................................................... 16

ACTIVATION, UPDATE AND LICENSE RENEWAL OF B-TP 1000 ............................................................................ 16

The upgrade and license renewal of the B-TP 1000 takes place during the connection of the

scantool to the PC, switching it into "ITALSENSOR TOOL MANAGER" mode and connecting it via the

USB cable. .......................................................................................................................................................................... 16

Installation of ITALSENSOR TOOL MANAGER ....................................................................................................... 16

WARNING: to download updates and allow the program to renew the instrument license, the PC

must be connected to the Internet. .......................................................................................................................... 17

First activation, updating and renewal of the B-TP 1000 license .................................................................... 17

LOW LEVEL PROGRAMMING MODE .............................................................................................................................. 17

B-TP 1000

3 ENGLISH

GENERAL NOTES

All rights reserved. Total or partial copy of this manual is prohibited under any form, either paper

forms or electronic forms. BRAIN BEE SPA and resources used for the drawing up of this manual will

not be held responsible for the incorrect use of the manual, while guarantee that information in the

manual have been duly checked. Products undergo constant control and improvement, hence we

reserve the right to modify information herein without notice.

MANUFACTURER IDENTIFICATION

B-TP 1000 is equipment being manufactured by:

Brain Bee S.p.A.

Via Quasimodo, 4/a

43126 Parma (Italy)

Tel. +39 0521 954411 – Fax +39 0521 954490

e-mail contact@brainbee.com

internet http://www.brainbee.com

TECHNICAL SERVICE CENTRES

As to technical service centres, please view the list on the website www.brainbee.com or contact your

reseller.

DISPOSAL

SYMBOLS

The following warning symbols are aimed at ensuring an easier and simpler consultation of the

manual.

SAFETY INSTRUCTIONS

Precautions for operators safety

Before using the equipment, read and follow the instructions included in the user manual.

Do not use broken or damaged connection cables.

Do not use the equipment in direct contact with heat sources.

Do not use the equipment in environments with explosive atmosphere.

The product complies with the requir

ements of the Community Directive 2002/96/EC.

Disposal shall be made in compliance with local regulations on waste disposal: do not

dump the product with normal household waste but take it to specific collection centres on

the territory, in line with current regulations in force.

Operations representing a situation of potential danger for operators are highlighted using

the symbol shown alongside.

Operations requiring particu

lar attention are highlighted using the symbol alongside. Such

operations shall be performed correctly in order to avoid damaging objects or the

surrounding environment. This symbol also highlights information special attention shall be

paid to.

B-TP 1000

ENGLISH 4

Battery use and safety

Warning: The equipment includes two Li-ion batteries. These batteries can only be replaced by

Brain Bee authorized technical service centre.

Recharge the batteries using the battery charger or the battery power cable supplied with

the equipment.

The user must not remove or replace the battery. The attempt to remove or replace the

battery may damage the battery and cause burns and injuries.

Do not try to disassemble or repair the equipment. The attempt to disassemble or repair the

battery may damage the battery and cause burns and injuries.

Batteries performance is significantly reduced if the equipment is used outside the required

temperature range.

If the equipment is not used for a long period of time, batteries need to be periodically

recharged. If the battery runs completely flat, this will jeopardize its duration.

Do not use damaged cables for connection to the vehicle and comply with the connection-

related instructions.

Improper use of the batteries and failure to comply with the conditions of use indicated

herein might cause risk of fire, deflagration or fluid outflow.

Battery recharge

Notes for the recharge of the product’s internal battery

For an efficient recharge of the battery, the equipment and the battery charger must be kept

at ambient temperature during recharge.

The new batteries are not supplied fully charged.

A new battery or a battery that has not been used in a long time may require a longer

recharge time.

The equipment, the internal batteries and the recharge system are provided with safety

circuits against possible overcharges.

The internal battery is recharged using the battery recharger supplied with the equipment.

During the whole recharge phase, the “IN CHARGE” warning light is ON. Once the recharge

has been completed, the warning light turns off.

When operating on the engine

protect face, hands and feet, with suitable clothes, avoid contact with hot surfaces, such as

sparking plugs, radiators, pipings of the cooling system, exhaust pipes. Catalytic mufflers

reach extremely high temperatures and can cause burns or fires.

Do not smoke and do not use open flames when operating on the engine.

In the vehicles, the cooling fan starts automatically by means of a temperature sensor even

when the engine is off; always pay attention when operating close to it and disconnect it if

needed.

Precautions for equipment use

We recommend a first charging cycle of the battery for at least 8 consecutive hours.

Do not pour water or other fluids onto the system

Protect the equipment from rain or excessive humidity to avoid damaging it irremediably.

