Brain Bee 9000 Bus Plus Operating instructions

9000 BUS PLUS

Mod. 9000 BUS PLUS

Service station for air conditioning systems of vehicles

with refrigerant gas R-134a.

User and maintenance manual

Ver. 1.0

ENGLISH 2 / 73 CAP. 1 - CONTENTS

9000 BUS

Page intentionally left blank

CAP. 1 - CONTENTS 3 / 73 ENGLISH

9000 BUS

PLUS

CAP. 1 - CONTENTS

CAP. 1 - CONTENTS ..........................................................................................................3

CAP. 2 - GENERAL INSTRUCTIONS......................................................................................5

2.1 GENERAL

NOTES...........................................................................................................5

2.2 GENERAL

INSTRUCTIONS ..............................................................................................5

2.3 MANUFACTURER

IDENTIFICATION ................................................................................5

2.4 WARRANTY....................................................................................................................6

2.5 TECHNICAL

SERVICE CENTERS.......................................................................................7

2.5.1 Repairs ..........................................................................................................7

2.6 MARKING......................................................................................................................7

CAP. 3 - SAFETY CONDITIONS ...........................................................................................8

3.1 PERSONAL

SAFETY INFORMATION.................................................................................8

3.1.1 Definitions .....................................................................................................8

3.1.2 Personal safety information .............................................................................8

3.2 IMPORTANT

SERVICE EQUIPMENT SAFETY INFORMATION............................................13

3.3 SAFETY

DEVICES ..........................................................................................................13

CAP. 4 - LAYOUT AND USE OF THE MANUAL ....................................................................14

4.1 USE

OF THE MANUAL ..................................................................................................14

4.2 SYMBOLS....................................................................................................................14

4.2.1 Safety..........................................................................................................14

4.3 GLOSSARY..................................................................................................................15

4.4 GUIDELINES

FOR HANDLING REFRIGERANT.................................................................16

4.4.1 Precautions for refrigerant storage.................................................................16

4.4.2 Refrigerant conditions...................................................................................16

4.4.3 Recycling capacity........................................................................................16

CAP. 5 - GENERAL DESCRIPTION ......................................................................................17

5.1 FRONT

VIEW (EXTERIOR) ..............................................................................................18

5.2 FRONT

VIEW (INTERIOR) ..............................................................................................19

5.3 REAR

VIEW (EXTERIOR)..................................................................................................20

5.4 REAR

VIEW (INTERIOR)..................................................................................................21

5.5 RIGHT

SIDE VIEW .........................................................................................................22

5.6 LEFT

SIDE VIEW ............................................................................................................23

5.7 FRONT

SIDE VIEW........................................................................................................24

5.8 TOUCHSCREEN...........................................................................................................25

5.9 STATUS

BAR.................................................................................................................26

5.10 FUNCTION

KEYS ....................................................................................................28

5.11 ECO

LOCK® QUICK COUPLERS .............................................................................30

5.12 INCLUDED

ACCESSORIES .......................................................................................30

5.13 OPTIONAL

ACCESSORIES .......................................................................................30

5.13.1 AGRI&WORK FUNCTION (OPTION ).............................................................31

CAP. 6 - TECHNICAL FEATURES ........................................................................................32

CAP. 7 - INSTALLATION....................................................................................................34

7.1 EQUIPMENT

INSTALLATION.........................................................................................34

7.1.1 Unpacking 9000 BUS PLUS ...........................................................................34

CAP. 8 - COMMISSIONING ..............................................................................................36

8.1 CONNECTIONS..........................................................................................................36

8.2 P

OSITIONING AND CONNECTION ......................................................................................36

8.3 FIRST

TANK FILLING .....................................................................................................37

8.4 NEW

OIL BOTTLE FILLING............................................................................................38

8.5 TRACER

BOTTLE FILLING ..............................................................................................38

CAP. 9 - SETUP ................................................................................................................39

CAP. 10 - A/C SYSTEM RECHARGE....................................................................................42

ENGLISH 4 / 73 CAP. 1 - CONTENTS

9000 BUS

10.1 REMARKS................................................................................................................42

10.2 NON-CONDENSABLE

GAS DISCHARGE..................................................................43

10.3 QUICK

MODE AND ZERO TOLERANCE RECHARGE MODE.......................................44

CAP. 11 - AUTOMATIC CYCLES ........................................................................................45

11.1 AUTOMATIC

A/C SYSTEM SERVICE ..........................................................................45

11.2 AUTOMATIC

CYCLE (BUSES) ...................................................................................45

11.2.1 Last cycle.....................................................................................................45

11.2.2 User-defined cycles.......................................................................................45

11.3 AUTOMATIC

CYCLE (OTHER VEHICLES)...................................................................45

11.4 V

EHICLE SELECTION FROM DATABASE (FOR OTHER VEHICLES ONLY)......................................45

11.5 L

AST CYCLE...............................................................................................................45

11.6 U

SER-DEFINED CYCLES ................................................................................................46

11.6.1 Automatic cycle parameters configuration ......................................................46

11.6.2 OIL TYPE REPLACEMENT...............................................................................47

CAP. 12 - MANUAL CYCLES..............................................................................................48

12.1 PRELIMINARY

OPERATIONS.....................................................................................48

12.2 RECOVERY..............................................................................................................48

12.3 VACUUM

PHASE .....................................................................................................48

12.4 INJECTION.............................................................................................................49

12.5 FLUSHING

(WITH OPTIONAL ACCESSORIES)....................................................................50

12.6 PRESSURE

CHECK (EXCLUDING BUSES) ...................................................................50

12.7 EMPTYING

HOSES ..................................................................................................51

12.8 NITROGEN

LEAK TEST.............................................................................................51

CAP. 13 - MAINTENANCE.................................................................................................52

13.1 SELF

LEAK TEST .......................................................................................................53

13.2 PRESSURE

ZERO......................................................................................................53

13.3 LONG

LIFE PUMP SPECIAL FUNCTION -VACUUM PUMP OIL CHANGE.....................53

13.4 FILTERS

REPLACEMENT............................................................................................55

13.4.1 DRYER FILTER CHANGE ................................................................................55

13.4.2 MESSAGE FOR FILTERS ALMOST EXHAUSTED ................................................56

13.5 COUNTERS............................................................................................................56

