Brainchild C21 User manual

User's ManualUser's Manual

BRAINCHILD

UM0C911D

DIN EN ISO 9001

Certificate: 01 100 98505

C21 / C91

Auto-Tune Fuzzy / PID

Process / Temperature Controller

C21 /C91

Auto-Tune Fuzzy /PID

Process /Temperature Controller

R

R

Warning SymbolWarning Symbol

Use the ManualUse the Manual

The Symbol calls attention to an operating procedure, practice, or the

like, which, if not correctly performed or adhered to, could result in

personal injury or damage to or destruction of part or all of the

product and system. Do not proceed beyond a warning symbol until

the indicated conditions are fully understood and met.

Installers

System Designer

Expert User

Read Chapter 1, 2

Read All Chapters

Read Page 12

NOTE:

It is strongly recommended that a process should incorporate a

LIMIT CONTROL like L91 which will shut down the equipment at

a preset process condition in order to preclude possible

damage to products or system.

It is strongly recommended that aprocess should incorporate a

LIMIT CONTROL like L91 which will shut down the equipment at

apreset process condition in order to preclude possible

damage to products or system.

Information in this user's manual is subject to change without notice.

Copyright April 2003, The Brainchild Corporation, all rights

reserved. No part of this publication may be reproduced, transmitted,

transcribed or stored in a retrieval system, or translated into any

language in any form by any means without the written permission of

the Brainchild Corporation.

a

UM0C911C2

This manual is applicable for the products with software version

23 and later version.

This manual is applicable for the products with software version

23 and later version.

UM0C911A 3

Contents

Chapter 1 OverviewChapter 1Overview

1-1 General -------------------------5

1-2 Ordering Code ---------------8

1-3 Programming Port ------------9

1-4 Keys and Displays ---------10

1-5 Menu Overview -------------12

1-6 Parameter Descriptions ---13

Page No

Chapter 2 Installation

Chapter 2Installation

2-1 Unpaking ----------------------20

2-2 Mounting ----------------------20

2-3 Wiring precautions ----------22

2-4 Power Wiring -----------------25

2-5 Sensor Installation ----------

Guidlines----------------------25

2-6 Sensor Input Wiring --------26

2-7 Control Output Wiring -----26

2-8 Alarm Wiring -----------------30

2-9 Data Communication ------31

Chapter 3 Programming

Chapter 3Programming

3-1 Lockout ------------------------33

3-2 Signal Input -------------------33

3-3 Control Outputs --------------34

3-4 Alarm ---------------------------39

3-5 Configure Display -----------40

3-6 Ramp ---------------------------41

3-7 Dwell Timer -------------------42

3-8 PV Shift ------------------------43

3-9 Digital Filter -------------------44

3-10 Failure Transfer -------------45

3-11 Auto-tuning ------------------46

3-12 Manual tuning --------------47

3-13 Manual Control -------------48

3-14 Data Communication -----50

3-15 PV Retransmission --------50

Chapter 4 Applications

Chapter 4Applications

Chapter 5 Calibration --------55Chapter 5Calibration

Chapter 6 Specifications ----60Chapter 6Specifications

Page No

4-1 Heat Only Control with --

Dwell Timer ------------------51

4-2 Cool Only Control -----------52

4-3 Heat-Cool Control -----------53

Appendix

A-1 Error Codes ------------------76

A-2 Warranty ----------------------77

Chapter 7

Modbus Communications---66

Chapter 7

Modbus Communications

7-1 Functions Supported -------66

7-2 Exception Responses -----68

7-3 Parameter Table -------------69

7-4 Data Conversion ------------73

7-5 Communication Examples-73

Figures & TablesFigures &Tables Page No

Figure 1.1 Fuzzy Control Advantage ----------------------------------------------------------------6

Figure 1.2 Programming Port Overview ------------------------------------------------------------9

Figure 1.4 Display of Initial Stage -------------------------------------------------------------------11

Figure 2.1 Mounting Dimensions -------------------------------------------------------------------21

Figure 2.2 Lead Termination for C91 -------------------------------------------------------------23

Figure 2.3 Lead Termination for C21---------------------------------------------------------------23

Figure 2.4 Rear Terminal Connection for C21--------------------------------------------------23

Figure 2.5 Rear Terminal Connection for C91----- --------------------------------------------24

Figure 2.7 Power Supply Connections ------------------------------------------------------------25

Figure 2.8 Sensor Input Wiring ----------------------------------------------------------------------26

Figure 2.9 Output 1 Relay or Triac (SSR) to Drive Load ---------------------------------------26

Figure 2.10 Output 1 Relay or Triac (SSR) to Drive Contactor -------------------------------27

Figure 2.11 Output 1 Pulsed Voltage to Drive SSR ---------------------------------------------27

Figure 2.12 Output 1 Linear Current ---------------------------------------------------------------28