The equipment shall never be directly exposed to excessive dust.

Use exclusively original connection cables.

Do not place the equipment on live electrical terminals.

Shall the following technical problems occur, do not use the equipment and contact the

authorized technical service centre or your reseller:

o A fluid has been spilled on the equipment.

o The equipment is not working properly

B-TP 1000

5 ENGLISH

Cleaning of the equipment

For LCD display cleaning, use a soft, clean and dry cloth, spraying a small amount of (non

abrasive) glass cleaner. Rub softly.

Do not spray detergent on the display.

Never use acid base or abrasive cleansers to clean the body of plastic components. Use a

soft, clean and dry cloth, spraying a small amount of detergent and rubbing softly.

GENERAL TECHNICAL FEATURES

TPMS sensors activation:

125kHz (LF) ra

dio transmitter

Sensor parameters reading:

433M

Hz radio receiver

Equipment power supply:

Internal Li

-

Ion battery pack. Battery r

echarge with external 12VDC @

2A power supply unit (supplied with the equipment)

Max. battery life (after

complete recharge)

≈8h without activations

or

> 650 reading cycles

or

> 400 programming cycles

Max. recharge time

4h

User interface:

3,5” TFT LCD display 240x320 16bpp brightness 700cd/m2 and

membrane keypad for equipment control.

Internal memory:

µ

SDcard => 4GByte

Communication ports:

1 USB communication port for

Firmware

update and communication

to PC and/or Touch line diagnostic module.

Operating temperature

:

5°

-

40° C with humidity 0

-

95% without condensation

Dimensions:

210x98x35mm.

Weight:

500g.

MARKING

B-TP 1000 is manufactured in compliance with the Community Directives being relevant and applicable

to its placing on the market. The characteristic data of the equipment are described on the rear side of

the equipment itself. The equipment meets the requirements of the R&TTE Directive 1999/5/EC

It is prohibited to remove damage or tamper with the equipment “data plate”.

DECLARATION OF CONFORMITY

The declaration of conformity can be downloaded from the website www.brainbee.com/ce, in the B-TP

1000 manuals section.

EQUIPMENT DESCRIPTION

B-TP 1000 is an equipment dedicated to maintenance and diagnosis of both direct and indirect TPMS

systems.

Diagnosis of indirect systems can be done with a scantool of the Touch line connected in bluetooth

mode to the B-TP 1000. Any malfunction is detected using the ABS, ESP rpm sensors: the presence of a

flat tyre can be detected based on the rotation speed of every single tyre.

Diagnosis of direct TPMS systems (pressure and temperature sensors fitted in each tyre) includes the

following functions:

Sensor wake-up via radio (LF 125kHz) with different activation pulse according to the specific

sensor, or by deflating the tyre in the cases indicated by the equipment.

B-TP 1000

ENGLISH 6

Reading of the characteristic parameters of the original sensor via radio (UHF – 433 MHz)

o Battery status

o Sensor ID (both decimal and hexadecimal)

o Tyre pressure

o Tyre temperature

Realignment of TPMS sensors on the vehicle in case of “tyre change” or sensor replacement

o via EOBD with optional B-TP EOBD module

o by means of direct or indirect manual procedures

Universal sensors programming: the function allows programming or setting up the

universal sensors that can be used to replace the original sensor on a vehicle. The

programming or setting up phase of the universal sensor is done with radio transmission in

LF range. The types of universal sensors currently supported are:

o EZ Sensor®, EZ Sensor 2.0® - Schrader

o IntelliSens - Huf

o Sens.it® - Alligator

o Italsensor® - Italmatic

o Alcar by Schrader – Alcar

o EU-PRO/T-PRO, EU-PRO1/T-PRO1, EU-PRO2/T-PRO2, EU-PRO Hybryd/T-PRO

Hybryd – Hamaton

o Simple sensor / Direct Fit - Orange

Database with technical information regarding the sensor and tightening torques, original

and universal spare parts codes, and tools codes

Management of automatic updates with UP&GO software

Front vie

w

Bottom view

1.

Antenna

2. LCD display

3. Keypad

4.

