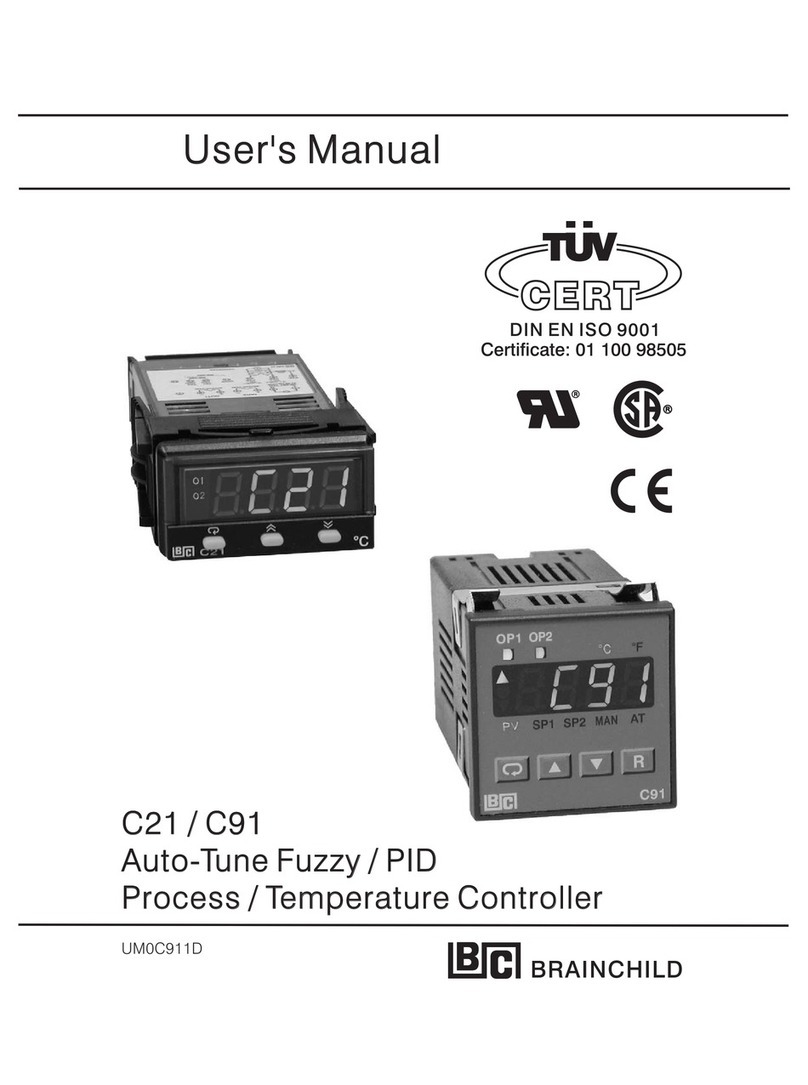

Brainchild P41 User manual

User's ManualUser's Manual

P41 / P91

Auto-Tune Fuzzy / PID

Profiling Controller

P41 /P91

Auto-Tune Fuzzy /PID

Profiling Controller

UM0P411D

DIN EN ISO 9001

Certificate: 01 100 98505

R

L

R

LISTED

U

2UM0P411A

Warning SymbolWarning Symbol

Use the ManualUse the Manual

The Symbol calls attention to an operating procedure, practice, or the

like, which, if not correctly performed or adhered to, could result in

personal injury or damage to or destruction of part or all of the

product and system. Do not proceed beyond a warning symbol until

the indicated conditions are fully understood and met.

The Symbol calls attention to an operating procedure, practice, or the

like, which, if not correctly performed or adhered to, could result in

personal injury or damage to or destruction of part or all of the

product and system. Do not proceed beyond a warning symbol until

the indicated conditions are fully understood and met.

Installers

System Designer

Expert User

Installers

System Designer

Expert User

Read Chapter 1, 2

Read All Chapters

Read Page 15,16

Read Chapter 1, 2

Read All Chapters

Read Page 15,16

NOTE:

It is strongly recommended that a process should incorporate a

LIMIT CONTROL like L91 which will shut down the equipment at

a preset process condition in order to preclude possible

damage to products or system.

It is strongly recommended that aprocess should incorporate a

LIMIT CONTROL like L91 which will shut down the equipment at

apreset process condition in order to preclude possible

damage to products or system.

Information in this user's manual is subject to change without notice.Information in this user's manual is subject to change without notice.

Copyright February 2007, The Brainchild Corporation, all rights

reserved. No part of this publication may be reproduced, transmitted,

transcribed or stored in a retrieval system, or translated into any

language in any form by any means without the written permission of

the Brainchild Corporation.

aCopyright February 2007, The Brainchild Corporation, all rights

reserved. No part of this publication may be reproduced, transmitted,

transcribed or stored in a retrieval system, or translated into any

language in any form by any means without the written permission of

the Brainchild Corporation.

a

This manual is applicable for the products with software version

12 and later version.

This manual is applicable for the products with software version

12 and later version.