Figure 2.13 Output 1 Linear Voltage ---------------------------------------------------------------28

Figure 2.14 Output 2 Relay or Triac (SSR) to Drive Load -------------------------------------28

Figure 2.15 Output 2 Relay or Triac (SSR) to Drive Contactor -------------------------------29

Figure 2.16 Output 2 Pulsed Voltage to Drive SSR ---------------------------------------------29

Figure 2.17 Output 2 Linear Current ---------------------------------------------------------------29

Figure 2.18 Output 2 Linear Voltage --------------------------------------------------------------30

Figure 2.19 Alarm Output to Drive Load ----------------------------------------------------------30

Figure 2.20 Alarm Output to Drive Contactor ----------------------------------------------------30

Figure 2.21 RS-485 Wiring ---------------------------------------------------------------------------31

Figure 2.22 RS-232 Wiring ---------------------------------------------------------------------------32

Figure 2.23 Configuration of RS-232 Cable ------------------------------------------------------32

Figure 3.1 Conversion Curve for Linear Type Process Value ---------------------------------34

Figure 3.2 Heat Only ON-OFF Control ------------------------------------------------------------35

Figure 3.3 Output 2 Deviation High Alarm --------------------------------------------------------38

Figure 3.4 Output 2 Process Low Alarm ----------------------------------------------------------38

Figure 3.5 RAMP Function ---------------------------------------------------------------------------41

Figure 3.6 Dwell Timer Function --------------------------------------------------------------------42

Figure 3.7 PV Shift Application ----------------------------------------------------------------------43

Figure 3.8 Filter Characteristics ---------------------------------------------------------------------44

Figure 3.9 Effects of PID Adjustment -------------------------------------------------------------49

Figure 4.1 Heat Control Example -------------------------------------------------------------------51

Figure 4.2 Cooling Control Example ---------------------------------------------------------------52

Figure 4.3 Heat-Cool Control Example ------------------------------------------------------------53

Figure 5.1 RTD Calibration ---------------------------------------------------------------------------57

Figure 5.2 Cold Junction Calibration Setup ------------------------------------------------------58

Table 1.1 Display Form of Characters -------------------------------------------------------------11

Table 3.1 Heat-Cool Control Setup Value ---------------------------------------------------------34

Table 3.2 PID Adjustment Guide --------------------------------------------------------------------48

Table A.1 Error Codes and Corrective Actions --------------------------------------------------66

Figure 1.3 Front Panel Description -----------------------------------------------------------------11

UM0C911B4

Chapter 1 OverviewChapter 1Overview

1-1 General1-1 General

The Fuzzy Logic plus PID microprocessor-based controller series,

incorporate a bright, easy to read 4-digit LED display, indicating

process value or set point value. The Fuzzy Logic technology

enables a process to reach a predetermined set point in the

shortest time, with the minimum of overshoot during power-up or

external load disturbance.

C21 is a 1/32 DIN size panel mount controller. C91 is a 1/16 DIN size

panel mount controller. These units are powered by 11-26 or 90-250

VDC/VAC supply, incorporatinga2amp.controlrelayoutput as

standard. The second output can be used as cooling control, an

alarm or dwell timer. Both outputs can select triac, 5V logic output,

linear current or linear voltage to drive external device. There are

six types of alarm plus a dwell timer can be configured for the

second output.The units are fully programmable for PT100 and

thermocouple types J,K, T, E, B, R, S, N, L with no need to modify the

unit. The input signal is digitized by using a 18-bit A to D converter.

Its fast sampling rate allows the unit to control fast processes.

Digital communications RS-485 or RS-232 ( for C21, C91) are

available as an additional option. These options allow the units to be

integrated with supervisory control system and software.

A programming port is available for automatic configuration,

calibration and testing without the need to access the keys on front

panel.

By using proprietary Fuzzy modified PID technology, the control

loop will minimize the overshoot and undershoot in a shortest

time. The following diagram is a comparison of results with and

without Fuzzy technology.

UM0C911B 5

UM0C911A6

PID control with properly tuned

PID + Fuzzy control

Warm Up Load Disturbance

Set

point

Temperature

Time

High AccuracyHigh Accuracy

The series are manufactured with custom designed ASIC(Application

Specific Integrated Circuit ) technology which contains a 18-bit A to

D converter for high resolution measurement ( true 0.1 F resolution

for thermocouple and PT100 ) and a 15-bit D to A converter for linear

current or voltage control output. The ASIC technology provides

improved operating performance, low cost, enhanced reliability and

higher density.

B

Fast Sampling Rate

Fast Sampling Rate

The sampling rate of the input A to D converter reaches 5 times/second.

The fast sampling rate allows this series to control fast processes.

