Brainchild HMI 4.3 User manual

UMHW01A

Rev 3/2012

User Manual

HMI Hardware

2

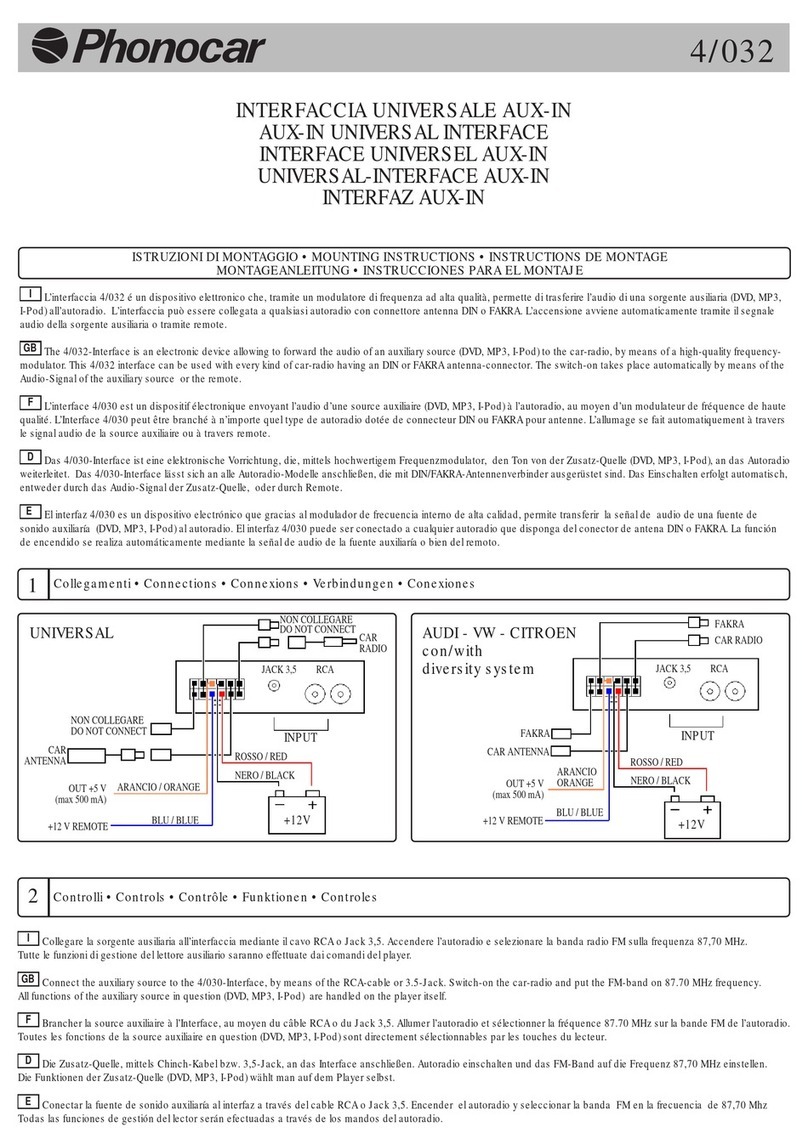

GRAPHIC SYMBOLS

INFORMATION, it helps users with more details about the topic and failure

to follow may lead to unpredictable results.

WARNING, Failure to follow may lead to minor in ury or damage /

malfunctioning of equipment

DANGER, Failure to follow may lead to in ury or fatal accident to operating

personal or damage/malfunctioning of equipment

CAUTION, Failure to follow may lead to malfunctioning of equipment,

damage or repair

Protective Earth

DC Supply

PREFACE

Original equipment manufacturer reserves the right to change information

available in this document without notice. Original Equipment manufacturer is not

liable for any damages incurred to equipment/personal during installation or use

of equipment as explained in this document. User must acquire sufficient

knowledge & skills prior to use the equipment in the application and follow all the

local standards & regulations to meet safety requirements

WinCE is registered trade mark of Microsoft Corporation

3

TABLE OF CONTENTS

1. GENERAL .............................................................................................. 4

1.1

I

NSTRUCTIONS

...............................................................................................................4