3

UM0P411B

Contents

Chapter 1 OverviewChapter 1Overview

Page No

Chapter 2 Installation

Chapter 2Installation

Chapter 3 ConfigurationChapter 3Configuration

3-1 Password---------------------- 44

3-2 Signal Input ------------------ 44

3-3 Event Input ------------------- 45

3-4 Control Outputs ------------- 46

3-5 Alarms ------------------------- 51

3-6 Configure Home Page ----- 55

3-7 User Calibration ------------- 55

3-8 Digital Filter ------------------- 57

3-9 Failure Transfer -------------- 58

3-10 Auto-tuning ----------------- 59

3-11 Manual tuning ------------- 60

3-12 Manual Mode -------------- 62

3-13 Data Communication ---- 62

3-14 Retransmission ------------ 63

3-15 Output Scaling ------------- 64

Chapter 4 Profiler Operation

Chapter 4Profiler Operation

Chapter 5 Applications -------78Chapter 5Applications

Chapter 6 Specifications ---- 80Chapter 6Specifications

Page No

Appendix A-1 ------------------ 97

Appendix A-2 ------------------ 98

Appendix A-1

Appendix A-2

Chapter 7

Modbus Communications --- 86

Chapter 7

Modbus Communications

7-1 Functions Supported -------86

7-2 Exception Responses ------88

7-3 Parameter Table -------------88

7-4 Number System -------------89

7-5 Communication Example --89

1-1 General ------------------------- 5

1-2 Ordering Code ---------------- 9

1-3 Programming Port ---- ----- 11

1-4 Keys and Displays ----------12

1-5 Key Operation Flowchart---15

1-6 Parameter Descriptions ----17

-

2-1 Unpacking -------------------- 32

2-2 Mounting --------------------- 32

2-3 Wiring precautions --------- 34

2-4 Power Wiring ---------------- 36

2-5 Sensor Input Wiring -------- 36

2-6 Control Output Wiring ----- 36

2-7 Alarm /Event Output Wiring ---

----------------------------------- 40

2-8 Event Input Wiring ---------- 41

2-9 Retransmission Output ----tt

Wiring ------------------------- 41

2-10 Data Communication ---- 42

4-1 What is set point profiler ---

4-2 Segment connection -------

4-3 Profiler Modes ---------------

4-4 Running, holding and ----------

aborting a profile -----------

4-5 Viewing and modifying --------

profile progress ------------

4-6 Start ----------------------------

4-7 Holdback ---------------------

4-8 Power failure -----------------

4-9 Configuring the profiler ----

4-10 Viewing and creating a -------

profile ------------------------

4-11 Event Outputs and PID -------

Selection --------------------

65

66

66

67

68

68

68

71

73

73

77

Chapter 8

Manual Calibration ----------- 95

Chapter 8

Manual Calibration

4UM0P411A

Figure 1.1 Fuzzy Control Advantage ------------------------------------------------------------------------------- 6

Figure 1.2 Programming Port Overview -------------------------------------------------------------------------- 11

Figure 1.3 Front Panel Description ------------------------------------------------------------------------------- 13

Figure 1.4 Program code display --------------------------------------------------------------------------------- 14

Figure 2.1 ounting Dimensions --------------------------------------------------------------------------------- 33

Figure 2.2 Lead Termination for P41------------------------------------------------------------------------------ 34

Figure 2.3 Lead Termination for P91------------------------------------------------------------------------------ 34

Figure 2.4 Rear Terminal Connection for P41 -------------------------------------------------------------------35

Figure 2.5 Rear Terminal Connection for P91 ------------------------------------------------------------------ 35

Figure 2.6 Power Supply Connections -------------------------------------------------------------------------- 36

Figure 2.7 Sensor Input Wiring ------------------------------------------------------------------------------------ 36

Figure 2.8 Output 1 Relay or Triac (SSR) to Drive Load ------------------------------------------------------ 36

Figure 2.9 Output 1 Relay or Triac (SSR) to Drive Contactor ------------------------------------------------ 37

Figure 2.10 Output 1 Pulsed Voltage to Drive SSR ------------------------------------------------------------ 37

Figure 2.11 Output 1 Linear Current ----------------------------------------------------------------------------- 38

Figure 2.12 Output 1 Linear Voltage ----------------------------------------------------------------------------- 38

Figure 2.13 Output 2 Relay or Triac (SSR) to Drive Load -----------------------------------------------------38

Figure 2.14 Output 2 Relay or Triac (SSR) to Drive Contactor ---------------------------------------------- 39

Figure 2.15 Output 2 Pulsed Voltage to Drive SSR ----------------------------------------------------------- 39

Figure 2.16 Output 2 Linear Current ----------------------------------------------------------------------------- 39

Figure 2.17 Output 2 Linear Voltage ----------------------------------------------------------------------------- 40

Figure 2.18 Alarm / Event output wiring ------------------------------------------------------------------------- 40

Figure 2.19 Alarm Output to Drive Contactor ------------------------------------------------------------------ 40

Figure 2.20 Event Input wiring ------------------------------------------------------------------------------------ 41

Figure 2.21 Retransmit 4-20 / 0-20 mA Wiring ----------------------------------------------------------------- 41

