Brainchild L91 User manual

User's Manual

BRAINCHILD

TEMPERATURE LIMIT CONTROLLER L91

DIN EN ISO 9001

Certificate: 01 100 98505

R

R

APPROVED

UM0L911C

Warning Symbol

Use the Manual

The Symbol calls attention to an operating procedure, practice, or

the like, which, if not correctly performed or adhered to, could result

in personal injury or damage to or destruction of part or all of the

product and system. Do not proceed beyond a warning symbol

until the indicated conditions are fully understood and met.

Installers

System Designer

Expert User

Read Chapter 1, 2

Read All Chapters

Read Page 12

NOTE:

It is strongly recommended that a process should incorporate

a LIMIT CONTROL like L91 which will shut down the equipment

at a preset process condition in order to preclude possible

damage to products or system.

Information in this user's manual is subject to change without notice.

Copyright a October 2000, Brainchild Electronic Co., Ltd. all rights

reserved. No part of this publication may be reproduced,

transmitted, transcribed or stored in a retrieval system, or translated

into any language in any form by any means without the written

permission of the Brainchild Electronic Co., Ltd.

UM0L911C

2

This manual is applicable for the products with software version

19 and later version.

UM0L911C 3

Contents

Chapter 1 Overview

1-1 General

1-2 Ordering Code

1-3 Programming Port

1-4 Keys and Display

1-5 Menu Overview

1-6 Limit Control Operation

1-7 Parameter Descriptions

Chapter 2 Installation

2-1 Unpacking

2-2 Mounting

2-3 Wiring Precautions

2-4 Power Wiring

2-5 Sensor Installation

Guidelines

2-6 Thermocouple Input

Wiring

2-7 RTD Input Wiring

2-8 Linear DC Input Wiring

2-9 Event Input Wiring

2-10 Output 1 Wiring

2-11 Output 2 Wiring

2-12 RS-485

Chapter 3 Programming

3-1 Process Input

3-2 Limit Control

3-3 Set point Range

3-4 PV Shift

3-5 Digital Filter

3-6 Process Alarms

3-7 RS-485 Communication

3-8 Display Mode

3-9 Signal Conditioner DC

Power Supply

3-10 Remote Reset

3-11 Remote Lock

3-12 Limit Annunciator

Chapter 4 Applications

Chapter 5 Calibration

Chapter 6 Specifications

Page No Page No

5

6

7

7

12

13

16

22

22

23

25

25

26

27

28

29

30

31

32

33

34

34

35

35

36

37

38

38

40

40

41

42

43

48

3-13 Reference Data 41

Chapter 7

Modbus Communications

52

Appendix

A-1 Error codes 61

4

Figures & Tables

Figure 1-1 Programming Port Location

Figure 1-2 Front Panel Display

Figure 1-3 Power Up Sequence

Figure 1-4 High Limit Operation

Figure 1-5 Low Limit Operation

Figure 1-6 High/Low Limit Operation

Figure 2-1 Mounting Diagram

Figure 2-2 Lead Termination

Figure 2-3 Rear Terminal Connection Diagram

Figure 2-4 Power Supply Connections

Figure 2-5 Thermocouple Input Wiring

Figure 2-6 RTD Input Wiring

Figure 2-7 Linear Voltage Input Wiring

Figure 2-8 Linear Current Input Wiring

Figure 2-9 Event Input Wiring

Figure 2-10 Output 1 Wiring

Figure 2-11 Output 2 Wiring

Figure 2-12 RS-485 Wiring

Figure 3-1 Conversion Curve for Linear Type Process Value

Figure 3-2 Filter Characteristics

Figure 3-3 Normal Process Alarm

Figure 3-4 Latching Process Alarm

Figure 3-6 Remote Reset Application

Figure 3-7 Remote Lock Application

Figure 4-1 Over Temperature Protection with Remote Reset

Figure 5-1 Flow chart for Manual Calibration

Figure 5-2 Cold Junction Calibration Setup

Figure 5-3 RTD Calibration

Table 1-1 Display Form of Characters

Table 6-1 Input Characteristics

Page No

7

8

10

13

14

15

23

24

24

25

27

27

28

28

29

30

31

32

33

35

37

37

39

40

42

44

45

46

9

49

Figure 3-5 DC Power Supply Application

40

UM0L911C

Temperature limit control is a safety limit device with a L91

latching output, that removes power in an abnormal condition

during the process is higher than the high limit set point or

lower than the low limit set point.