1.2

S

TANDARDS

,

C

ERTIFICATES AND

A

PPROVALS

..................................................................6

1.3

B

ASE

S

TANDARDS FOR

EMC

&

S

AFETY

..........................................................................6

1.4

P

ROTECTIVE CLASS

........................................................................................................6

1.5

T

RANSPORT

&

S

TORAGE CONDITIONS

.............................................................................7

1.6

O

PERATING CONDITIONS

.................................................................................................7

1.7

LCD

SPECIFICATIONS

.....................................................................................................8

1.8

P

ACKAGE CHECK LIST

.....................................................................................................8

2. PRO UCTS OVERVIEW ....................................................................... 9

2.1.1

Technical Specifications .......................................................................................9

3. OR ERING CO E ............................................................................... 11

3.1

HMI

ORDERING CODE

...................................................................................................11

3.2

HMI

S

PARES PART LIST

................................................................................................12

3.2.1

HMI 4.3” ..............................................................................................................12

3.2.2

HMI 7” (Low Cost)...............................................................................................12

3.2.3

HMI 7” (High Performance).................................................................................12

3.2.4

HMI 10” ...............................................................................................................13

3.2.5

HMI 15” ...............................................................................................................13

3.3

R

ESERVED

...................................................................................................................14

3.4

A

CCESSORIES PART NUMBERS

......................................................................................14

4. INSTALLATION.................................................................................... 15

4.1

I

NSTALLATION

...............................................................................................................15

4.2

D

IMENSIONAL DRAWINGS

..............................................................................................17

4.2.1

Dimensional drawings of the HMI 4.3” ................................................................17

4.2.2

Dimensional drawings of the HMI 7” ...................................................................18

4.2.3

Dimensional drawings of the HMI 10” .................................................................19

4.2.4

Dimensional drawings of the HMI 15” .................................................................20

4.3

M

OUNTING

...................................................................................................................21

4.4

P

OWER

S

UPPLY

...........................................................................................................22

4.5

I

NTERFACES

.................................................................................................................24

4.5.1

COM1 port, DB9 male (RS232C)........................................................................24

4.5.2

COM2 port, DB25 Female (RS232C/RS422/RS485) .........................................25

4.5.3

COM3 (Reserved)...............................................................................................26

4.5.4

Ethernet...............................................................................................................26

4.5.5

USB Host ............................................................................................................26

4.5.6

SD slot.................................................................................................................26

4.5.7

Sound input/Output .............................................................................................27

4.5.8

Reserved.............................................................................................................27

4.6

R

EAL

T

IME

C

LOCK

........................................................................................................27

4.7

HMI

R

ESET

P

ROCEDURE

..............................................................................................27

4

1. General

1.1 Instructions

Read Installation and Operation manuals carefully before installation, repairs, or

commissioning of the equipment

Follow all local standards/regulations for using electrical power supply, connection to the

equipment, grounding, shielding during installation and commissioning.

Obtain sufficient skills and training before using the equipment.

If any damages are observed in transportation, inform (to) the supplier with supporting

information including product details and photographs.

General Precaution

Use Restriction

These products are not authorized for use in life supporting systems, aircraft

navigation control systems, military systems and any other application where

performance failure could be life threatening or otherwise catastrophic.

isassembling or Modification

Do not disassemble or modify LCD module. It may damage sensitive parts inside

LCD module and may cause scratches of dust on display. Manufacturer does not

warrant the module if customers disassemble or modify LCD module.

Breakage of LC display

If LCD display is broken and liquid crystal spills out, do not ingest or inhale liquid

crystal and do not contact liquid crystal with skin.

If liquid crystal comes in contact mouth or eyes, rinse out with water immediately.

If liquid crystal comes in contact with skin or clothes, wash it off immediately with alcohol

and rinse thoroughly with water.

Handle carefully any chips of glass it may cause in ury, when glass is broken.

5

Absolute ratings

Do not exceed the absolute maximum rating values such as supply voltage,

environment temperature etc, otherwise LCD module might get damaged.

Please do not leave LCD module in the environment of high humidity and high

temperature for long time.