Fuzzy ControlFuzzy Control

The function of Fuzzy control is to adjust PID parameters from time to

time in order to make manipulation output value more flexible and

adaptive to various processes. The results is to enable a process to

reach a predetermined set point in the shortest time, with the minimum

of overshoot and undershoot during power-up or external load

disturbance.

Digital Communication

Digital Communication

The units are equipped with RS-485 or RS-232 interface card to

provide digital communication. By using the twisted pair wires there

are at most 247 units can be connected together via RS-485 interface

to a host computer.

Figure 1.1

Fuzzy Control

Advantage

Figure 1.1

Fuzzy Control

Advantage

Programming PortProgramming Port

A programming port is used to connect the unit to a hand-held

programmer or a PC for quick configuration, also can be connected

to an ATE system for automatic testing & calibration.

Auto-tune

The auto-tune function allows the user to simplify initial setup for a

new system. A clever algorithm is provided to obtain an optimal set

of control parameters for the process, and it can be applied either as

the process is warming up ( cold start ) or as the process has been

in steady state ( warm start ).

Lockout Protection

Lockout Protection

According to actual security requirement, one of four lockout levels

can be selected to prevent the unit from being changed abnormally.

Bumpless Transfer

Bumpless Transfer

Bumpless transfer allows the controller to continue to control by

using its previous value as the sensor breaks. Hence, the process

can be well controlled temporarily as if the sensor is normal.

Soft-start Ramp

Soft-start Ramp

The ramping function is performed during power up as well as any

time the set point is changed. It can be ramping up or ramping

down. The process value will reach the set point with a predetermined

constant rate.

Digital FilterDigital Filter

A first order low pass filter with a programmable time constant is used

to improve the stability of process value. This is particularly useful in

certain application where the process value is too unstable to be read.

UM0C911A 7

UM0C911D

8

Power InputPower Input

4: 90 - 250 VAC,

47-63 HZ

5: 11 - 26 VAC or VDC,

SELV, Limited Energy

4: 90 - 250 VAC,

47-63 HZ

5: 11 - 26 VAC or VDC,

SELV, Limited Energy 0: None

1: RS-485 interface (for C21)

2: RS-232 interface (for C21)

3: Retransmit 4-20 mA / 0-20

mA (for C21)

4: Retransmit 1-5V /0-5V

(for C21)

5: Retransmit 0-10V (for C21)

9: Special order

0: None

1: RS-485 interface (for C21)

2: RS-232 interface (for C21)

3: Retransmit 4-20 mA / 0-20

mA (for C21)

4: Retransmit 1-5V /0-5V

(for C21)

5: Retransmit 0-10V (for C21)

9: Special order

Communications

0: None

1: Relay rated 2A/240VAC

2: Pulsed voltage to drive SSR,

5V/30mA

3: Isolated4-20mA/0-20mA

4: Isolated1-5V/0-5V

5: Isolated0-10V

6: Triac output 1A / 240VAC,SSR

C: Pulsed voltage to drive SSR,

14V/40mA

9: Special order

0: None

1: Relay rated 2A/240VAC

2: Pulsed voltage to drive SSR,

5V/30mA

3: Isolated 4 - 20mA / 0 - 20mA

4: Isolated 1 - 5V / 0 - 5V

5: Isolated 0 - 10V

6: Triac output 1A / 240VAC,SSR

C: Pulsed voltage to drive SSR,

14V/40mA

9: Special order

Output 1Output 1

1: Standard Input

Thermocouple: J, K, T, E, B,

R, S, N, L

RTD: PT100 DIN, PT100 JIS

2:0-60mA

3:0-1V

4:0-5V

5:1-5V

6:4-20mA

7:0-20mA

8:0-10V

9: Special Order

1: Standard Input

Thermocouple: J, K, T, E, B,

R, S, N, L

RTD: PT100 DIN, PT100 JIS

2: 0 - 60 mA

3: 0 - 1V

4: 0 - 5V

5: 1 - 5V

6: 4 - 20 mA

7: 0 - 20 mA

8: 0 - 10 V

9: Special Order

Signal InputSignal Input

C21-

C91-

C21-

C91-

0: None

1: Form A relay 2A/240VAC

2: Pulsed voltage to

drive SSR, 5V / 30mA

3: Isolated4-20mA/0-20mA

4: Isolated1-5V/0-5V

5: Isolated0-10V

6: Triac output, 1A / 240VAC, SSR

7: Isolated 20V/25mA transducer

power supply

8: Isolated 12V/40mA transducer

power supply

9: Isolated 5V/80mA transducer

power supply

A: RS-485 interface (for C91)

C: Pulsed voltage to drive SSR,

14V/40mA

D: Retransmit 4-20mA/0-20mA

(for C91)

E: Retransmit 1-5V/0-5V (for C91)

F: Retransmit 0-10V (for C91)