The unit is powered by 90-264 VAC or 11-26VAC/VDC supply,

incorporating a 2 amp. form C relay for limit control, an universal

input which is fully programmable for PT100, thermocouple types J,

K, T, E, B, R, S, N, L and 0~60mV, an option port available for one

of the following functions: alarm output, RS-485 communication

interface, DC power supply output, limit annunciator output and

event input. Alternative output options include SSR drive and triac .

The input signal is digitized by using a converter. Its 18-bit A to D

fast sampling rate (5 times/second) allows the L91 to control fast

process such as pressure and flow.

Digital communication RS-485 is available as an additional option.

This option allows L91 to be integrated with supervisory control

system. An alarm output is another option. A variety of alarm

function and alarm mode can be programmed for a specific

application. The DC power supply output option is used for an

external sensor or transmitter. The event input option can be

programmed for remote reset or remote lock signal input. The limit

annunciator option can be used to control an alarm buzzer.

Three kinds 1. of method can be used to program L91. use keys on

front panel to program the unit manually, Use a PC and setup 2.

software to program the unit via RS-485 port and Use a pc and 3.

configuration software to program the unit via programming port.

and High accuracy, maximum flexibility, fast response user

friendly are the main features of L91.

Chapter 1 Overview

1-1 General

5

UM0L911C

1-2 Ordering Code

Accessories

OM94-6 = Isolated 1A / 240VAC Triac Output Module ( SSR )

OM94-7 = 14V/40mA SSR Drive Module

DC94-1 = Isolated 20V / 25mA DC Output Power Supply

DC94-2 = Isolated 12V / 40mA DC Output Power Supply

DC94-3 = Isolated 5V / 80mA DC Output Power Supply

CM96-1 = Isolated RS-485 Interface Module

CM96-3 = Isolated 4-20mA / 0-20mA Retransmission Module

CM96-4 = Isolated 1-5V / 0-5V Retransmission Module

CM96-5 = Isolated 0-10V Retransmission Module

EI96-1 = Event Input Module

CC91-2 = Programming port cable for L91

UM0L911C = L91 User's Manual

Power Input

4: 90 - 264 VAC, 50/60 HZ

5: 11 - 26 VAC or VDC

9: Special Order

1: Standard Input

Thermocouple: J, K, T, E, B,

R, S, N, L, C, P

RTD: PT100 DIN, PT100 JIS

mV: 0~60 mV

2: Voltage: 0-1 V

3: Voltage : 0-10 V

4: Current: 0-20mA

9: Special Order

Signal Input

1: Form C relay rated 2A/240VAC

2: Pulsed voltage to drive SSR,

5V/30mA

6: Triac Output 1A / 240VAC,SSR

C: Pulsed voltage to drive SSR,

14V/40mA

9: Special order

Output 1

1 2 3

L91

Standard Model:

L91-4110

90 - 264 operating voltage

Input: Standard Input

Output 1: Relay

Option: None

Example

4

0: None

1: Form A Relay 2A/240VAC

2: Pulsed voltage to drive SSR, 5V / 30mA

6: Triac Output, 1A / 240VAC, SSR

7: Isolated 20V / 25mA DC Output

Power Supply

8: Isolated 12V / 40mA DC Output

Power Supply

9: Isolated 5V / 80mA DC Output

Power Supply

A: RS-485

B: Event input

C: Pulsed voltage to drive SSR, 14V/40mA

D: Retransmit 4-20mA / 0-20mA

E: Retransmit 1-5V / 0-5V

F: Retransmit 0-10V

H: Special order

Option

UM0L911C

6

Related Products

SNA10A = Smart Network Adaptor for Third Party Software,

Converts 255 channels of RS-485 or RS-422 to

RS-232 Network

SNA12A = Smart Network Adaptor for programming port to RS-232

interface.

BC-Set = Configuration Software

1-3 Programming Port

1-4 Keys and Display

Note: The programming port is used for off-line setup and

calibration procedures only. Don't attempt to make any

connection to these jumpers when the unit is used for a

normal control purpose.