13.6 VESSELFILLING (A/C SERVICE STATION TANK).........................................................57

13.7 NON-CONDENSABLE

GAS DISCHARGE..................................................................58

13.8 MULTIPASS.............................................................................................................58

13.9 SYSTEM

INFORMATION ..........................................................................................58

13.10 MAINTENANCE

OF PRINTER....................................................................................58

13.11 PERIODIC

CHECKS .................................................................................................59

CAP. 14 - DISPOSAL.........................................................................................................62

14.1 A/C

SERVICE UNIT DISPOSAL ..................................................................................62

14.2 RECYCLED

MATERIALS DISPOSAL ............................................................................62

14.3 PACKAGING

DISPOSAL...........................................................................................62

CAP. 15 - SPARE PARTS.....................................................................................................63

CAP. 16 - MESSAGE AND ALARM CODES ..........................................................................64

CAP. 17 - MAINTENANCE FORMS .....................................................................................70

ENGLISH 5 / 73 CAP. 2 - GENERAL INSTRUCTIONS

9000 BUS

PLUS

CAP. 2 - GENERAL INSTRUCTIONS

2.1 GENERAL NOTES

All rights reserved.

This manual may not be reproduced, in part or entirely, either in printed or digital form.

It may be printed out solely for use by the user and operators of the equipment to which it refers.

BRAIN BEE SPA and its staff (authors of the manual) are not liable for any consequences of

improper use of the manual or equipment, and guarantees that the information given in the

manual has been thoroughly verified.

The product can be subject to changes and improvements. Brain Bee reserves the right to change

without notice the information contained in the manual.

2.2 GENERAL INSTRUCTIONS

Pressure equipment undergoes checks before commissioning and periodical checks during

operation in compliance with rules and law provisions in force in the country where the tool is

used.

The operator is responsible for operating the equipment in conformity with local legislation.

The equipment is designed for recovering and recycling R134a refrigerant fluid from A/C systems

of buses, cars and similar vehicles.

The equipment is intended to be used by repair and service garages for buses, cars and similar

vehicles.

This equipment is intended solely for use by professionally trained operators familiar with the

basics of refrigeration, refrigeration systems, refrigerants and the hazards associated with

pressurised equipment.

Acareful reading of the present manual by the owners, the users and the operators is required

for a correct and safe use of the tool.

The user shall not be entitled to open the product since maintenance operations are reserved to

the authorised service center.

2.3 MANUFACTURER IDENTIFICATION

The 9000 BUS PLUS equipment is manufactured by:

Brain Bee S.p.A.

Via Quasimodo, 4/a

43126 Parma (Italy)

Tel. +39 0521 954411 – Fax +39 0521 954490

e-mail cont[email protected]

internet http://www.brainbee.com

CAP. 2 - GENERAL INSTRUCTIONS 6 / 73 ENGLISH

9000 BUS PLUS

2.4 WARRANTY

DEFINITION

The warranty provides for free replacement or repair of faulty components due to fabrication.

APPLICATION

The following warranty conditions are inclusive and substitute and legal guarantees in relation to

failures of conformity, and exclude any other liability of the manufacturer and reseller in relation

to the product. The purchaser may not make any claim other than those envisaged in these

warranty conditions, for damages, reduced price or cancellation of the contract. Once the

warranty has expired, no claims may be made against the reseller or manufacturer.

WARRANTY PERIOD

-12 (twelve) months from the date of online activation by the reseller.

- 6 (six) months for replacement parts

EXCLUSIONS

This warranty is provided on condition of full payment of the purchase price and the purchaser

may not make claim under it if he has suspended payments for any reason whatever. The

warranty does not cover parts found to be defective for reasons of:

1. negligent use (failure to follow the operating instructions):

2. incorrect installation or maintenance;

3. maintenance by unauthorised persons;

4. shipping damage;

5. or any circumstances not resulting from fabrication defects.

The warranty does not cover any work done to install and connect the equipment to its power

supplies and feeds.

The following are excluded from the warranty / advance replacement:

-consumables (including: batteries, paper, filters, oil);

-normal wear and tear.

The warranty is void in all cases of improper use and failure to run the scheduled maintenance

detailed in the manual. Brain Bee S.p.A. accepts no responsibility for any damage deriving from

the non respect of the prescriptions indicated in the instructions and in particular those

concerning the tool installation, use and maintenance.

ENGLISH 7 / 73 CAP. 2 - GENERAL INSTRUCTIONS

9000 BUS

PLUS

2.5 TECHNICAL SERVICE CENTERS

Alist of authorised Brain Bee service centres for CLIMA stations is available on the website

www.brainbee.it

2.5.1 Repairs

In case of failures or anomalies, the user can contact directly or through his own regional

reseller a Brain Bee S.p.A authorised service centre to get help.

2.6 MARKING

9000 BUS PLUS is fabricated in conformity with the Community Directives detailed in the

Declaration of Conformity provided with the pressurised equipment.

The equipment falls in the PED risk category II (97/23/EC).

The characteristic data of the equipment are indicated on the specific data plate applied onto the

equipment side part.

It is prohibited to remove damage or tamper with the equipment “data plate”.

NAMEPLATE

CE MARKING: The present CE declaration is enclosed to the tool. Store correctly and provide on

request.

Fac-Simile

CAP. 3 - SAFETY CONDITIONS 8 / 73 ENGLISH

9000 BUS PLUS

CAP. 3 - SAFETY CONDITIONS

3.1 PERSONAL SAFETY INFORMATION

3.1.1 Definitions

DANGEROUS AREAS:

Any area within or close to the equipment implying risk for the safety and health of exposed

persons.

EXPOSED PERSON:

Any person completely or partially standing in a dangerous area.

OPERATOR:

The person/s charged with operating the machine for its intended purpose.