B: Special order

0: None

1: Form A relay 2A/240VAC

2: Pulsed voltage to

drive SSR, 5V / 30mA

3: Isolated 4 - 20mA / 0 - 20mA

4: Isolated 1 - 5V / 0 - 5V

5: Isolated 0 - 10V

6: Triac output, 1A / 240VAC, SSR

7: Isolated 20V/25mA transducer

power supply

8: Isolated 12V/40mA transducer

power supply

9: Isolated 5V/80mA transducer

power supply

A: RS-485 interface (for C91)

C: Pulsed voltage to drive SSR,

14V/40mA

D: Retransmit 4-20mA/0-20mA

(for C91)

E: Retransmit 1-5V/0-5V (for C91)

F: Retransmit 0-10V (for C91)

B: Special order

Output 2Output 2

1-2 Ordering Code1-2 Ordering Code

0: Red color

1: Green color

0: Red color

1: Green color

Display ColorDisplay Color

OM94-6 = Isolated 1A / 240VAC Triac Output Module ( SSR )

OM94-7 = 14V / 40 mA SSR Drive Module

OM96-3 = Isolated 4 - 20 mA /0-20mAAnalog Output Module

OM96-4 = Isolated1-5V/0-5VAnalog Output Module

OM96-5 = Isolated 0 -10V Analog Output Module

CM94-1 = Isolated RS-485 Interface Module for C21

CM94-2 = Isolated RS-232 Interface Module for C21

CM94-3 = Isolated 4 - 20 mA /0-20mARetrans Module for C21

CM94-4 = Isolated1-5V/0-5VRetrans Module for C21

CM94-5 = Isolated 0 -10V Retrans Module for C21

CM96-1 = Isolated RS-485 Interface Module for C91

DC94-1 = Isolated 20V/25mA DC Output Power Supply

DC94-2 = Isolated 12V/40mA DC Output Power Supply

DC94-3 = Isolated 5V/80mA DC Output Power Supply

CC94-1 = RS-232 Interface Cable ( 2M )

CC91-1 = Programming port cable for C21

CC91-2 = Programming port cable for C91

OM94-6 = Isolated 1A / 240VAC Triac Output Module ( SSR )

OM94-7 = 14V / 40 mA SSR Drive Module

OM96-3 = Isolated 4 - 20 mA / 0 - 20 mA Analog Output Module

OM96-4 = Isolated 1 - 5V / 0 - 5V Analog Output Module

OM96-5 = Isolated 0 -10V Analog Output Module

CM94-1 = Isolated RS-485 Interface Module for C21

CM94-2 = Isolated RS-232 Interface Module for C21

CM94-3 = Isolated 4 - 20 mA / 0 - 20 mA Retrans Module for C21

CM94-4 = Isolated 1 - 5V / 0 - 5V Retrans Module for C21

CM94-5 = Isolated 0 -10V Retrans Module for C21

CM96-1 = Isolated RS-485 Interface Module for C91

DC94-1 = Isolated 20V/25mA DC Output Power Supply

DC94-2 = Isolated 12V/40mA DC Output Power Supply

DC94-3 = Isolated 5V/80mA DC Output Power Supply

CC94-1 = RS-232 Interface Cable ( 2M )

CC91-1 = Programming port cable for C21

CC91-2 = Programming port cable for C91

Accessories

SNA10B = Smart Network Adaptor for BC-Net software, which

converts 255 channels of RS-485 or RS-422 to RS-232

network.

SNA10B = Smart Network Adaptor for BC-Net software, which

converts 255 channels of RS-485 or RS-422 to RS-232

network.

SNA10A = Smart Network Adaptor for third party software, which

converts 255 channels of RS-485 or RS-422 to RS-232

Network.

SNA10A = Smart Network Adaptor for third party software, which

converts 255 channels of RS-485 or RS-422 to RS-232

Network.

Related ProductsRelated Products

BC-Set = Configuration SoftwareBC-Set = Configuration Software

SNA12A = Smart Network Adaptor for programming port to RS-232

interface

SNA12A = Smart Network Adaptor for programming port to RS-232

interface

UM0C911C 8-1

1-3 Programming Port1-3 Programming Port

Figure 1.2 Programming Port OverviewFigure 1.2 Programming Port Overview

A special connector can be used to touch the programming port

which is connected to a PC for automatic configuration, also can be

connected to an ATE system for automatic calibration and testing.

The programming port is used for off-line automatic setup and testing

procedures only. Don't attempt to make any connection to these pins

when the unit is used for a normal control purpose.

UM0C911B

Front

Panel Rear

Terminal

Access Hole

1

3

46 2

5

C21

Open the housing

TopviewofC91

Programming Port

control board

Power board

pin 1

9

1- 4 Keys and Displays1- 4 Keys and Displays

KEYPAD OPERATIONKEYPAD OPERATION

SCROLL KEY :

UP KEY :

DOWN KEY :

RESET KEY :

ENTER KEY :

This key is used to select a parameter to be viewed or adjusted.