It is recommended to employ protection circuit for power supply.

Operation

Do not touch, push or rub the LCD display surface with any thing harder than HB

pencil lead.

Use fingerstalls of soft gloves in order to keep clean display quality.

When LCD display surface is dusty, please wipe gently with absorbent cotton or other

soft material.

Wipe off saliva or water drops as soon as possible. If saliva or water drops contact with

polarizer for a long time, they may cause deformation or color fading.

When cleaning the adhesives, please use absorbent cotton wetted with a little petroleum

benzene or other adequate solvent.

Static Electricity

Protection film must remove very slowly from the surface of LCD module to

prevent from electrostatic occurrence. Persons handle the LCD display should be

grounded through adequate methods.

Strong light exposure

The LCD display shall be not exposed to strong light such as direct sunlight. LCD

display characteristics may be changed.

isposal

When disposing LCD module, obey the local environmental regulations.

6

1.2 Standards, Certificates and Approvals

The table below shows the approvals that may be available.

escription etails

UL approval UL 508 and CSA C22.2 No.142

Low Voltage Directive 2006/95/EC

EMC Directive 2004/108/EC

Requirements for Emission EN 61000-6-4 :2007

Requirements for Interference

Immunity

EN 61000-6-2 :2005

Tick mark for Australia AS/NZS CISPR 11:2004

FCC FCC Part 15, Subpart B, Class A

1.3 Base Standards for EMC & Safety

escription etails

Electrostatic discharge IEC 61000-4-2: 2008

Radiated radio-frequency

electromagnetic fields

IEC 61000-4-3: 2006 + A1:2007 +

A2:2010

Electrical fast transient/burst IEC 61000-4-4: 2004 + A1: 2010

Surge IEC 61000-4-5: 2005

Conducted disturbances induced

by radio-frequency fields

IEC 61000-4-6: 2008

Power frequency magnetic field IEC 61000-4-8: 2009

Voltage dips, short interruptions

and voltage variations

IEC 61000-4-11: 2004

Emission from Electromagnetic

fields

CISPR 11:2009 + A1:2010 Class A

Harmonics Current IEC61000-3-2:2005 + A1:2008 +

A2:2009

Voltage Fluctuation and Flicks IEC61000-3-3:2008

Requirements for Safety EN61010-1:2001

1.4 Protective class

escription etails

Standard enclosures IP 65 (Front), IP20 housing and

terminals

Stainless steel front – Option IP 66K (Front), IP20 housing and

terminals

7

1.5 Transport & Storage conditions

The following specifications apply

escription etails

Drop with packing conforming to

IEC 60068-2-31

10 drops from 60cm on 1 corner,

3 edges, 6 surfaces

Drop with out packing Nil

Temperature -20

0

C to + 60

0

C

Relative Humidity 10% to 90%, no condensation

Altitude 2000 meters maximum

Sinusoidal vibration conforming to

IEC 60068-2-6

5 to 10 Hz: 3.5 mm amplitude

10 to 150 Hz: 2g 1oct/min. 40

sweeps

Shock conforming to IEC 60068-2-

29

3 shocks per direction 11ms 15g

Best conditions for storage of LCD display modules

1. Room ambient temperature 15

0

to 35

0

C and 65% RH or less.

2. Do not store in surroundings containing organic solvent or corrosive gas.

3. Store HMI in anti-electrostatic container or bag.

1.6 Operating conditions

escription etails

Temperature 0

0

C to + 50

0

C

Relative Humidity 10% to 90%, no condensation

Altitude 2000 meters maximum

Pollution Degree 2

Sinusoidal vibration conforming to

IEC 60068-2-6

10 to 58Hz: 0.75mm amplitude

58 to 150Hz: 1g 1oct/min. 1

sweep

Shock conforming to IEC 60068-2-

29

3 shocks per direction 11ms 10g

In the case of temperatures below 0

O

C, the response time of liquid crystal

becomes slower and color of the display will be darker than normal. Do not operate HMI

in ambient temperature less than 0

O

C.