KEYPAD OPERATION

SCROLL KEY

This key is used to:

1. Select a set point to be displayed.

2. Select a parameter to be viewed or adjusted.

3. Advance display from a parameter code to the next parameter code.

7

Figure 1-1 Programming

Port Location

Open the housing

Top view of L91

Programming Port

control board

Power board

pin 1

UM0L911C

RESET

RESET

ENTER KEY 4 seconds, 8 seconds

Press the scroll key for 4 seconds the display will enter the setup

menu. Press this key for 8 seconds to enter the calibration mode.

UP KEY

This key is used to increase the selected parameter value during the

lock indicator is off.

DOWN KEY

This key is used to decrease the selected parameter value during

the lock indicator is off.

RESET KEY

This key is used to:

1.Reset the limit condition after the process is within the limit.

2.Revert the display to the normal display.

3.Reset the latching alarm, once the alarm condition is removed.

4.Reset the limit annunciator.

If the RESET key is left pressed, only ONE reset operation will Note:

occur. If the unit subsequently goes into a state where reset is

required again, the RESET key (or remote reset contacts) must be

released (opened) and pressed (closed) again.

UNLOCK KEY 4 seconds

Press the RESET key for 4 seconds to enable up/down key function,

also to reset the reference data ( ) and the lock indicatorSection 3-13

will be extinguished. However, this function is disabled when remote

lock is selected for EIFN (Event input function). .See section 3-11

8

LSP1

PV

OP1

HSP1

SP2

LOCK

RESET

OP2

BRAINCHILD

L91LIMIT CONTROL

LF

LC

Figure 1-2 Front Panel Display

INDICATORS

Op1: Output 1 status indicator

OP2: Output 2 status indicator

LC: Degree C indicator

LF: Degree F indicator

PV: Process value

HSP1: High limit set point 1

LSP1: Low limit set point 1

SP2: Set point 2 for output 2

LOCK: Lock status indicator

UM0L911C

For a number with decimal point the display will be shifted one digit right:

-19999 will be displayed as:

45536 will be displayed as:

How to display a 5-digit number :

-199.99 will be displayed as -199.9, 4553.6 will be displayed as 4553

For a number without decimal point the display will be divided into two

alternating phases:

: These characters are displayed differently.

Table 1-1 Display Form of Characters

AEINSX

BFJOTY

CGKPUZ

cHLQV

?

D h MRW=

DISPLAY FORM

-9999 will be displayed as:

NORMAL DISPLAY

During normal operation, the unit can be configured to display the

process value, high limit or low limit set point ( HSP1 or LSP1

dependent on OUT1 selection ) or the word SAFE.

ABNORMAL DISPLAY

Whenever the process is outside the normal range, the process

value will be displayed.

9

UM0L911C

SENSOR BREAK DISPLAY

If a break is detected in the sensor circuit, the display will show:

POWER UP SEQUENCE

10

All segments of display and indicators are

left off for 0.5 second.

All segments of display and indicators are

lit for 1 second.

Display program code of the product for 1

second. The left diagram shows program

no.2 with version 17.

Display Date Code for 1 second. The left

diagram shows Year 2001, Month February

(2), Date 25'th. This means that the product

is produced on February 25'th, 2001. Note

that the month code is for is A October, B

for and is for .November C December

A-D FAILURE DISPLAY

If failure is detected in the A-D converter circuit, the display will

show:

LSP1

PV

OP1

HSP1

SP2

LOC K

RESET

OP2

BRAINCHILD

L91LIMIT CONTROL

LF

LC

LSP1

PV

OP1

HSP1

SP2

LOC K

RESET

OP2

BRAINCHILD

L91LIMIT CONTROL

LF

LC

RESET

BRAINCHILD

L91LIMIT CONTROL

LSP1

PV

OP1

HSP1

SP2

LOC K

RESET

OP2

BRAINCHILD

L91LIMIT CONTROL

LF

LC

UM0L911C

Display the serial number ( 001~999 ) for 1

second.

Display the hours used for 2 seconds. The

left diagram shows that the unit has been

used for 23456.7 hours since production.

Figure 1-3 Power Up Sequence

Verify all electrical connections have been properly made

before applying power to the unit.

During power up, a self-test procedure is performed within 6.5

seconds. During self-test period all outputs are left off. When

the self-test procedure is complete, the unit reverts to normal

operation.