This key is used to increase the value of selected parameter.

This key is used to decrease the value of selected parameter.

This key is used to:

1. Revert the display to display the process value or set point value

(if DISP is set with SP1 for C21).

2. Reset the latching alarm, once the alarm condition is

removed.

3. Stop the manual control mode , auto-tuning mode and calibration

mode.

4. Clear the message of communication error and auto-tuning error.

5. Restart the dwell timer when the dwell timer has been time out.

6. Enter the manual control menu during failure mode occurs.

Press for 5 seconds or longer .

Press for 5 seconds to:

1. Ener setup menu. The display shows .

2. Enter manual control mode during manual control mode

or is selected.

3. Enter auto-tuning mode during auto-tuning mode AT(for C91)

or (for C21) is selected.

4. Perform calibration to a selected parameter during the

calibration procedure.

Press for 4.2 seconds to select calibration mode.

SCROLL KEY :

UP KEY :

DOWN KEY :

RESET KEY :

ENTER KEY :

R

UM0C911C

press for C91 and C92, press for C21press for C91 and C92, press for C21

10

: Confused Character: Confused Character

Table 1.1 Display Form of CharactersTable 1.1 Display Form of Characters

AEINSX

BFJOTY

CGKPUZ

cHLQV

?

Dh

MRW=

Figure 1.3 Front Panel DescriptionFigure 1.3 Front Panel Description

UM0C911C

The left diagram shows program no. 34

for C91 with version 24.

The program no. for C21 is 33.

Display program code of the product

for 2.5 seconds.

Figure 1.4

Display of Initial Stage

Figure 1.4

Display of Initial Stage

Output 2

Indicator

Output 2

Indicator

Output 1

Indicator

Output 1

Indicator

3 Silicone Rubber Buttons

for ease of control setup

and set point adjustment.

3Silicone Rubber Buttons

for ease of control setup

and set point adjustment.

C21

O1

O2

C

4 Buttons for ease of

control setup and

set point adjustment.

Output 2

Indicator Process Unit Indicator

Manual Mode Indicator

Auto-tuning Indicator

PV

MAN

AT

SP2SP1

F

C

C91

OP1

OP2

R

Output 1

Indicator

Deviation Indicator

11

PV

MAN

AT

SP2SP1

F

C

C91

OP1

OP2

R

1- 5 Menu Overview1- 5Menu Overview

SP1

SP2

PV

ADLO

ADHI

RTDL

CJLO

RTDH

CJHI

7.4 sec.

User menu *1User menu *1 Setup menu*1Setup menu*1 Calibration ModeCalibration Mode

Press for

5 seconds to

perform calibration.

UM0C911C

*2

H

C

PV

Apply these modes will

break the control loop

and change some of the

previous setting data.

Make sure that if the

system is allowable to

apply these modes.

The flow chart shows a

complete listing of all

parameters. For actual

application the number of

available parameters

depends on setup

conditions, and should be

less than that shown in

the flow chart.

Release , press

again for 2 seconds or

longer (but not longer

than 3 seconds), then

release to enter the

calibration menu.

*1:

*2:

2 sec.

LOCK

INPT

UNIT

DP

INLO

SP1L

INHI

SP1H

SHIF

FILT

DISP

OUT1

O1TY

O1FT

O1HY

CYC1

PB

TI

TD

OFST

RAMP

RR

OUT2

O2TY

O2FT

O2HY

CYC2

CPB

DB

ALMD

COMM

ADDR

BAUD

DATA

PARI

STOP

RELO

REHI

SEL1

SEL2

SEL3

SEL4

SEL5

SEL6

SEL7

SEL8

6.2 sec.

Value

Value

Value

Value

5 sec.

Manual

Mode

Manual

Mode

Manual

Mode

Manual

Mode

Auto-tuning

Mode

Auto-tuning

Mode

PV

SP1

SP2

MAN

AT

MAN

C91

User Menu *1User Menu *1

(DISP=PV) (DISP=SP1)

SP1

SP2

H

C

A-T

Manual

Mode

Manual

Mode

5 sec.

Auto-tuning

Mode

Auto-tuning

Mode

C21

or

PV SP1

Value

or

PV

Value

Manual

Mode

Manual

Mode

5 sec.

5 sec.

5 sec.

5 sec.

INPT

UNIT

DP

PB

TI

TD

CYC1

ADDR

Value

Value

INPT

UNIT

DP

PB

TI

TD

CYC1

ADDR

Value

Value

5sec.