USB port

5. Battery charger power input (DC IN)

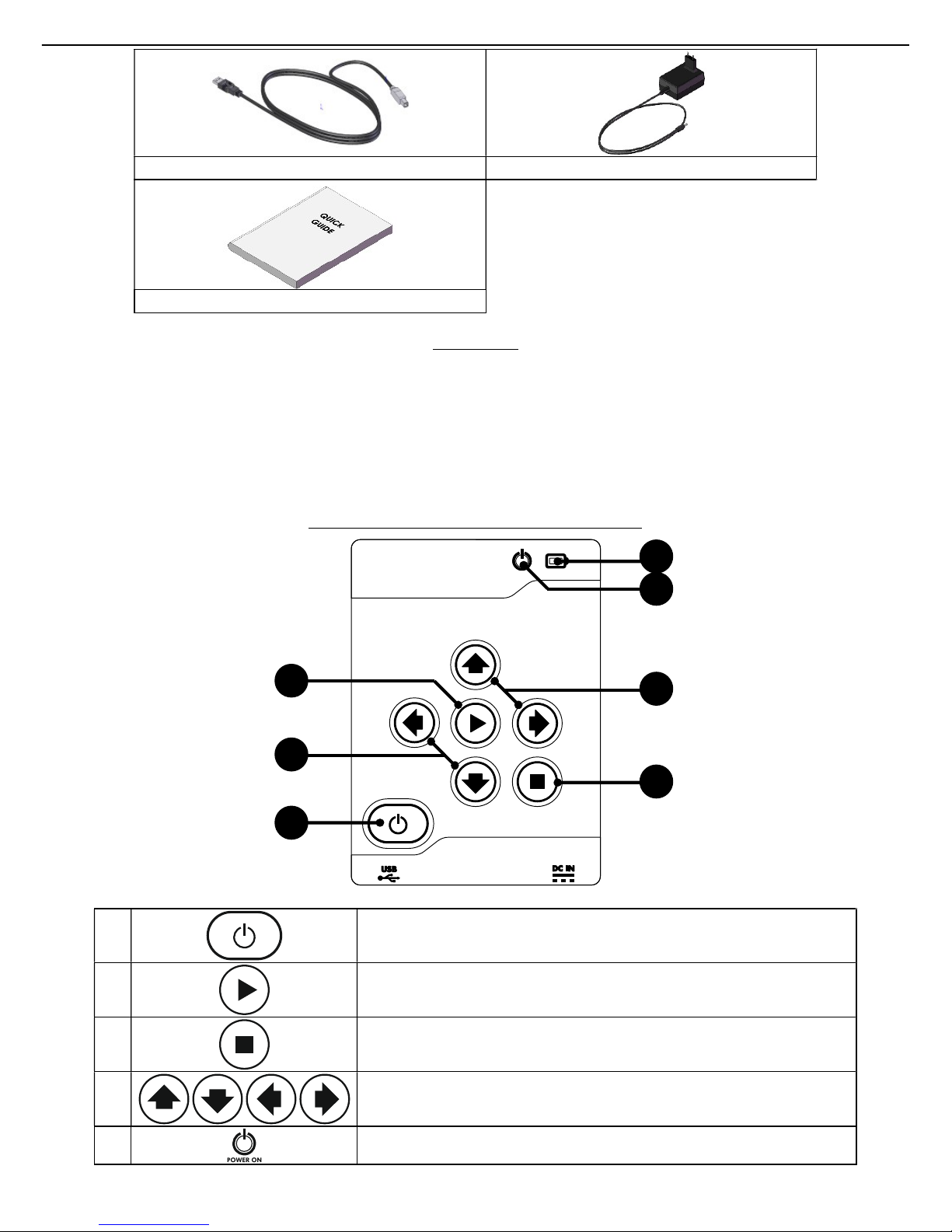

ACCESSORIES COMING WITH THE EQUIPMENT

Standard accessories may vary according to sales configurations. The items included in the standard

configuration are listed below.

4

5

1

2

3

B-TP 1000

7 ENGLISH

DATABASE

A database of vehicles and associated TPMS sensors with related technical data is stored in the

equipment: maker, model and code of the original sensor, tightening torques of the valve and sensor

fixing nut or screw, codes of the tools required for sensor assembly / disassembly.

Keep the database updated by downloading it from the website and reprogramming the equipment

using the USB cable supplied, as outlined in the paragraph ACTIVATION, UPDATE AND LICENSE

RENEWAL OF B-TP 1000.

DESCRIPTION OF KEYPAD AND CONTROLS

1

ON/OFF key: press to turn on the equipment. Keep it pressed for

at least 2 seconds to turn off the equipment.

2

OK key: press to confirm your selection or to access the menu.

3

ESC key: press to exit the menu.

4

Arrow keys: press to navigate inside the menu to the left, to the

right, up and down.

5

Power on light: It turns on when the equipment is ON.

USB CABLE

BATTERY CHARGER

QUICK GUIDE

1

4

2

3

4

5

6

B-TP 1000

ENGLISH 8

6

Battery charging warning light:

when the equipment is

connected to the battery charger, the light turns on when the

battery is recharging and turns off when the battery is charged.