8

1.7 LC specifications

escription etails

Touch operations 1,000,000 times using R 0.8

Polyacetal stylus with force 250g

Vibration test 10-55 Hz, Stroke: 1.5mm, Sweep:

10-55-10Hz, 2 hrs. for each

direction of X, Y, Z

Shock test 100 G, 6 ms, +/- X, +/- Y, +/- Z,

3 times for each direction

Package vibration test 0.015G*G/Hz from 5-200 Hz,

-6bB /Octave from 200-500 Hz,

2 hrs for each direction of X, Y, Z

Package drop test 10 drops from 60 cm on 1 corner,

3 edges, 6 surfaces

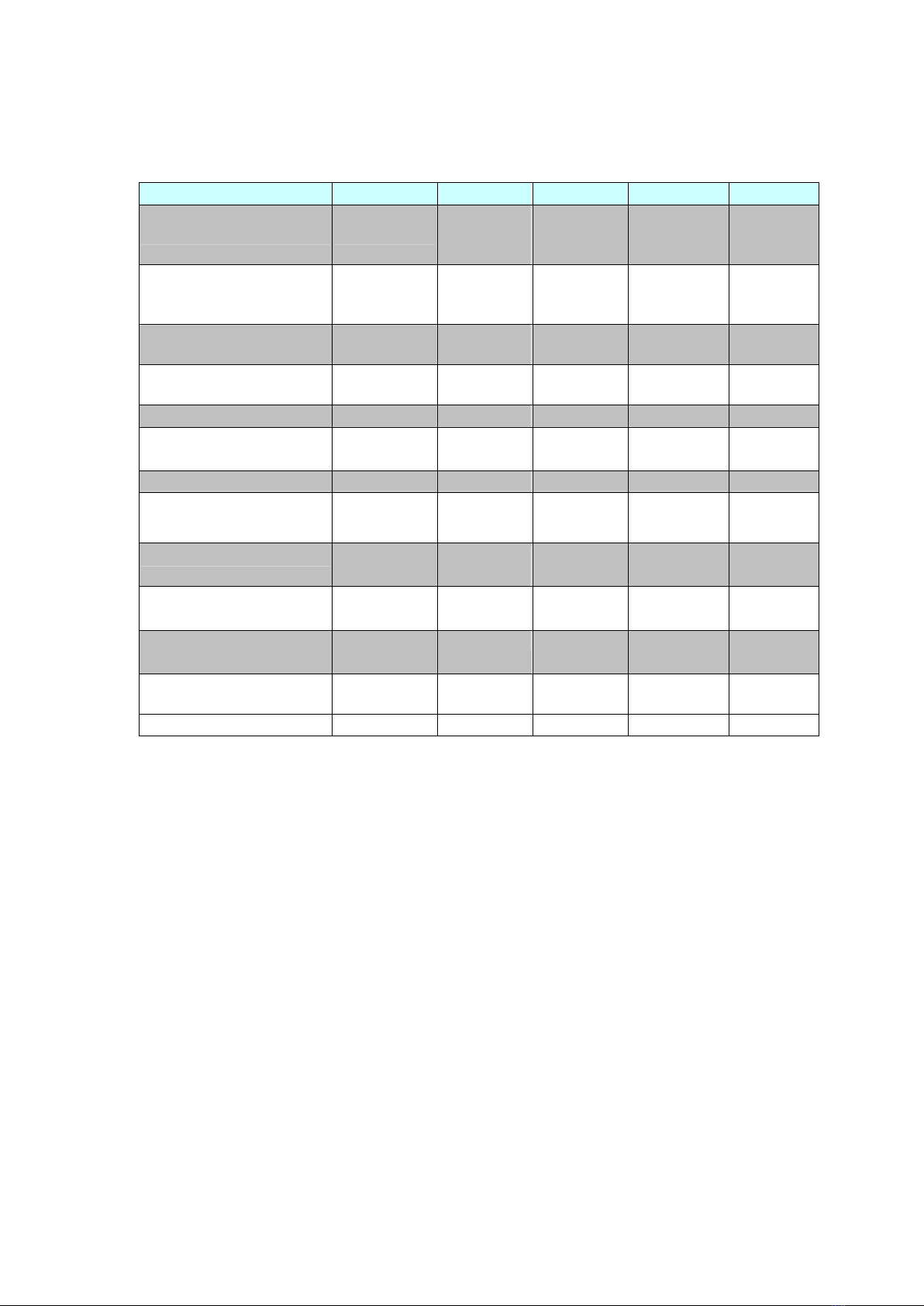

Typical View Angle

Model HMI 4.3” HMI 7”