11

LSP1

PV

OP1

HSP1

SP2

LOC K

RESET

OP2

BRAINCHILD

L91LIMIT CONTROL

LF

LC

LSP1

PV

OP1

HSP1

SP2

LOC K

RESET

OP2

BRAINCHILD

L91LIMIT CONTROL

LF

LC

LSP1

PV

OP1

HSP1

SP2

LOC K

RESET

OP2

BRAINCHILD

L91LIMIT CONTROL

LF

LC

UM0L911C

1-5 Menu Overview

PV Value

or SAFE

HSP1 Value

LSP1 Value

SP2 Value

INPT

UNIT

RESO

IN.LO

IN.HI

SHIF

FILT

OUT1

O1.HY

HSP.L

HSP.H

LSP.L

LSP.H

OUT2

ADDR

BAUD

PARI

AOFN

AOLO

AOHI

AL.FN

AL.MD

AL.HY

AL.FT

EIFN

DISP

Input type

Process unit

Display resolution

Low scale value for linear

input

High scale value for linear

input

PV shift (offset) value

PV filter time constant

Output 1 function

Output 1 hysteresis value

Lower limit of HSP1

Lower limit of LSP1

Upper limit of HSP1

Upper limit of LSP1

Output 2 function

Address for digital

communication

Baud rate

Parity bit

Analog output function

Analog output low scale

Analog output high scale

Alarm function

Alarm mode

Alarm hysteresis value

Alarm failure transfer

Event input function

Normal display format

Process

value

High limit

setpoint 1

value

Low limit

setpoint 1

value

Set point 2

value

Press

for 4 sec.

Setup Mode

12 UM0L911C

PV.HI

PV.LO

Max. historical PV

Min. historical PV

T.ABN Abnormal time

RESET

The flow charts show a complete listing of parameters. For

actual application the number of available parameters is

dependent on the setup conditions, and should be less than

that shown in the flow charts.

Press key for 4 seconds to enable up/down key

function, and the LOCK indicator will be extinguished.

Note 1.

Note 2.

1-6 Limit Control Operation

HIGH LIMIT OPERATION

If Hi. is selected for OUT1, the unit will perform high limit control.

When power is applied the OUT1 relay is de-energized. After 6.5

seconds self-test period, if the process is below the high limit set

point (HSP1), the output 1 relay will be energized and OP1 indicator

will go off. If the process goes above the high limit set point, the

relay will be de-energized, the OP1 indicator will go on and the

display will show the process value. After the process falls below the

high limit set point and the RESET key is pressed or the remote

reset input is applied, the relay will be energized and the OP1

indicator will go off.

HSP1

ON

OFF

OUT1 Relay

A, B ,C=Reset is applied

O1.HY= Output1 hysteresis

Figure 1-4 High Limit Operation

PV

A B C

13

HSP1 O1.HY

UM0L911C

LOW LIMIT OPERATION

If Lo. is selected for OUT1, the unit will perform low limit control.

When power is applied the OUT1 relay is de-energized. After 6.5

seconds self-test period, if the process is above the low limit set

point (LSP1), the output 1 relay will be energized and OP1 indicator

will go off. If the process goes below the low limit set point, the relay

will be de-energized, the OP1 indicator will go on and the display

will show the process value. After the process rises above the low

limit set point and the RESET key is pressed or the remote reset

input is applied, the relay will be energized and the OP1 indicator

will go off.

LSP1+O1.HY

LSP1

ON

OFF

OUT1 Relay

A, B ,C=Reset is applied

O1.HY= Output1 hysteresis

Figure 1-5 Low Limit Operation

A B C

14 UM0L911C

HIGH/LOW LIMIT OPERATION

If Hi.Lo is selected for OUT1, the unit will perform high/low limit

control. When power is applied the OUT1 relay is de-energized.

After 6.5 seconds self-test period, if the process is below the high

limit set point (HSP1) and above the low limit set point (LSP1), the

output 1 relay will be energized and OP1 indicator will go off. If the

process goes above the high limit set point or below the low limit set

point, the relay will be de-energized, the OP1 indicator will go on

and the display will show the process value. After the process is

within the normal operation range, and the RESET key is pressed or

the remote reset input is applied, the relay will be energized and the

OP1 indicator will go off.