12

1-6 Parameter Descriptions1-6 Parameter Descriptions

Parameter

Notation Default

Value

Select parameters to be

locked

0 : No parameter

is locked

1 : Setup data are

locked

2 : Setup data and

User data except Set

point are locked

3 : All data are locked

LOCK 0

Parameter Description Range

0

1

2

3

4

5

6

:

:

:

:

:

:

:

T type thermocouple

E type thermocouple

B type thermocouple

R type thermocouple

S type thermocouple

J type thermocouple

K type thermocouple

7

13

8

14

9

10

11

12

N type thermocouple

L type thermocouple

PT 100 ohms DIN

curve

PT 100 ohms JIS

curve

4 - 20 mA linear

current input

0 - 20 mA linear

current input

0 - 1V linear voltage

input

:

:

:

:

:

:

:

:0 - 60 mV linear

millivolt input

INPT Input sensor selection

UM0C911A

1

(0)

SP2

Set point for output 2

when output 2 performs

alarm function or dwell

timer

Low: -19999 High :45536

10.0 C

(18.0 F)

B

B

SP1 Set point for output 1 Low: SP1L High :SP1H

25.0 C

(77.0 F)

B

B

15

16

17

0 - 5V linear voltage

input

1 - 5V linear voltage

input

0 - 10V linear voltage

input

:

:

:

13

Parameter

Notation Default

Value

Parameter Description Range

UNIT Input unit selection

0

1

2

:

:

:

Degree C unit

Degree F unit

Process unit

0

(1)

DP Decimal point selection

0

1

2

3

1

:

:

:

:

No decimal

point

1 decimal digit

2 decimal digits

3 decimal digits

INLO

INHI

Input low sale value

Input high scale value

-19999

INLO+50

45486

45536

Low:

Low:

High:

High:

-17.8 C

(0F)

L

L

SHIF PV shift (offset) value -200.0 C

(-360.0 F)

L

L0.0

Low: 200.0 C

( 360.0 F)

L

L

High:

93.3 C

(200.0 F)

L

L

0

1

2

3

4

5

6

7

8

9

FILT Filter damping time

constant of PV

0 second time

constant

0.2 second time

constant

0.5 second time

constant

1 second time

constant

2 seconds time

constant

5 seconds time

constant

10 seconds time

constant

20 seconds time

constant

30 seconds time

constant

60 seconds time

constant

:

:

:

:

:

:

:

:

:

:

2

UM0C911A

SP1L

Low limit of set point

value -19999 High:

-17.8 C

(0 F)

L

L

SP1H

High limit of set point

value SP1L High:

537.8 C

(1000 F)

L

L

45536

Low:

45536

Low:

14

Parameter

Notation Default

Value

Parameter Description Range

0

O1TY Output 1 signal type

: Relay output

: Solid state relay

drive output

: Solid state relay

output

: 4-20 mA current

module

0

1

2

3

4

5

6

7

0 - 20 mA current

module

0 - 1V voltage

module

0 - 5V voltage

module

1 - 5V voltage

module

80 - 10V voltage

module

:

:

:

:

:

O1FT Output 1 failure transfer

mode

Select BPLS ( bumpless

transfer ) or 0.0 ~ 100.0 % to

continue output 1 control

function as the unit fails, or

select OFF (0) or ON (1)

for ON-OFF control.

0

O1HY Output 1 ON-OFF control

hysteresis Low: 0.1 High: 50.0 C(90.0 F)BB

0.1 C

(0.2 F)

L

L

CYC1 Output 1 cycle time Low: 0.1 High: 90.0 sec. 18.0

PB Proportional band value 10.0 C

(18.0 F)

L

L

Low: 0 500.0 C

(900.0 F)

L

L

High:

TI

TD

Integral time value

Derivative time value

0

0

100

25.0

Low:

Low:

3600 sec

360.0 sec

High:

High:

OFST Offset value for P control Low: 0 High: 100.0 % 25.0

UM0C911D

Output 1 function 0

OUT1

0

1

Reverse (heating )

control action

Direct (cooling)

control action

:

:

DISP Normal display selection

: Display process

value normally

0

: Display set point 1

value normally

1

0

15

RR Ramp rate 0.0

Low: 0 500.0 C

(900.0 F)

L

L

High:

Parameter

Notation Default

Value

Parameter Description Range

OUT2 Output 2 function

0 : Output 2 No Function

2 : Deviation High Alarm

3 : Deviation Low Alarm

6 : Process High Alarm

7 : Process Low Alarm

8 : Cooling PID Function

2

O2TY Output 2 signal type 0

0

1

2

3

Relay output

Solid state relay

drive output

Solid state relay

output

4 - 20 mA current

module

:

:

:

:

4

5

6

7

0 - 20 mA current

module

0 - 1V voltage

module

0 - 5V voltage

module

1 - 5V voltage

module

80 - 10V voltage

module

:

:

:

:

:

O2FT

Select BPLS ( bumpless transfer )

or 0.0 ~ 100.0 % to continue

output 2 control function as the

unit fails, or select ON (0) or

OFF (1) for alarm and dwell timer

function.