PROGRAMMING MODE

+

By pressing the

ESC

key and the

ON/OFF

key, the equipment is

started in programming mode: see paragraph LOW LEVEL

PROGRAMMING MODE

MENU STRUCTURE

The diagram above shows the schematic structure of B-TP 1000 software menus.

VEHICLE

SELECTION

SYSTEM

INFO

SETUP

REPORT

PRINT

MAKER MODEL SENSORS READING

SENSORS

REPLACEMENT

TECHNICAL

INFORMATION

LEARNING

PROCEDURES

MANUAL: DIRECT

TPMS

MANUAL:

INDIRECT TPMS

SERIAL NUMBER

SW VERSION

LICENSE DATA

MAC ADDRESS

LANGUAGE

UNITS OF MEASURE

GARAGE DATA

POWER SAFE

RESERVED

LAST

SELECTIONS

TEST RADIO

CONTROLS

CLONE

SAVED

VEHICLE

UP&GO

CLONE ALL

VEHICLE

SENSORS

B-TP 1000

9 ENGLISH

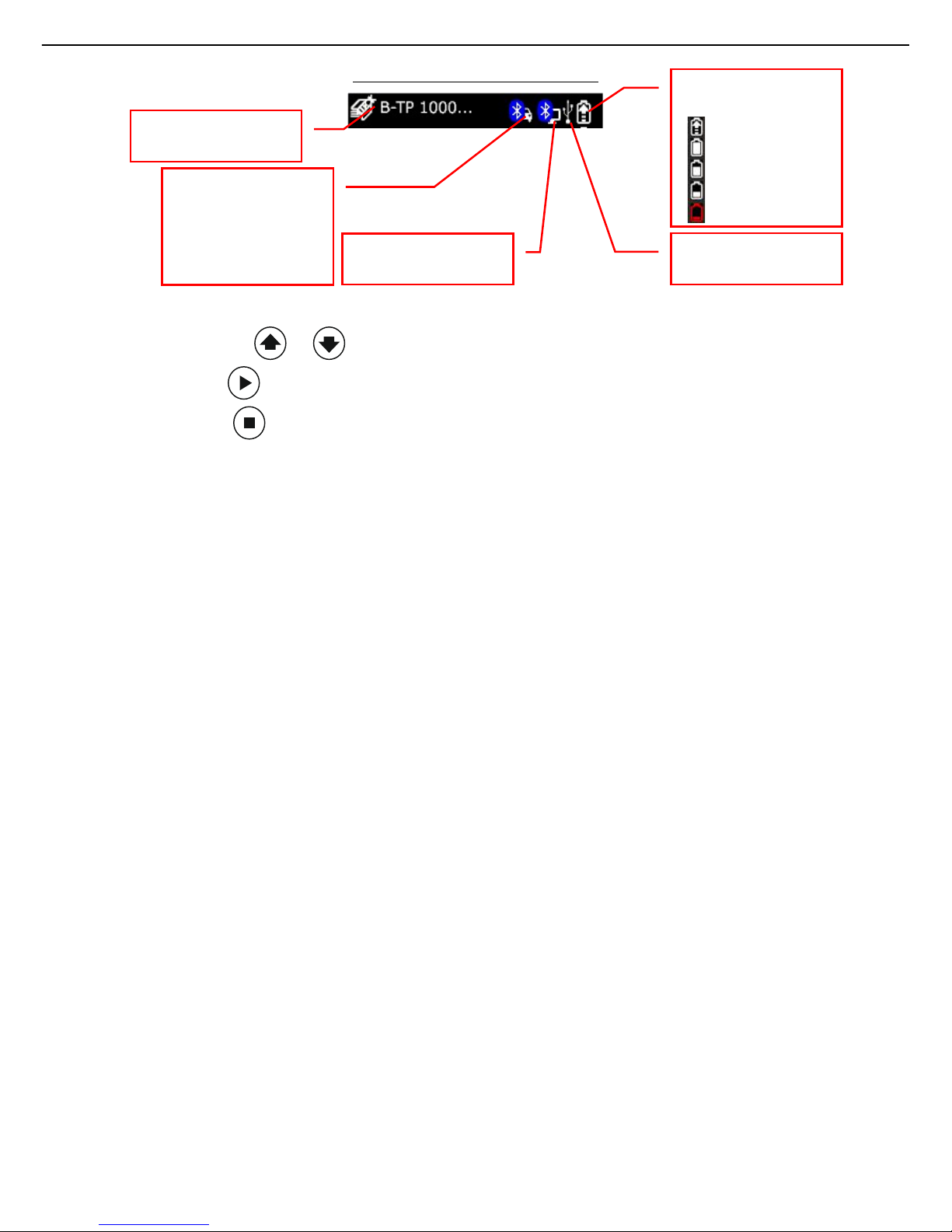

MAIN MENU AND STATUS BAR

When switched on, the equipment shows the main menu:

Press the arrow keys or for menu selection.