LSP1+O1.HY

HSP1

LSP1

HSP1 O1.HY

ON

OFF

OUT1 Relay

A, B, C, D, E, F =Reset is applied

O1.HY= Output1 hysteresis

Figure 1-6 High/Low Limit Operation

A B CD E F

15

UM0L911C

1-7 Parameter Descriptions

Parameter

Notation

Parameter

Description Range Default

Value

HSP1

LSP1

INPT

SP2

High Limit Set point 1

Low Limit Set point 1

Input Type Selection

Set point 2 Value for

Output 2

Low: HSP.L

High: HSP.H

Low: LSP.L

High: LSP.H

100.0 BC

(212.0 BF)

0 BC

(32.0 BF)

90.0 BC

(194.0 BF)

0 : J type

thermocouple

1 : K type

thermocouple

2 : T type

thermocouple

3 : E type

thermocouple

4 : B type

thermocouple

5 : R type

thermocouple

6 : S type

thermocouple

7 : N type

thermocouple

8 : L type

thermocouple

9 : C type

thermocouple

10 : P type

thermocouple

11 : PT100

ohms DIN curve

12 : PT100

ohms JIS curve

1

( 0 )

UM0L911C

16

Low: -19999

High: 45536

13 : 4~20

mA linear current

14 : 0~20

mA linear current

15 : 0~60

mV linear voltage

16 : 0~1 V

linear voltage

17 : 0~5 V

linear voltage

18 : 1~5 V

linear voltage

19 : 0~10V

linear voltage

Parameter

Notation

Parameter

Description Range Default

Value

INPT Input Type Selection 1

( 0 )

0

( 1 )

17

UM0L911C

UNIT

RESO

Process Unit

Display Resolution

0 :

Degree C unit

2 :

Process unit

1 :

Degree F unit

0 :

No decimal point

1 :

1 decimal point

2 :

2 decimal point

3 :

3 decimal point

1

IN.LO Low Scale Value for

Linear Input

Low: -19999

High: IN.HI 0

IN.HI

SHIF

High Scale Value for

Linear Input

PV Shift ( offset )

Value

Low: IN.LO

High: 45536

Low: -200.0 BC

(-360.0 BF)

High: 200.0 BC

(360.0 BF)

100.0

0.0

Parameter

Notation

Parameter

Description Range Default

Value

FILT PV Filter Time

Constant

3 : 1 second

time constant

0 : 0 second

time constant

4 : 2 seconds

time constant

5 : 5 seconds

time constant

6 : 10 seconds

time constant

7 : 20 seconds

time constant

8 : 30 seconds

time constant

9 : 60 seconds

time constant

1 : 0.2 second

time constant

2 : 0.5 second

time constant

2

OUT1 Output 1 Function

2 : High limit

control

3 : Low limit

control 2

18

4 : High/Low

limit control

UM0L911C

Parameter

Notation

Parameter

Description Range Default

Value

19

UM0L911C

O1.HY Output 1 Hysteresis

Value

Low: 0.1

High: 10.0 BC (18.0 BF) 0.1

HSP.L

LSP.L

HSP.H

LSP.H

Lower Limit of HSP1

Lower Limit of LSP1

Upper Limit of HSP1

Upper Limit of LSP1

Low: -19999

High: HSP.H

Low: -19999

High: LSP.H

Low: HSP.L

High: 45536

Low: LSP.L

High: 45536

0 BC

(32.0 BF)

0 BC

(32.0 BF)

1000.0 BC

(1832.0 BF)

-100.0 BC

(-148.0 BF)

OUT 2 Output 2 Function

5 :Event input

0 : No function

1 : DC power

supply output

2 : RS-485

Communication

3 :Alarm output

ADDR Address Assignment

of Digital COMM

Low: 1

High: 255

BAUD Baud Rate of Digital

COMM

0 : 0.3 Kbits/s

baud rate

1 : 0.6 Kbits/s

baud rate

4 : Limit

annunciator 4

1

6 :4-20mA analog

retransmission output

7 :0-20mA analog

retransmission output

8 :0-1V analog

retransmission output

9 :0-5V analog

retransmission output

10 :1-5V analog

retransmission output

11 :0-10V analog

retransmission output

Parameter

Notation

Parameter

Description Range Default

Value

6 : 14.4 Kbits/s

baud rate

7 : 19.2 Kbits/s

baud rate

8 : 28.8 Kbits/s

baud rate

9 : 38.4 Kbits/s

baud rate

BAUD Baud Rate of Digital

COMM 5

UM0L911C

20

PARI Parity Bit of Digital

COMM

0 : 8 bit

even parity

1 : 8 bit

odd parity

2 : 8 bit

none parity

0

5 : 9.6 Kbits/s

baud rate

3 : 2.4 Kbits/s

baud rate

4 : 4.8 Kbits/s

baud rate

2 : 1.2 Kbits/s

baud rate

AOFN Analog Output

Function

0 : Process

value

1 : High Limit

Set point 1

2 : Low Limit

Set point 1

0

AOLO Analog Output Low

Scale Value

Low: -19999

High: 45536

0 BC

(32.0 BF )