Output 2 failure

transfer mode 0

UM0C911A

RAMP Ramp function

selection

0 : No Ramp Function

2 : Use unit/hour as

Ramp Rate

1 : Use unit/minute as

Ramp Rate 0

1 : Dwell timer action

4 : Deviation band out of

band Alarm

5 : Deviation band in

band Alarm

16

Parameter

Notation Default

Value

Parameter Description Range

ALMD Alarm operation mode

0: Normal alarm action

1: Latching alarm action

2: Hold alarm action

3: Latching & actionHold

0

COMM Communication

function

0 : No communication

1 : Modbus RTU mode

protocol

1

UM0C911C

Heating-cooling dead

band (negative value=

overlap) 0

Low: -36.0 High: 36.0 %

DB

CPB Cooling proportional

band value 100

Low: 50 High: 300 %

CYC2 Output 2 cycle time Low: 0.1 High: 90.0 sec. 18.0

O2HY

Output 2 hysteresis

value when output 2

performs alarm

function

Low: 0.1 High: 50.0 C

(90.0 F)

L

L

0.1 C

(0.2 F)

L

L

BAUD

:

:

:

:

:

:

:

Baud rate of digital

communication 2

0

1

2

3

4

5

6

2.4 Kbits/s baud rate

4.8 Kbits/s baud rate

9.6 Kbits/s baud rate

14.4 Kbits/s baud rate

19.2 Kbits/s baud rate

28.8 Kbits/s baud rate

38.4 Kbits/s baud rate

ADDR Address assignment of

digital communication Low: 1 High: 255

2:4-20mA retransmission

output

3:0-20mA retransmission

output

:0-5V retransmission

output

4

:1-5V retransmission

output

5

:0-10V retransmission

output

6

17

Parameter

Notation Default

Value

Parameter Description Range

DATA Data bit count of digital

communication

0 : 7 data bits

1 : 8 data bits 1

PARI Parity bit of digital

communication

0 : Even parity

1 : Odd parity

2 : No parity bit

0

STOP Stop bit count of digital

communication

0 : One stop bit

1 : Two stop bits 0

UM0C911C

SEL1 Select 1'st parameter for

user menu

0:No parameter selected

2

1:LOCK is put ahead

2:INPT is put ahead

3:UNIT is put ahead

5:SHIF is put ahead

6:PB is put ahead

7:TI is put ahead

4:DP is put ahead

8:TD is put ahead

11 :OFST is put ahead

14 :CYC2 is put ahead

17 :ADDR is put ahead

12 :RR is put ahead

13 :O2HY is put ahead

15 :CPB is put ahead

16 :DB is put ahead

10 :CYC1 is put ahead

9:O1HY is put ahead

RELO Retransmission low

scale value Low: -19999 High: 45536 0.0 C

(32.0 F)

L

L

REHI Retransmission high

scale value Low: -19999 High: 45536

100.0 C

(212.0 F)