CLASSIFICATION OF OPERATORS

The operator can be classified according to two main categories, which, in some cases, refer to

one single person:

•The operator charged with the equipment operation has the duty to:

oStarting up and monitoring the machine's automatic cycle;

oCarry out simple setting operations;

oRemove the causes of equipment stop not implying breakings of members but

simple operation anomalies.

•Maintenance technician atechnician trained by an authorised Brain Bee S.p.A. service

centre, capable of working on the machine's mechanical and electrical components with

its guards open to make adjustments and to service and repair it.

USER

Body or person legally responsible for the equipment.

3.1.2 Personal safety information

Brain Bee 9000 BUS PLUS A/C service station is particularly simple and reliable due to its

adjustments and functions. When used correctly it presents no hazard for the operator, on

condition that he observes the following general safety instructions and that the service station is

regularly serviced (incorrect maintenance/use compromise the equipment's safety).

Before operating the service station for the first time, read these instructions carefully. If any part

of the instructions is unclear, contact your reseller or the Brain Bee head offices in Parma. This

service station may be used by only one equipment operator, familiar with A/C and refrigeration

systems and the hazards associated with refrigerants and high pressure equipment.

ENGLISH 9 / 73 CAP. 3 - SAFETY CONDITIONS

9000 BUS

PLUS

WORKPLACE: The equipment must be operated in the open or in a well-ventilated location (at

least 1 air change per hour). The workshop has to be equipped with ventilation systems able to

ensure the air change in every environment area or to carry out a periodical ventilation by

opening the environment areas. Use the tool away from heat sources or hot surfaces . The tool

has not to be used in explosion risk environments (potentially explosive atmospheres). Before

using it, put the tool on a levelled plane and secure position, blocking it with suitable wheel stops.

Do not expose the tool to direct sunrays, heat sources, rain and jets of water. Do not smoke close

to the equipment and during operations (keep at a distance of at least 1 m).

The work area must be monitored by the operator while the equipment is operating.

ATTENTION: the R134a refrigerant fumes/gases are heavier than air and can gather on the floor

or inside cavities/holes and cause choke by reducing the oxygen available for breathing.

At high temperatures, the refrigerant breaks down releasing toxic and aggressive substances,

harmful for the operator and the environment.) Avoid inhaling the system coolants and oils. The

exposure can irritate eyes and the respiratory tract.

ELECTRICAL CONNECTION: Connect the power cord solely to a mains supply which conforms

with the ratings on the machine's nameplate (mounted on its side). Make sure the mains socket is

grounded.

Never use the service station with a defective power cord or a different one from that supplied

with the machine; if damaged, immediately have it replaced with an original spare or equivalent

by a Brain Bee S.p.A. service centre. The service station is equipped with safety switches which

stops voltage supply in case of station components opening. Never rely on these protections only.

Before opening the service station, extract completely the supply cable from the plug, or you can

get an electric shock.

Do not tamper with or bypass the safety equipment and settings.

Do not leave the machine powered up when not in use; shut off the power supply before leaving

the equipment unused for a long time. Do not forget that the tool (pressure tool) must always be

protected.

CAP. 3 - SAFETY CONDITIONS 10 / 73 ENGLISH

9000 BUS PLUS

REFRIGERANTS AND LUBRICANTS - INDIVIDUAL SAFETY EQUIPMENT AND PRECAUTIONS: The

refrigerants and the pressure vessels have to be handled with care, otherwise there will be

possible health risks.

The operator must wear safety glasses, gloves and protective clothing suitable to the work. The

contact with the refrigerant can cause blindness (eyes) and other physical damages (freezing) to

the operator. Avoid the contact with skin; the low boiling temperature (about –26 °C for R134a)

may cause burns.

Further information about safety can be obtained from the safety sheets of lubricant and

refrigerant producers.

Do not inhale refrigerant or oil vapour. Keep away from the vent valves and ventilation coupling,

especially when non-condensable gas is being vented.

Never direct the quick couplings (taps) towards your face or other persons or animals.

OTHER PROHIBITIONS AND USE LIMITATIONS: Use only pure R134a refrigerant, and do not

use it on vehicles containing other types of refrigerants. The mixture with other types of refrigerant

produces serious damages to the conditioning and cooling systems. Mixed gases have to be

disposed of according to the current regulations. Do not use the 9000 BUS PLUS station with

compressed air systems.

Do not modify the calibration of safety devices. Do not remove the seals of the safety valves and

of the control systems. Do not use external tanks or other storage containers that are not

homologated or without safety valves.

Make sure the equipment's aeration and ventilation ports are not obstructed or covered while the

equipment is operating.

ENGLISH 11 / 73 CAP. 3 - SAFETY CONDITIONS

9000 BUS

PLUS

HOSE CONNECTIONS: Hoses may contain pressurised refrigerant. Before changing the service

couplers, check the respective pressures in the hoses (pressure gauge).

Before connection to a car A/C system, to an external tank/vessel, check that the quick couplers

are closed (unscrewed HP and LP valves).

Scrupulously follow the instructions on the equipment's display.

QUICK COUPLERS CLOSING/OPENING:

MAINTENANCE/GENERAL CLEANING: The tool has to be serviced at the intervals indicated by

the tool itself. These controls include also a leak self-test that the tool performs automatically.

The service station maintenance has to be performed according to the procedures described in

this manual and to the current safety regulations.

Use only Brain Bee original parts.

When the equipment requires the dryer filter and the vacuum pump oil change, you have to be

careful in the replacement.

A/C service station maintenance can be carried out exclusively by a trained operator or by a

service man of a Brain Bee certified seller. If the maintenance is not performed according to the

expected schedule, the tool will be blocked.

Do not use chemical agents for the service station cleaning as they could attack the material or

the surface.

Closing (detach from the vehicle):

counter-clockwise

Opening (connect to the vehicle):

clockwise

CAP. 3 - SAFETY CONDITIONS 12 / 73 ENGLISH

9000 BUS PLUS

STOP FOR LONG PERIOD: Store the equipment in a safe place, disconnected from the mains,

away from excessive temperatures, humidity and the risk of damaging impact.