(LOW

COST)

HMI 7” (HIGH

PERFORMANCE)

HMI 10” HMI 15”

Vertical

(Up/Down)

50

O

/ 70

O

50

O

/ 70

O

50

O

/ 70

O

60

O

/ 70

O

80

O

/ 80

O

Horizontal

(Left/Right)

70

O

/ 70

O

70

O

/ 70

O

70

O

/ 70

O

75

O

/ 75

O

85

O

/ 85

O

1.8 Package check list

escription etails

HMI device

Power supply Connector

Mounting kit

CD with BSP and User manual

9

2. Products Overview

Five HMI models HMI 4.3”, HMI 7” (Low Cost), HMI 7” (High Performance), HMI 10” &

HMI 15” are available.

2.1.1 Technical Specifications

Model HMI 4.3”

HMI 7”

(LOW

COST)

HMI 7” (HIGH

PERFORMANCE)

HMI 10”

HMI 15”

Size 4.3" 7" 7" 10" 15"

Resolution

(W X H in pixels)

480 x 272 800 x 480

800 x 480 1024 x 768

1024 x 768

Display type TFT, Wide

touch

Screen

TFT, Wide

touch

Screen

TFT, Wide touch

Screen

TFT touch

screen

TFT touch

screen

Colors 65,536 65,536 65,536 65,536 65,536

Touch screen Type Resistive

analog

Resistive

analog Resistive analog

Resistive

analog

Resistive

analog

Active display area

(W X H mm)

95 X 54 152 X 91

152 X 91 203 X 152

304 X 228

MTBF back light at 25

0

C

30,000 hrs 50,000 hrs

50,000 hrs 50,000 hrs 50,000 hrs

Backlight LED LED LED LED CCFL

Brightness Ad ustment Yes Yes Yes Yes Yes

Screen Saver Yes Yes Yes Yes Yes

Language Fonts Yes Yes Yes Yes Yes

Main Hardware

Processor, CPU speed ARM11,

533Mhz

ARM11,

533Mhz ARM Cortex-A8,

667Mhz

ARM

Cortex-A8,

667Mhz

ARM

Cortex-A8,

667Mhz

Flash Memory(ROM) 128 MB 128 MB 128 MB 128 MB 128 MB

SDRAM(RAM) 128 MB 128 MB 256 MB 256 MB 256 MB

Operating system WinCE 6.0 WinCE 6.0

WinCE 6.0 WinCE 6.0 WinCE 6.0

Real Time Clock Yes Yes Yes Yes Yes

Buzzer Yes Yes Yes Yes Yes

Sound Output N.A N.A Option Option Option

SD card slot Yes N.A Yes Yes Yes

Communication

ports/Interfaces

RS232C, DB9 Male 1 1 1 1 1

RS232C/ RS422/

RS485, DB25 Female 1 1 1 1 1

Ethernet 10/100 Mbps,

RJ45

Option Option 1 2 2

USB Host 1 1 1 1 1

10

General specifications

Rated Voltage 24 V DC

24 V DC,

110/220V

AC

24 V DC,

110/220V

AC

24 V DC,

110/220V

AC

24 V DC,

110/220V

AC

Power supply

11-36V DC 11-

36V DC,

90-250V

AC

11-

36V DC,

90-250V

AC

11-36V DC,

90-250V AC

11-36V

DC, 90-

250V AC

Rated Current 0.91A (DC)

1.09A

(DC),

0.27A (AC)

1.18 A(DC),

0.29A(AC)

1.36A (DC),

0.33A(AC)

2.46A(DC)

, 0.6A(AC)