AOHI Analog Output High

Scale Value

Low: -19999

High: 45536

100.0 BC

(212.0 BF )

6 : Process

value high alarm

7 : Process

value low alarm

AL.FN Alarm function 6

Table of contents

Other Brainchild Controllers manuals

Popular Controllers manuals by other brands

Sensus

Sensus 121 Series Installation and maintenance instructions

Siemens

Siemens SIMATIC S7-1200 CP 1243-8 IRC operating instructions

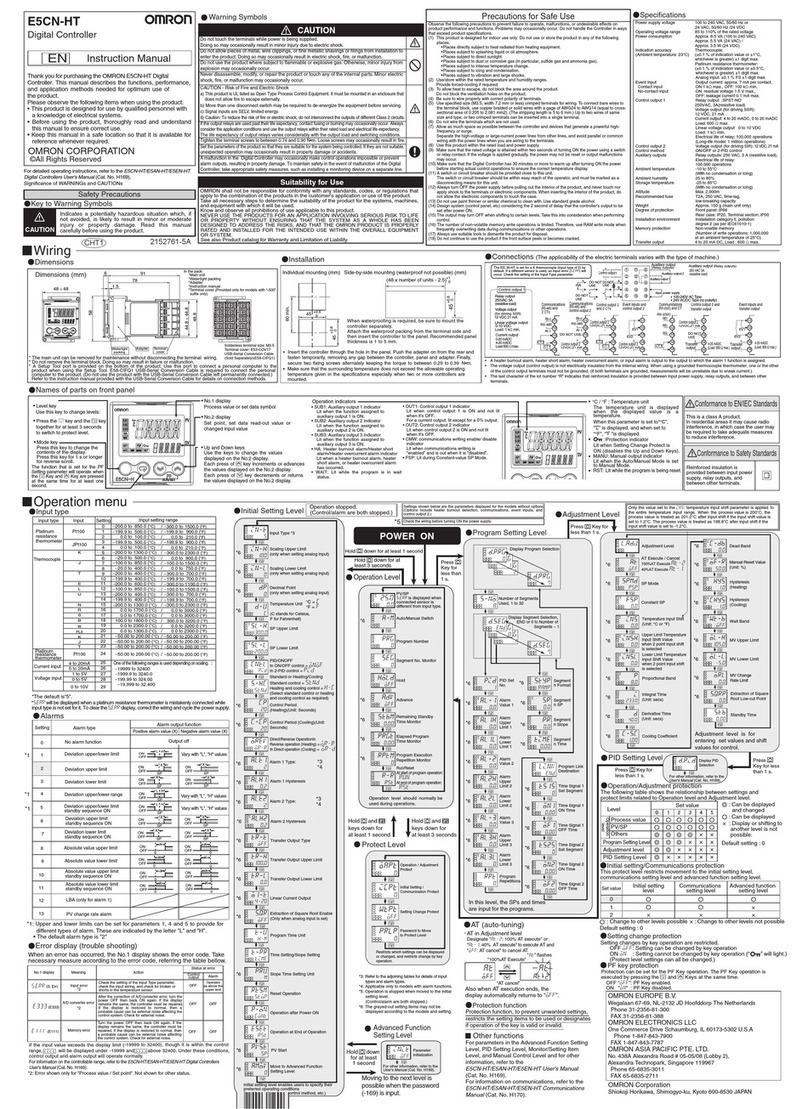

Omron

Omron E5CN-HT instruction manual

London Electronics

London Electronics INTUITIVE-I manual