Contact the Technical Service to run a safety shutdown of the equipment, and if scrapping the

unit, to drain and recycle the R134a gas as required by local legislation.

To resume operation, repeat the installation (there is no need to register the unit anew with

www.brainbee.com) and run the commissioning trials and regular operational checks as required

by local legislation.

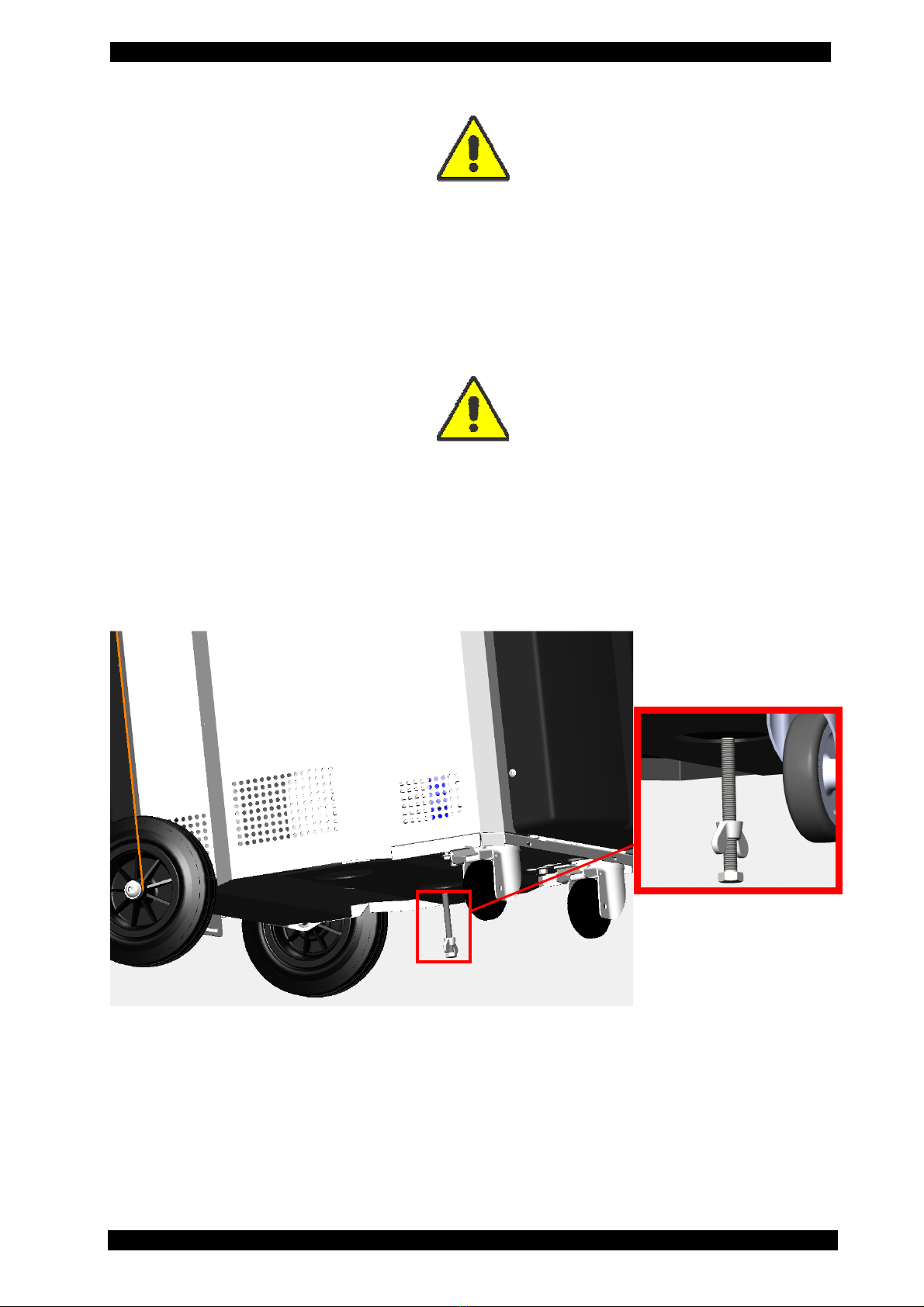

TRANSPORT: If the tool has to be transported, you have to screw the safety screw for the tool

scale fixation. The safety device for transport is on the back of the tool and it consists of a bolt

with wing-nut. Commissioning: Slacken the wing-nut, unscrew the screw for about 4 mm. and fix

it again with the wing-nut. Transport: slacken the wing-nut, screw the screw by hand and then fix

it again with the wing-nut. For the transport of the R134a refrigerant specific regulations are in

force in every country. Therefore, refer to your reseller or your authorised service centre for

information.

ENGLISH 13 / 73 CAP. 3 - SAFETY CONDITIONS

9000 BUS

PLUS

3.2 IMPORTANT SERVICE EQUIPMENT SAFETY INFORMATION

When using the tool, the following operations are not allowed as they might cause, under certain

circumstances, danger for persons and cause permanent damage to the tool itself.

-Do not remove or make unreadable labels, signs and/or dangers signs placed

on the tool and in the area nearby.

-Do not disable the unit's safety equipment.

-Use only fuses identical to the originals as specified on the nameplate; do not

tamper with or attempt to repair the fuses.

If the power supply is known or can be expected to vary beyond the limits

specified for the service equipment, immediately disconnect it.

-The electrical system to which the service equipment is connected must be

configured as provided by local legislation.

-Only operators or qualified staff instructed or certified for the tool maintenance

can open the tool. The equipment contains parts which can cause electrocution:

shut off power to the equipment before servicing/repairing it.

3.3 SAFETY DEVICES

9000 BUS PLUS is equipped with the following safety devices:

SAFETY PRESSURE SWITCH:It stops the compressor in case of excessive

pressure.

SAFETY VALVES: The safety valve opens when the pressure inside the system

reaches a level higher than the fixed limits.