Press the OK key to confirm your selection or access the menu.

Press the ESC key to exit the menu.

The top status bar shows the selected menu during navigation or the selected vehicle during sensors

reading or programming. The icons top right show the status of the equipment battery and the

connection to the different devices via bluetooth or USB.

VEHICLE SELECTION is used to select maker, model and production year of the vehicle and

the function to be run:

o Sensors reading is used to read the pressure and temperature values measured

by the sensor inside the tyre

o Sensor replacement is used to program the type and ID number of the sensor

o Clone all vehicle sensors is used to program all the set of sensors in a sequence

after the reading phase on the vehicle

o Technical information shows information as to the technical characteristics of the

sensor and tightening torque for assembly, as well as the codes of the original or

universal spare part

o Learning procedures show instructions as to the learning procedure of the

sensor, which may be of manual type, or may require the use of the diagnostic

tool.

LAST SELECTIONS show the last vehicles selected, which can be easily re-selected

SYSTEM INFO includes serial number, software and hardware version, Bluetooth MAC

address and firmware version of the equipment

SETUP is used to set:

o language of the equipment

o the units of measure for measured pressure (Psi or bar) and measured

temperature (°C or °F)

o garage data for report printing

o auto-off timer

o reserved menu (requires password)

REPORT PRINT manages the report printing with the set garage data

TEST RADIO CONTROLS manages the radio controls test

CLONE SAVED VEHICLE it is used to write all the set of sensors starting from the data

stored into the tool in a previous session

Indicates the battery

status:

charging

100% charged

75% charged

50% charged

running out

Indicates USB

connection to the PC

Indica

tes

bluetooth

connection to the

PC

Indica

tes

bluetooth

connection to the

EOBD port of the

vehicle by means of

B

-

TP EOBD (optional)