Figure 2.22 RS-485 Wiring ---------------------------------------------------------------------------------------- 42

Figure 2.23 RS-232 Wiring -----------------------------------------------------------------------------------------43

Figure 2.24 Configuration of RS-232 Cable -------------------------------------------------------------------- 43

Figure 3.1 Conversion Curve for Linear Type Process Value ------------------------------------------------ 45

Figure 3.2 Heat Only ON-OFF Control -------------------------------------------------------------------------- 47

Figure 3.3 Heat - cool Control ------------------------------------------------------------------------------------- 49

Figure 3.4 Process high alarm 1 operation --------------------------------------------------------------------- 51

Figure 3.5 Process low alarm 1 operation ---------------------------------------------------------------------- 51

Figure 3.6 Deviation high alarm 1 operation ------------------------------------------------------------------- 52

Figure 3.7 Deviation low alarm 1 operation -------------------------------------------------------------------- 52

Figure 3.8 Deviation band alarm 1 operation ------------------------------------------------------------------ 53

Figure 3.9 Two point user calibration ---------------------------------------------------------------------------- 56

Figure 3.10 Filter Characteristics -------------------------------------------------------------------------------- 57

Figure 3.11 Effects of PID Adjustment --------------------------------------------------------------------------- 61

Figure 3.12 Output scaling function ----------------------------------------------------------------------------- 64

Figure 4.1 Set point profile ---------------------------------------------------------------------------------------- 65

Figure 4.2 Holdback operation ----------------------------------------------------------------------------------- 70

Figure 4.3 Recovery from profile at dwell segment ----------------------------------------------------------- 71

Figure 4.4 Recovery from profile at ramp segment ------------------------------------------------------------71

Figure 4.5 Recovery from PV at dwell segment --------------------------------------------------------------- 72

Figure 4.6 Recovery from PV at ramp segment --------------------------------------------------------------- 72

Figure 4.7 Profiling curve example ------------------------------------------------------------------------------- 75

Figure 5.1 A Heat Treatment Oven ------------------------------------------------------------------------------- 78

Figure 5.2 Temperature profile of the Heat Treatment Oven -------------------------------------------------79

Table 3.1 Password operation ------------------------------------------------------------------------------------ 44

Table 3.2 Heat-Cool control configuration value -------------------------------------------------------------- 46

Table 3.3 Alarm mode description ------------------------------------------------------------------------------- 54

Table 3.4 PID Adjustment Guide ---------------------------------------------------------------------------------- 60

Table 4.1 Segment types ------------------------------------------------------------------------------------------- 65

Table 4.2 Profiler odes -------------------------------------------------------------------------------------------- 67

Table 4.3 Parameters that follow segment type ---------------------------------------------------------------- 74

Table 7.1 Exception Code Table ---------------------------------------------------------------------------------- 88

Table 7.2 Number Conversion Table ----------------------------------------------------------------------------- 89

Table A.1 Error Codes and Corrective Actions ---------------------------------------------------------------- 95

Figures & TablesFigures &Tables Page No

Chapter 1 OverviewChapter 1Overview

1-1 General1-1 General

The Fuzzy Logic plus PID microprocessor-based profiling controller

series, incorporate two bright, easy to read 4-digit LED displays,

indicating process value and set point value. The Fuzzy Logic

technology enables a process to reach a predetermined set point in

the shortest time, with the minimum of overshoot during power-up or

external load disturbance.

P91 is a 1/16 DIN size panel mount profiling controller. It can also be

used for rail mount by adding a rail mount kit. P41 is a 1/4 DIN size

panel mount controller. These units are powered by 11-26 or

90-250 VDC/VAC supply, incorporatinga2amp.controlrelayoutput

as standard. The second output can be used as cooling control, an

event output or an alarm. Both outputs can select triac, logic output,

linear current or linear voltage to drive external device. The units are

fully programmable for PT100 and thermocouple types J, K, T, E, B, R,

S, N, L, C, P with no need to modify the unit. The input signal is

digitized by using a 18-bit A to D converter. Its fast sampling rate

allows the unit to control fast processes.

There are more functions than the heating and cooling control could be

configured for the controller outputs, these include: up to three alarm

outputs, up to three event outputs and up to two analog retransmission

outputs.

Digital communications RS-485 or RS-232 are available as an

additional option. These options allow the units to be integrated with

supervisory control system and software.

A programming port is available for automatic configuration,

calibration and testing without the need to access the keys on front

panel.

By using proprietary Fuzzy modified PID technology, the control

loop will minimize the overshoot and undershoot in a shortest

time. The following diagram is a comparison of results with and

without Fuzzy technology.

profiling

UM0P411A 5

PID control with properly tuned

PID + Fuzzy control

Warm Up Load Disturbance

Set

point

Temperature

Time

Figure 1.1

Fuzzy Control

Advantage

Figure 1.1

Fuzzy Control

Advantage

The series can be configured as a single set point controller (static

mode) or a ramp and dwell profiling controller (profile mode). The

profile mode feature allows the user to program up to 9 profiles of

up to 64 free-format (ramp, dwell, jump or end) segments each. The

total segments available for the product is 288 segments.