L

L

18

Parameter

Notation Default

Value

Parameter Description Range

SEL2 Select 2'nd parameter

for user menu 3

Same as SEL1

SEL3 Select 3'rd parameter

for user menu 4

Same as SEL1

SEL4 Select 4'th parameter

for user menu 6

Same as SEL1

SEL5 Select 5'th parameter

for user menu 7

Same as SEL1

SEL6 Select 6'th parameter

for user menu 8

Same as SEL1

SEL7 Select 7'th parameter

for user menu 10

Same as SEL1

SEL8 Select 8'th parameter

for user menu 17

Same as SEL1

UM0C911A

19

This manual suits for next models

1

Table of contents

Other Brainchild Controllers manuals

Popular Controllers manuals by other brands

GF

GF EA25 instruction manual

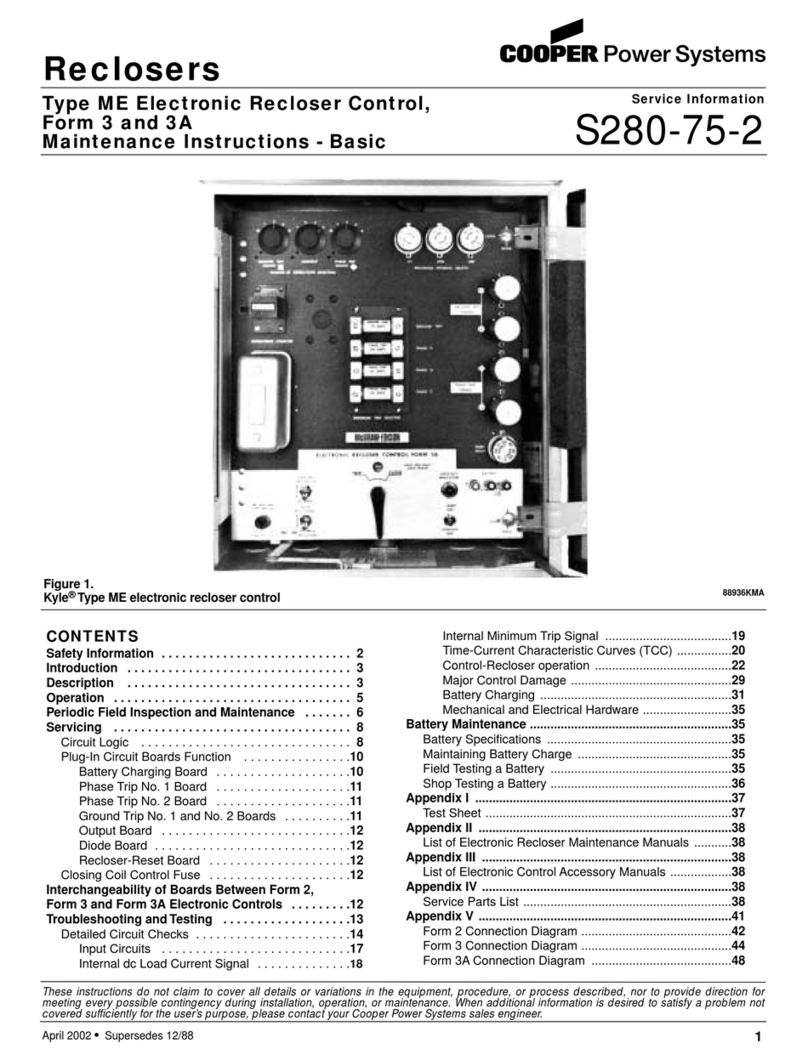

Cooper Power Systems

Cooper Power Systems Kyle Type ME Series Maintenance instructions

SOMFY

SOMFY CB 230 RTS installation instructions

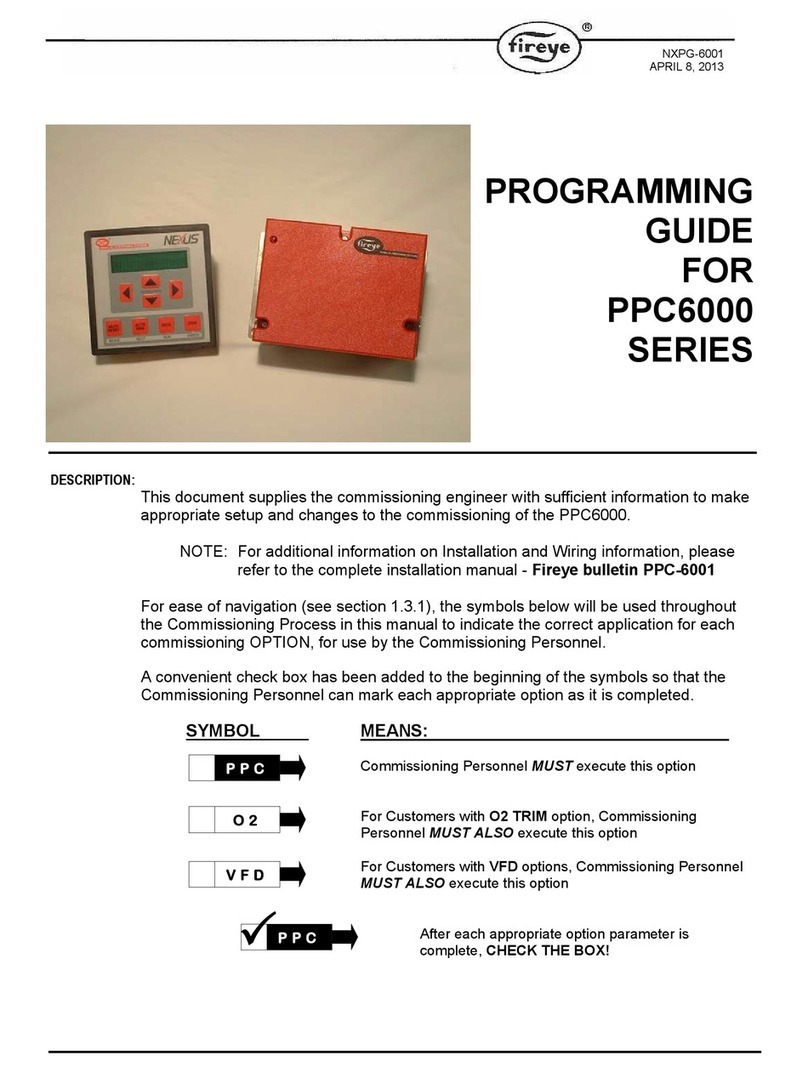

Fireye

Fireye PPC6000 Series Programming guide

Adaptec

Adaptec 2930U2 - Storage Controller Ultra2 SCSI 80... User reference

Tyco

Tyco iSTAR eX Installation and configuration guide