Indi

ca

tes menu or

vehicle selected

B-TP 1000

ENGLISH 10

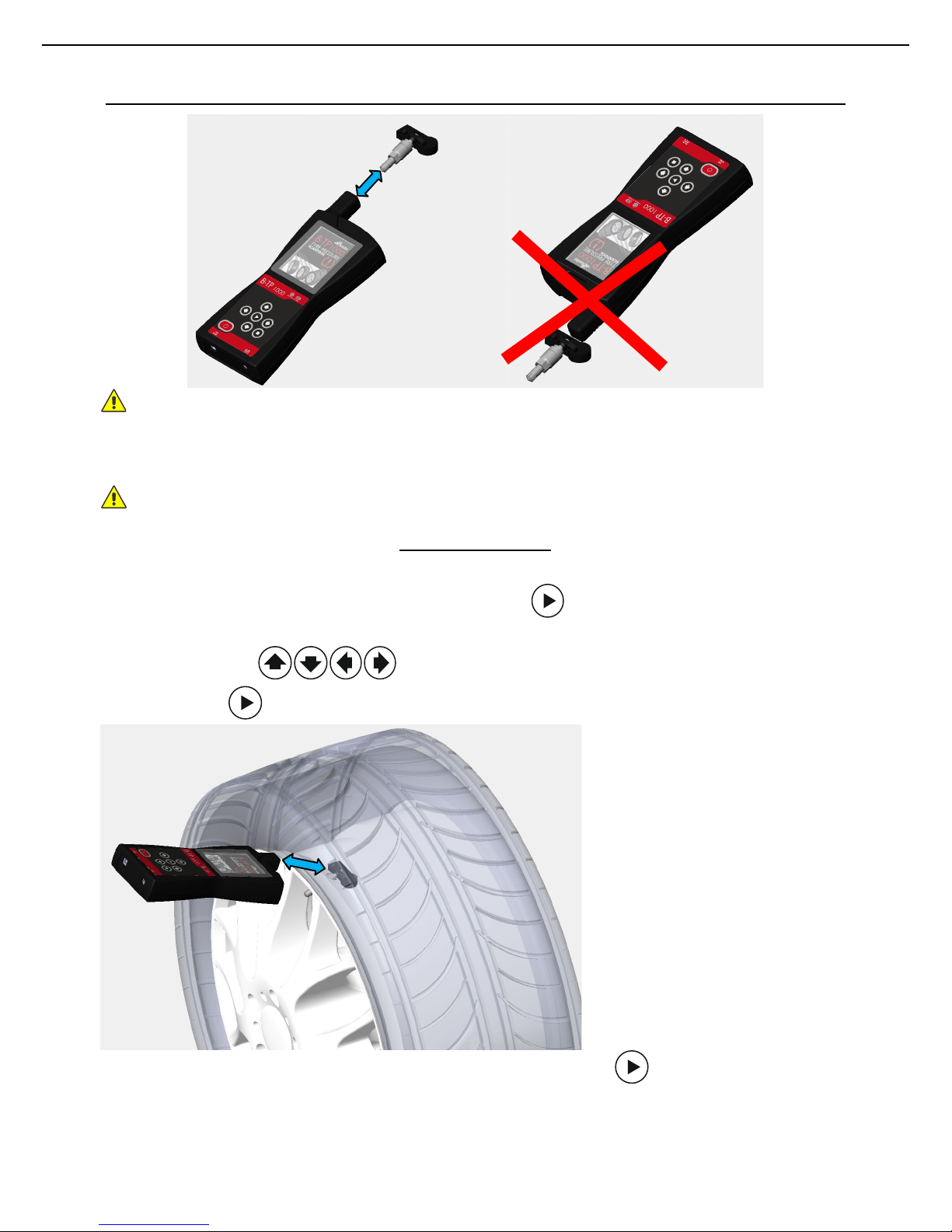

CORRECT POSITIONING OF THE EQUIPMENT ON THE TYRE FOR READING PURPOSES

The correct positioning of the equipment on the sensor ensures the radio communication for the

activation and decoding of the sensor itself. Position the equipment on the tyre, at the same height as

the TPMS sensor, directing the aerial towards the sensor, as shown above. DO NOT touch the metal

rim, which may act as a shield for radio waves, but rather direct the equipment through the tyre.

B-TP 1000

11 ENGLISH

CORRECT POSITIONING OF THE EQUIPMENT ON THE SENSOR FOR PROGRAMMING PURPOSES

Warning! We recommend programming the sensors before installing them onto the tyre.

Position the equipment in line with the valve, in contact with it or at a distance not greater than 5 cm.

Warning! Do not position the equipment on the backside of the valve next to the sensor body.