The profiling controllers contain the following features:

Flexible Configuration of ProgramFlexible Configuration of Program

Thereareupto64segmentscanbedefinedforaprofile.Each

segment can be configured as a ramp or a dwell (soak) segment or

defining a repeat number of cycles at arbitray location within the profile

and finally terminated by an end segment.The user can edit a currently

running profile.

Maximum Capacity of Program

Maximum Capacity of Program

There are at most 9 profiles can be defined and 288 segments totally

available for all profiles. The profiles are divide into three kinds of length.

The short length profile contains 16 segments, the medium length profile

contains 32 segments while the long length profile contains 64 segments

at most.

Event Input

Event Input

The event input feature allows the user to select one of eight functions:

enter profile run mode, enter profile hold mode, abort profile mode,

enter manual mode, perform failure transfer, enter off mode, advance

to the next segment and select second set of PID values.

UM0P411A

6

Programmable Event OutputsProgrammable Event Outputs

Up to three relays are configurable for event outputs and the state of

each output can be defined for each segment and end of profile.

Analog Retransmission

Analog Retransmission

The output 5 and output 4 (P41 only) of the products can be equipped

with analog output module. The output can be configured for transmitting

the process value as well as set point value.

High Accuracy

High Accuracy

The series are manufactured with custom designed ASIC(Application

Specific Integrated Circuit ) technology which contains a 18-bit A to

D converter for high resolution measurement ( true 0.1 F resolution

for thermocouple and PT100 ) and a 15-bit D to A converter for linear

current or voltage control output. The ASIC technology provides

improved operating performance, low cost, enhanced reliability and

higher density.

B

Fast Sampling Rate

Fast Sampling Rate

The sampling rate of the input A to D converter reaches 5 times/second.

The fast sampling rate allows this series to control fast processes.

Fuzzy ControlFuzzy Control

The function of Fuzzy control is to adjust PID parameters from time to

time in order to make manipulation output value more flexible and

adaptive to various processes. The results is to enable a process to

reach a predetermined set point in the shortest time, with the minimum

of overshoot and undershoot during power-up or external load

disturbance.

Digital Communication

Digital Communication

The units are equipped with RS-485 or RS-232 interface card to

provide digital communication. By using the twisted pair wires there

are at most 247 units can be connected together via RS-485 interface

to a host computer.

UM0P411A 7

Programming PortProgramming Port

A programming port is used to connect the unit to a hand-held

programmer or a PC for quick configuration, also can be connected

to an ATE system for automatic testing & calibration.

Auto-tune

The auto-tune function allows the user to simplify initial setup for a

new system. A clever algorithm is provided to obtain an optimal set

of control parameters for the process, and it can be applied either as

the process is warming up ( cold start ) or as the process has been

in steady state ( warm start ).

Lockout Protection

Lockout Protection

According to actual security requirement, a password is provided to

prevent the unit from being changed abnormally.

Bumpless Transfer

Bumpless Transfer

Bumpless transfer allows the controller to continue to control by

using its previous value as the sensor breaks. Hence, the process

can be well controlled temporarily as if the sensor is normal.

Digital Filter

Digital Filter

A first order low pass filter with a programmable time constant is used

to improve the stability of process value. This is particularly useful in

certain application where the process value is too unstable to be read.

SEL Function

SEL Function

The units have the flexibility for user to select those parameters which

are most significant to him and put these parameters in the home page.

There are at most 8 parameters can be selected to allow the user to

build his own display sequence.

UM0P411A

8

Power InputPower Input

4: 90 - 250 VAC, 47-63 Hz

5: 11 - 26 VAC or VDC,

SELV, Limited Energy

4: 90 -250 VAC, 47-63 Hz

5: 11 -26 VAC or VDC,

SELV, Limited Energy

0: None

1: Relay rated 2A/240VAC

2: Pulsed voltage to drive SSR, 5V/30mA

3: Retransmit 4 - 20mA / 0 - 20mA

4: Retransmit 1 - 5V / 0 - 5V/0 - 10V

6: Triac output 1A / 240VAC,SSR

7: Isolated 20V/25mA

transducer power supply

8: Isolated 12V/40mA

transducer power supply

A: Isolated 5V/80mA

transducer power supply

C: Pulsed voltage to drive SSR, 14V/40mA

9: Special order

0: None

1: Relay rated 2A/240VAC

2: Pulsed voltage to drive SSR, 5V/30mA

3: Retransmit 4 - 20mA /0-20mA

4: Retransmit 1 - 5V /0-5V/0 -10V

6: Triac output 1A /240VAC,SSR

7: Isolated 20V/25mA

transducer power supply

8: Isolated 12V/40mA

transducer power supply

A: Isolated 5V/80mA

transducer power supply

C: Pulsed voltage to drive SSR, 14V/40mA

9: Special order

Output 4Output 4

1: Standard Input

Thermocouple:

J, K, T, E, B, R, S, N, L,

C, P

RTD: PT100 DIN, PT100 JIS

Voltage: 0-60mV

5: 0-10V, 0-1V, 0-5V, 1-5V

6: 0-20/4-20 mA

9: Special Order

1: Standard Input

Thermocouple:

J, K, T, E, B, R, S, N, L,

C, P

RTD: PT100 DIN, PT100 JIS

Voltage: 0-60mV

5: 0-10V, 0-1V, 0-5V, 1-5V

6: 0-20/4-20 mA

9: Special Order

Signal InputSignal Input

0: None

1: Relay rated 2A/240VAC

2: Pulsed voltage to drive SSR, 5V/30mA

3: Isolated 4 - 20mA / 0 - 20mA

4: Isolated 1 - 5V / 0 - 5V/0 - 10V

6: Triac output 1A / 240VAC,SSR

7: Isolated 20V/25mA transducer power supply

8: Isolated 12V/40mA transducer power supply

A: Isolated 5V/80mA transducer power supply

C: Pulsed voltage to drive SSR, 14V/40mA

9: Special order

0: None

1: Relay rated 2A/240VAC

2: Pulsed voltage to drive SSR, 5V/30mA

3: Isolated 4 - 20mA / 0 - 20mA

4: Isolated 1 - 5V / 0 - 5V/0 -10V

6: Triac output 1A /240VAC,SSR

7: Isolated 20V/25mA transducer power supply

8: Isolated 12V/40mA transducer power supply

A: Isolated 5V/80mA transducer power supply

C: Pulsed voltage to drive SSR, 14V/40mA

9: Special order

P91-

1-2 Ordering Code1-2 Ordering Code

0: Panel mount IP50 standard

1: Panel mount IP65 water resistant

rubber installed

2: DIN rail mount with IP50

(for P91 only)

3: DIN rail mount with IP65

(for P91 only)

0: Panel mount IP50 standard

1: Panel mount IP65 water resistant

rubber installed

2: DIN rail mount with IP50

(for P91 only)

3: DIN rail mount with IP65

(for P91 only)

Options

0: None

1: Relay rated 2A/240VAC

2: Pulsed voltage to drive SSR, 5V/30mA

6: Triac output 1A / 240VAC,SSR

7: Isolated 20V/25mA transducer power supply

8: Isolated 12V/40mA transducer power supply

A: Isolated 5V/80mA transducer power supply

C: Pulsed voltage to drive SSR, 14V/40mA

9: Special order

0: None

1: Relay rated 2A/240VAC

2: Pulsed voltage to drive SSR, 5V/30mA

6: Triac output 1A /240VAC,SSR

7: Isolated 20V/25mA transducer power supply

8: Isolated 12V/40mA transducer power supply

A: Isolated 5V/80mA transducer power supply

C: Pulsed voltage to drive SSR, 14V/40mA

9: Special order

Output 3Output 3

0: None

1: Relay rated 2A/240VAC

2: Pulsed voltage to drive SSR,

5V/30mA

3: Isolated 4 - 20mA / 0 - 20mA

4: Isolated 1 - 5V / 0 - 5V/0 - 10V

6: Triac output 1A / 240VAC,SSR

C: Pulsed voltage to drive SSR,

14V/40mA

9: Special order

0: None

1: Relay rated 2A/240VAC

2: Pulsed voltage to drive SSR,

5V/30mA

3: Isolated 4 - 20mA /0-20mA

4: Isolated 1 - 5V / 0 - 5V/0 -10V

6: Triac output 1A /240VAC,SSR

C: Pulsed voltage to drive SSR,

14V/40mA

9: Special order

Output 2Output 2

UM0P411C

Output 1Output 1

9

Output 5Output 5

0: None

3: Retransmit 4 - 20mA / 0 - 20mA

4: Retransmit 1 - 5V / 0 - 5V/0 - 10V

7: Isolated 20V/25mA

transducer power supply

8: Isolated 12V/40mA

transducer power supply

A: Isolated 5V/80mA

transducer power supply

D: Isolated RS-485 interface

E: Isolated RS-232 interface

0: None

3: Retransmit 4 - 20mA /0-20mA

4: Retransmit 1 - 5V / 0 - 5V/0 -10V

7: Isolated 20V/25mA

transducer power supply

8: Isolated 12V/40mA

transducer power supply

A: Isolated 5V/80mA

transducer power supply

D: Isolated RS-485 interface

E: Isolated RS-232 interface

P41-

0

Standard leave blank

Special Order AA-ZZ

Standard leave blank

Special Order AA-ZZ

OM94-6 = Isolated 1A / 240VAC Triac Output Module ( SSR )