SWITCHES: Switches the equipment off by interrupting the power supply. It is

advisable to pull the power cord plug out of the mains socket in any case

before starting maintenance work.

ANY TAMPERING WITH THE ABOVE-MENTIONED SAFETY DEVICES IS

PROHIBITED.

Failure to observe any of the above safety instructions voids the equipment's warranty.

CAP. 4 - LAYOUT AND USE OF THE MANUAL 14 / 73 ENGLISH

9000 BUS PLUS

CAP. 4 - LAYOUT AND USE OF THE MANUAL

4.1 USE OF THE MANUAL

This manual is an integral part of the equipment and must be kept in the

equipment's immediate vicinity by the purchaser

•If the equipment is sold on to a new user, this manual must accompany it.

•The content of this manual has been drawn up in compliance with the guide lines of the

UNI standard 10893:2000.

•Diffusion, modification or use of this manual for own aims is forbidden.

•The manual uses symbols which call the reader's attention to specific points to facilitate

its use.

•It includes all technical, operating, shutdown, maintenance, spare parts and safety

information.

•In case of doubts on the correct interpretation of the instructions, please contact our

technical service to obtain the required clarifications.

Operations which are potentially hazardous for the operator are highlighted

with this symbol.

Such operations can cause serious injury.

Operations requiring special attention are highlighted with this symbol.

Such operations shall be carried out correctly to avoid causing damage to

objects or to the surrounding environment. This symbol also highlights

information to which special attention must be paid.

Operations which require careful reading of the manual's instructions are

highlighted with this symbol.

4.2 SYMBOLS

This paragraph describes the safety symbols which may be posted on the service equipment's

housing.

4.2.1 Safety

ALTERNATING CURRENT

SAFETY GROUNDING

CONSULT THE INSTRUCTIONS MANUAL

CAUTION! ELECTROCUTION HAZARD

CAUTION !: DO NOT REMOVE THE COVER

(maintenance technicians only)

SEE THE USER MANUAL

USE PROTECTIVE GLOVES

WEAR PROTECTIVE GOGGLES

ENGLISH 15 / 73 CAP. 4 - LAYOUT AND USE OF THE MANUAL

9000 BUS

PLUS

4.3 GLOSSARY

To facilitate the comprehension of the manual, we list below the most important technical terms

used in it.

Refrigerant: Refrigerant fluid used in advanced motor vehicle A/C systems.

The following refrigerant fluids may be used:

oR-134a C2H2F4 - 1,1,1,2-Tetrafluoroethane

A/C system: Motor vehicle air conditioning system.

Equipment: 9000 BUS PLUS service station for recovery, recycling, vacuum, charge of A/C

system.

External tank: Refrigerant bottle used to fill the internal tank.

Internal tank: container for the refrigerant storage.

Phase: Performance of a single function.

Cycle: Sequence of steps.

Recovery: Extraction of refrigerant from the vehicle.

Recycling:Cleaning of the refrigerant, includes: separating out oils, removal of non-condensable

gas and single/multiple pass through filters to reduce the humidity, acidity and particulate

content of the fluid.

Disposal:disposal of refrigerant for storage followed by destruction/scrapping by an authorised

waste management centre.

Vacuum cycle: Draining out of a motor vehicle A/C system and separation out of condensed

matter and humidity, using only the vacuum pump.

Oil injection: Injection of oil into an A/C system to ensure the correct charge as specified by the

vehicle's manufacturer.

Charge: filling of refrigerant into the A/C system in the amount specified by the manufacturer.

System flushing: Cleaning phase for the removal of possible polluting substances from the A/C

system or parts of it.

Non condensable gases: Gas stored in the gaseous phase, including air and nitrogen.

CAP. 4 - LAYOUT AND USE OF THE MANUAL 16 / 73 ENGLISH

9000 BUS PLUS

4.4 GUIDELINES FOR HANDLING REFRIGERANT

4.4.1 Precautions for refrigerant storage

The refrigerant removed from the A/C system must be handled with care to prevent or minimise

the risk of mixing with other refrigerants.

The external canisters used to store the refrigerants must be clearly marked to prevent mixing

different refrigerants.

The canisters must be free of oil and other contaminants.