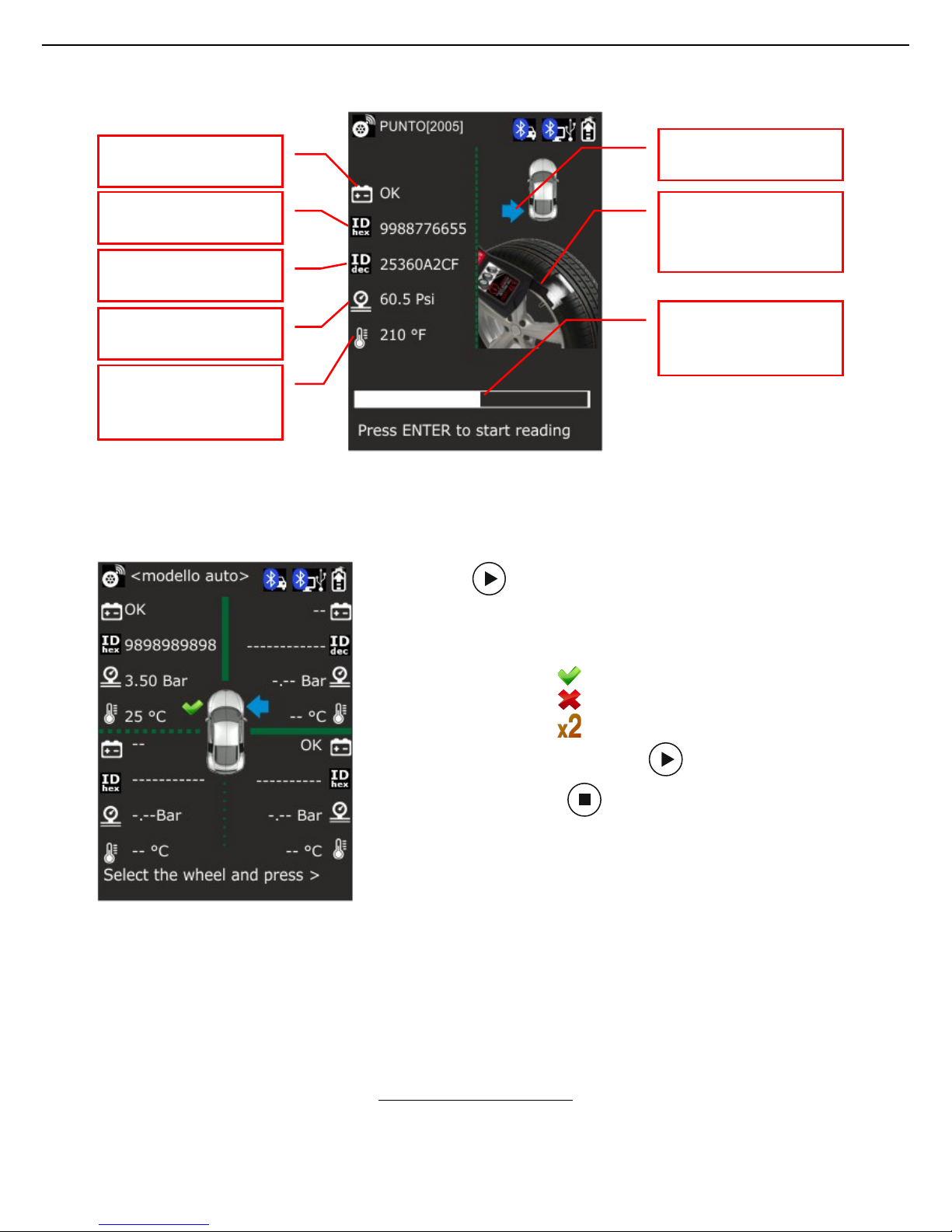

SENSORS READING

To wake up and read the parameters of the TPMS sensors, you need to select the vehicle (maker and

model), select “SENSORS READING” and confirm using the to access it: the tyre selection menu

will be shown.

Using the arrow keys , select the chosen tyre: the arrow and specific dial will turn

on. Press the key to confirm the sensor reading position.

Position the equipment close to the selected sensor and press the key to start the reading

procedure. The following items will be shown:

Sensor battery status

Identification number of the sensor in hexadecimal code (hex ID) and in decimal code (dec

ID)

B-TP 1000

ENGLISH 12

The pressure measured by the sensor in Psi or bar according to the equipment settings

The temperature measured by the sensor in °C or °F according to the equipment settings

Press the key to return to the tyre selection menu:

back from the reading page, the next dial (clockwise) is selected.

In the dial corresponding to the read sensor, the icon with the

reading result is shown near the tyre

a. sensor detected

b. sensor not detected

c. IDs duplicated

In case of non-detected sensor, press to run the reading

procedure again, or press to exit the tyre selection menu:

make sure you have positioned the equipment aerial

close to the sensor valve of the selected tyre.

Make sure you have selected the right vehicle

If the sensor is still not being detected, it may be faulty

or not properly set.

In case of duplicated IDs:

make sure you have read the sensor indicated by the blue arrow on the related dial

make sure there are no sensors programmed with the same ID number

IMPORTANT: there can't be duplicated sensors on the vehicle, otherwise the ECU cannot distinguish

the origin of the measured values. In case of duplicated sensors, one of these will have to be

reprogrammed with a different ID code.

SENSORS REPLACEMENT

If you need to replace a TPMS sensor with a universal sensor, you need to program it with an ID code

so that it can be acknowledged by the car ECU.

Warning! We recommend programming the sensors before installing them onto the tyre.

Indica

tes the status of

the

sensor

batter

y

Indica

tes the sensor

ID

number (decimal)

Indica

tes the tyre

press

ure

Indica

tes the tyre inner

temperature

Indica

tes the sensor ID

number (hexadecimal)

Indica

tes the position of

the selected senso

r

Indica

tes the aiming of

the aerial at the sensor

Indica

tes the reading

progress bar

B-TP 1000

13 ENGLISH

To access the programming page:

select the vehicle (maker and model)

select the “SENSORS REPLACEMENT” menu and confirm with the key

select the sensor manufacturer and confirm with the key

select the type of programming to be run and confirm with the key on:

o copy sensor ID: allows copying the ID code of the faulty sensor to be replaced (if

it can be read using B-TP 1000) and programming it into a universal sensor

o create sensor ID: allows creating a random ID code to program a universal sensor

o enter sensor ID: allows entering an ID code using the keypad to program a

universal sensor

IMPORTANT: the ID code of the faulty sensor can be read on the TPMS valve stem or in the

parameters of the vehicle diagnostic system.

COPY SENSOR ID

Position the equipment close to the faulty sensor whose ID code is to be copied and press the key

to read it. The following items will be shown:

Sensor battery status

Identification number of the sensor in hexadecimal code (hex) and in decimal code (dec)

The pressure measured by the sensor in Psi or bar according to the equipment settings

The temperature measured by the sensor in °C or °F according to the equipment settings

B-TP 1000

ENGLISH 14

Position the equipment close to the universal sensor to be programmed with the ID code previously

copied and press the key .

CREATE SENSOR ID

Position the equipment close to the sensor and press the key to program it with a random ID

code generated by the equipment according to the sensor manufacturer previously selected.