Power Consumption

(with out sound output) 10 W 12W 13W 15W 27W

Power on LED indicator

Yes Yes Yes Yes Yes

Outer dimensions

(W X H X D mm)

140 X 116 X

57

212 X 156

X 57

212 X 156

X 57

325 X 263 X

56

400 X 310

X 56

Mounting depth (mm) 51 51 51 50 50

Panel cut (W X H mm) 123

+1

X 99

+1

197

+1

X

141

+1

197

+1

X

141

+1

310

+1

X

248

+1

367

+1

X

289

+1

Protection

IP65 front,

IP20 rear

IP65 front,

IP20 rear

IP65 front,

IP20 rear

IP65 front,

IP20 rear

IP65 front,

IP20 rear

Front bezel, housing

Plastic,

plastic

Plastic,

plastic

Aluminum,

plastic

Aluminum,

metal

Aluminum,

metal

Stainless Steel front

bezel (Option)

N.A N.A Option,

IP66K

Option,

IP66K

Option,

IP66K

Installation

Panel

Mount

Panel

Mount

Panel

Mount

Panel

Mount

Panel

Mount

Net Weight (Kg) 0.5 1.2 1.4 3.6 5.1

11

3. Ordering Code

3.1 HMI ordering code

HMI 4.3”

HMI 7”

(Low Cost)

HMI 7”

(High Performance)

HMI 10”

HMI 15”

Power supply Enclosure

1: 11 to 36V DC 0: Standard

2: 90 to 250 V AC 1: Stainless Steel

Sound Input, Output,

3 I, 3 O

0: None

1: Yes

S card slot

0: None

1: Yes

Ethernet

0: None

1: Yes

Other Networks

0: None

Software

0: None

Specify WinCE Core or WinCE Professional version as special note at Software

1

0

1

0

0

0

1

1

1

1

1

1

0

0

12

3.2 HMI Spares part list

3.2.1 HMI 4.3”

Part Number Part number

Main Board HMA045

IO Board HIO045

LCD Display Module 321MODU-LM0451-A0

Power Fuse 4 Amp (DC power) 10350-15402-01-00

DC power plug 10343-11027-00-00

3.2.2 HMI 7” (Low Cost)

Part Number Part number

Main Board HMA073

IO Board HIO073

90-250VAC power board HPM751

11-36VDC power board HPM752

LCD Display Module 322MODU-LM0731-A0

Power Fuse 4 Amp (DC power) 10350-15402-01-00

DC power plug 10343-1103A-00-00

AC power plug 10343-1103A-01-00

Resistor 2.4/1w (AC power) 10301-42409-55-00

3.2.3 HMI 7” (High Performance)

Part Number Part number

Main Board HMA075

IO Board HIO075

Sound Board HSB075

90-250VAC power board HPM751

11-36VDC power board HPM752

LCD Display Module 323MODU-LM0751-A0

Power Fuse 4 Amp (DC power) 10350-15402-01-00

Resistor 2.4/1w (AC power) 10301-42409-55-00

DC power plug 10343-1103A-00-00

AC power plug 10343-1103A-01-00

DI/DO plug 10343-1208B-00-00

13

3.2.4 HMI 10”

Part Number Part number

Main Board HMA105

Display Board HDP105

Connection Board HCB105

Sound Board HSB105

90-250VAC power board HPM751

11-36VDC power board HPM752

LCD Display Module 324MODU-LM1051-A0

Power Fuse 4 Amp (DC power) 10350-15402-01-00

Resistor 2.4/1w (AC power) 10301-42409-55-00

DC power plug 10343-1103A-00-00

AC power plug 10343-1103A-01-00

DI/DO plug 10343-1208B-00-00

3.2.5 HMI 15”

Part Number Part number

Main Board HMA155

Backlight Board HBL155

Sound Board HSB105

90-250VAC power board HPM751

11-36VDC power board HPM754

LCD Display Module 325MODU-LM1551-A0

Power Fuse 6.3 Amp (AC power)

10350-15632-01-00

Resistor 2.4/1w (AC power) 10301-42409-55-00

DC power plug 10343-1103A-00-00

AC power plug 10343-1103A-01-00

DI/DO plug 10343-1208B-00-00

It is possible to change power supply from AC to DC and vice versa (Except HMI

4.3”) by replacing power supply board, after replacing power board, the label for marking

power input range located on the enclosure has to be changed.