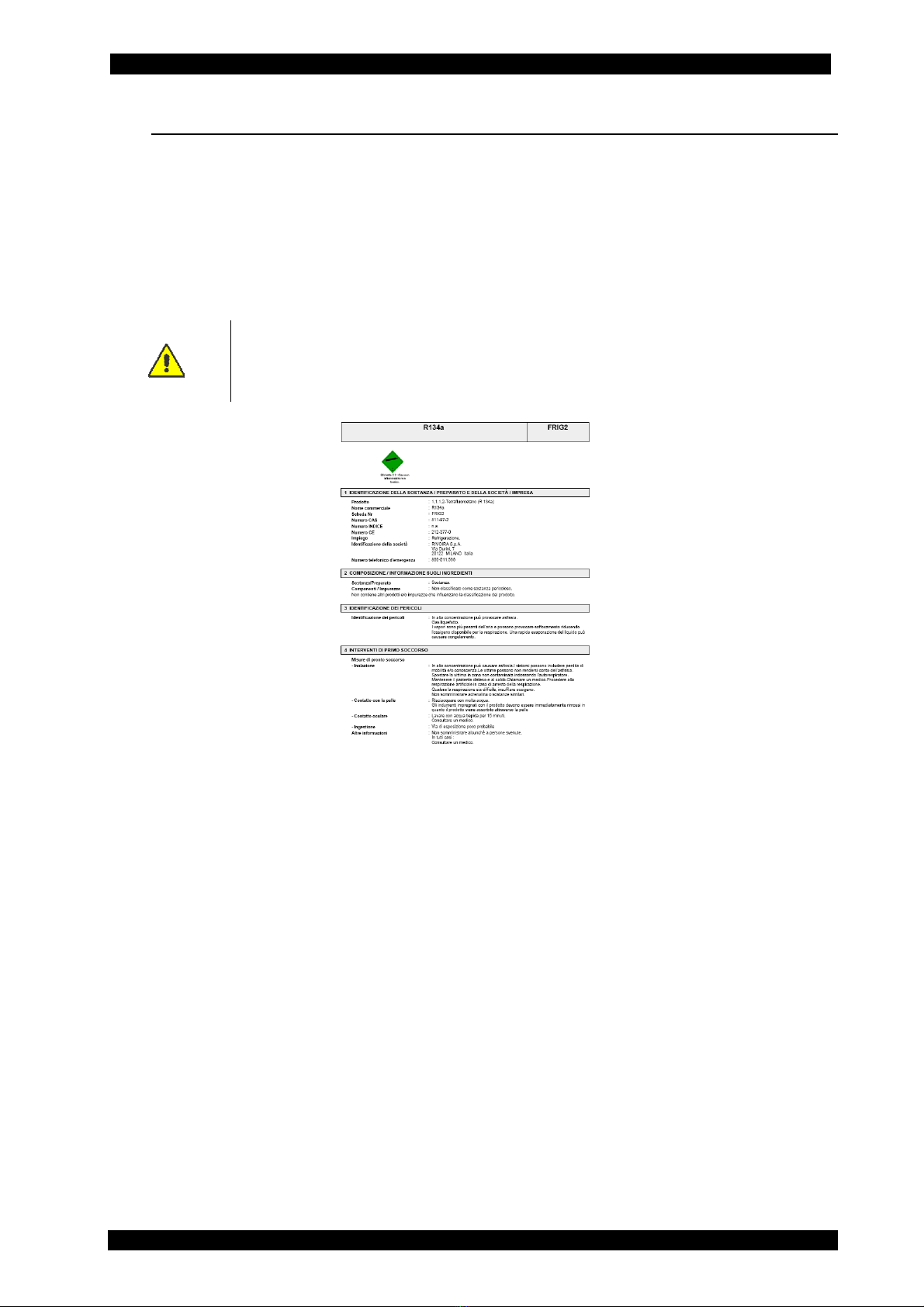

ATTENTION: when handling, using and storing R-134a gas and dealing with

emergency situations, MAKE SURE to refer to the product's safety sheet.

OBTAIN THE SAFETY SHEET FROM YOUR REFRIGERANT SUPPLIER AND

FOLLOW ITS INSTRUCTIONS

4.4.2 Refrigerant conditions

The condition of the refrigerant is critical to the operation of the vehicle's A/C system. Running

repairs properly following failure of damage safeguards the quality of the refrigerant itself

(particulates, acids and water).

4.4.3 Recycling capacity

The service equipment's filtering systems must be replaced regularly (see maintenance messages)

to ensure effective recycling.