OM94-7 = 14V / 40mA SSR Drive Module

OM98-3 = Isolated 4 - 20 mA /0-20mA Analog Output Module

OM98-5 = Isolated 0 -10V Analog Output Module

CM94-1 = Isolated RS-485 Interface Module for P41 Output 5

CM94-2 = Isolated RS-232 Interface Module for P41 Output 5

CM94-3 = Isolated 4-20mA/0-20mA Retrans Module for P41 Output 5

CM94-5 = Isolated 0-10V Retrans Module for P41 Output 5

CM97-1 = Isolated RS-485 Interface Module for P91 Output 5

CM97-2 = Isolated RS-232 Interface Module for P91 Output 5

CM97-3 = Isolated 4-20mA/0-20mA Retrans Module for P91 Output 5

CM97-5 = Isolated 0-10V Retrans Module for P91 Output 5

DC94-1 = Isolated 20V/25mA DC Output Power Supply

DC94-2 = Isolated 12V/40mA DC Output Power Supply

DC94-3 = Isolated 5V/80mA DC Output Power Supply

DC97-1 = Isolated 20V/25mA DC Output Power Supply for P91 Output 5

DC97-2 = Isolated 12V/40mA DC Output Power Supply for P91 Output 5

DC97-3 = Isolated 5V/80mA DC Output Power Supply for P91 Output 5

CC94-1 = RS-232 Interface Cable ( 2M )

CC91-1 = Programming Port Cable

RK91-1 = Rail Mount kit for BTC-9100 / P91

DC21-1 = Isolated 20V/25mA DC Output Power Supply for P41 Output 5

DC21-2 = Isolated 12V/40mA DC Output Power Supply for P41 Output 5

DC21-3 = Isolated 5V/80mA DC Output Power Supply for P41 Output 5

OM94-6 = Isolated 1A / 240VAC Triac Output Module ( SSR )

OM94-7 = 14V / 40mA SSR Drive Module

OM98-3 = Isolated 4 - 20 mA / 0 - 20 mA Analog Output Module

OM98-5 = Isolated 0 -10V Analog Output Module

CM94-1 = Isolated RS-485 Interface Module for P41 Output 5

CM94-2 = Isolated RS-232 Interface Module for P41 Output 5

CM94-3 = Isolated 4-20mA/0-20mA Retrans Module for P41 Output 5

CM94-5 = Isolated 0-10V Retrans Module for P41 Output 5

CM97-1 = Isolated RS-485 Interface Module for P91 Output 5

CM97-2 = Isolated RS-232 Interface Module for P91 Output 5

CM97-3 = Isolated 4-20mA/0-20mA Retrans Module for P91 Output 5

CM97-5 = Isolated 0-10V Retrans Module for P91 Output 5

DC94-1 = Isolated 20V/25mA DC Output Power Supply

DC94-2 = Isolated 12V/40mA DC Output Power Supply

DC94-3 = Isolated 5V/80mA DC Output Power Supply

DC97-1 = Isolated 20V/25mA DC Output Power Supply for P91 Output 5

DC97-2 = Isolated 12V/40mA DC Output Power Supply for P91 Output 5

DC97-3 = Isolated 5V/80mA DC Output Power Supply for P91 Output 5

CC94-1 = RS-232 Interface Cable ( 2M )

CC91-1 = Programming Port Cable

RK91-1 = Rail Mount kit for BTC-9100 / P91

DC21-1 = Isolated 20V/25mA DC Output Power Supply for P41 Output 5

DC21-2 = Isolated 12V/40mA DC Output Power Supply for P41 Output 5

DC21-3 = Isolated 5V/80mA DC Output Power Supply for P41 Output 5

Accessories

SNA12A = Smart Network Adapter for programming port to RS-232

interface

BC-Set = Configuration Software

SNA12A = Smart Network Adapter for programming port to RS-232

interface

BC-Set = Configuration Software

Related ProductsRelated Products

UM0P411A

10

SNA10A = Smart Network Adaptor for Brainchild Software Communicator

- or third party software, which converts 255 channels of

- RS-485 or RS-422 to RS-232 Network.

SNA10A = Smart Network Adaptor for Brainchild Software Communicator

-or third party software, which converts 255 channels of

-RS-485 or RS-422 to RS-232 Network.

1-3 Programming Port1-3 Programming Port

A special connector can be used to touch the programming port

which is connected to a PC for automatic configuration, also can be

connected to an ATE system for automatic calibration and testing.

The programming port is used for off-line automatic setup and testing

procedures only. Don't attempt to make any connection to these pins

when the unit is used for a normal control purpose.

UM0P411A 11

Front

Panel

Rear

Terminal

Access HoleAccess Hole

1

3

!

4

"

6

$

Figure 1.2

Programming Port

Overview

Figure 1.2

Programming Port

Overview

2

5

#

1- 4 Keys and Displays1- 4 Keys and Displays

KEYPAD OPERATIONKEYPAD OPERATION

SCROLL KEY :

UP KEY :

DOWN KEY :

PAGE KEY:

This key is used to select a parameter to be viewed or adjusted.

This key is used to increase the value of selected parameter.

This key is used to decrease the value of selected parameter.

This key is used to select desired page of parameters.

SCROLL KEY :

UP KEY :

DOWN KEY :

PAGE KEY:

Press both and keys to :

1. Revert the display to display the process value.

2. Reset the latching alarm, once the alarm condition is

removed.

3. Stop the manual control mode , auto-tuning mode and off

mode, then enters the static mode.

4. Clear the message of communication error, holdback time

out error and auto-tuning error.

5. To reset new profile start segment to 1.00 after earlier profile is

completed when " RUN" and "HLD" LED's are blinking together.