14

3.3 Reserved

3.4 Accessories part numbers

Part Number Description

WPG045 Gasket for HMI 4.3” (For dust and Moisture protection)

WPG073

Gasket for HMI 7” (LOW COST)/ HMI 7” (HIGH

PERFORMANCE) (For dust and Moisture protection)

WPG105 Gasket for HMI 10” (For dust and Moisture protection)

WPG155 Gasket for HMI 15” (For dust and Moisture protection)

HMB045 HMI Mounting Brackets

15

4. Installation

4.1 Installation

Guidelines

Stainless steel front HMI has sharp edges and more weight. Enough care should

be taken while inserting HMI into enclosure/panels using proper hand gloves. Improper

handing may cause in ury personal during installation of HMI into enclosure/panels.

1. The HMI is intended for indoor use and not in any hazardous area.

2. HMI device should be installed in suitable enclosure/panels/cabinets/housings.

3. Avoid facing of HMI screen directly exposed to sun light.

4. Avoid installation in high vibration area/ moving parts.

5. Avoid installation near to high radiation/noise emitting devices like motors,

transformers, variable frequency drives, inverters, UPS, cellular towers etc.

6. Avoid installation in areas where there is the presence of vapors, gases, oils,

lubricants, chemicals etc.

7. Install HMI at suitable height and location which is easy accessible to operators.

8. When HMI is installed inside main panel, make sure that proper vents are available

for the main panel, ambient temperature inside the panel is not exceeded beyond

HMI specifications, operator is alerted incase of exceeding temperature limits.

9. When HMI is installed on panel front door, check depth of the HMI and make sure

that there is enough clearance available inside the panel after closing the main panel

door.

10. A sufficient panel gage should be used in the main panel to firmly install HMI. Take

care when using stainless steel fronts as weight is heavy compared with alloy or

plastic fronts. Use rubber gaskets properly to achieve degree of Ingress Protection.

11. Use panel cut out as specified and firmly attach all mounting clips.

12. Maintain proper clearances around the HMI panel approx: 50 mm on all directions to

make sure that it is easy to remove HMI for maintenance purpose and temperature

dissipates by natural air cooling method.

13. Use proper line protections in power supply line via fuses, circuit breakers etc.

14. Connect earth properly to the HMI enclosures/panels/cabinets/housings.

16

15. Use proper cables, connect to ground properly before connecting power supply to

HMI

16. Thoroughly check voltage levels accepted by HMI, measure voltage levels with a

multimeter before connecting them with HMI.

17. While using HMI with stainless steel front for wash down applications, make sure

that panels/enclosures/cabinets/housings are perfectly closed to avoid water entry

inside panels causing damages to the equipment and in ury to operating personal.

18. Improper installation voids warranty.

17

4.2 imensional drawings

4.2.1 imensional drawings of the HMI 4.3”

Note: All dimensions are in mm. Tolerance +/- 1 mm.

Panel cutout: 123

+1

X 99

+1

B9, Male

Network option

LAN, Ethernet (RJ45)

S slot

B25, Female

USB port

Power supply

18

4.2.2 imensional drawings of the HMI 7”

Note: All dimensions are in mm. Tolerance +/- 1 mm

Panel cutout: 197

+1

X 141

+1

B9, Male

LAN, Ethernet (RJ45)

S slot

B25, Female

USB port

Power supply

Network option

Terminals for I/ O (future use)