Fac-Simile

ENGLISH 17 / 73 CAP. 5 - GENERAL DESCRIPTION

9000 BUS

PLUS

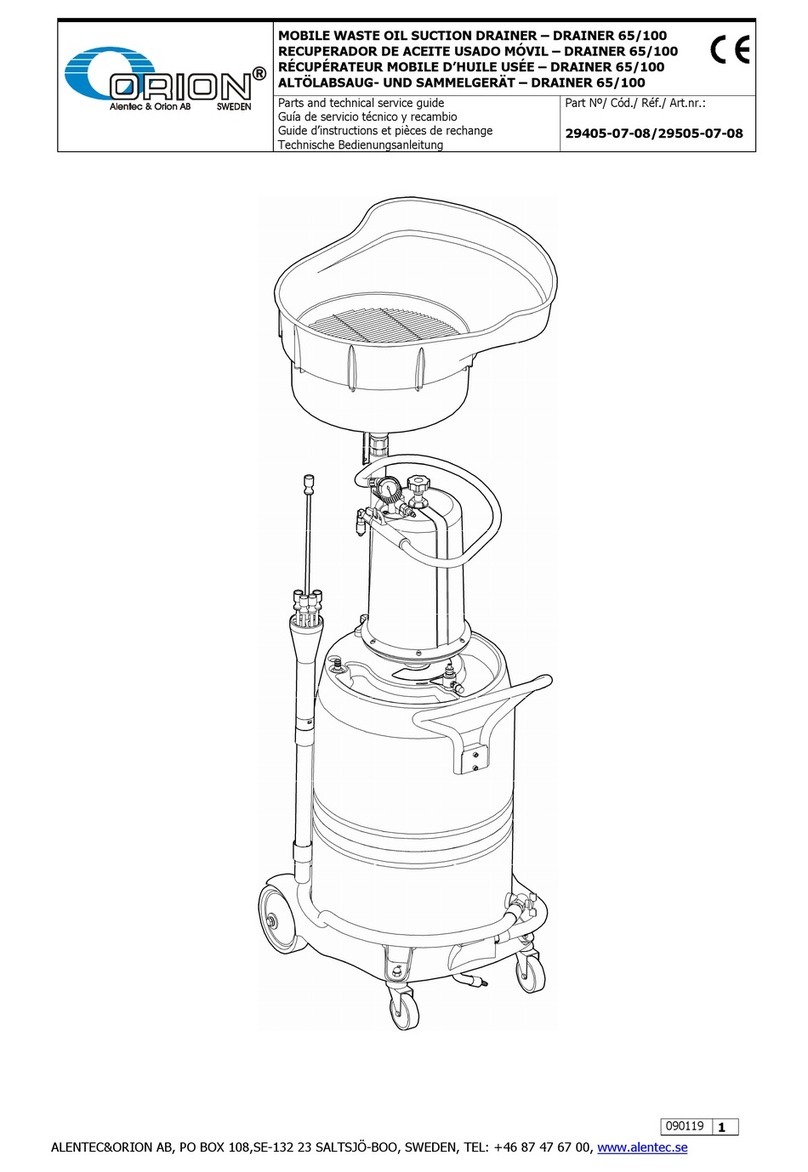

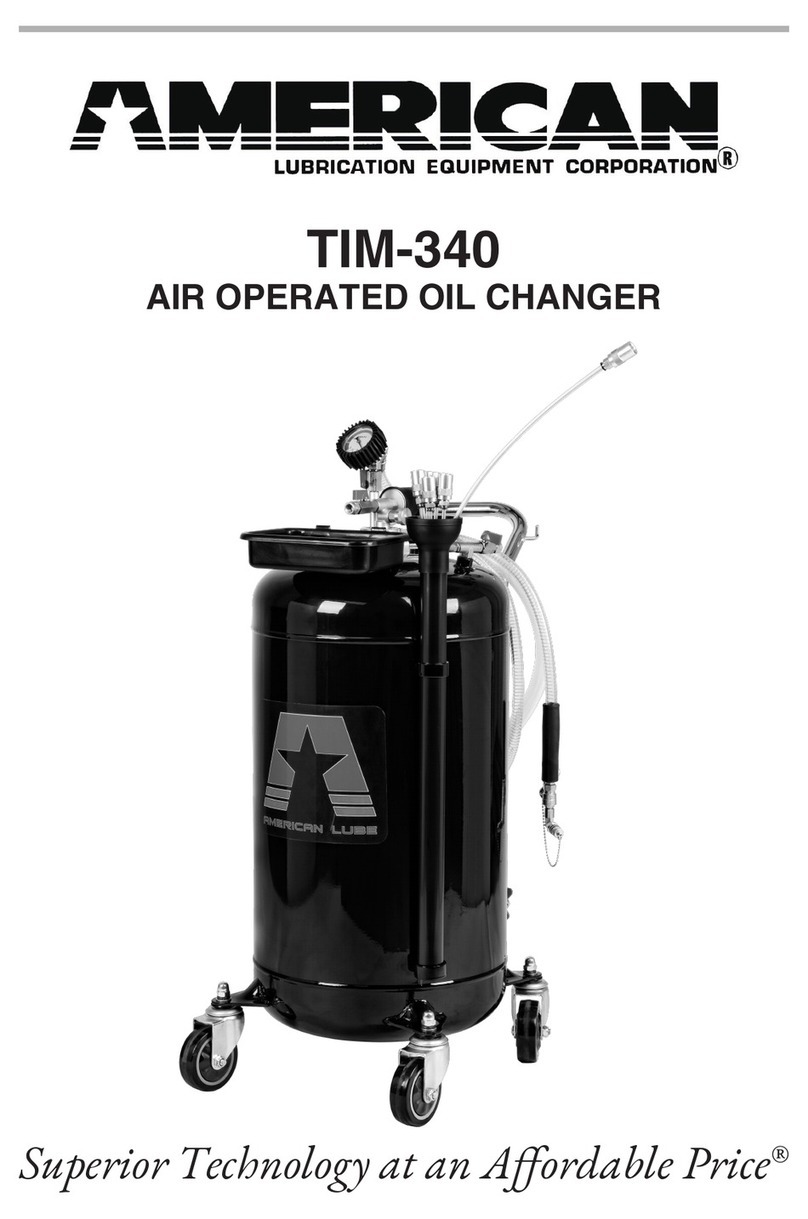

CAP. 5 - GENERAL DESCRIPTION

The advanced technology and innovative concept employed in designing and fabricating the

9000BUS PLUS makes it extremely simple and reliable in operation.

With its vessel holding up to 32 kg of refrigerant, 9000BUS PLUS has been specifically designed

for the maintenance and service of vehicle A/C systems containing large amounts of refrigerant,

particularly buses.

However, it can also be used to recharge vehicles with smaller amounts, such as cars.