ENTER KEY : Press for 5 seconds to :

1. Enter the selected mode to run.

2. Execute calibration procedure for the low point and high point

calibration.

ENTER KEY :

UM0P411B

12

REVERSE SCROLL :REVERSE SCROLL :

Press both and keys to jump to the previous parameter.

RESET KEY :RESET KEY :

P41

Out3

Out4

Out2

Out1

RUN

HLD

58

28

LCLC

LFLF

Output Status

indicators for

output1~output 4

Upper Display, to display process value,

menu symbol and error code etc.

Lower Display, to display set point value,

parameter value or control output value etc.

4 Buttons for ease of control setup and

set point adjustment.

On : profile held

Flashing: profile in holdback

state

On : profile running

Flashing: profile in delayed state

: Running ramp up segment

:Running ramp down segment

: Running dwell segment

: profile held or in static

mode

Both off

Figure 1.3 Front Panel DescriptionFigure 1.3 Front Panel Description

UM0P411B 13

OP1 OP2 OP3

RUN

P91

CF

HLD

4 Buttons for ease of control setup and

set point adjustment.

: Running ramp up segment

:Running ramp down segment

: Running dwell segment

: profile held or in static

mode

Both off

Upper Display, to display process

value, menu symbol and error code

etc.

Lower Display, to display set point

value, parameter value or control

output value etc.

Output Status indicators for output1~output 3

On : profile held

Flashing: profile in holdback state

On : profile running

Flashing: profile in delayed state

Figure 1.4 Program code displayFigure 1.4 Program code display

The unit will display the program code

for 2.5 seconds during power up.

The display shows program number 37

with program version 12.

The program no. for P41 is 37 and for

P91 is 38.

UM0P411A

14

P41

Out3

Out4

Out2

Out1

RUN

HLD

58

28

LCLC

LFLF

DLLT

P2EV

HB

TGSP

P2EV

HB

DLLT

P2EV

HB

SEG

CYCL

SGNO

SGTY

FSP

CYCL

SEG

CYCL

SGNO

SGTY

TGSP

P2EV

HB

( 1-9 )

HBBD

STSP

RMPU

DLLU

SGNO

SGTY

FSP

CYCL

UM0P411B

1-5 Key Operation Flowchart1-5 Key Operation Flowchart

ASP1

PASS

ASP2

ASP3

INPT

DP

UNIT

PB1

TI1

TD1

DLAY

CYC1

PV

Home PageHome Page Mode PageMode Page

58

PV

TIME

CYCL

PV

PV

(MODE)

(Profile run mode)

(Profile hold mode)

(Static mode)

(Automatic tuning PID1 mode)

(Manual mode)

(Off mode)

Home

Display

Home

Display

(Automatic tuning PID2 mode)

Using / key to select

desired mode, then

5sec.

Enters the selected mode

Profile PageProfile Page

15

(CALO)

(OFSTL)

PV

Using or key to

adjust the offset low value

(lower display) until the

process value (higher display)

is equal to the required value,

then

(CAHI)

(OFSTH)

PV

Using or key to

adjust the offset high value

(lower display) until the

process value (higher display)

is equal to the required value,

then

5sec.

Complete calibration

procedure for the

high point calibration.

5sec.

Complete calibration

procedure for the

low point calibration.

Low

Calibration

Page

Low

Calibration

Page

High

Calibration

Page

High

Calibration

Page

UM0P411C

INPT

UNIT

DP

INLO

SPLO

FILT

O1HY

INHI

O1FT

SPHI

EIFN

CYC1

OP1L

OP1H

OUT2

O2FT

CYC2

PB1

PB2

OUT1

TI1

TI2

TD1

TD2

OFST

CPB

DB

OP2L

OP2H

O3FT

OUT3

OUT4

O4FT

OUT5

REH4

REL4

OP4H

OP4L

OP5L

OP5H

REL5

REH5

ADDR

BAUD

PARI

ALF1

A1MD

A1HY

Configuration

Page

Configuration

Page

ALF2

A2MD

A2HY

ALF3

A3MD

A3HY

STAR

END

DLAY

PFR

HBT

CODE

SEL1

SEL2

SEL3

SEL4

SEL5

SEL6

SEL7

SEL8

INPT

16

5sec.

5sec.

1-6 Parameter Descriptions1-6 Parameter Descriptions

Parameter

Notation

Parameter Description Range Default

Value

Indicate the current

Profile/Segment

number

Time remaining for

the current segment

Low: 1.00 High: 9.63

Low: 00.00 High: 99.59

TIME

CYCL cycle remaining for

the current profile

Low: 1 High: 9999

10000=infinite

Set point for alarm 1 Low: -32768 High: 32767 10.0 C

(18.0 F)

B

B

ASP1

Set point for alarm 2 10.0 C

(18.0 F)

B

B

Set point for alarm 3 10.0 C

(18.0 F)

B

B

ASP2

ASP3

Password entry 1

SP1 Controller (Static mode)

Set point value Low: SPLO High: SPHI 25.0 C

(77.0 F)