19

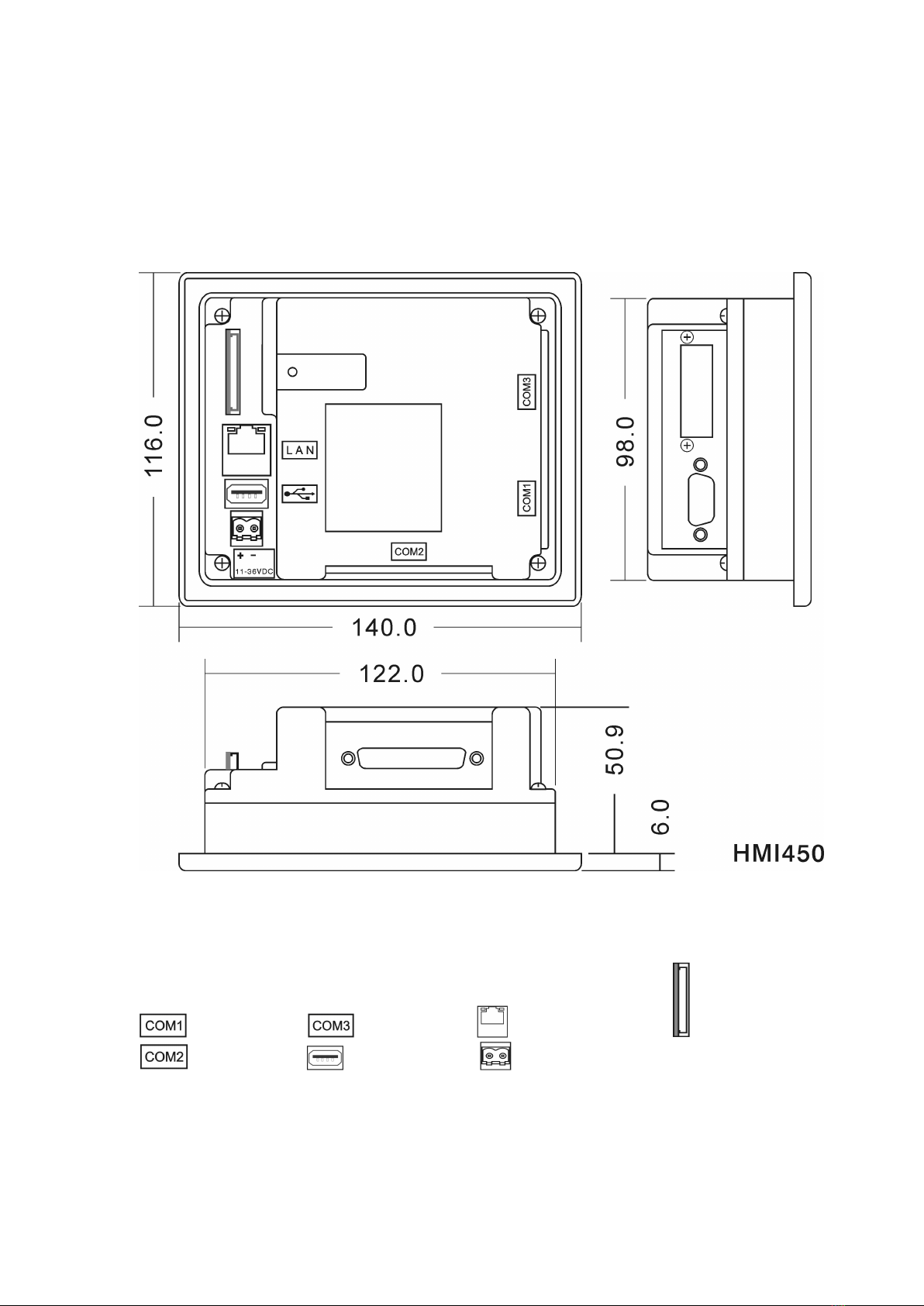

4.2.3 imensional drawings of the HMI 10”

Note: All dimensions are in mm. Tolerance +/- 1 mm

Panel cutout: 310

+1

X 248

+1

B9, Male

Network option

LAN1, Ethernet (RJ45)

S slot

B25, Female

LAN2, Ethernet (RJ45)

Power supply

USB port

20

4.2.4 imensional drawings of the HMI 15”

Note: All dimensions are in mm. Tolerance +/- 1 mm

Panel cutout: 367

+1

X 289

+1

B9, Male

LAN1, Ethernet (RJ45)

S slot

B25, Female

LAN2, Ethernet (RJ45)

Power supply

Network option

USB port

This manual suits for next models

3

Table of contents