B-TP 1000

15 ENGLISH

ENTER SENSOR ID

Enter the ID code selecting the numbers and letters from the keypad on the screen using the arrow

keys and confirming with the key .

Position the equipment close to the sensor and press the key to program it with the ID code

previously set.

CLONE ALL VEHICLE SENSORS

In case of replacement of all the sensors of a vehicle, it is possible to operate using the cloning

procedure of all TPMS sensors.

As first step, select the model of universal sensors to use for that vehicle;

then proceed with the reading of all the vehicle sensors.

The tool shows that the reading phase is ended when four different sensors have been read; at this

point the programming phase of the universal sensors, sorted previously, begins, one sensor at time.

The indications on the display, both in reading and programming phase, allow the operator to execute

a corret flow of operations.

With this function it is not possible to set different ID codes from the ones read from the vehicle.

CLONE SAVED VEHICLE

In case of replacement of all the sensors of a vehicle, it is possible to operate using the cloning

procedure of all TPMS sensors, starting from data saved on the tool in a previous session.

As first step, select the saved vehicle with the sensors to clone; after that it is requested to select the

model of universal sensors to use.

At this point the programming phase of the universal sensors, sorted previously, begins, one sensor at

time.

The indications on the display, both in reading and programming phase, allow the operator to execute

a corret flow of operations.

With this function it is not possible to set different ID codes from the ones read from the vehicle.

B-TP 1000

ENGLISH 16

TECHNICAL INFORMATION

Once the vehicle has been selected, you can select the

“TECHNICAL INFOS" menu and confirm with the key :

the display will show maker, model and codes of the spare parts

available for the original sensor, tightening torques of the valve

and sensor fixing nut or screw, codes of the tools required for

sensor assembly / disassembly.

SENSORS LEARNING PROCEDURES

This procedure must be used when a sensor ID has been changed or if the position of a sensor on the

vehicle has been changed.

If you need to have the vehicle ECU relearn the ID number of the sensors, you can check in the

equipment database, whether to do it with a manual learning procedure or with an EOBD procedure:

In case of manual procedure, all the steps to be carried out will be shown on the screen: for

some vehicles, you just need to press a button and drive for a certain amount of time;

whereas for other vehicles, you will have to activate the learning procedure and wake-up the

valves using B-TP 1000

In case of EOBD procedure, you will have to connect the optional accessory, B-TP EOBD, or a

device of the Touch line, to the vehicle EOBD socket: B-TP 1000 will read in sequence all the

IDs of the TPMS sensors fitted on the vehicle and will transmit them via Bluetooth to the

accessory connected to the EOBD socket, which will then inform the vehicle ECU about the

new ID numbers or the new position of the TPMS sensors fitted into the tyres.

ACTIVATION, UPDATE AND LICENSE RENEWAL OF B-TP 1000

The upgrade and license renewal of the B-TP 1000 takes place during the connection of the scantool

to the PC, switching it into "ITALSENSOR TOOL MANAGER" mode and connecting it via the USB cable.

Installation of ITALSENSOR TOOL MANAGER

First of all it is necessary to install the program, which will be updated automatically as soon as a new

version is available; for the installation follow the following steps:

1) Turn on the B-TP 1000 instrument

2) Select "SETTINGS" and then select "INSTALL ITALSENSOR TOOL MANAGER ON PC";

Then press

3) Press at the next question and connect the instrument via USB cable to the PC

B-TP 1000

17 ENGLISH

3) Search in Computer resources on PC and open the new disk that has been created

(ITALSENSOR ...)

4) Within the disk, run setup.exe to install ITALMATIC TOOL MANAGER on the PC

5) At the end of the operation, switch off the B-TP 1000 and disconnect it from the PC

6) At the end of the installation, an icon is created on the PC desktop, for the following uses of

the program; an automatic update of the program is also launched, if a more recent version

is available.

WARNING: to download updates and allow the program to renew the instrument license, the PC must

be connected to the Internet.

First activation, updating and renewal of the B-TP 1000 license

The process of activation, updating and renewal of licenses is unique and automatic; it is performed as

follows:

1) Turn the B-TP 1000 on

2) Execute ITALMATIC TOOL MANAGER on PC

3) Connect the instrument to the PC and confirm the desire to connect to ITALSENSOR TOOL

MANAGER. If this option does not appear, select "ITALSENSOR TOOL MANAGER" from the

main menu and press

4) On the PC will appear the request to format a disk: ALWAYS deny this request

5) In the PC program, press the upper right button, in the "Italmatic Tool update" area and wait

for the end of the operations.

LOW LEVEL PROGRAMMING MODE

By pressing the key and the key, the equipment is started in programming mode

Table of contents