Massoth

Massoth DiMAX Navigator manual

Siemens

Siemens SINAMICS PM240-2 Hardware installation manual

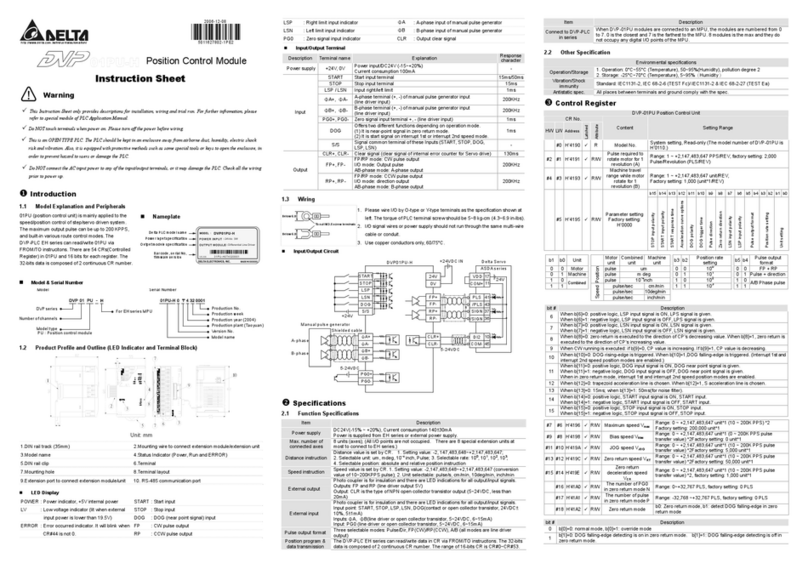

Delta Electronics

Delta Electronics Position Control Module DVP01PU-H instruction sheet

Ekinex

Ekinex EK-AG1-TP quick start guide

OJ Electronics

OJ Electronics PRH Series instructions

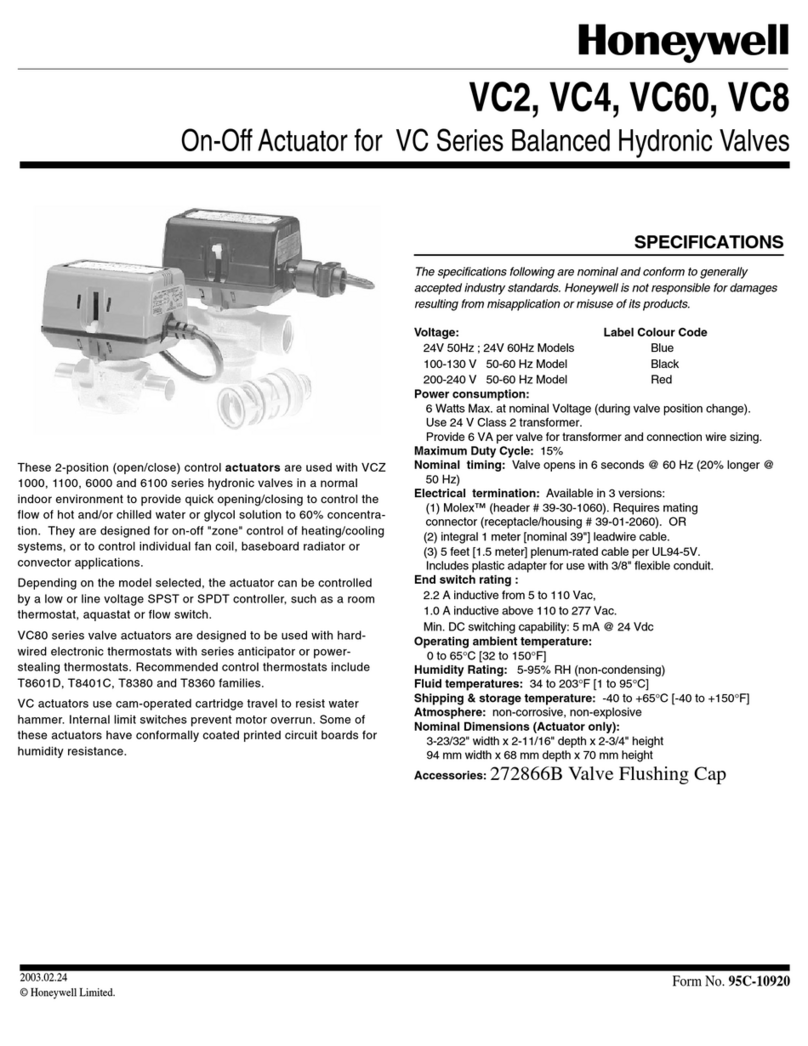

Honeywell

Honeywell VC2 Series, VC4 Series, VC60 Series,... quick start guide

Belimo

Belimo FGVL Series QUICK MOUNT VISUAL INSTRUCTION MANUAL

Smartgen

Smartgen FPC1700 user manual