CAP. 5 - GENERAL DESCRIPTION 18 / 73 ENGLISH

9000 BUS PLUS

5.1 FRONT VIEW (EXTERIOR)

1. New PAG oil container 1000 cc

2. Exhausted oil container 1000 cc

3. UV contrast fluid container 250 cc

4. Handles

ONLY MAINTENANCE TECHNICIANS MAY REMOVE THE FRONT AND REAR

DOORS OR THE TOP COVER

4

1

3

2

ENGLISH 19 / 73 CAP. 5 - GENERAL DESCRIPTION

9000 BUS

PLUS

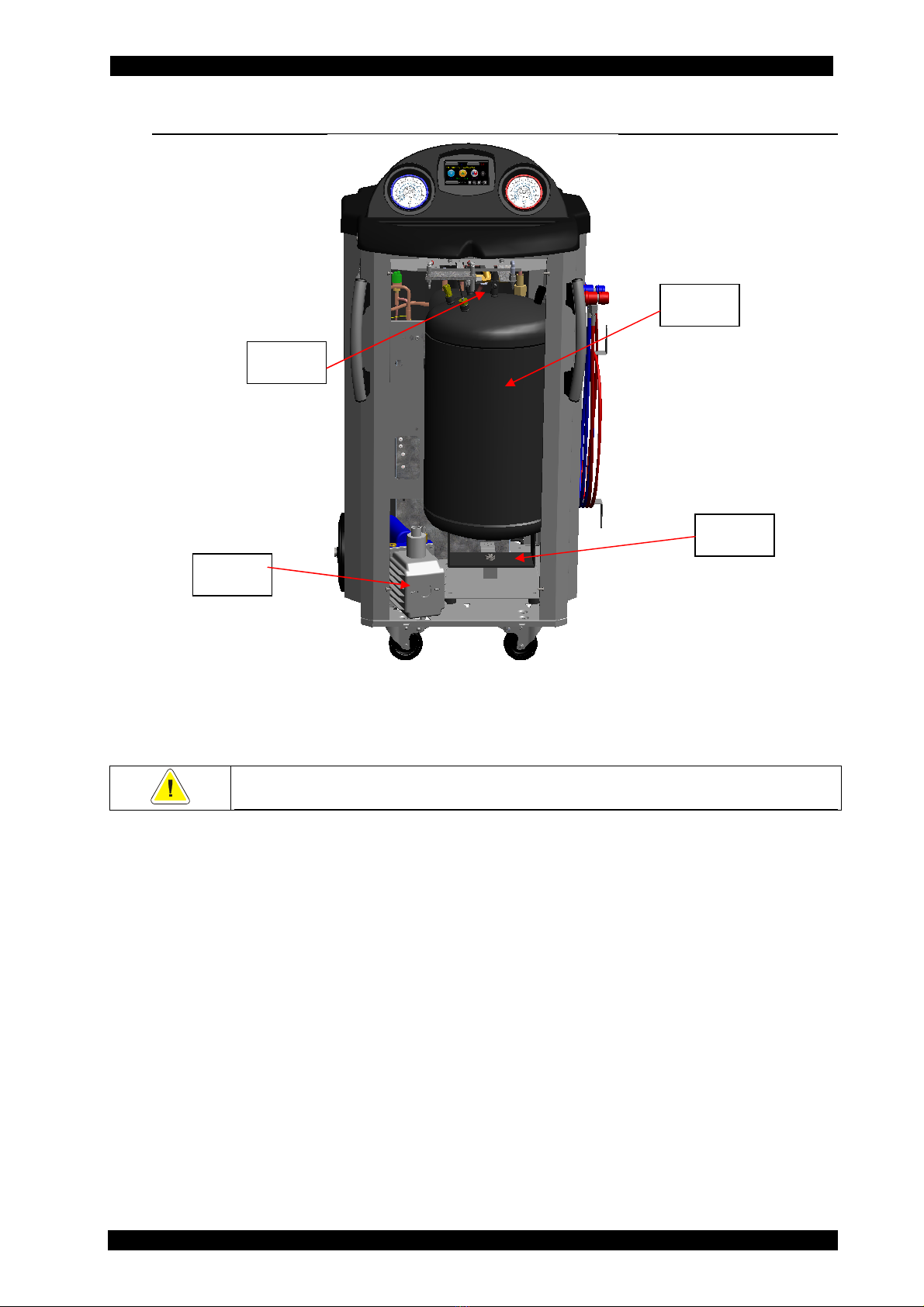

5.2 FRONT VIEW (INTERIOR)

5. Vacuum pump

6. Refrigerant tank 40 L

7. Load cell

8. Non-condensable gas vent valve (automatic)

ONLY MAINTENANCE TECHNICIANS MAY REMOVE THE FRONT AND REAR

DOORS OR THE TOP COVER

5

6

7

8

CAP. 5 - GENERAL DESCRIPTION 20 / 73 ENGLISH

9000 BUS PLUS

5.3 REAR VIEW (EXTERIOR)

9. Caster wheels, with brakes

10. Handling wheels

11. Rear door

ONLY MAINTENANCE TECHNICIANS MAY REMOVE THE FRONT AND REAR

DOORS OR THE TOP COVER

9

10

11

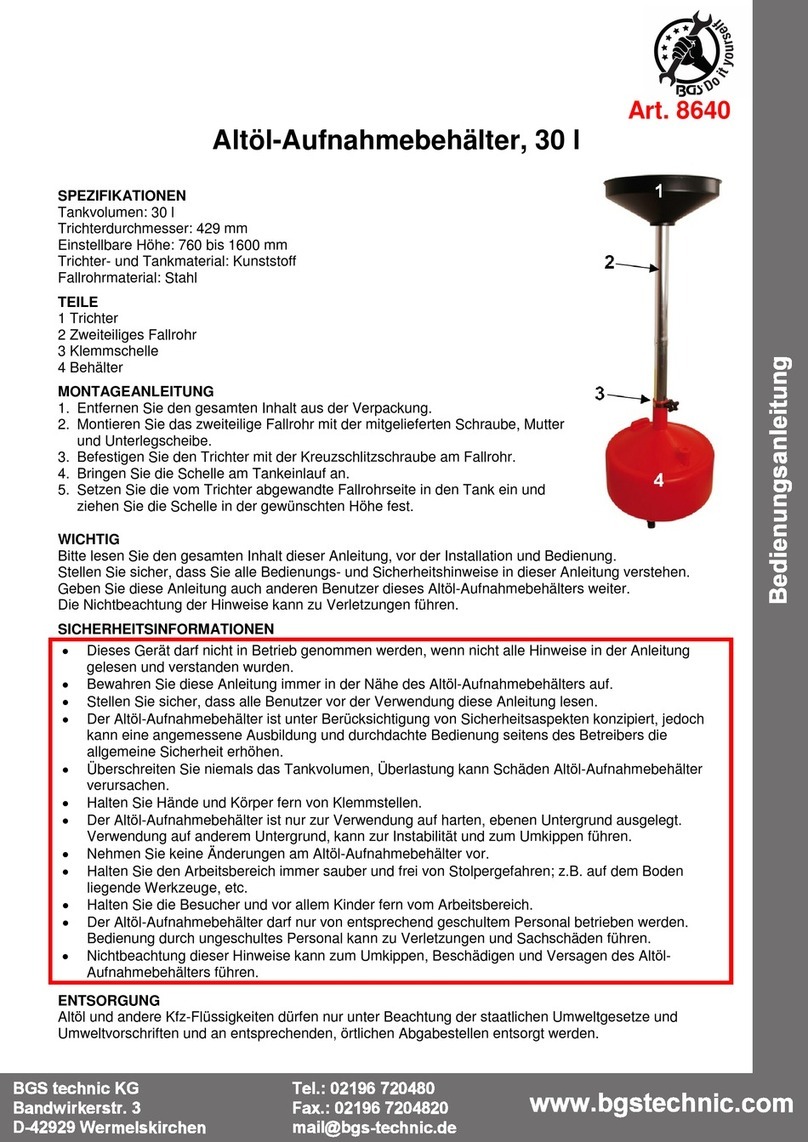

Table of contents

Popular Service Equipment manuals by other brands

BGS technic

BGS technic 70110 manual

Zuwa

Zuwa Solarcheck Mobilcenter P80 operating instructions

Hedson

Hedson IRT-UVA 1 PrepCure 3 Digital Assembly, Operation and Spares Manual

MAC TOOLS

MAC TOOLS WD1500A owner's manual

BGS technic

BGS technic 8640 instruction manual

BGS technic

BGS technic 3001 instruction manual