B

B

Profile number

Segment number

Register

Address

0

Data

type

R/W

1

2

3

5

6

7

R/W

PFSG

Low: -32768 High: 32767

Low: -32768 High: 32767

R/W

R/W

R/W

4Low: 0 High: 9999 R/W

UM0P411A

R/W

R

1.00

PASS

INPT

0

1

2

3

4

5

6

: T type T/C

: E type T/C

: B type T/C

: R type T/C

: S type T/C

: J type T/C

: K type T/C

7

8

11

12

: N type T/C

: L type T/C

: PT 100 ohms

DIN curve

: PT 100 ohms

JIS curve

Input sensor

selection

1

(0)

9

10

: C type T/C

: P type T/C

R/W

8

(T/C=thermocouple)

17

UM0P411A

UNIT

DP

15

16

13

14

: 4 - 20 mA linear

current input

: 0 - 20 mA linear

current input

: 0 - 1V linear

voltage input

: 0 - 60 mV linear

millivolt input

17

18

19

: 0 - 5V linear

voltage input

: 1 - 5V linear

voltage input

: 0 - 10V linear

voltage input

Input unit

selection

0

1

2

: Degree C unit

: Degree F unit

: Process unit

0

(1)

Decimal point

selection

0

1

2

3

1

: No decimal point

: 1 decimal digit

: 2 decimal digits

: 3 decimal digits

Parameter

Notation

Parameter

Description Range Default

Value

Register

Address

Data

type

9

10

R/W

R/W

INPT Input sensor

selection

81

(0) R/W

MODE

11 Operation mode

0 :Profile run mode

1 :Profile hold mode

2 :Static mode

3 :Automatic tuning

PID1 mode

4 : Automatic tuning

PID2 mode

6 :Off mode

R/W

0

5 :Manual mode

INLO

INHI

Input low scale

value

Input high scale

value

-32768

INLO+50

INHI-50

32767

Low:

Low:

High:

High:

-17.8 C

(0F)

L

L

93.3 C

(200.0 F)

LL

12

13

R/W

R/W

18

SPLO

SPHI

FILT

OUT1

Low limit of set

point value

-17.8 C

(0 F)

L

L

High limit of set

point value

537.8 C

(1000 F)

L

L

-32768 High: SPHI

Low:

SPLO High: 32767

Low:

Filter damping

time constant

of PV

00 second time

constant

:

1 0.2 second time

constant

:

830 seconds time

constant

:

960 seconds time

constant

:

720 seconds time

constant

:

610 seconds time

constant

:

55 seconds time

constant

:

42 seconds time

constant

:

31 second time

constant

:

20.5 second time

constant

:

2

3

Output 1

function

Parameter

Notation

Parameter

Description Range Default

Value

Register

Address

Data

type

16

17

14

EIFN

15

0 : No function

1 : Heating on-off control

4 : Cooling on-off control

2 : Heating time

proportioning control

3 : Heating linear control

5 : Cooling time

proportioning control

6 : Cooling linear control

0 : No function

1 : Program run mode

2 : Program hold mode

3 : Abort profile mode

7 : Pass to the next

segment

8 : Select PB2 TI2 &

TD2 for control

18

0

UM0P411A

R/W

R/W

R/W

R/W

R/W

Event input

function

6 : Off mode

4 : Manual mode

5 : Failure Transfer

19

O1FT

O1HY

CYC1

Output 1 failure

transfer status

Select BPLS ( bumpless

transfer ) or 0.0 ~ 100.0 % to

continue output 1 control

function as the unit fails, or

select OFF (0) or ON (1) for

ON-OFF control.

0

Output 1 ON-OFF

control hysteresis

Low: 0.1 High:50.0 C(90.0 F)BB

0.1 C

(0.2 F)

L

L

Output 1 cycle

time Low: 0.1 High: 90.0 sec. 18.0

Proportional

band value 1

10.0 C

(18.0 F)

L

L

Low: 0 High: 500.0 C

(900.0 F)

L

L

Integral time

value 1

Derivative time

value 1

100

25.0

Low: 0

Low: 0

High: 3600 sec

High: 900.0 sec

OP1L Low limit value for

output 1 Low: 0 High: 100.0 % 0

OP1H High limit value

for output 1 Low: 0 High: 120.0 % 100.0

Parameter

Notation

Parameter

Description Range Default

Value

Register

Address

Data

type

19

20

21

22

23

24

25

26

PB1

TI1

TD1

Proportional

band value 2

10.0 C

(18.0 F)

L

L

Low: 0 High: 500.0 C

(900.0 F)

L

L

Integral time

value 2

Derivative time

value 2

100

25.0

Low: 0

Low: 0

High: 3600 sec

High: 900.0 sec

27

28

29

PB2

TI2

TD2

Offset value for

P control (TI=0) Low : 0.0 25.0

High : 100.0%

30 OFST

31

32

OUT2 Output 2 function

0 : No function

1 : Cooling time

proportioning control

2 : Cooling linear control

5 : Event 1 output

3

33

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Reserved

Reserved

UM0P411A

6 : DC power supply

output

20

3 : Alarm 1 output

4 : Reverse alarm 1

Output

This manual suits for next models

1

Table of contents

Other Brainchild Controllers manuals